Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "High compression density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material containing a mixed lithium-metal oxide

InactiveUS20120129052A1High compression densityIncrease electrode densityMaterial nanotechnologySecondary cellsLithium metalLithium-ion battery

A composite material containing particles, in part provided with a pyrocarbon coating, of a mixed lithium metal oxide, as well as particles, in part provided with a pyrocarbon layer, of elementary carbon. Also, a process for producing such a composite material as well as an electrode containing the composite material and a secondary lithium-ion battery containing an electrode comprising the composite material.

Owner:JOHNSON MATTHEY PLC

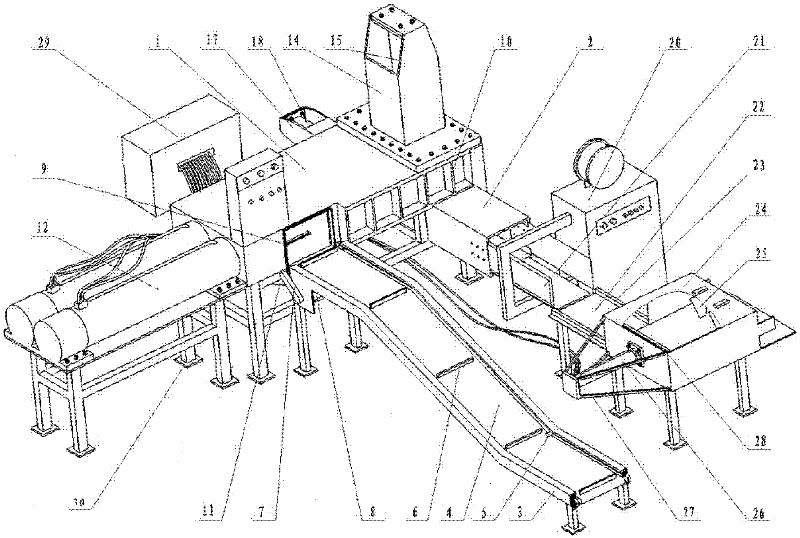

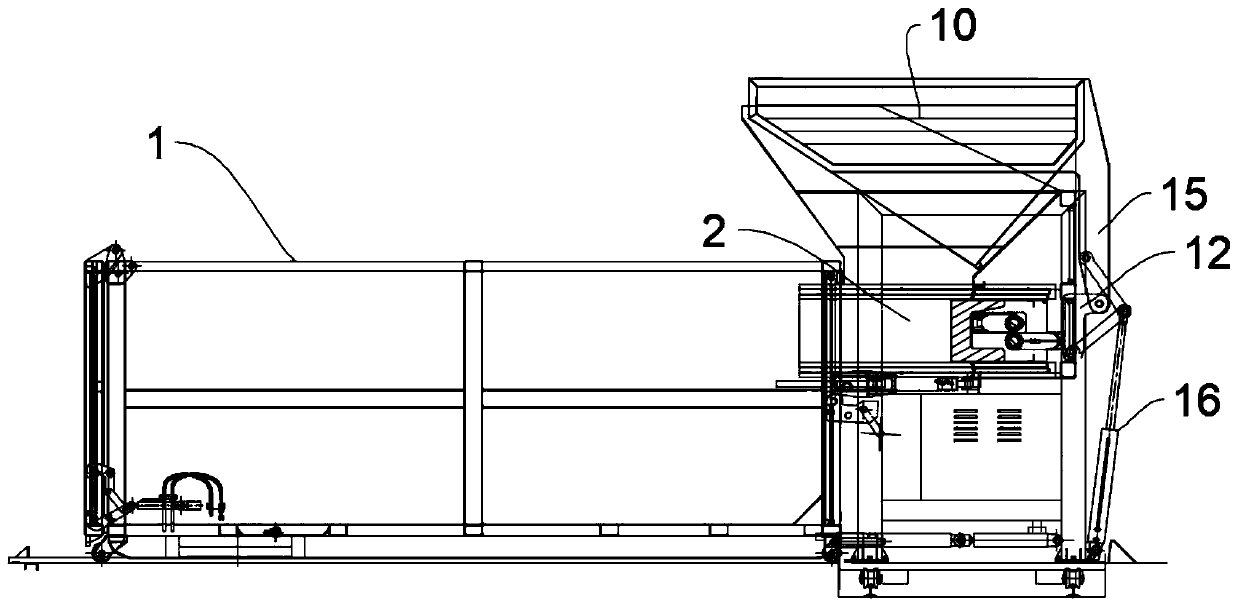

Waste compression device

ActiveCN104609077APromote reductionReduce moisture contentRefuse transferringLoading/unloadingCompression deviceWaste collection

The invention discloses a waste compression device. The waste compression device comprises a waste inlet, movable compression rolls, a crushing roll, a conveying line and extruding-in rolls. The waste compression device is connected with a waste collecting platform through the waste inlet in a butt joint mode. The movable compression rolls are arranged at the waste inlet, and waste on the waste collecting platform enters the movable compression rolls through the waste inlet. The crushing roll is arranged above the movable compression rolls in a telescopic mode and used for crushing the waste located above the movable compression rolls. The conveying line is used for conveying the waste which is extruded by the movable compression rolls to a waste outlet. The extruding-in rolls are arranged at the waste outlet, and the waste on the conveying line enters a dustbin through the extruding-in rolls. The maximum reduction of the waste is achieved through the waste compression device.

Owner:广西玉柴专用汽车有限公司

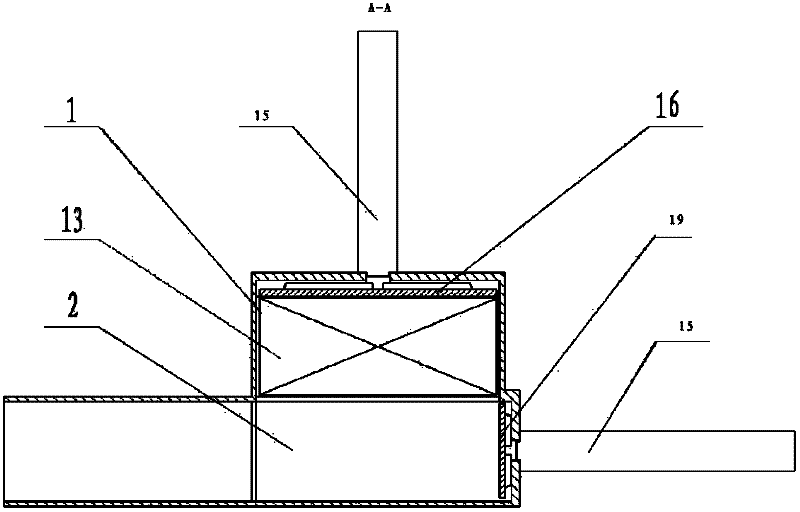

Secondary compression moulding device for bale

The invention discloses a secondary compression moulding device for a bale. The device comprises a feeding mechanism, a compression cavity, a pressure maintaining cavity, a compression mechanism, a vertical pushing mechanism, a horizontal pushing mechanism, a strapping mechanism and a cutting mechanism; the bale output end of the feeding mechanism is communicated with a feeding hole disposed on a sidewall in the length direction of the compression cavity; the pressure maintaining cavity is disposed on the lower part of the end part of the compression cavity opposite with the compression mechanism and communicated with the compression cavity; the pressure maintaining cavity extends towards one end along the width direction of the compression cavity; the top part of the end part of the compression cavity at a place corresponding to the pressure maintaining cavity is connected with the vertical pushing mechanism; the end part of the non-extending part of the compression cavity is connected with the horizontal pushing mechanism; and the extending part of the pressure maintaining cavity is orderly connected with the strapping mechanism and the cutting mechanism. The secondary compression moulding device for a bale disclosed by the invention has the advantages of being low in noise, large in compression density, high in production rate and capable of producing a secondarily-compressed bale with uniform weight and good appearance; and the square funnel-shaped design of the feeding hole of the compression cavity and the arrangement of a guide boss are good for smooth feeding for bale without blockage.

Owner:CHINA AGRI UNIV

Ferrite powders for bonded magnet, process for the production of the powders, and bonded magnet made by using the same

InactiveUS20100295643A1High magnetizationWide particle size distribution widthSynthetic resin layered productsCellulosic plastic layered productsFerrite powderParticle-size distribution

The present invention provides ferrite powders for bonded magnet capable of suppressing increase of SFD, while widening a particle size distribution for obtaining flowability and compressed density, and also capable of suppressing deterioration of orientation and magnetizability, and provides a process for a production magnetoplumbite-type ferrite powders containing an oxide of at least one or more kinds of transition metals selected from a group consisting of Zr, Ti, Zn, Co, Mn, and Ni, having a mean particle size of 0.20 μm or more and less than 5.00 μm, being the ferrite powders for bonded magnet with the ratio of particles having particle size of 1 μm or less being 20 mass % or more in the magnetoplumbite-type ferrite powder size distribution obtained by a laser diffraction type particle size distribution analyzer.

