Preparation method of secondary lithium-sulfur battery anode adhesive

A lithium-sulfur battery and adhesive technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low solubility of β-cyclodextrin, and achieve the effects of stable cycle performance, enhanced contact, and high capacity retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 1 g of β-cyclodextrin to 5 g of 10 wt% H 2 o 2 In an aqueous solution, keep warm at 50°C for 48 hours to form a carbonylated β-cyclodextrin aqueous solution, and then dry to remove water and hydrogen peroxide to obtain a carbonylated β-cyclodextrin for secondary lithium-sulfur battery positive electrode binder. Cyclodextrin.

[0023] The infrared spectrum comparison results of carbonylated β-cyclodextrin and β-cyclodextrin used in the positive electrode binder of secondary lithium-sulfur batteries are as follows figure 1 As shown, the ratio of carbonylated β-cyclodextrin to β-cyclodextrin is 1733cm -1 There is one more C=O bond, that is, the carbonyl group, which can be seen through the H 2 o 2 After the aqueous solution is modified, a new chemical bond—carbonyl group is formed on the β-cyclodextrin molecule, thereby improving the solubility of the β-cyclodextrin in water.

[0024] Sulfur-based composite material, carbonylated β-cyclodextrin, and acetylene blac...

Embodiment 2

[0028] Add 5 g of β-cyclodextrin to 1 g of 20 wt% H 2 o 2 In an aqueous solution, keep warm at 70°C for 24 hours to form a carbonylated β-cyclodextrin aqueous solution, and then dry to remove water and hydrogen peroxide to obtain a carbonylated β-cyclodextrin for secondary lithium-sulfur battery positive electrode binder. Cyclodextrin.

[0029] Sulfur-based composite material, carbonylated β-cyclodextrin, and acetylene black are uniformly dispersed in water at a mass ratio of 85:5:10, then coated on aluminum foil, dried and pressed to obtain a positive electrode for a lithium-sulfur secondary battery ; Among them, the sulfur-based composite material is obtained by mixing 6g of elemental sulfur with 1g of polyacrylonitrile, heating to 280°C under nitrogen protection and keeping it warm for 6h.

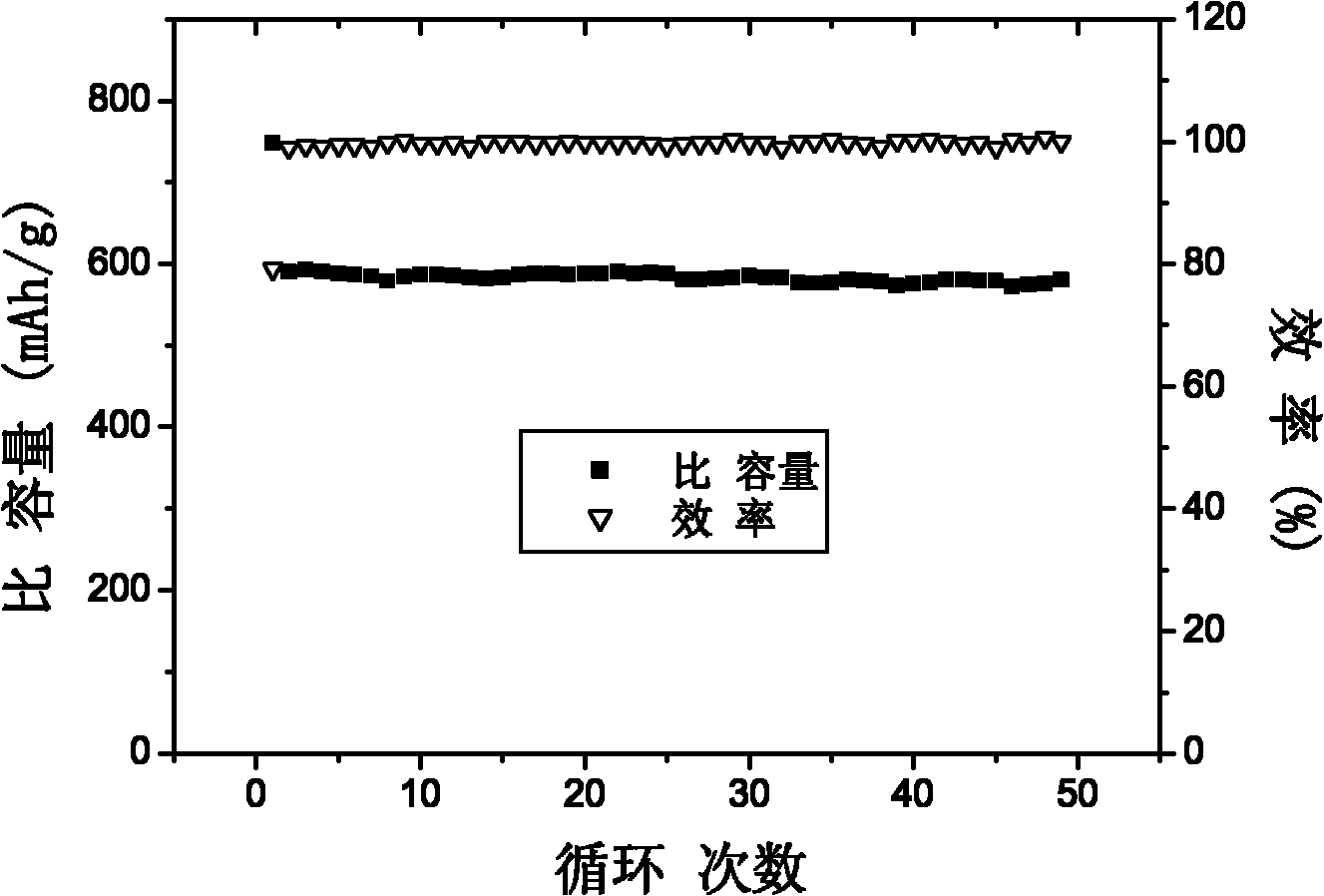

[0030] The test results of the lithium-sulfur battery made of the positive electrode binder of the secondary lithium-sulfur battery are as follows: image 3 As shown, under the disch...

Embodiment 3

[0032] Add 5 g of β-cyclodextrin to 3 g of 30 wt% H 2 o 2 In an aqueous solution, keep warm at 90°C for 12 hours to form a carbonylated β-cyclodextrin aqueous solution, and then dry to remove water and hydrogen peroxide to obtain a carbonylated β-cyclodextrin for secondary lithium-sulfur battery positive electrode binder. Cyclodextrin.

[0033] The sulfur-based composite material, carbonylated β-cyclodextrin, and acetylene black are uniformly dispersed in water at a mass ratio of 90:5:5, and then coated on carbon-coated aluminum foil, dried and pressed into tablets to obtain a lithium-sulfur The positive electrode of the secondary battery; the sulfur-based composite material is obtained by heating 8g of elemental sulfur and 1g of polyacrylonitrile under the protection of nitrogen to 280°C and keeping it warm for 6h.

[0034] The cycle results of the lithium-sulfur battery made of the positive electrode binder of the secondary lithium-sulfur battery at room temperature and 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com