Positive pole active substance, positive pole and battery

A positive electrode active material and a positive electrode technology, applied in the field of positive electrodes and batteries including the positive electrodes, can solve the problems of low electronic conductivity, poor cycle performance, and low specific capacity of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the positive electrode can adopt various methods commonly used in the art, for example, a positive electrode active material, a binder and a conductive agent optionally contained are prepared into a positive electrode slurry with a solvent, and then the prepared positive electrode slurry is drawn The slurry is coated on the positive electrode current collector, dried and pressed, and then cut into pieces to obtain the positive electrode. The drying temperature may be 100-150° C., and the drying time may be 2-10 hours.

[0034]The solvent used in the positive electrode slurry can be various solvents used in the prior art, such as can be selected from N-methylpyrrolidone (NMP), dimethylformamide (DMF), diethylformamide (DEF) , dimethyl sulfoxide (DMSO), tetrahydrofuran (THF), and one or more of water and alcohols. The amount of the solvent added is well known to those skilled in the art, and can be flexibly adjusted according to the viscosity an...

Embodiment 1

[0046] LiFePO 4 and LiNiO 2 Mix evenly according to the molar ratio of 1:0.02, then add starch as a carbon source according to the content of carbon in the positive electrode active material generated as 5% by weight, ball mill for 10 hours, and mix evenly; After drying, the dried powder was heated up to 600°C at a rate of 10°C / min in an argon atmosphere, and then sintered at a constant temperature for 20 hours to obtain the positive electrode active material LiFePO 4 / LiNiO 2 / C mixed crystals.

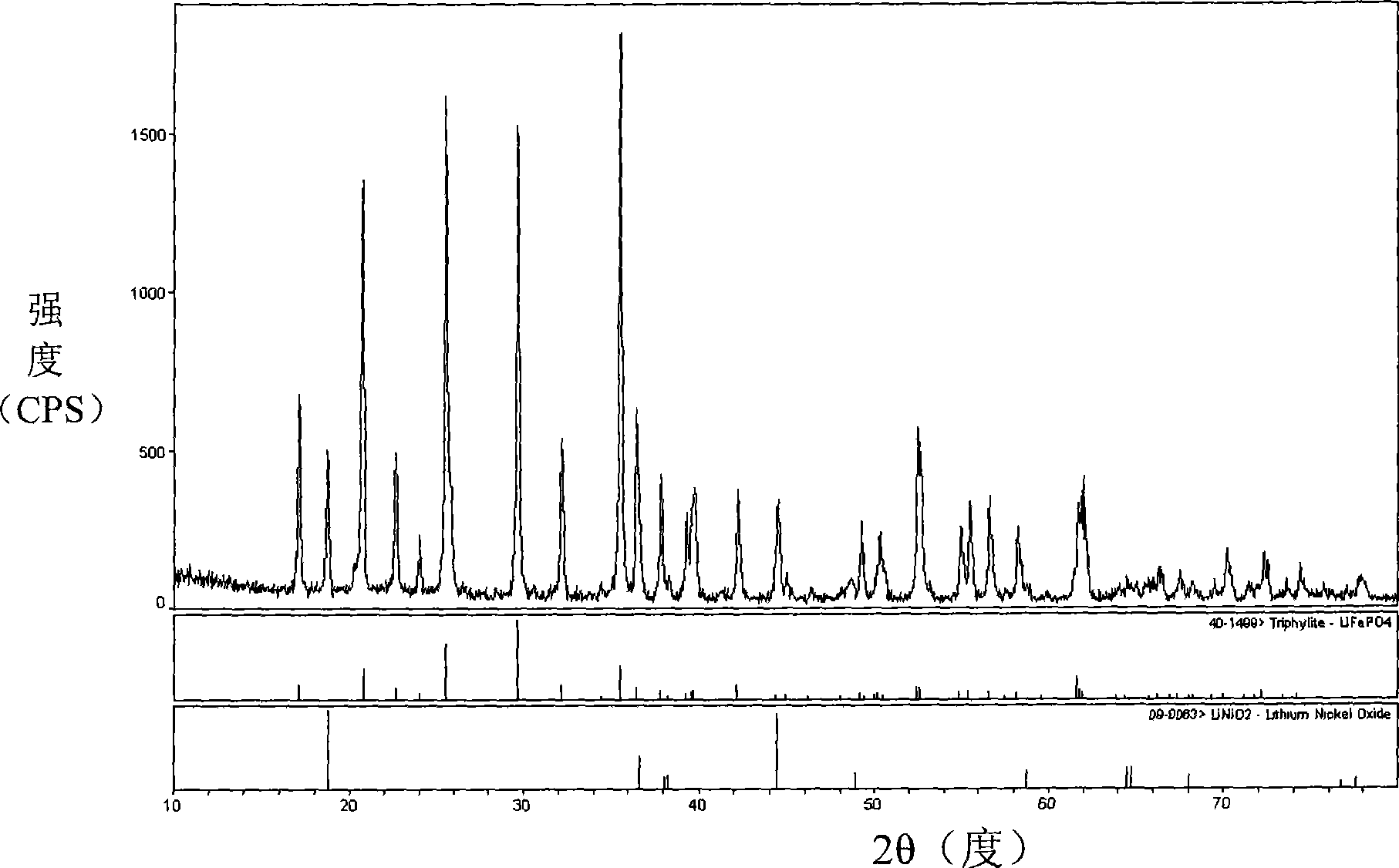

[0047] The XRD diffraction pattern of this positive electrode active material measured by the D / MAX-2200 / PC type X-ray powder diffractometer of Rigaku company is as follows figure 1 shown, from figure 1 It can be seen that in the diffraction peaks of the positive active material obtained after sintering, except for LiFePO 4 and LiNiO 2 No new characteristic peaks were found except for the characteristic peaks of the positive electrode active material, thus indicating that the L...