Owner:DOWA ELECTRONICS MATERIALS CO LTD +1

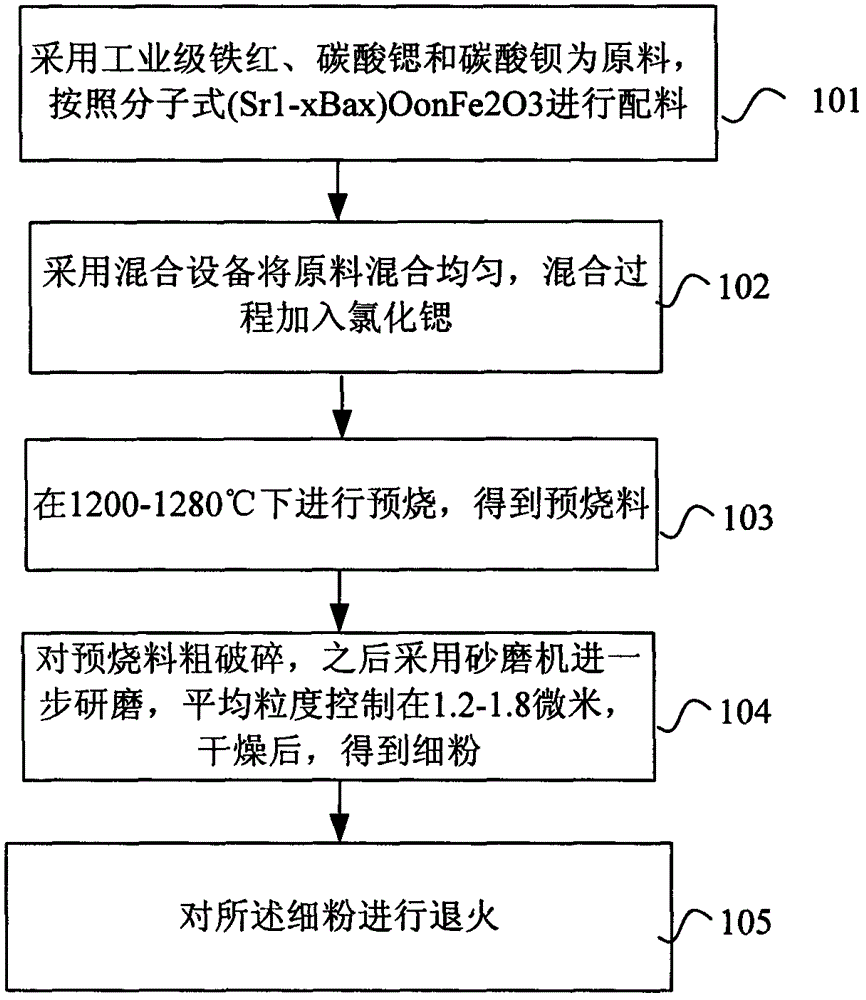

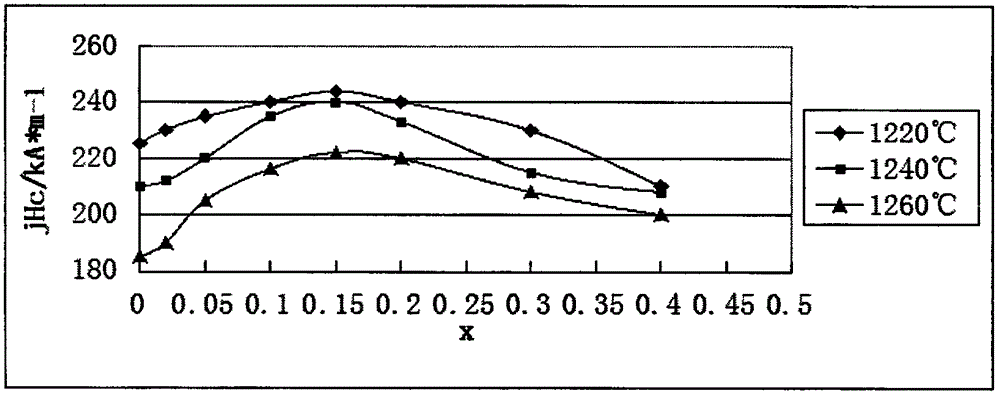

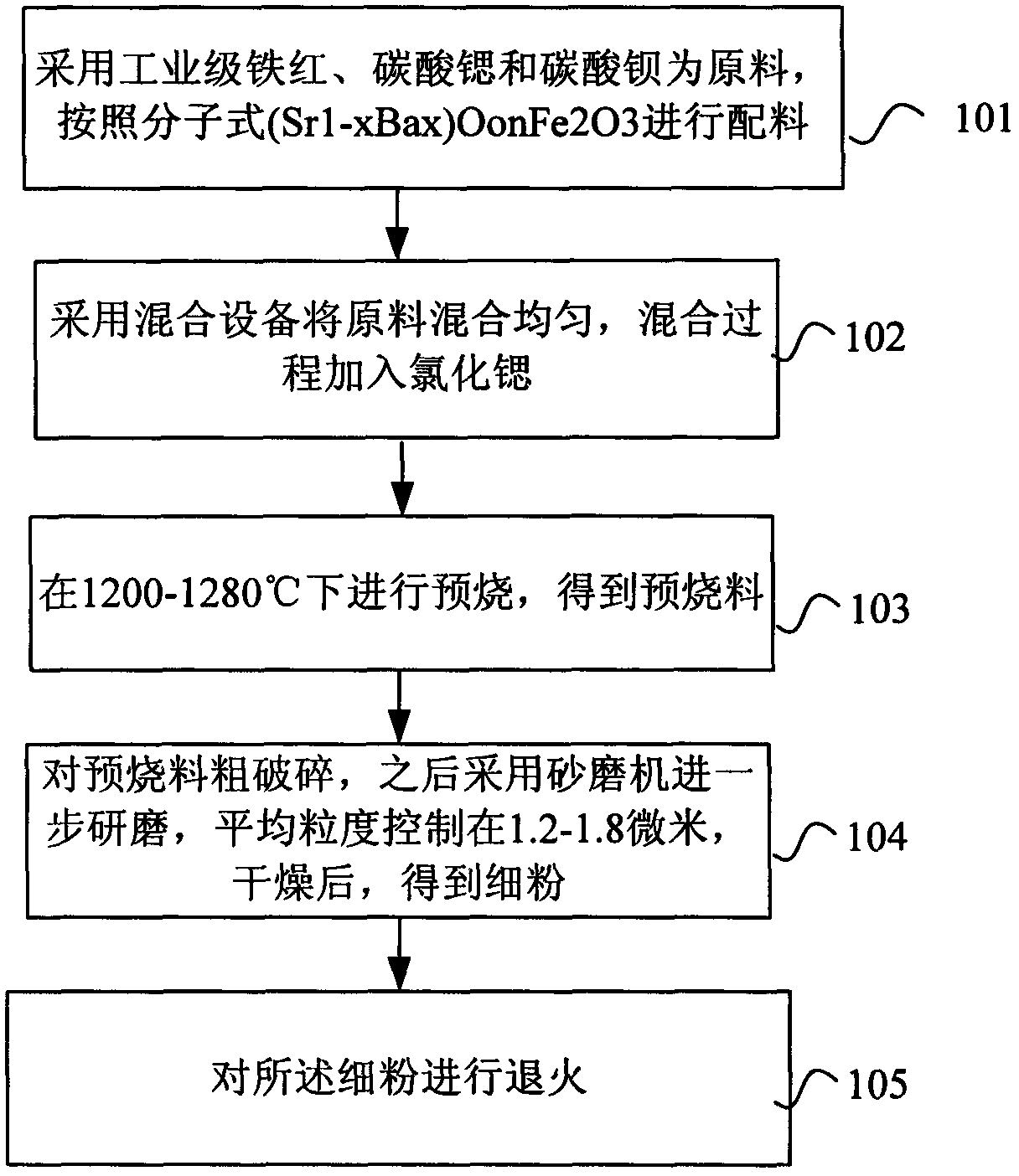

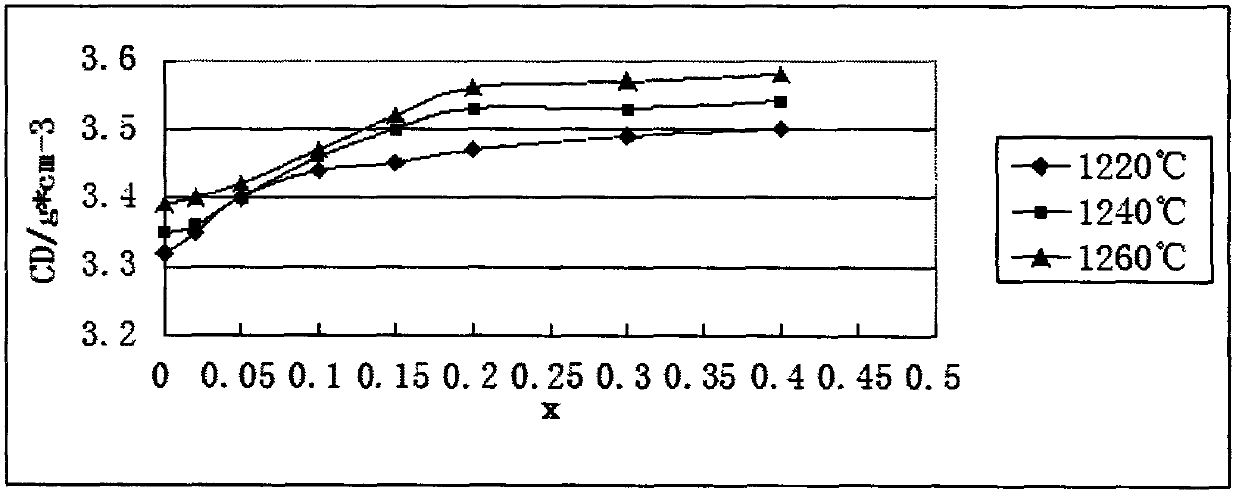

Bonded ferrite magnetic powder, bonding magnet and preparation method thereof

ActiveCN105836808AHigh compression densityIncrease filling volumeIron compoundsMagnetic materialsStrontium carbonateNylon 6

The invention provides a bonded permanent magnetic ferrite powder, a bonding magnet and a preparation method thereof. The bonded ferrite magnetic powder has a main phase shown as the following molecular formula: (Sr1-xBax)O.nFe2O3, wherein, n represents molar ratio and meets n=6.11- 6.30, and x is greater than or equal to 0.10 and smaller than or equal to 0.20. The preparation method of the bonded permanent magnetic ferrite powder includes taking industrial grade iron oxide red, strontium carbonate and barium carbonate as the raw materials, conducting burdening accordance to the molecular formula of (Sr1-xBax)O.nFe2O3, mixing the raw materials uniformly, and adding strontium chloride in the mixing process; performing pre-sintering at 1200-1280DEG C to obtain a pre-sintered material; carrying out coarse crushing and grinding on the pre-sintered material, and performing drying to obtain fine powder; annealing the fine powder; mixing the obtained magnetic powder with nylon 6 and related additives evenly, and conducting granulation and injection molding so as to obtain the bonded magnet with BR greater than 310mT.

Owner:ANTE MAGNETIC MATERIAL CO LTD

garbage compactor

ActiveCN104609077BPromote reductionReduce moisture contentRefuse transferringLoading/unloadingWaste collectionCompression device

The invention discloses a waste compression device. The waste compression device comprises a waste inlet, movable compression rolls, a crushing roll, a conveying line and extruding-in rolls. The waste compression device is connected with a waste collecting platform through the waste inlet in a butt joint mode. The movable compression rolls are arranged at the waste inlet, and waste on the waste collecting platform enters the movable compression rolls through the waste inlet. The crushing roll is arranged above the movable compression rolls in a telescopic mode and used for crushing the waste located above the movable compression rolls. The conveying line is used for conveying the waste which is extruded by the movable compression rolls to a waste outlet. The extruding-in rolls are arranged at the waste outlet, and the waste on the conveying line enters a dustbin through the extruding-in rolls. The maximum reduction of the waste is achieved through the waste compression device.

