Anode active material, preparation method of anode active material, high-performance anode slurry containing anode active material, and all-solid-state lithium ion battery

A positive electrode active material and positive electrode slurry technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that limit the development of large-capacity batteries, and the electrochemical performance of all-solid-state lithium-ion batteries is difficult to meet the actual use requirements. To achieve the effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

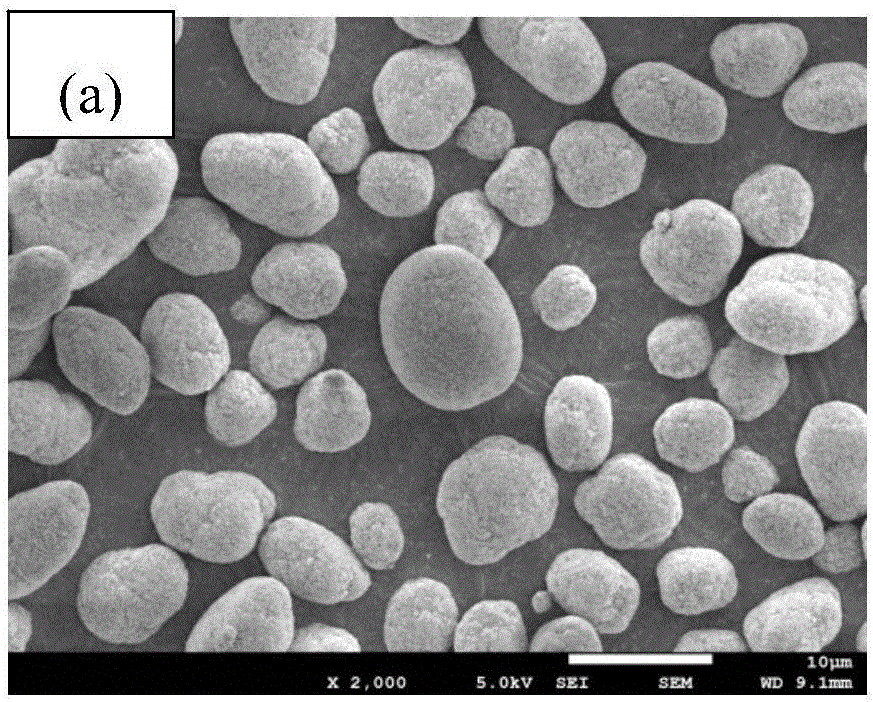

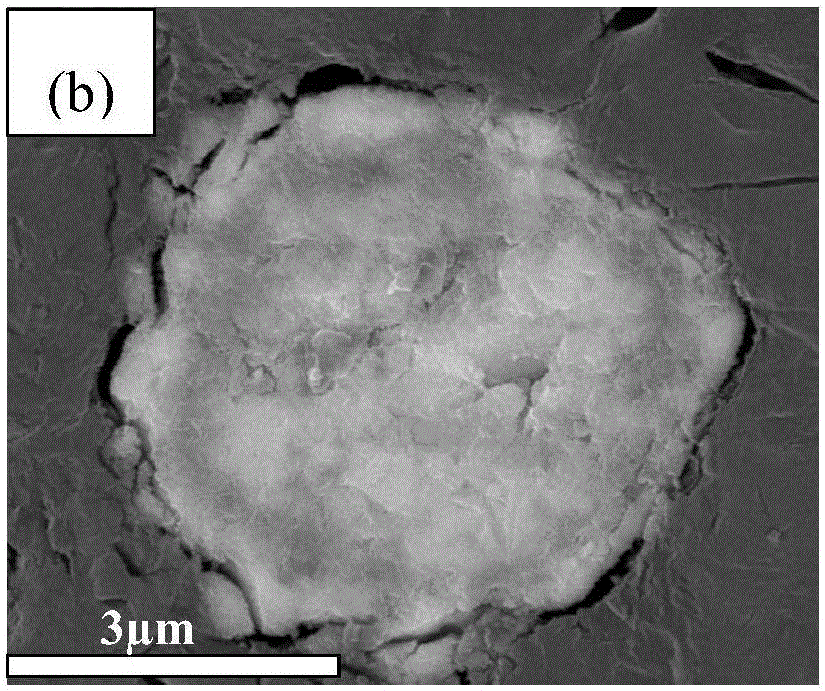

[0099] (1) A positive electrode active material, the positive electrode active material is a nickel-rich type core-shell structure particle coated with an inorganic compound coating on the surface (i.e. a nickel-rich type core-shell structure particle and an inorganic compound coating layer on its surface ), wherein the core of the nickel-rich type core-shell structure particle is nickel-cobalt lithium manganese oxide, and the molar ratio of the three elements Ni, Co, and Mn is 8:1:1, and the shell of the nickel-rich type core-shell structure particle is LiNi 0.8 co 0.15 Al 0.15 o 2 , the mass of nickel-cobalt-lithium manganese oxide in the inner core accounts for 60% of the total mass of nickel-rich core-shell structure particles, and the inorganic compound coating layer is 0.5nm thick Li 3 PO 4 cladding layer, Li 3 PO 4 The mass of the cladding layer accounts for 6% of the total mass of the nickel-rich type core-shell structure particles covered with the inorganic compo...

Embodiment 2

[0111] (1) A positive electrode active material, the positive electrode active material is a nickel-rich type core-shell structure particle coated with an inorganic compound coating on the surface (i.e. a nickel-rich type core-shell structure particle and an inorganic compound coating layer on its surface ), wherein the core of the nickel-rich type core-shell structure particle is nickel-cobalt lithium manganese oxide, and the molar ratio of Ni, Co, and Mn is 6:2:2, and the shell of the nickel-rich type core-shell structure particle is LiNi 0.8 co 0.15 Al 0.15 o 2 , the mass of nickel-cobalt lithium manganese oxide in the core accounts for 95% of the total mass of nickel-rich core-shell structure particles, and the inorganic compound coating layer is 20nm thick LiNiPO 4 Cladding layer, LiNiPO 4 The mass of the cladding layer accounts for 0.001% of the total mass of the nickel-rich core-shell structure particles coated with the inorganic compound cladding layer.

[0112] (2...

Embodiment 3

[0122] (1) A positive electrode active material, the positive electrode active material is a nickel-rich type core-shell structure particle coated with an inorganic compound coating on the surface (i.e. a nickel-rich type core-shell structure particle and an inorganic compound coating layer on its surface ), wherein the core of the nickel-rich type core-shell structure particle is nickel-cobalt lithium manganese oxide, and the molar ratio of the three elements Ni, Co, and Mn is 8:1:1, and the shell of the nickel-rich type core-shell structure particle is LiNi 0.8 co 0.15 Al 0.15 o 2 , the quality of nickel-cobalt lithium manganese oxide in the core accounts for 70% of the total mass of nickel-rich core-shell structure particles, and the inorganic compound coating is 5nm thick Li 2 O-ZrO 2 cladding layer, Li 2 O-ZrO 2 The mass of the coating layer accounts for 1% of the total mass of the nickel-rich type core-shell structure particles coated with the inorganic compound coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com