Silicon-carbon composite cathode material with three-dimensional preformed hole structure and preparation method thereof

A silicon-carbon composite and negative electrode material technology, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of difficult process control, complex CVD process, and easy damage to the carbon shell, and achieve the effect of structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

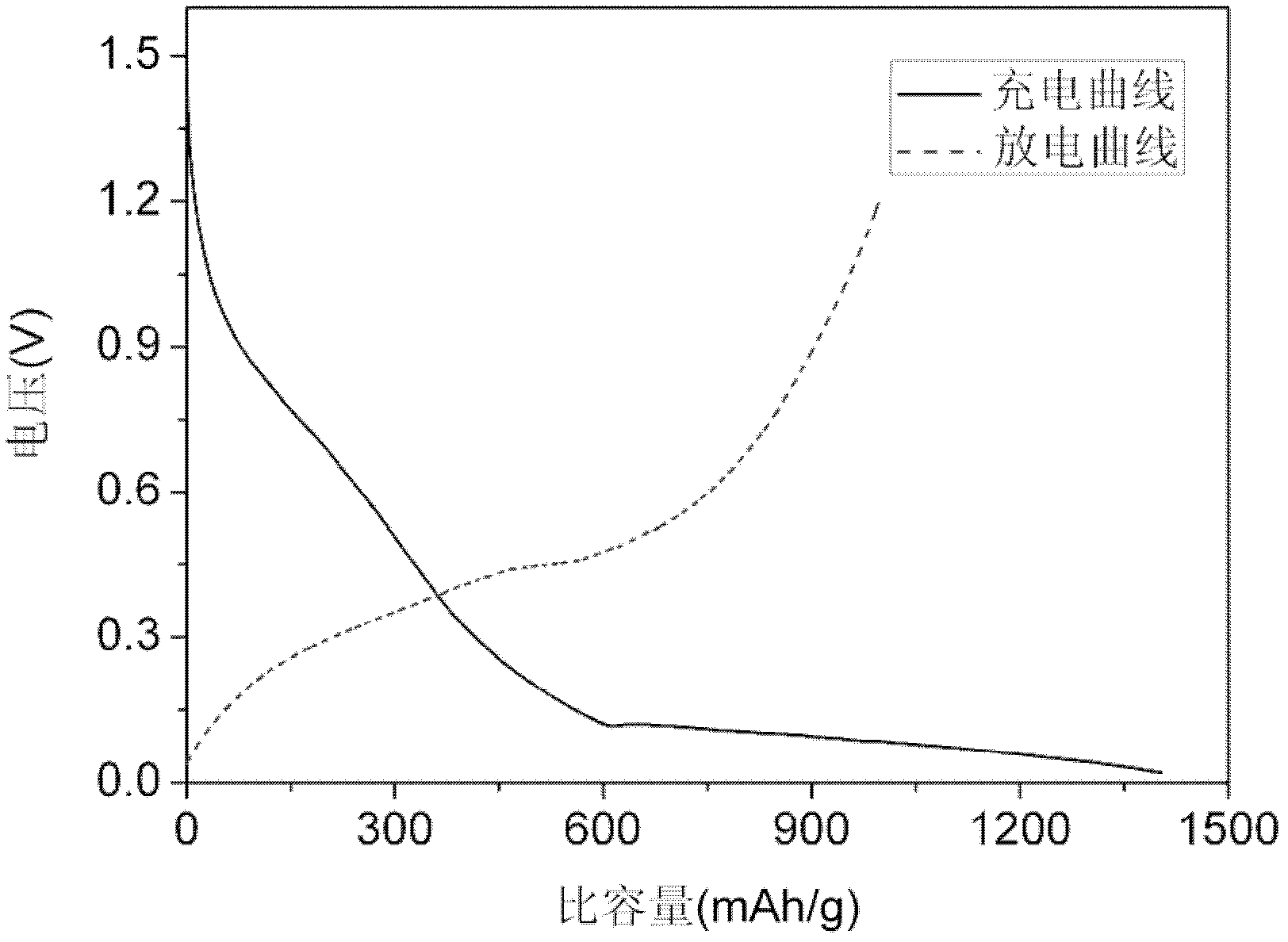

Examples

Embodiment 1

[0037] Step 1: Surface modification of silicon particles

[0038] Take 1g of nano-silicon particles with an average particle size of 30nm, add them to 100mL of absolute ethanol solution, and disperse them ultrasonically for 30min, wherein the ultrasonic power is 200W and the ultrasonic frequency is 45kHz to form a uniform silicon particle suspension; place the silicon particle suspension in Stir in a stirrer, add 0.2 g of cetyltrimethylammonium bromide at a stirring intensity of 1000 r / min, and continue stirring for 2 hours to obtain a surface-modified high-capacity silicon particle dispersion;