Owner:广西玉柴专用汽车有限公司

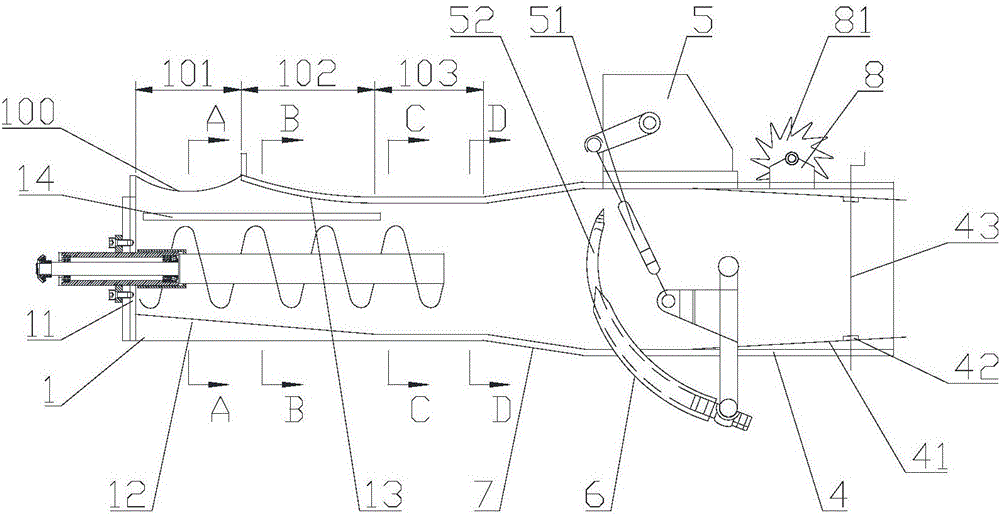

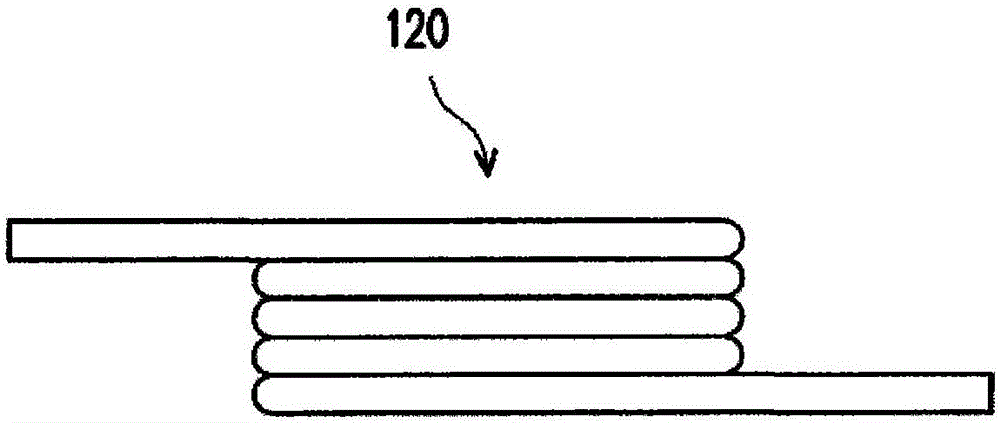

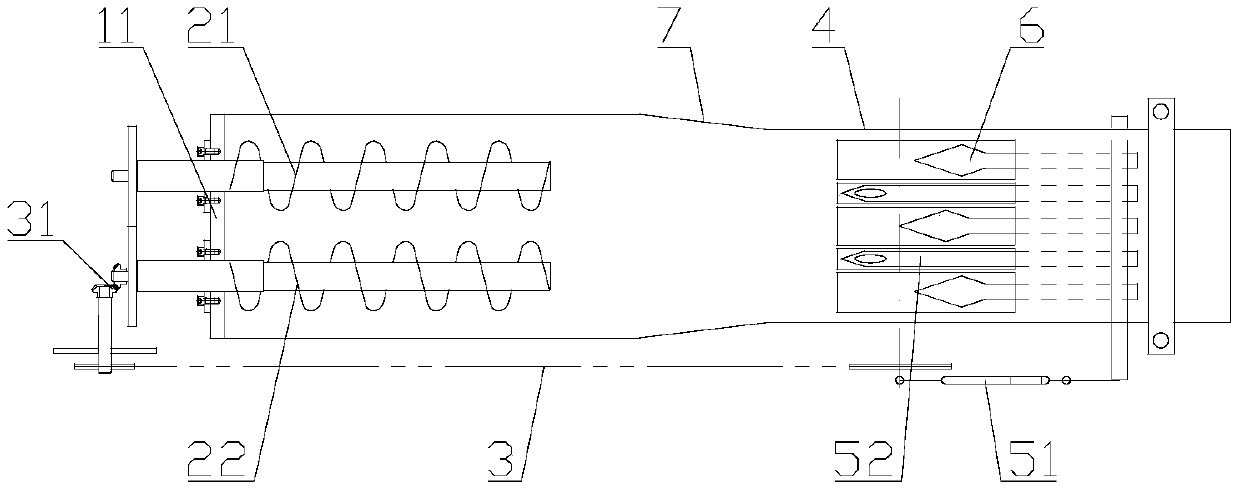

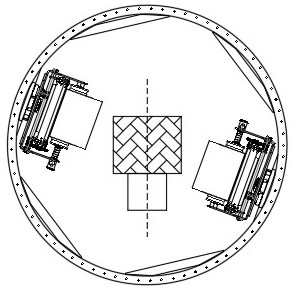

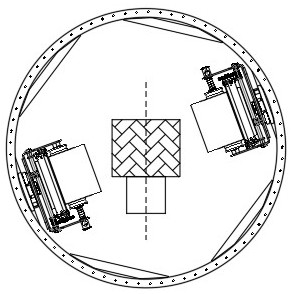

Twin-screw compression straw baler

The invention discloses a twin-screw compression straw baler, and belongs to the field of agricultural machinery. The problems of complex structure and heavy weight of a baler in the prior art are solved. According to the technical scheme, the twin-screw compression straw baler mainly comprises a twin-screw straw compressor, a baling device and a driving device, wherein the twin-screw straw compressor comprises a charging barrel, a first helical blade and a second helical blade; the charging barrel is provided with a feed inlet; the first and second helical blades are arranged abreast in the charging barrel; the charging barrel is communicated with the baling device, and is used for delivering straws to the baling device through the first and second helical blades; the first and second helical blades are driven by the driving device; the helical directions of the first and second helical blades are opposite; the rotating directions of the first and second helical blades are opposite and back to the feed inlet. The twin-screw compression straw baler is mainly used for compressing and baling the straws.

Owner:平阳县凯达包装机械厂

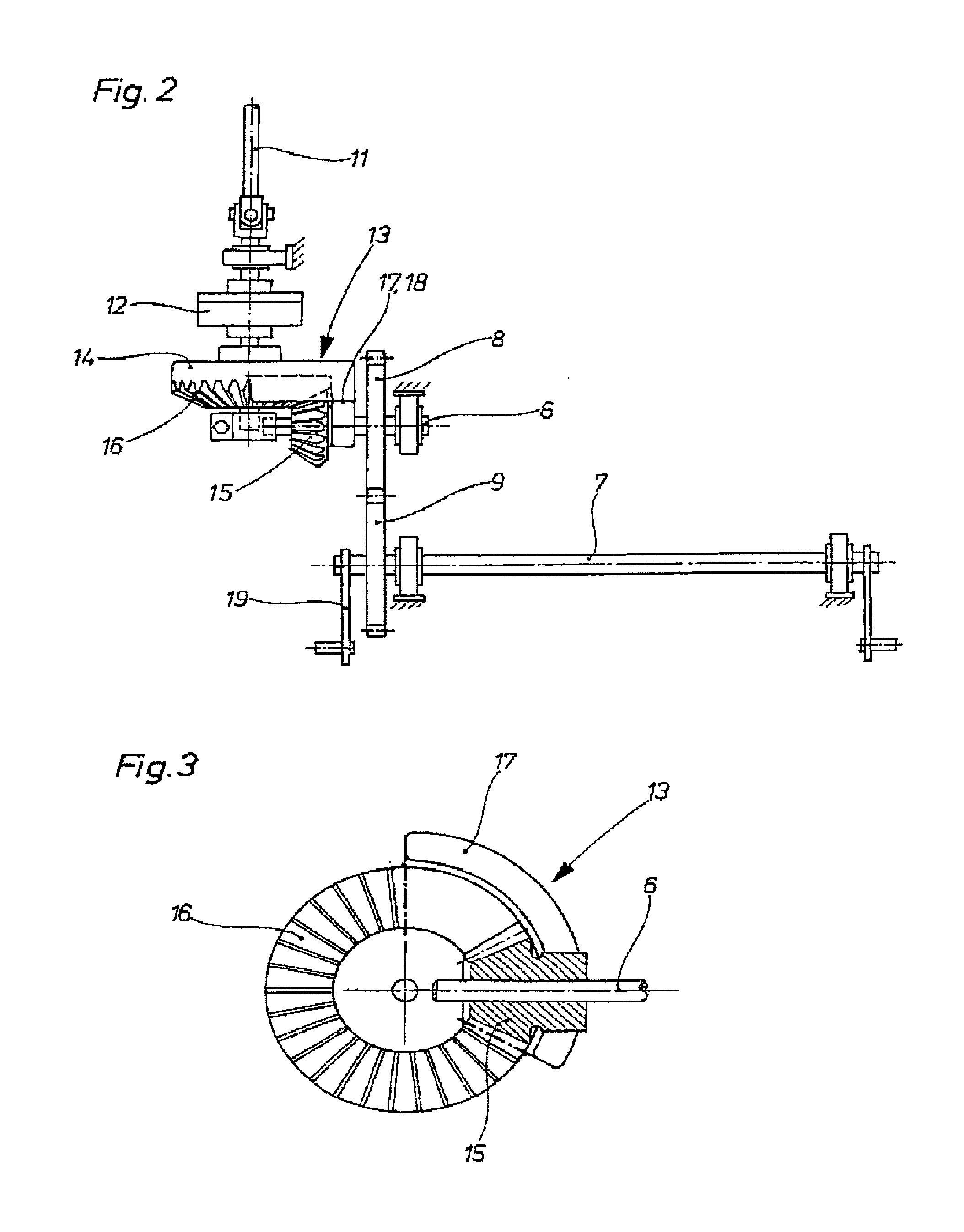

Binding device for a big baler

A binding device for a baler including at least one twine needle, a knotter shaft for driving the needle, a one-stop clutch for connecting the knotter shaft with the plunger drive and for intermittently driving the knotter shaft, and a transmission unit provided between the one-stop clutch and the knotter shaft and including elements which insure that for one complete revolution of the one-stop clutch, the knotter shaft also performs one complete revolution but with a higher speed than the one-stop clutch.

Owner:LELY VERMEER MASCHFAB

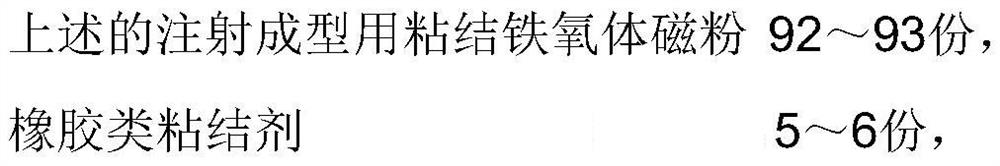

Method for manufacturing magnetic encoder

ActiveUS20170082456A1Improve coercive forceGood molding effectMagnetsInductances/transformers/magnets manufactureNitrile rubberMagnetic flux

