Electrode and preparation method therefor

An electrode and conductive agent technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high resistance and adverse effects of normal use of lithium-ion batteries, and achieve the effect of improving safety performance and improving the high conductivity at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

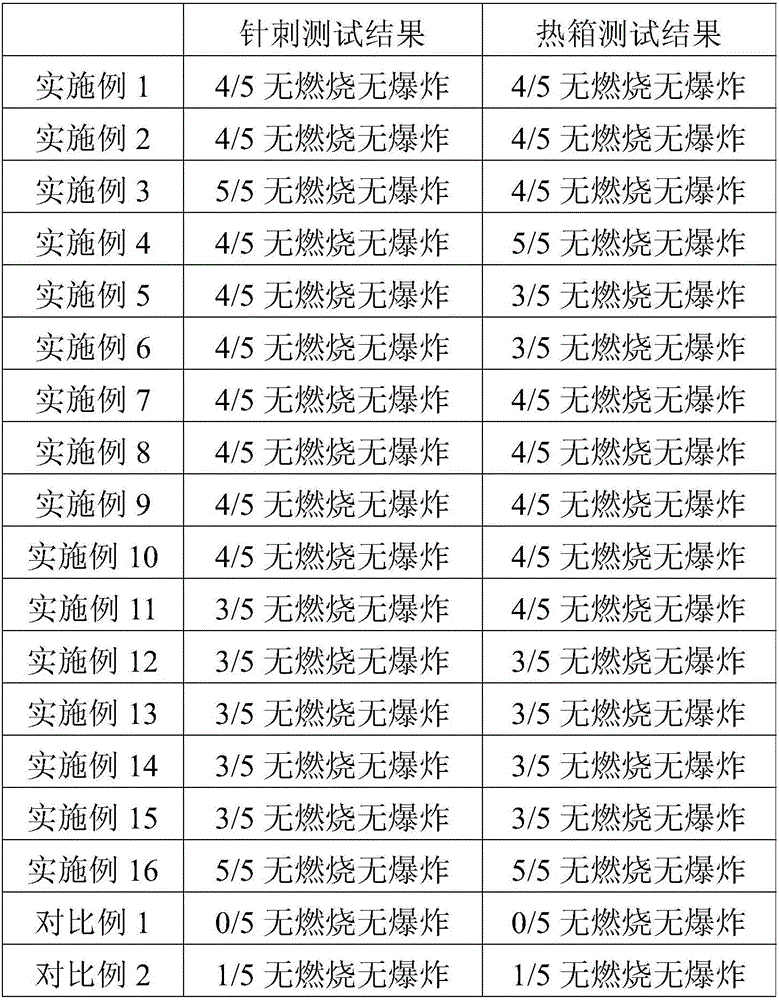

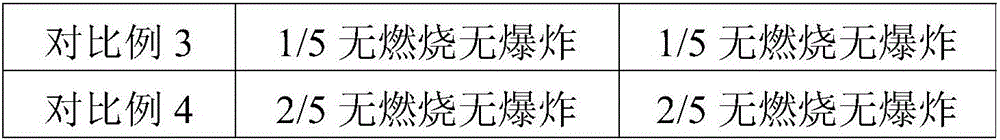

Examples

preparation example Construction

[0025] Next, the preparation method of the electrode according to the second aspect of the present invention is described, which is used to prepare the electrode described in the first aspect of the present invention, comprising the steps of: adding a conductive agent to a polymer matrix in a molten state or a solution state, and mixing uniformly to obtain a slurry Materials, wherein the polymer matrix is selected from low-density polyethylene, high-density polyethylene, epoxy resin, polyvinylidene fluoride, ethylene-ethyl acrylate copolymer, ethylene-vinyl acetate copolymer, polybutene, cellulose acetate , one or more of polyamides, and the conductive agent is selected from one or more of thorny Ni powder, thorny Cu powder, thorny Al powder, and thorny tungsten carbide; the slurry is uniformly It is coated on the current collector, and the coating is obtained after drying; a layer of active material slurry is coated on the coating, and the active material layer is formed aft...

Embodiment 1

[0032] (1) Preparation of electrolyte

[0033] Using 1M lithium hexafluorophosphate (LiPF 6 ) as a lithium salt, using a mass ratio of 50:50 EC:PC mixed non-aqueous solvent mixed as the electrolyte.

[0034] (2) Preparation of positive electrode sheet

[0035] In terms of mass fraction, 96% of the positive electrode active material LiCoO 2 , 2% of the binder polyvinylidene fluoride (PVDF), 2% of the conductive agent Super-P are added to the solvent N-methylpyrrolidone (NMP) and mixed to obtain a uniformly dispersed black paste. The black slurry is coated on the front and back sides of the positive electrode current collector Al foil with a thickness of 12 μm by roller coating and then dried. After the black slurry is dried, a positive electrode active material layer is formed, and then cold pressed, edge trimmed, After cutting, slitting, and welding the positive ear, the positive electrode piece is obtained.

[0036] (3) Preparation of negative electrode sheet

[0037] In t...

Embodiment 2

[0042] (1) Preparation of electrolyte

[0043] With embodiment 1.

[0044] (2) Preparation of positive electrode sheet

[0045] In terms of mass fraction, 70% of the polymer matrix low-density polyethylene is melted, and then 20% of the conductive agent thorny Al powder and 10% of the inorganic particles are added. 2 o 3 (particle size is 1 μm), after mixing evenly, it is evenly coated on the front and back sides of the positive electrode current collector Al foil with a thickness of 12 μm by roller coating, and the coating is obtained after drying, and the thickness of the coating is 3 μm.

[0046] In terms of mass fraction, 96% of the positive electrode active material LiCoO 2 , 2% of the binder polyvinylidene fluoride (PVDF), 2% of the conductive agent Super-P are added to the solvent N-methylpyrrolidone (NMP) and mixed to obtain a uniformly dispersed black paste. The black slurry is coated on the above-mentioned coating by roller coating, and the positive electrode act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com