Embodiment 2

[0049] LiFePO 4 and LiCoO 2 Mix evenly according to the molar ratio of 1:0.04, then add acetylene black as carbon source according to the content of carbon in the positive electrode active material generated as 2% by weight, ball mill for 10 hours, and mix evenly; °C drying, and then the dried powder was heated to 500 °C at a heating rate of 5 °C / min in an argon atmosphere, and then sintered at a constant temperature for 30 hours to obtain the positive electrode active material LiFePO 4 / LiCoO 2 / C mixed crystals.

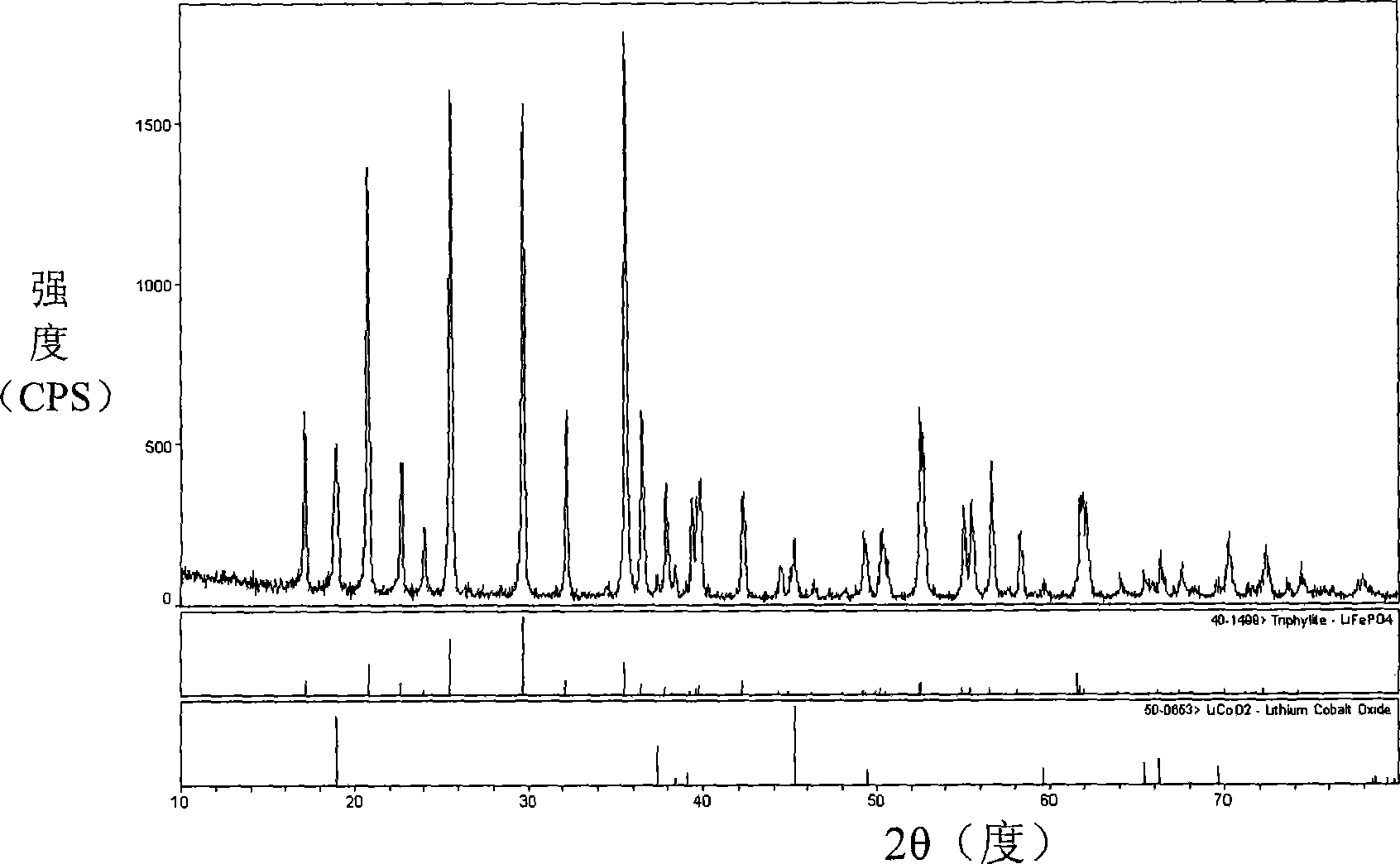

[0050] The XRD diffraction pattern of this positive electrode active material measured by the D / MAX-2200 / PC type X-ray powder diffractometer of Rigaku company is as follows figure 2 shown, from figure 2 It can be seen that in the diffraction peaks of the positive active material obtained after sintering, except for LiFePO 4 and LiCoO 2 No new characteristic peaks were found except for the characteristic peaks of the positive electrode active material, thus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com