Provided is a method for a magnetic encoder having a magnetic body comprised of a magnetic rubber molded article, comprising a mixing step of mixing and then kneading a nitrile rubber (A), a ferrite magnetic powder (B) and a vulcanizing agent (C) to provide a magnetic rubber composition; and a molding step of molding and vulcanizing the magnetic rubber composition in a mold to which a magnetic field is applied to provide the magnetic rubber molded article, wherein a content of the ferrite magnetic powder (B) is 700 to 1500 parts by mass based on 100 parts by mass of the nitrile rubber (A); and a compressed density of the ferrite magnetic powder (B) is 3.5 g / cm3 or more. According to this method, a magnetic encoder having a magnetic body with high coercivity and residual magnetic flux density can be produced by vulcanizing a magnetic rubber composition having favorable moldability.

Owner:UCHIYAMA MFG

Straw baling machine

InactiveCN108476750AHigh compression densityReduce volumeBalingHydraulic cylinderProgrammable logic controller

The invention relates to a straw baling machine, comprising a material bin and a screw feeder. The bottom wall of the material bin is provided with a discharge pipe; a compression bin is fixed below the material bin; a hydraulic cylinder that telescopes transversely is fixed to one side of the compression bin and is in control connection with a PLC (programmable logic controller); a piston rod endof the hydraulic cylinder is extended into the compression bin and is fixedly connected with a push plate in slidable contact with the inner peripheral wall of the compression bin; the side, close tothe hydraulic cylinder, of the top end of the push plate is fixedly provided with a retaining plate horizontally arranged; the side, far away from the hydraulic cylinder, of the compression bin is connected with a squeeze bin in horn shape and having gradually decreasing diameter; the side, far away from the compression bin, of the squeeze bin is connected with a forming bin; the side, far away from the squeeze bin, of the forming bin is provided with an outlet. The screw feeder, the hydraulic cylinder and the squeeze bin are combined for use such that material compression density is higher and straw size is greatly decreased; therefore, straws are convenient to store and convey, and the whole straw baling machine is simple in structure, small in size, light in weight, low in energy consumption and convenient to move.