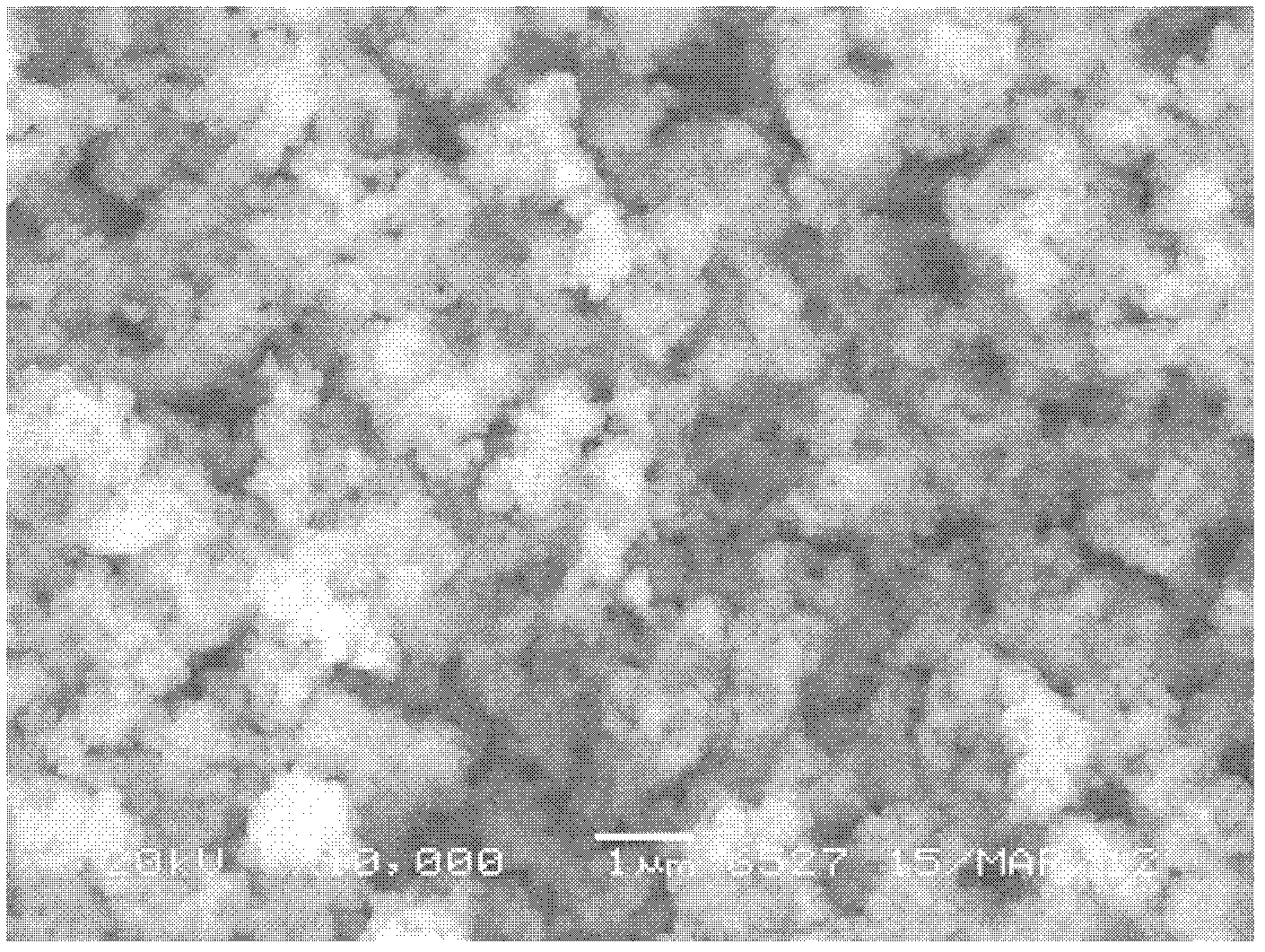

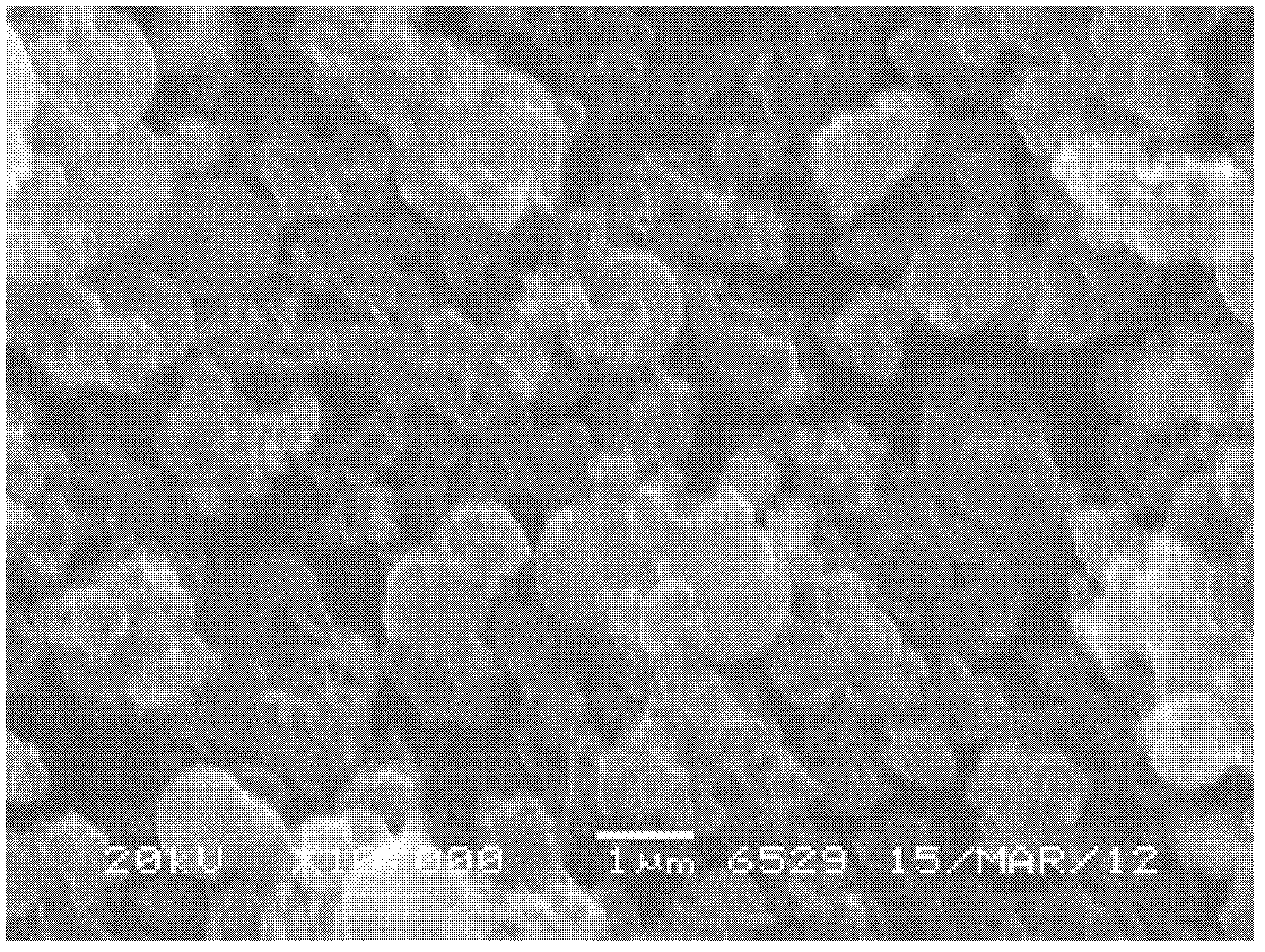

[0039] Step 2: Silica-coated silicon particles

[0040] Take 50mL of the silicon particle dispersion after the first step of modification treatment. During the ultrasonic process, use ammonia water as the pH regulator to adjust the pH of the solution to 9 to form a uniformly dispersed alkaline suspension; then slowly add 21mL orthosilicon In the mixed solution of ethyl orthosilicate ...

Embodiment 2

[0050] Step 1: Surface modification of silicon particles

[0051] Take 1g of nano-silicon particles with an average particle size of 80nm, add them to 100mL of absolute ethanol solution, and disperse them ultrasonically for 30 minutes, wherein the ultrasonic power is 200W and the ultrasonic frequency is 45kHz to form a uniform suspension of silicon particles; Stir in a stirrer, add 0.2 g of cetyltrimethylammonium bromide at a stirring intensity of 1000 r / min, and continue stirring for 2 hours to obtain a surface-modified high-capacity silicon particle dispersion.

[0052] Step 2: Silica-coated silicon particles

