Method for producing edible camellia oleosa seed oil

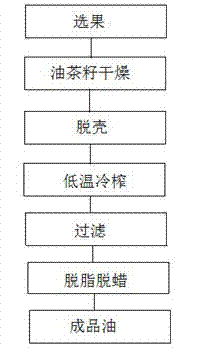

A technology of camellia oleifera seed oil and production method, which is applied in the field of edible oil, can solve the problems of decreased health care function, shortened product shelf life, time-consuming, laborious and costly costs, etc., and achieves the effects of high nutrient content, reduced refining links, and simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Determination of the picking time of camellia oleifera fruit as raw material for production of camellia oleifera seed oil

[0041] Ordinary white-flowered Camellia oleifera is selected as the raw material. According to experience, the annual frost (generally in the middle and late October) is the ripening time of camellia oleifera fruit, which is suitable for picking. In order to determine a reasonable picking time, the present invention, through many years of research, picks camellia oleifera seeds and fruits at different times in combination with the process of the present invention and the traditional process for comparative analysis, from which the rules are summarized. Below this embodiment is illustrated with the data summarized in one of the experiments as an example. This embodiment begins to pick Camellia oleifera fruit in September, measures several main chemical components in its nuts, and extracts the oil in the nuts, and measures and evaluates Came...

Embodiment 2

[0047] Embodiment 2 Determination of drying method

[0048] This embodiment mainly provides the analysis of the influence of drying method on important several indexes in camellia oleifera seed oil:

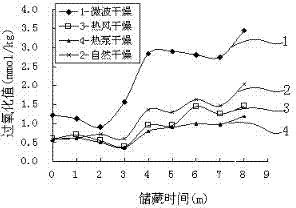

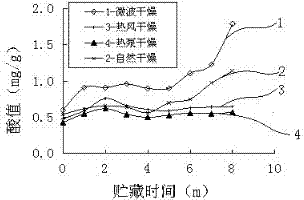

[0049] ① Effect of drying method on the peroxide value of oil in camellia oleifera seed

[0050] Peroxide value (POV) is one of the important indicators for evaluating rancidity. The picked camellia oleifera fruits are dried in the sun (natural drying), hot air drying, heat pump drying and microwave drying (continuous tunnel microwave drying equipment, power 6 ~ 200KW Adjustable) Four different methods and different process conditions are used to dry to basically the same water content. The dried camellia seeds are stored at room temperature, and samples are taken regularly to measure the peroxide value (POV) of the oil contained in it, and the change rule is analyzed. The results are attached figure 2 shown. attached figure 2 Among them, curve 1 is microwave drying, cu...

Embodiment 3

[0059] Embodiment 3 Determination of drying process conditions

[0060] ① Effect of drying temperature on moisture content of camellia oleifera seeds

[0061] Take a number of equal amounts of fresh camellia oleifera seeds, place them at 40°C, 55°C, and 70°C for heat pump drying according to a certain loading capacity, with a wind speed of 1.5 m / s, and take samples at regular intervals to measure the moisture content of camellia oleifera seeds, and obtain different drying temperatures. The moisture content change curve of Camellia oleifera seed is attached Figure 5 shown. attached Figure 4 Among them, curve 1 is 40°C, curve 2 is 55°C, and curve 3 is 70°C.

[0062] attached by Figure 5 It can be seen that the moisture content of camellia oleifera seeds decreased rapidly in the early stage of drying, and the moisture content decreased slowly in the later stage of drying. The higher the drying temperature, the faster the water content of camellia oleifera seeds decreases,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com