Owner:李卫涛

Bonded ferrite magnetic powder for injection molding as well as preparation method and application of bonded ferrite magnetic powder

PendingCN113889309AImprove liquidityImprove stabilityInorganic material magnetismInductances/transformers/magnets manufacturePlasticizerBall mill

The invention discloses bonded ferrite magnetic powder for injection molding as well as a preparation method and application of bonded ferrite magnetic powder. The bonded ferrite magnetic powder for injection molding is prepared by adding fine ferrite magnetic powder with the average particle size of 0.5-1.2 microns and coarse ferrite magnetic powder with the average particle size of 3.0-6.0 microns into a ball mill according to the weight ratio that the fine ferrite magnetic powder accounts for 10-35wt%, and carrying out ball milling, thereby obtaining coarse and fine mixed magnetic powder. The bonded ferrite magnetic powder for injection molding can be mixed with a rubber binder, a plasticizer and a stabilizer to prepare an injection-molded flexible bonded magnet. The flowability of the magnetic powder and the magnetic performance of the magnet can be greatly improved and exceed the level of existing like products, and the upper limit of the use temperature of the injection molding flexible bonded magnet can be improved to 125 DEG C from 80 DEG C, so that the application field of the injection molding flexible bonded magnet is widened, and the stability and the reliability of the injection molding flexible bonded magnet are improved.

Owner:BGRIMM TECH CO LTD

Silage block film wrapping and packaging method

ActiveCN113173302AImprove compression efficiencyHigh compression densityWrapping material feeding apparatusWeb rotation wrappingStructural engineeringLower face

The invention discloses a silage block film wrapping and packaging method. The silage block film wrapping and packaging method is completed through cooperation of a set of integrated equipment, the equipment sequentially comprises a compression cavity, a shape maintaining cavity, a film wrapping device and a platform, wherein the film wrapping and packaging method comprises the basic steps that firstly, a cuboid material block is generated through compression of the compression cavity; then the cuboid material block is made to horizontally move forwards through the shape maintaining cavity to penetrate through the center of a winding plate, a film roll is controlled to be in a horizontal state, the winding plate is made to rotate to drive the film roll to conduct circular motion around the material block while the material block moves forwards, and horizontal film winding is conducted on the upper face, the lower face, the left face and the right face of the material block; and finally, the film roll is controlled to be turned over to be in a vertical state, the material block is moved to the platform, the platform is controlled to drive the material block to rotate in the plane, vertical film winding is conducted on the front face, the rear face, the left face and the right face of the material block, and therefore the film winding task of the six faces of the cuboid material block is completed.

Owner:ANYANG INST OF TECH

Straw baler

The invention relates to a straw baler comprising a feeding bin, a PLC and a spiral feeding rod. The two ends of the spiral feeding rod are rotationally installed on the feeding bin through bearings.One end of the spiral feeding rod is connected with a drive mechanism. The top of one end of the feeding bin is provided with a material inlet. The bottom of the other end of the feeding bin is provided with a material outlet. The bottom wall of the feeding bin is fixedly provided with a compression bin. The top wall of the compression bin is provided with an inlet corresponding to the material outlet of the feeding bin. A hydraulic cylinder is fixedly arranged on one side of the compression bin. The piston end of the hydraulic rod extends into the compression bin and is fixedly connected witha material pushing plate which is in sliding contact with the inner peripheral wall of the compression bin. The side, far away from the hydraulic cylinder, of the compression bin is connected with asqueezing bin. The side, far away from the compression bin, of the squeezing bin is connected with a forming bin. The side, far away from the squeezing bin, of the forming bin is provided with an outlet. The straw baler enables the material compression density to be larger, the volume of the materials is greatly reduced, material storage and transportation are convenient, and the straw baler is simple in overall structure and light in weight.

Owner:李卫涛

Plasma arc cutting torch

The invention provides a plasma arc cutting torch. The plasma arc cutting torch comprises cutting torch body, an electrode and a nozzle and is characterized in that the inner hole of the nozzle is of a sectional circular horn shape and provided with a central hole in the center, and the nozzle is main made of red copper. The electrode is arranged in the nozzle and mounted on an electrode base, the middle section of the electrode is concave inwardly to form a calabash shape, the space between the nozzle and the electrode is expanded, positive electric ions on the electrode can be prevented from being transmitted to the nozzle from a non-central-hole position, and a double-arc effect is avoided.

Owner:CHANGZHOU JIUSHENG WELDING EQUIP

Inductor and method of making the same

ActiveCN101901668BImprove magnetic permeabilityReduce magnetic lossTransformers/inductances coils/windings/connectionsInorganic material magnetismHardnessInductor

The invention relates to an inducer and a production method thereof. The inducer comprises a magnetic body and a lead, wherein the magnetic body comprises first magnetic powder and second magnetic powder; the Vickers hardness of the first magnetic powder is greater than that of the second magnetic powder; the average grain diameter of the first magnetic powder is greater than that of the second magnetic powder; and the first magnetic powder is mixed with the second magnetic powder.

