Nano-aluminum powder/paraffin energy-containing composite particle and preparation method and application thereof

A technology of composite particles and nano-aluminum powder, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not being able to control the particle size of aluminum powder, affecting the coating effect of the coating agent, Complex process and other issues, to achieve the effect of low cost, improved activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

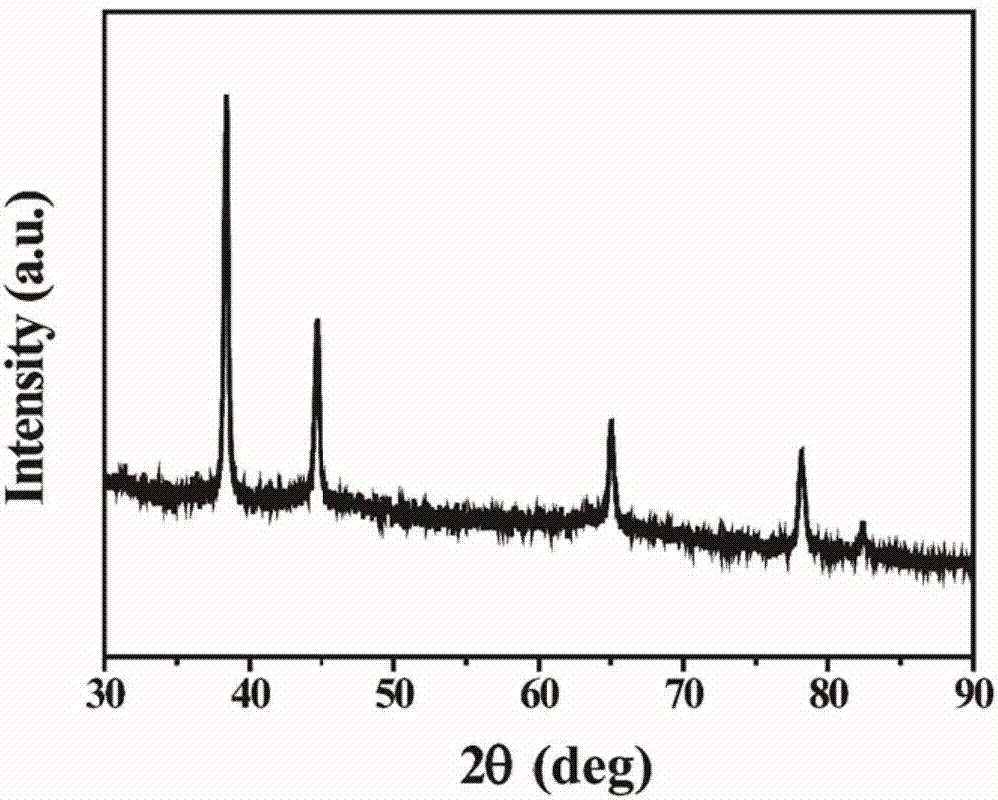

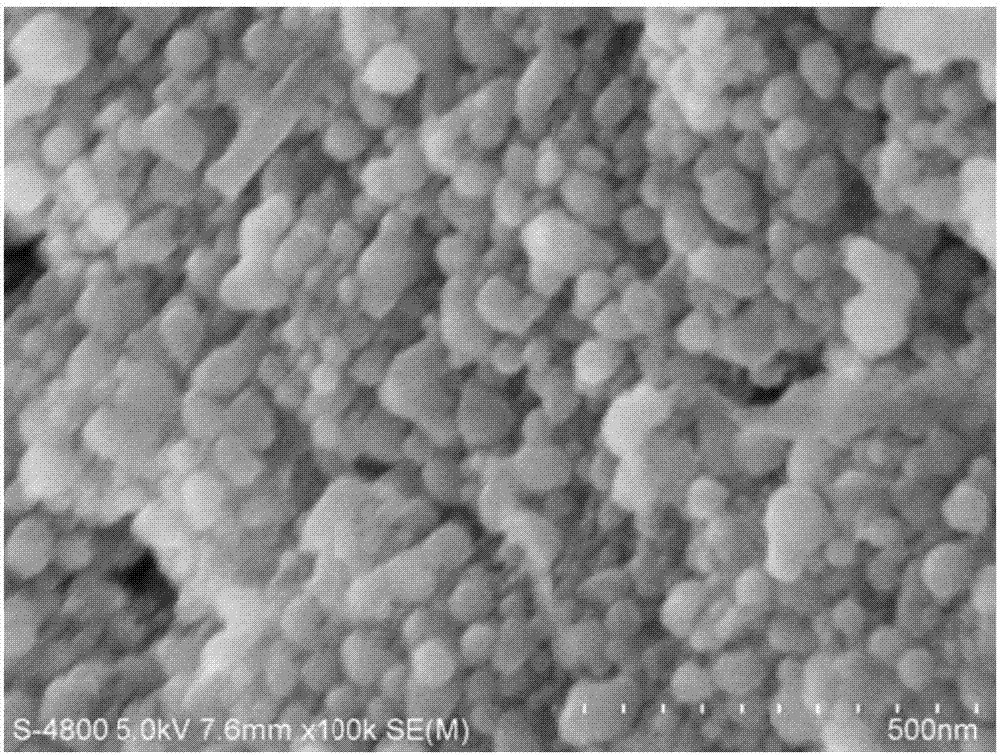

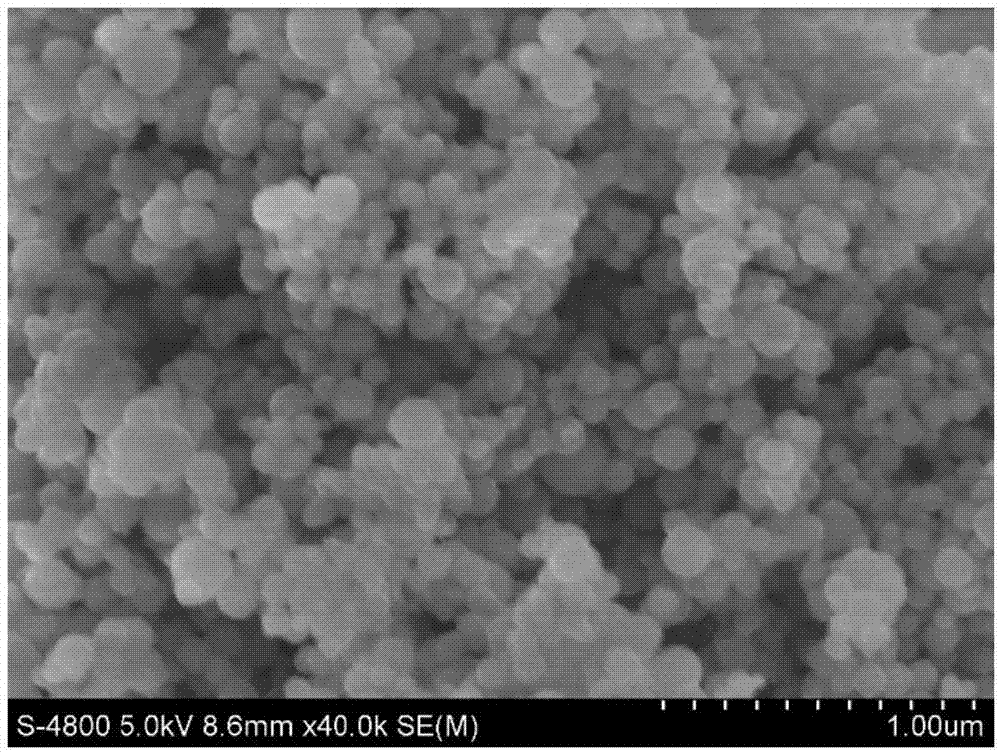

[0045] A method for synthesizing nano aluminum powder / paraffin energetic composite particles, comprising the following steps:

[0046] (1) Preparation of precursor solution: at room temperature (20°C), 0.01mol anhydrous AlCl 3 Dispersed into 20mL of toluene solution, 0.04mol of N((CH 3 ) 2 C 2 h 5 ) was added to AlCl at a rate of 1-2 drops / second 3 in the toluene solution. With N((CH 3 ) 2 C 2 h 5 ), solid AlCl 3 Dissolve gradually. To be AlCl 3 Dissolve completely, slowly add 0.06molLiAlH 4 Add it into the above system, continue to stir and react for 4 hours, centrifuge at a speed of 5000-8000 rpm, and take 5-15 minutes to obtain AlH 3 ·N((CH 3 ) 2 C 2 h 5 ) serum.

[0047] (2) Preparation of nano-aluminum powder / paraffin energetic composite particles: AlH 3 ·N(C 2 h 5 ) 3 Put the supernatant liquid and 40mL, 0.01g / mL paraffin toluene solution together into a three-necked flask with a constant pressure funnel at the top, pass through the system with argo...

Embodiment 2

[0060] A method for synthesizing nano aluminum powder / paraffin energetic composite particles, comprising the following steps:

