Preparation method of spherical lithium iron phosphate

A lithium iron phosphate, spherical technology, applied in the field of lithium battery cathode materials, can solve the problems of large particle size of spherical lithium iron phosphate, difficult coating process, complicated process flow, etc., and achieves easy subsequent coating, good sealing, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

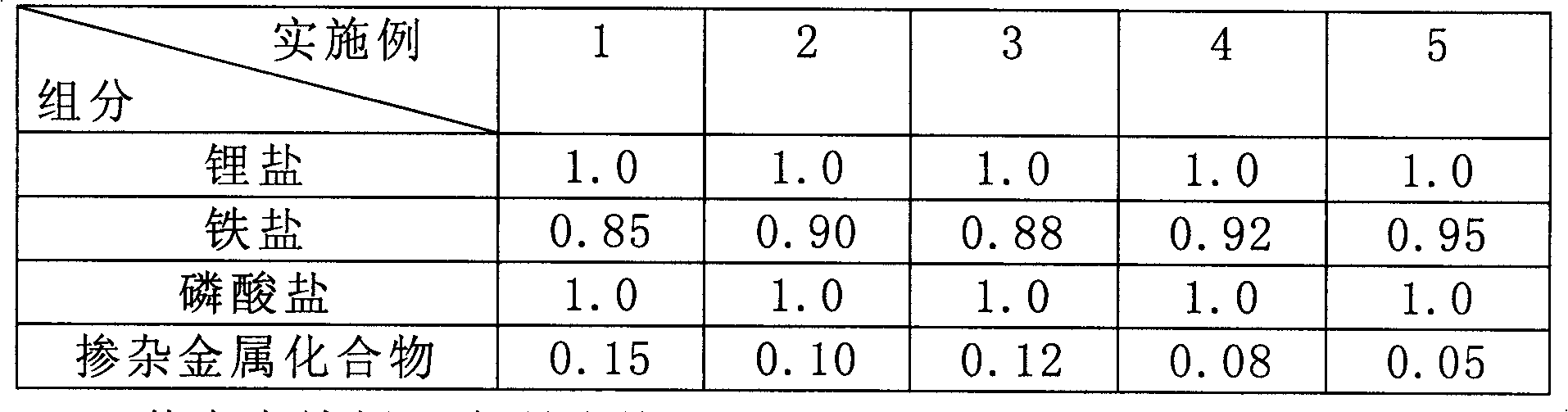

[0036] Mix the raw material of Example 1 in Table 1 with 13.2 g of carbon black and 51.8 g of sucrose, then add it into 200 g of absolute ethanol solution, and stir thoroughly so that the raw material mixture is fully dissolved at 40-60° C. The aqueous solution is dried and compacted, placed in an inert atmosphere reaction furnace, slowly heated to 600-700°C, maintained at this temperature for 20-25 hours, and then slowly cooled to room temperature to obtain primary lithium iron phosphate powder.