Owner:CYNTEC

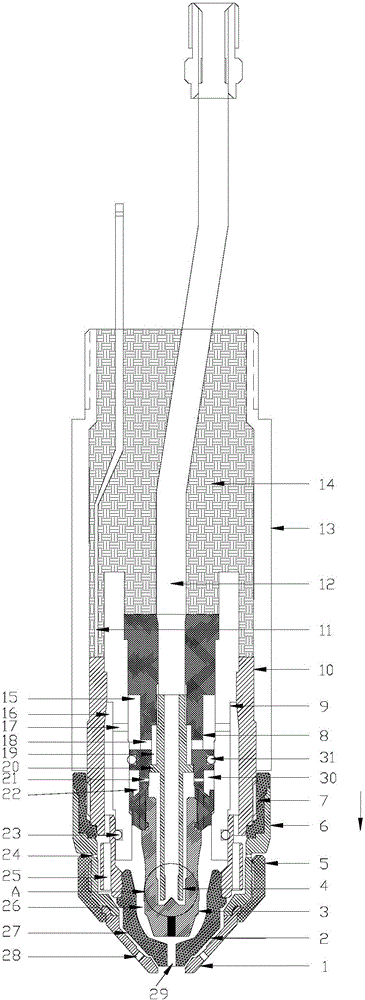

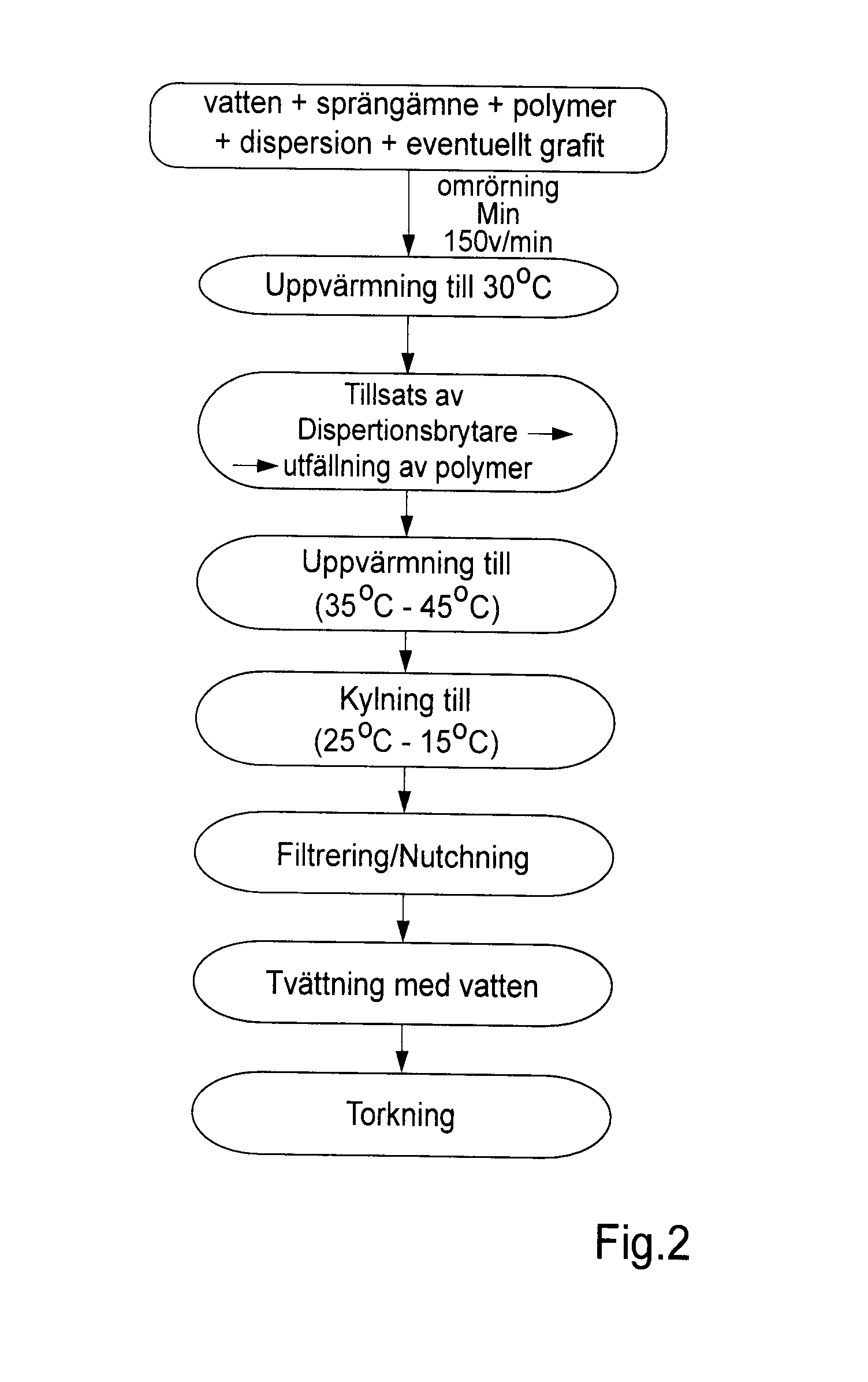

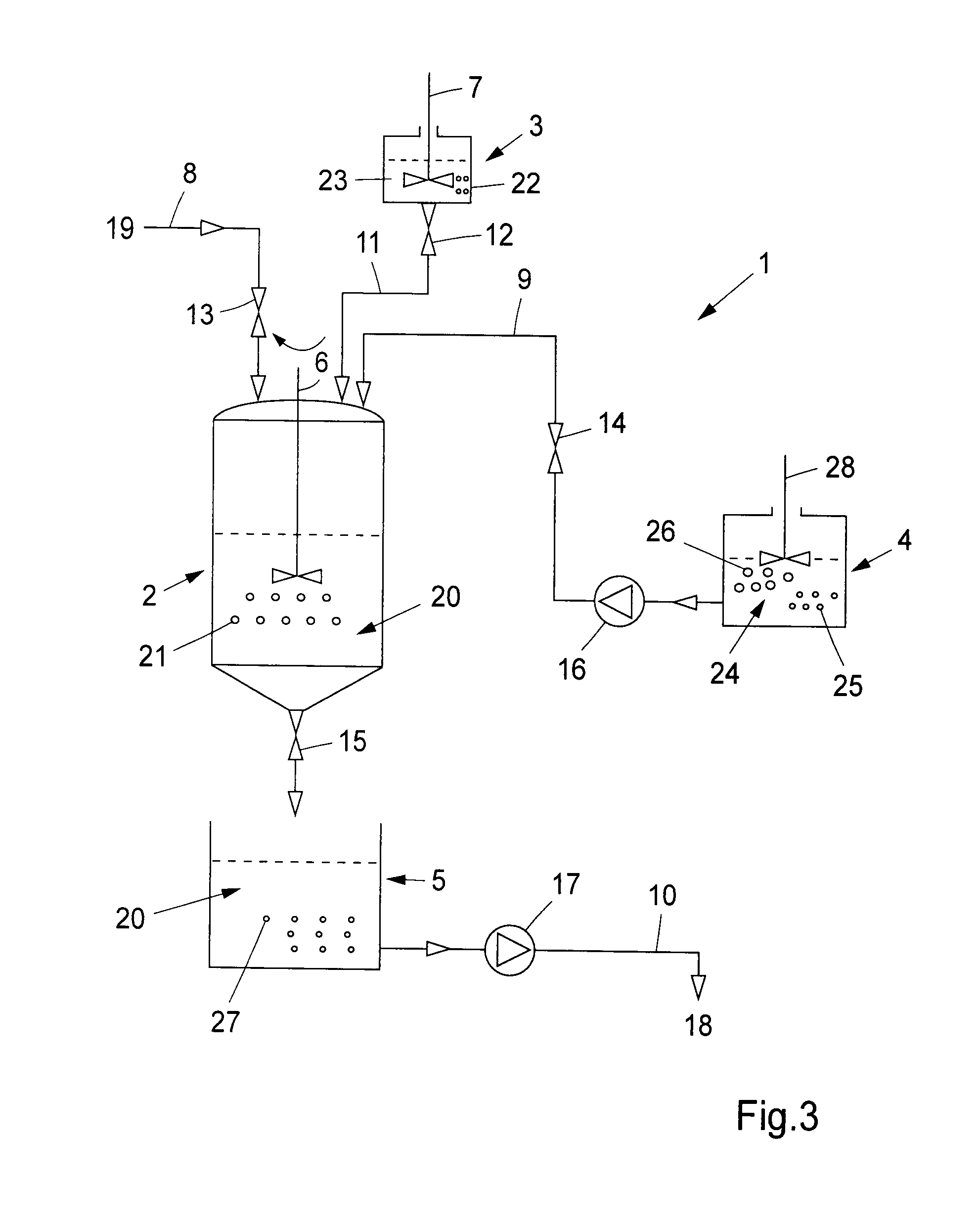

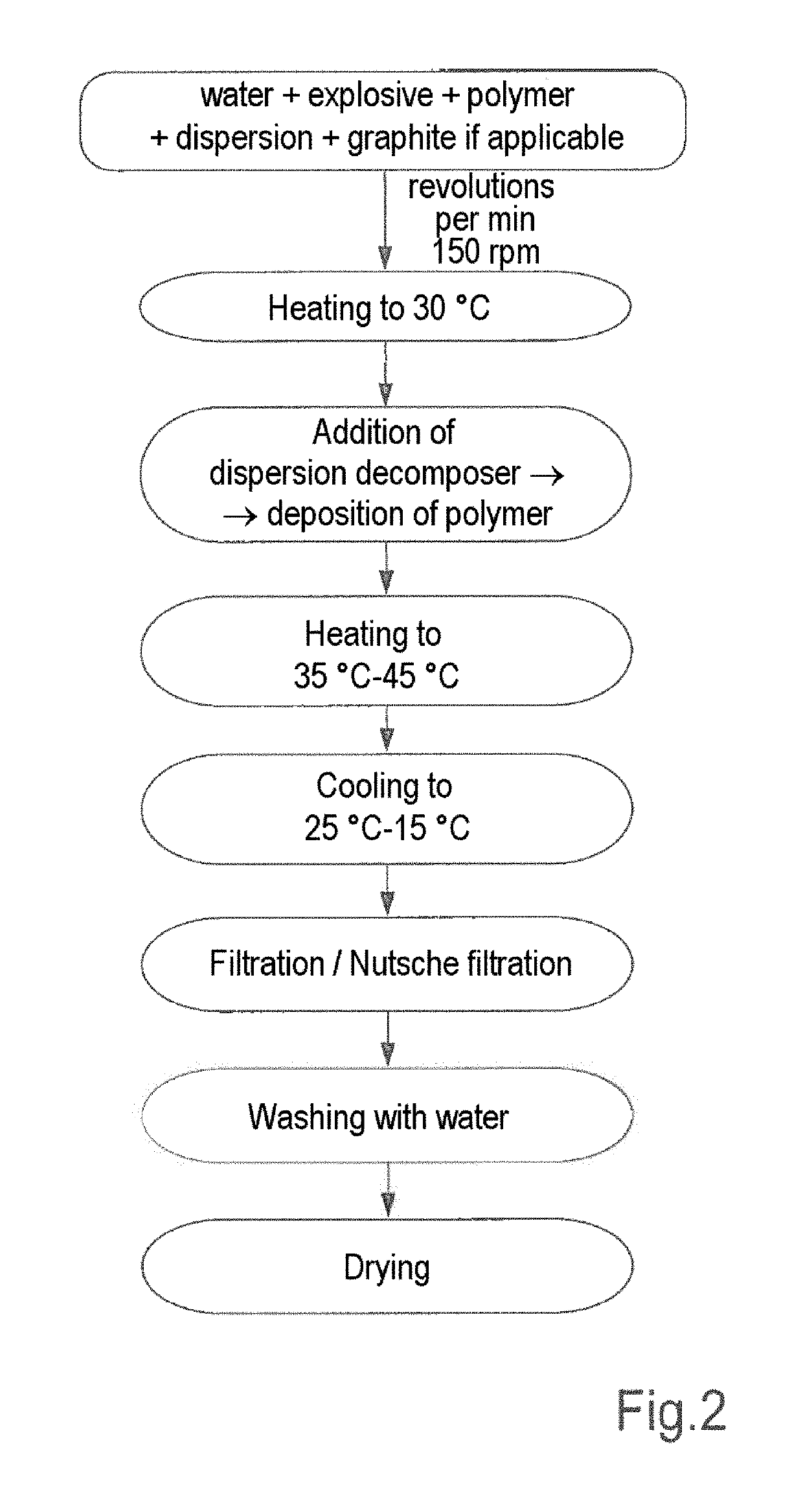

Phlegmatisation of an explosive in an aqueous suspension

ActiveUS20160137566A1High compression densityLow impact sensitivityLiquid surface applicatorsElectric shock equipmentsExplosive materialChemistry

A method for phlegmatising an explosive in an aqueous suspension including a dispersed phlegmatising agent. The phlegmatising agent is deposited on a surface of the explosive at low temperature utilizing opposite electric charges of the phlegmatising agent and the explosive. Also a device and a phlegmatised explosive.

