Porous silicon negative material of lithium ion battery and preparation method and application of material

A technology for lithium ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of complex preparation methods, high costs, and difficulty in large-scale production, and achieves the effects of simple methods, low costs, and improved conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

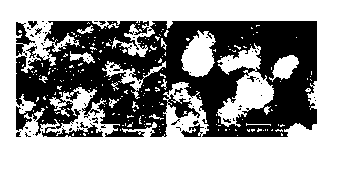

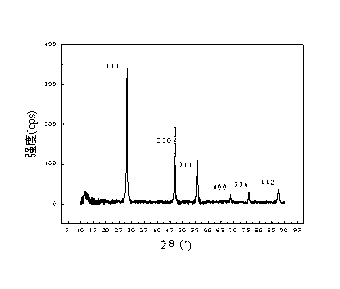

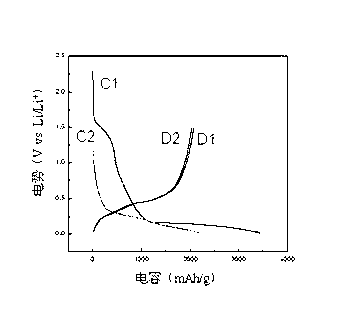

[0025] The porous nano-silicon material is prepared by etching SiAl alloy powder with hydrochloric acid. Weigh a certain mass of silicon-aluminum alloy (composition: 80% Al, 20% Si, particle size about 15 μm) powder, add it to excess 8% HCl (AR) aqueous solution in batches, and stir continuously with a magnetic stirrer. The reaction product was washed three times with deionized water to remove AlCl 3 . Then placed in 2% HF ethanol solution and stirred for 2h to dissolve the SiO on the silicon surface2 . Then wash with deionized water and absolute ethanol several times. Finally, it is placed in a vacuum oven and dried at 80° C. to obtain a porous nano-silicon powder. Such as figure 1 Shown is the SEM image of porous silicon powder. It can be seen that the particles of the material are less than 20 μm, and have an obvious sponge-like porous structure composed of nanoparticles. The fine and dense pores in the particles are formed after the aluminum component in the silicon-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com