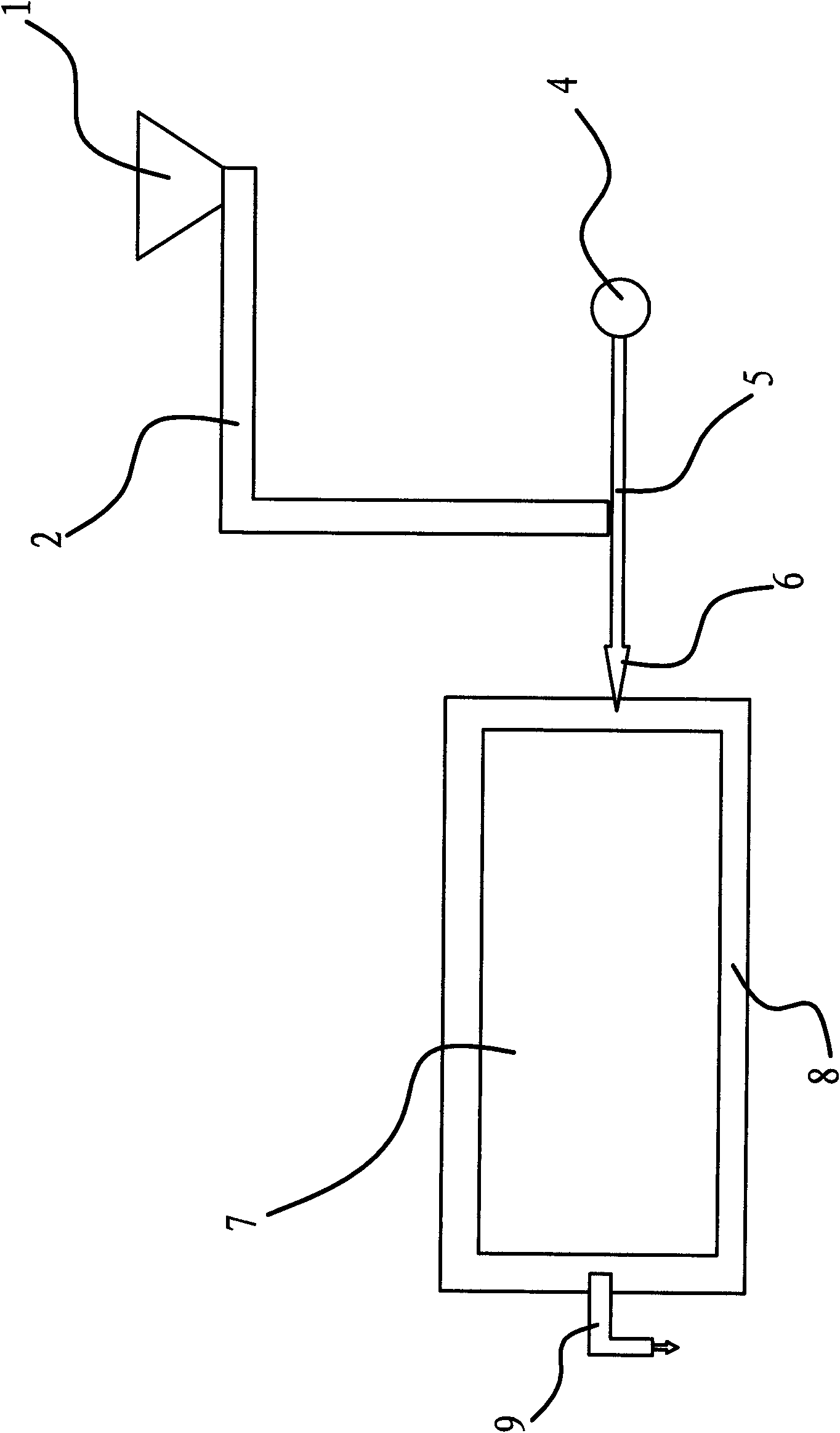

[0037] Such as figure 1 As shown, the cooled primary lithium iron phosphate powder is put into the material sealing collection device 1, and the lithium iron phosphate powder is sent to the spiral heating and rolling feeding device 3 under the protection of an inert atmosphere with the low-pressure blower 2, and the high-pressure blower 4 The lithium iron phosphate powder at the bottom of the spiral heating and rolling feeding device 3 is blown into the accelerator 5 to accelerate t...

Embodiment 2

[0039] Mix the raw material of Example 2 in Table 1 with 12.8 g of acetylene black and 52.6 g of glucose, then add it into 200 g of absolute ethanol solution, and stir thoroughly to make the raw material mixture fully dissolve at 40-60°C, and then dissolve it at 80-90°C The aqueous solution is dried and compacted, placed in a nitrogen atmosphere reaction furnace, slowly heated to 700-800°C, maintained at this temperature for 15-20 hours, and then slowly cooled to room temperature to obtain primary lithium iron phosphate powder.

[0040] Put the cooled primary lithium iron phosphate powder into the material sealing collection device 1, send the lithium iron phosphate powder under the protection of nitrogen atmosphere to the spiral heating and rolling feeding device 3 with the low-pressure blower 2, and use the high-pressure blower 4 to heat the spiral The lithium iron phosphate powder at the bottom of the rolling feeding device 3 is blown into the accelerator 5 and accelerated t...

Embodiment 3

[0042] Mix the raw material of Example 3 in Table 1 with 13.2 g of flake graphite and 50.8 g of polyvinyl alcohol, then add it into 200 g of absolute ethanol solution, stir fully, and fully dissolve the raw material mixture at 40-60 ° C, and dissolve it in 90- Dry the aqueous solution at 100°C, briquette, place in a nitrogen atmosphere reaction furnace, slowly heat to 800-900°C, keep this temperature for 10-15 hours, and then slowly cool to room temperature to obtain primary lithium iron phosphate powder.

[0043] Put the cooled primary lithium iron phosphate powder into the material sealing collection device 1, send the lithium iron phosphate powder under the protection of nitrogen atmosphere to the spiral heating and rolling feeding device 3 with the low-pressure blower 2, and use the high-pressure blower 4 to heat the spiral The lithium iron phosphate powder at the bottom of the rolling feeding device 3 is blown into the accelerator 5 and accelerated to the nozzle 6 under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com