Owner:EURENCO BOFORS

Telescopic mold structure and foaming preparation method thereof

PendingCN113134936AHigh compression densityImprove thermal conductivityEngineeringMechanical engineering

The invention discloses a telescopic mold structure and a foaming preparation method thereof. The telescopic mold structure comprises an upper cover and a bottom cover, wherein the upper cover covers the bottom cover, and an accommodating space is formed between the upper cover and an inwards concave part of the bottom cover; and a telescopic structure is arranged between the upper cover and the bottom cover, so that the range of the accommodating space can be adjusted; Through the design of the telescopic mold structure, pressurization or multiple times of pressing can be properly carried out according to the requirements of the foaming materials in the foaming preparation method, the compression density between the foaming materials is improved, the heat conductivity is improved, the forming density and thickness of foaming forming can be controlled, the surface flatness is improved, and the product yield is improved.

Owner:HERLIN UP CO LTD

Binding device for a big baler

A binding device for a baler including at least one twine needle, a knotter shaft for driving the needle, a one-stop clutch for connecting the knotter shaft with the plunger drive and for intermittently driving the knotter shaft, and a transmission unit provided between the one-stop clutch and the knotter shaft and including elements which insure that for one complete revolution of the one-stop clutch, the knotter shaft also performs one complete revolution but with a higher speed than the one-stop clutch.

Owner:LELY VERMEER MASCHFAB

Inductor and manufacturing method thereof

ActiveCN105914003AImprove magnetic permeabilityReduce magnetic lossMagnetic materialsInductance with magnetic coreInductorHardness

The invention relates to an inductor and a manufacturing method thereof. The inductor comprises a magnetic body and a wire; the magnetic body comprises first magnetic powder and second magnetic powder, wherein the Vickers hardness of the first magnetic powder is larger than that of the second magnetic powder, the mean particle diameter of the first magnetic powder is larger than that of the second magnetic powder, and the first magnetic powder and the second magnetic powder are mixed with each other.

Owner:CYNTEC

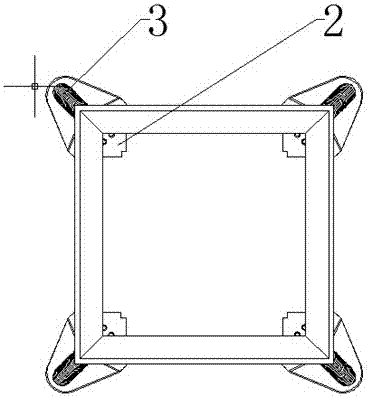

Garbage compression station

PendingCN111470227AEasy dockingEasy to removeRefuse transferringStorage devicesComputer hardwareEngineering

The invention relates to the technical field of garbage compression equipment, and discloses a garbage compression device and a garbage compression station. The garbage compression device comprises afeeding mechanism and a push-pull box mechanism, wherein the feeding mechanism comprises a push head stock bin for feeding materials into a box body, the push-pull box mechanism comprises a box body guide rail extending towards the feeding mechanism and a driving device for driving the box body to horizontally move along the box body guide rail so as to enable a feeding hole of the box body to bebutted with the push head stock bin. According to the garbage compression device and the garbage compression station, the effective height needed by butt joint of the box bodies of the garbage stationis reduced, the current situation that the space height of the garbage station is limited can be better adapted, large size utilization space and feasibility are provided for transformation of an existing garbage station, a double-station or multi-station operation mode of one machine with one box or two boxes or multiple boxes is adopted, use is more reasonable and convenient, the utilization rate is higher, and the garbage treatment efficiency is higher.

Owner:重庆捌拾玖度环保科技有限公司

Method for manufacturing magnetic encoder

ActiveUS10203222B2Improve coercive forceGood molding effectPermanent magnetsInductances/transformers/magnets manufactureNitrile rubberMagnetic flux

Provided is a method for a magnetic encoder having a magnetic body comprised of a magnetic rubber molded article, comprising a mixing step of mixing and then kneading a nitrile rubber (A), a ferrite magnetic powder (B) and a vulcanizing agent (C) to provide a magnetic rubber composition; and a molding step of molding and vulcanizing the magnetic rubber composition in a mold to which a magnetic field is applied to provide the magnetic rubber molded article, wherein a content of the ferrite magnetic powder (B) is 700 to 1500 parts by mass based on 100 parts by mass of the nitrile rubber (A); and a compressed density of the ferrite magnetic powder (B) is 3.5 g / cm3 or more. According to this method, a magnetic encoder having a magnetic body with high coercivity and residual magnetic flux density can be produced by vulcanizing a magnetic rubber composition having favorable moldability.

Owner:UCHIYAMA MFG

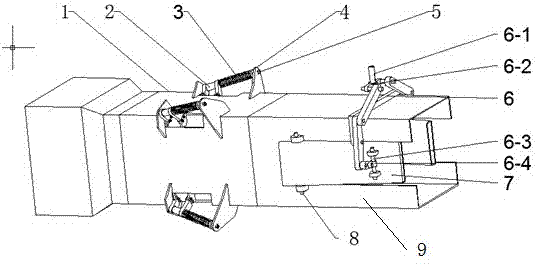

An open straw compression box with a two-stage density adjustment mechanism

ActiveCN106003795BControl the opening and closing angleHigh compression densityPressesHigh densityEngineering

The invention discloses an open type straw compressing box with two density adjusting mechanisms. The open type straw compressing box comprises a first compression box body and a second compression box body, wherein the first compression box body is provided with the first density adjusting mechanism, and the second compression box body is provided with the second density adjusting mechanism. The first density adjusting mechanism comprises blocking slide blocks, springs, adjusting nuts and guiding rods. The guiding rods are fixed to lateral edges of the first compression box body, the first guiding rod is provided with the corresponding blocking slide block, the corresponding spring and the corresponding adjusting nut, and the corresponding blocking slide block stretches into the first compression box body. The second density adjusting mechanism comprises reversing manipulators and inclined lateral pressing plates, the inclined lateral pressing plates are arranged on the two opposite sides of the second compression box body through hinge pins, and the ends of the inclined lateral pressing plates are connected with the corresponding manipulators. Through the two density adjusting mechanisms, a first bundle which is actually bundled can be compressed in a high-density mode, and the two density adjusting mechanisms provide resistance at the same time, so that the compression density is greatly improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

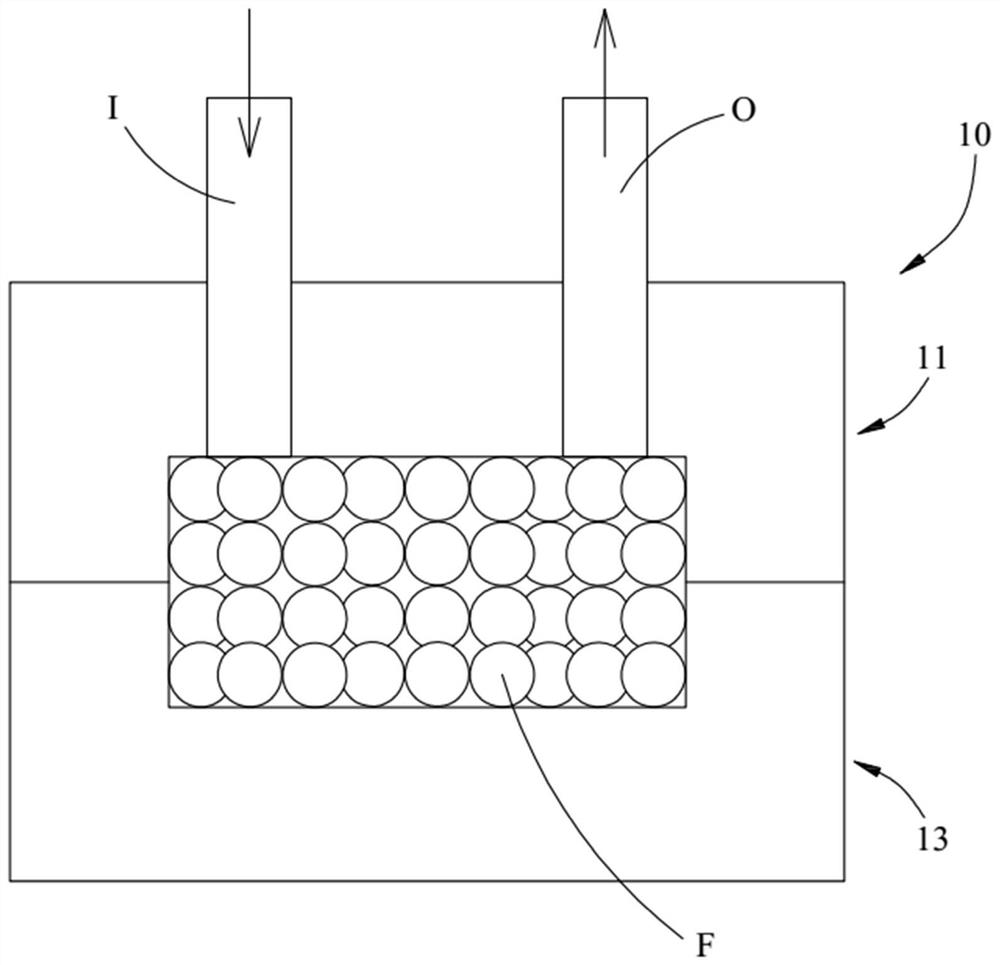

Superconducting missile type variable-frequency enthalpy increasing air energy source heat pump unit system