[0053] Take 50mL of the silicon particle dispersion after the first step of modification treatment. During the ultrasonic process, use ammonia water as the pH regulator to adjust the pH of the solution to 9 to form a uniformly dispersed alkaline suspension; then slowly add 22mL orthosilicon In the mixed solution of ethyl orthosilicate and ethanol, wherein the volume ...

Embodiment 3

[0061] Step 1: Surface modification of silicon particles

[0062] Take 1g of nano-silicon particles with an average particle size of 30nm, add them to 100mL of absolute ethanol solution, and disperse them ultrasonically for 30min, wherein the ultrasonic power is 200W and the ultrasonic frequency is 45kHz to form a uniform silicon particle suspension; place the silicon particle suspension in Stir in a stirrer, under the stirring intensity of 1000r / min, add 2mL KH550 type silane coupling agent, continue to stir and react for 2h, and obtain a surface-modified high-capacity silicon particle dispersion.

[0063] Step 2: Silica-coated silicon particles

[0064] Take 50mL of the silicon particle dispersion after the first step of modification treatment. During the ultrasonic process, use ammonia water as the pH regulator to adjust the pH of the solution to 9 to form a uniformly dispersed alkaline suspension; then slowly add 21mL orthosilicon In the mixed solution of ethyl orthosilic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com