[0061] (1) Preparation of precursor solution: at 30°C, 0.01mol anhydrous AlCl 3 Dispersed into 20mL of xylene solution, 0.04mol of N(CH 3 ) 3 Add to AlCl at a rate of 1-2 drops / sec 3 in the toluene solution. With N(CH 3 ) 3 The addition of solid AlCl 3 Dissolve gradually. To be AlCl 3 Dissolve completely, slowly add 0.03molLiAlH 4 Add it into the above system, continue to stir and react for 4 hours, centrifuge at a speed of 5000-8000 rpm, and take 5-15 minutes to obtain AlH 3 ·N(CH 3 ) 3 Serum.

[0062] (2) Preparation of nano-aluminum powder / paraffin energetic composite particles: AlH 3 ·N(CH 3 ) 3 Put the supernatant liquid into a three-necked flask with a constant pressure funnel at the top, pass through the system with argon for three to five cycles to evacuate, maintain the argon atmosphere, heat the above solution to 80°C with sti...

Embodiment 3

[0064] A method for synthesizing nano aluminum powder / paraffin energetic composite particles, comprising the following steps:

[0065] (1) Preparation of precursor solution: at room temperature (20°C), 0.01mol anhydrous AlCl 3 Dispersed into 20mL of toluene solution, 0.04mol of N(C 2 h 5 ) 3 Add to AlCl at a rate of 1-2 drops / sec 3 in the toluene solution. With N(C 2 h 5 ) 3 The addition of solid AlCl 3 Dissolve gradually. To be AlCl 3 Dissolve completely, slowly add 0.04molLiAlH 4 Add it into the above system, continue to stir and react for 4 hours, centrifuge at a speed of 5000-8000 rpm, and take 5-15 minutes to obtain AlH 3 ·N(C 2 h 5 ) 3 Serum.

[0066] (2) Preparation of nano-aluminum powder / paraffin energetic composite particles: AlH 3 ·N((CH 3 ) 2 C 2 h 5 ) supernatant into a three-necked flask with a constant pressure funnel at the top, and the system was pumped with argon for three to five cycles to maintain the argon atmosphere, and the above solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com