High-strength and high-toughness reactive powder concrete of carbon doped nano-tube and preparation method of high-strength and high-toughness reactive powder concrete

A carbon nanotube and active powder technology, applied in the field of active powder concrete and its preparation, can solve the problems of high cost and low compressive strength, achieve good bonding performance, improve cracking strength, and solve the effects of low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1 (three products are arranged in this example, and its serial number is respectively marked as 1-1,1-2,1-3):

[0060] The active powder concrete doped with carbon nanotubes described in this implementation includes P O52.5 ordinary Portland cement, quartz powder, silica fume, S105 grade slag powder, silica sand, industrial water, water reducing agent, end hook steel fiber, carbon Nanotube, fly ash, carbon nanotube dispersant. The quality of each component is shown in Table 1 below, and Table 1 shows the mix ratio of carbon nanotube active powder concrete (shown in the table as the parts of each component quality):

[0061]

[0062] The preparation method of reactive powder concrete described in the present embodiment is as follows:

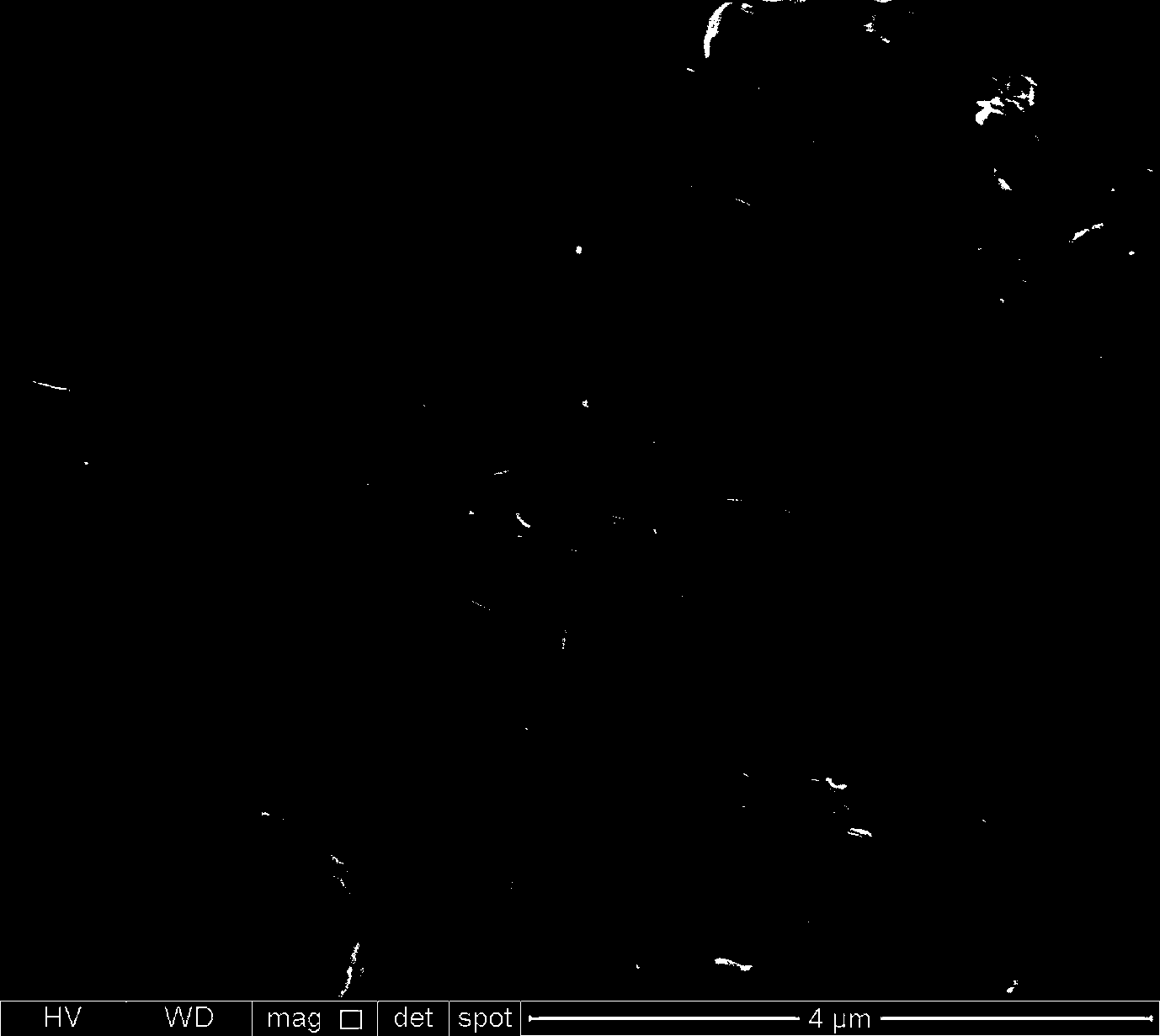

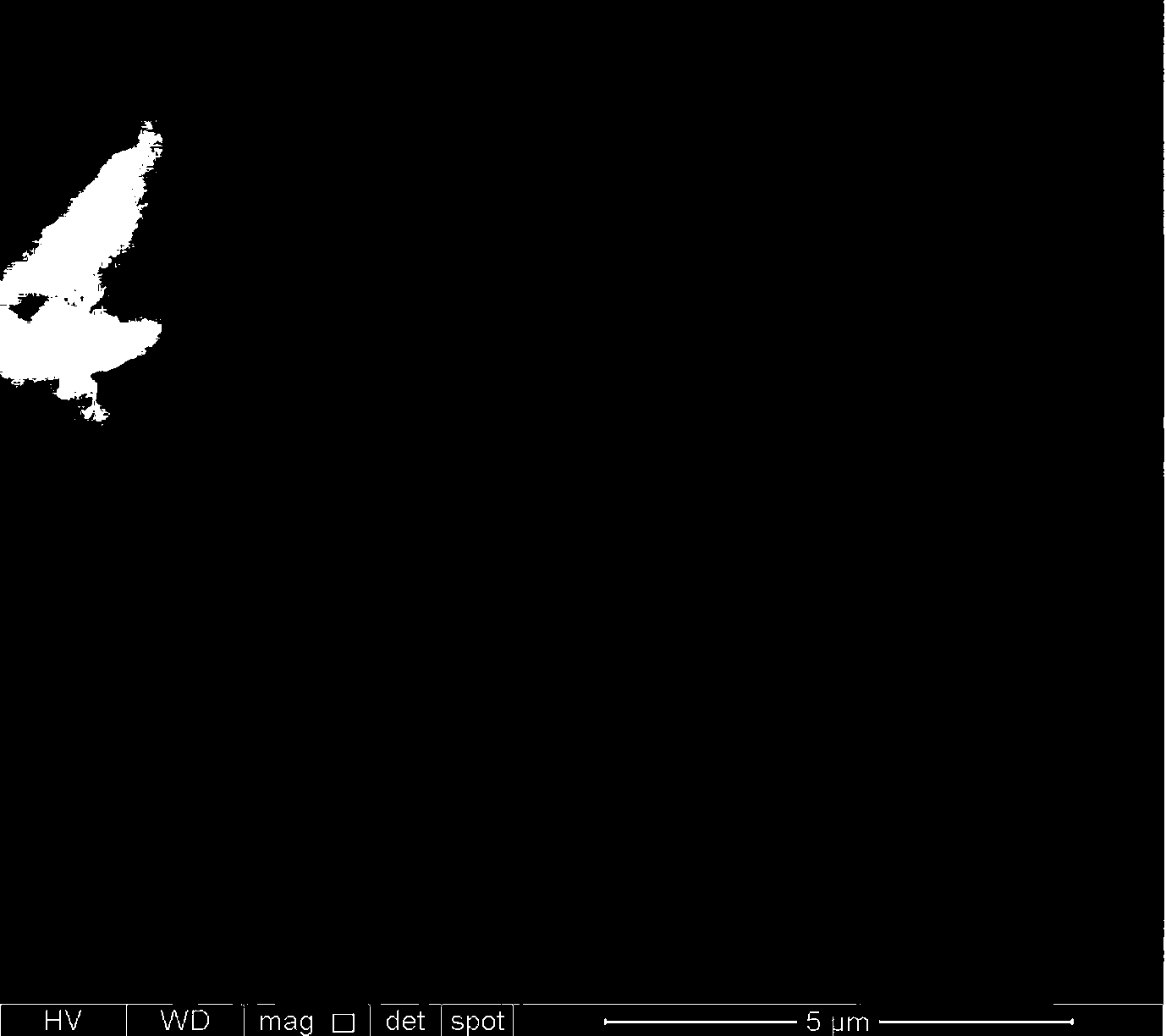

[0063] (1) The carbon nanotube powder and carbon nanotube dispersant described in Table 1 are added to the water required for mixing, and the resulting mixed solution is placed in an ultrasonic cleaning machine for 15 minute...

Embodiment 2

[0071] Embodiment 2 (two products are arranged in this example, its serial number is respectively marked as 2-1,2-2,2-3):

