Molded laminate for optical use

A molding layer, optical technology, applied in the field of molding laminates, can solve the problems of uneconomical production methods, unpredictable color tone changes, etc., and achieve the effect of high polarization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

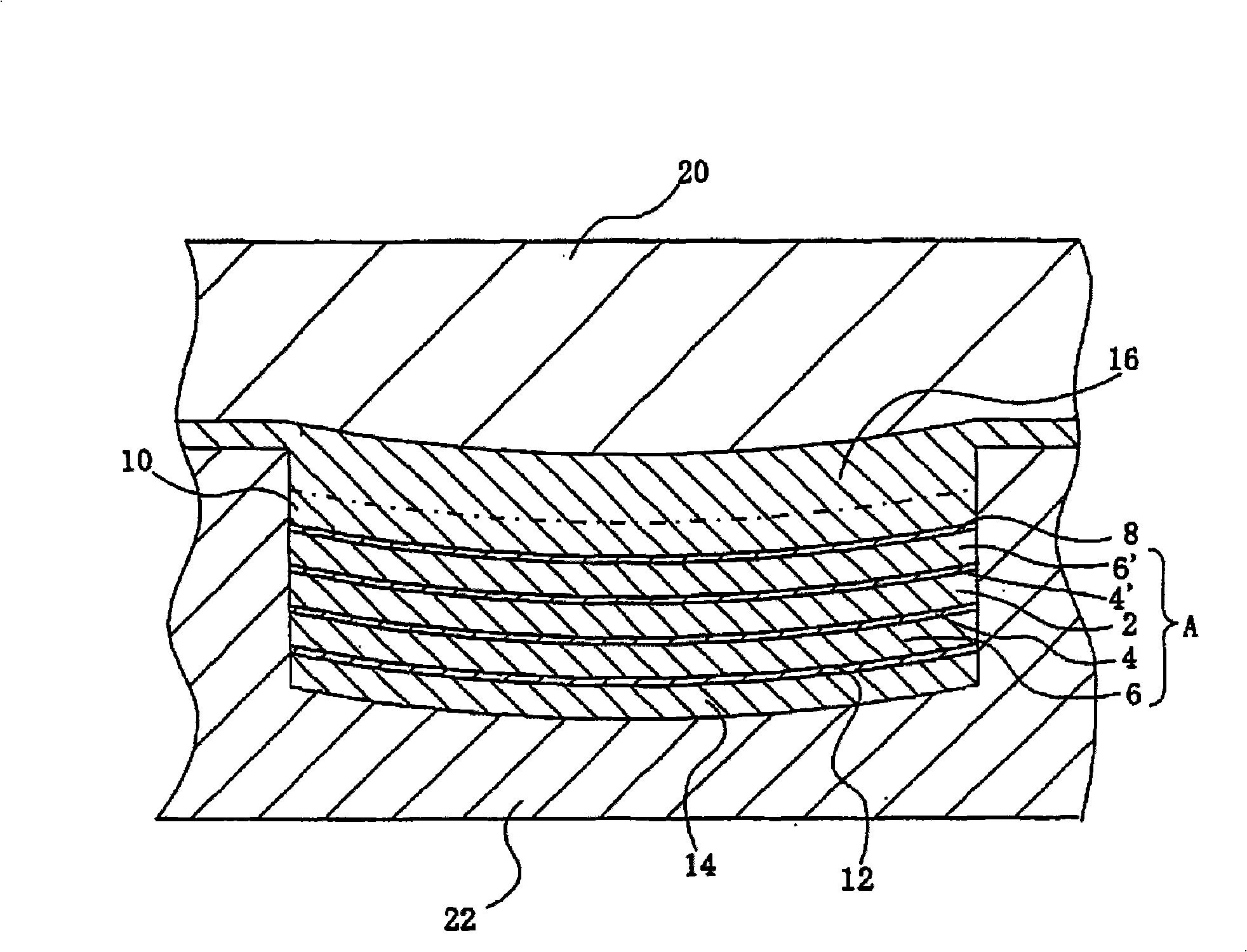

[0050] Used from Sumitomo Chemical Company, Limited called The polarizer of SQ-1852A has a thickness of 0.18 mm and a light transmittance of 43.7%. The polarizer includes first and second cellulose triacetate films on respective opposing surfaces of a polyvinyl alcohol polarizing film dyed with an iodine-based dye (dye stuff), each of the first and second cellulose triacetate films Has a thickness of 0.08mm. The polarizing film had a thickness of 0.02 mm and a degree of polarization of 99.95%. Bonding a polycarbonate resin film having a thickness of 0.15 mm and having a light transmittance of 89% to the exposed surface of the first cellulose triacetate film of the polarizer by using a two-component type polyurethane resin as an adhesive, The polycarbonate resin film is compatible or fusible with lens forming polycarbonate resins.

[0051] Then, a third cellulose triacetate film that does not contain an ultraviolet absorber and has a thickness of 0.05 mm is bonded to the ex...

Embodiment 2

[0055] A polyallyl ester-based film was bonded to the exposed surface of the first cellulose triacetate film of the same polarizer as used in Example 1 by using a two-component polyether polyurethane resin adhesive, the polyolefin The acrylic film had a thickness of 0.14 mm, exhibited a light transmission of 88%, and was compatible or fusible with lens forming polyallyl resins.