InactiveCN109520171AFix damagePoor resolutionMechanical apparatusEvaporators/condensersFour-way valveUnit system

The invention relates to the technical field of heat pump equipment, in particular to a superconducting missile type air energy source heat pump unit system. The superconducting missile type air energy source heat pump unit system comprises a heat pump type compressor, a four-way valve, a special efficient heat exchanger, filters, an electronic expansion valve, a diversion head, an evaporator, a plate type heat exchanger, a missile-shaped subsonic-speed heating part, superconducting liquid, a gas-liquid separator, a fan, an airtight pipeline, a water inlet, a water outlet and an insulating water tank. The application range of the superconducting missile type air energy source heat pump unit system is widened to the areas in the south and the north, heat, cool air and hot water can be supplied, the product performance is safe and reliable, and use is convenient. In addition, experiments prove that the heat efficiency is far higher than that of an existing air energy source heat pump water heating unit under the ultralow-temperature working condition, and under the ultralow-temperature condition, the heat efficiency is not attenuated or slightly reduced, and the energy saving effectis very obvious.

Owner:王子忠

Twin-screw compression straw baler

The invention discloses a twin-screw compression straw baler, and belongs to the field of agricultural machinery. The problems of complex structure and heavy weight of a baler in the prior art are solved. According to the technical scheme, the twin-screw compression straw baler mainly comprises a twin-screw straw compressor, a baling device and a driving device, wherein the twin-screw straw compressor comprises a charging barrel, a first helical blade and a second helical blade; the charging barrel is provided with a feed inlet; the first and second helical blades are arranged abreast in the charging barrel; the charging barrel is communicated with the baling device, and is used for delivering straws to the baling device through the first and second helical blades; the first and second helical blades are driven by the driving device; the helical directions of the first and second helical blades are opposite; the rotating directions of the first and second helical blades are opposite and back to the feed inlet. The twin-screw compression straw baler is mainly used for compressing and baling the straws.

Owner:平阳县凯达包装机械厂

A kind of silage block wrapping film packing method

ActiveCN113173302BImprove compression efficiencyHigh compression densityWrapping material feeding apparatusWeb rotation wrappingClassical mechanicsStructural engineering

A film wrapping and packaging method for silage blocks, the method is completed by a set of integrated equipment, and the equipment sequentially includes a compression cavity, a shape-preserving cavity, a film wrapping device, and a platform; the basic steps of the film wrapping method are: firstly The cuboid block is compressed by the compression cavity; then the cuboid block is moved forward through the center of the reel through the shape-preserving cavity, and the film is controlled to be in a horizontal state, and the reel is rotated while the block is advancing. The material block moves in a circular motion, and the upper, lower, left and right sides of the material block are horizontally wrapped; finally, the film roll is controlled to be turned over to a vertical state, and the material block is moved to the platform, and the platform is controlled to drive the material block. Rotate in the plane, and vertically wrap the front, rear, left and right sides of the block, so as to complete the film wrapping task of the six sides of the cuboid block.

Owner:ANYANG INST OF TECH

Secondary compression moulding device for bale

The invention discloses a secondary compression moulding device for a bale. The device comprises a feeding mechanism, a compression cavity, a pressure maintaining cavity, a compression mechanism, a vertical pushing mechanism, a horizontal pushing mechanism, a strapping mechanism and a cutting mechanism; the bale output end of the feeding mechanism is communicated with a feeding hole disposed on a sidewall in the length direction of the compression cavity; the pressure maintaining cavity is disposed on the lower part of the end part of the compression cavity opposite with the compression mechanism and communicated with the compression cavity; the pressure maintaining cavity extends towards one end along the width direction of the compression cavity; the top part of the end part of the compression cavity at a place corresponding to the pressure maintaining cavity is connected with the vertical pushing mechanism; the end part of the non-extending part of the compression cavity is connected with the horizontal pushing mechanism; and the extending part of the pressure maintaining cavity is orderly connected with the strapping mechanism and the cutting mechanism. The secondary compression moulding device for a bale disclosed by the invention has the advantages of being low in noise, large in compression density, high in production rate and capable of producing a secondarily-compressed bale with uniform weight and good appearance; and the square funnel-shaped design of the feeding hole of the compression cavity and the arrangement of a guide boss are good for smooth feeding for bale without blockage.

Owner:CHINA AGRI UNIV

A bonded ferrite magnetic powder, bonded magnet and preparation method thereof

ActiveCN105836808BHigh compression densityIncrease filling volumeInorganic material magnetismIron compoundsStrontium carbonateFerrite powder

The invention provides a bonded permanent magnetic ferrite powder, a bonding magnet and a preparation method thereof. The bonded ferrite magnetic powder has a main phase shown as the following molecular formula: (Sr1-xBax)O.nFe2O3, wherein, n represents molar ratio and meets n=6.11- 6.30, and x is greater than or equal to 0.10 and smaller than or equal to 0.20. The preparation method of the bonded permanent magnetic ferrite powder includes taking industrial grade iron oxide red, strontium carbonate and barium carbonate as the raw materials, conducting burdening accordance to the molecular formula of (Sr1-xBax)O.nFe2O3, mixing the raw materials uniformly, and adding strontium chloride in the mixing process; performing pre-sintering at 1200-1280DEG C to obtain a pre-sintered material; carrying out coarse crushing and grinding on the pre-sintered material, and performing drying to obtain fine powder; annealing the fine powder; mixing the obtained magnetic powder with nylon 6 and related additives evenly, and conducting granulation and injection molding so as to obtain the bonded magnet with BR greater than 310mT.

Owner:ANTE MAGNETIC MATERIAL CO LTD

Method, device and computer program for encoding digital image

InactiveUS20060056718A1Loss increaseEasy to compressCharacter and pattern recognitionTelevision systemsComputer programDigital image

The invention relates to a method, device, and computer program on a carrier for encoding a digital image. Until the encoded image fits into a desired amount of data, the method repeats: encoding the image into an encoded image, the encoding comprising quantizing causing lossy compression; decoding the encoded image into an image, the decoding comprising inverse quantizing; and increasing the losses in compression caused by the quantizing.

Owner:SIMULA HEIGE

Phlegmatisation of an explosive in an aqueous suspension

ActiveUS10287219B2High compression densityReduce exudationLiquid surface applicatorsTransportation and packagingExplosive materialChemistry

A method for phlegmatizing an explosive in an aqueous suspension including a dispersed phlegmatizing agent. The phlegmatizing agent is deposited on a surface of the explosive at low temperature utilizing opposite electric charges of the phlegmatizing agent and the explosive. Also a device and a phlegmatized explosive.

Owner:EURENCO BOFORS

Open type straw compressing box with two density adjusting mechanisms

ActiveCN106003795AControl the opening and closing angleHigh compression densityPressesHigh densityEngineering

The invention discloses an open type straw compressing box with two density adjusting mechanisms. The open type straw compressing box comprises a first compression box body and a second compression box body, wherein the first compression box body is provided with the first density adjusting mechanism, and the second compression box body is provided with the second density adjusting mechanism. The first density adjusting mechanism comprises blocking slide blocks, springs, adjusting nuts and guiding rods. The guiding rods are fixed to lateral edges of the first compression box body, the first guiding rod is provided with the corresponding blocking slide block, the corresponding spring and the corresponding adjusting nut, and the corresponding blocking slide block stretches into the first compression box body. The second density adjusting mechanism comprises reversing manipulators and inclined lateral pressing plates, the inclined lateral pressing plates are arranged on the two opposite sides of the second compression box body through hinge pins, and the ends of the inclined lateral pressing plates are connected with the corresponding manipulators. Through the two density adjusting mechanisms, a first bundle which is actually bundled can be compressed in a high-density mode, and the two density adjusting mechanisms provide resistance at the same time, so that the compression density is greatly improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com