[0072] The active powder concrete doped with carbon nanotubes described in this implementation includes P O52.5 ordinary Portland cement, quartz powder, silica fume, S105 grade slag powder, silica sand, industrial water, water reducing agent, long straight steel fiber, carbon Nanotube, fly ash, carbon nanotube dispersant. The quality of each component is shown in Table 3 below, and the mixing ratio of the carbon nanotube-doped living powder concrete in Table 3 (shown in the table is the parts by weight of each component).

[0073]

[0074] The preparation method of reactive powder concrete described in the present embodiment is as follows:

[0075] (1) Add the weighed carbon nanotube powder and carbon nanotube dispersant into all the water according to Table 3, put them into an ultrasonic cleaner for 15 minutes of ultrasonic dispersion and use a centr...

Embodiment 3

[0082] Embodiment 3 (there are three products in this example, and its serial number is respectively marked as 3-1,3-2,3-3):

[0083] The active powder concrete doped with carbon nanotubes described in this implementation includes P O52.5 ordinary Portland cement, quartz powder, silica fume, S105 grade slag powder, silica sand, industrial water, water reducing agent, end hook steel fiber, carbon Nanotube, fly ash, carbon nanotube dispersant. The quality of each component is shown in Table 5 below, and Table 5 shows the mix ratio of carbon nanotube-doped active powder concrete (shown in the table is the parts by weight of each component).

[0084]

[0085] The preparation method of reactive powder concrete described in the present embodiment is as follows:

[0086](1) Add the carbon nanotube powder and carbon nanotube dispersant in Table 5 to all the water, place them in an ultrasonic cleaner for 15 minutes for ultrasonic dispersion, and use a centrifuge to accelerate preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com