[0056] Then, on the exposed surface of the second cellulose triacetate film, an adhesive is applied to a thickness of 0.01 mm, through which the third cellulose triacetate that does not contain an ultraviolet absorber and has a thickness of 0.05 mm The film was bonded to a second cellulose triacetate film, whereby a laminated sheet was obtained. The adhesive used to bond the third cellulose triacetate film to the second cellulose triacetate film is 1-(2-methoxy-5-nitrobenzyl)-3,3-di Methylspiro[indoline-2,3′-(3H)-naphtho(2,1-b)-pyran] 1.5% by weight two-component polyester polyurethane resin, the wei...

Embodiment 3

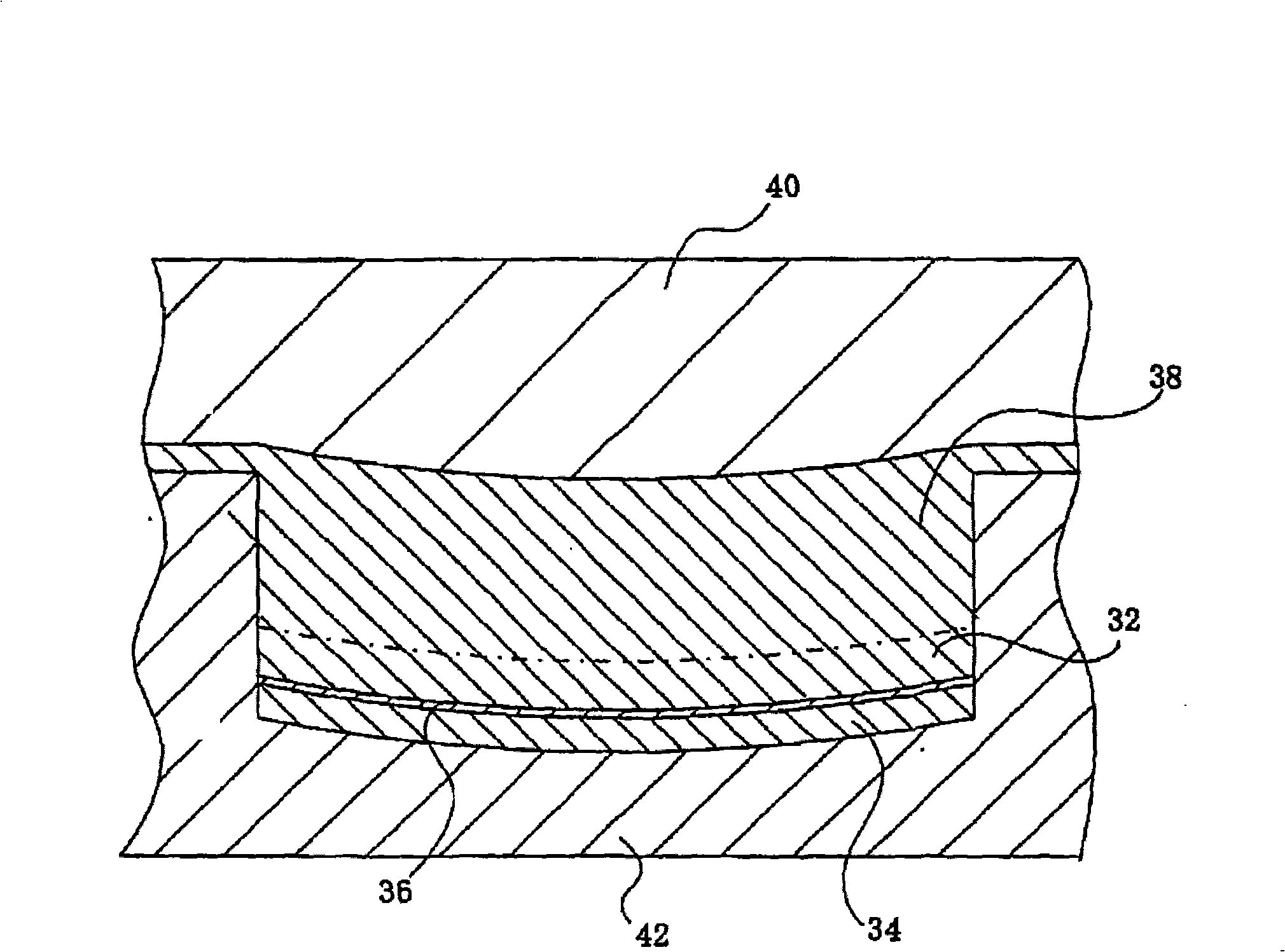

[0060] The polycarbonate resin and polybutylene terephthalate were uniformly blended in a weight ratio of 60:40, thereby preparing a transparent thermoplastic film having a thickness of 0.2 mm. On the transparent plastic film thus prepared, the same two-component polyether polyurethane adhesive containing a photochromic compound as used in Example 1 was applied to a thickness of 0.02 mm, and on the adhesive A cellulose triacetate film containing no ultraviolet absorber and having a thickness of 0.05 mm was placed to form a laminated sheet.

[0061] The laminate was heat bent to a shape in which the exposed cellulose triacetate film exhibited a convex surface and the exposed surface of the thermoplastic film exhibited a concave surface. The heat-bent laminate was placed in an injection mold, and the same resin as that of the thermoplastic film was injected on the exposed surface of the thermoplastic film, thereby forming an optical lens having a thickness of 2.0 mm.

[0062] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com