Garbage compression station

A garbage compression and box technology, which is applied in garbage transmission, garbage collection, presses, etc., can solve the problems of lowering the installation height, reducing the loading capacity of the garbage box, increasing the weight of the garbage station (box), etc., reaching the height of the device and occupying an area Small area, optimized use and structure, and flexible and changeable transport methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

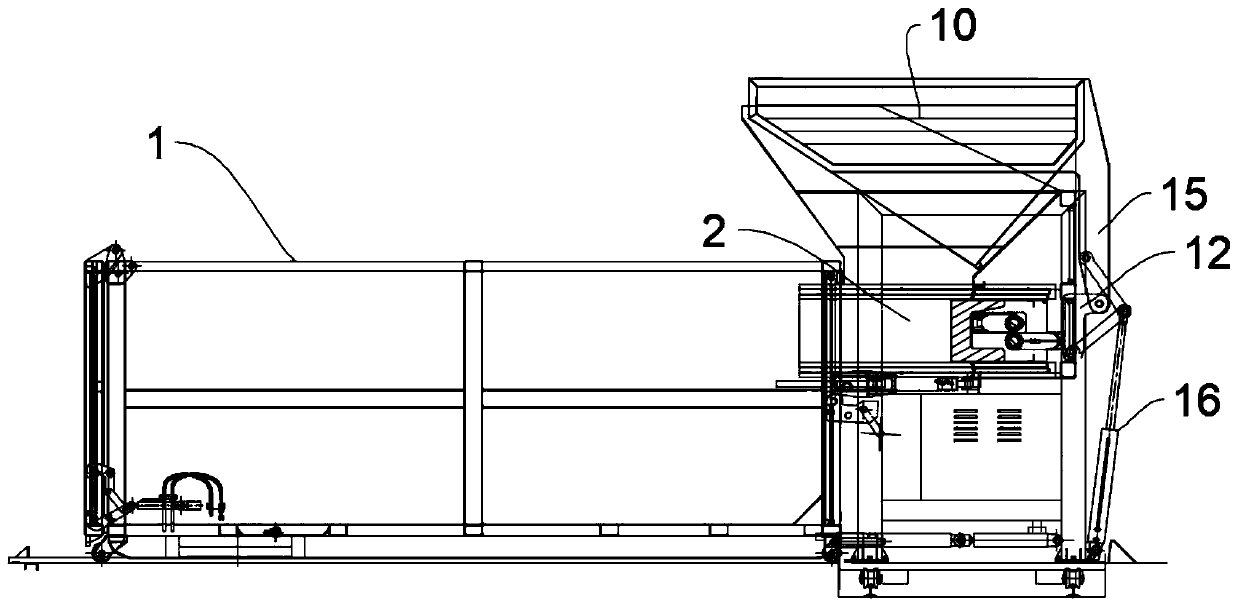

[0094] like Figure 2-Figure 12 As shown, this embodiment provides a garbage compression device station, including a feeding mechanism and a push-pull box mechanism. 3 and a drive device that drives the box body 1 to move horizontally along the box body guide rail 3 to make the feed port 4 of the box body 1 dock with the pusher bin 2 .

[0095] In this technical solution, the push-pull box mechanism drives the box body 1 to move to realize the docking between the feed port 4 of the box body 1 and the pusher silo 2, and the feeding port 4 is docked with the pusher silo 2 to facilitate feeding. After the feeding is completed, The driving device drives the box body 1 to move horizontally, so that the feed port 4 is separated from the pusher silo 2, and the box body 1 is horizontally moved out of the feeding mechanism. 1. In terms of the method of leaving enough vertical space for tilting transfer, if it is moved horizontally out of the pusher silo 2, there is no need to lift and...

Embodiment 2

[0101] This embodiment is optimized on the basis of the above-mentioned Embodiment 1.

[0102] like Figure 13-Figure 19 As shown, it also includes a lifting mechanism that drives the pusher silo 2 to move up and down.

[0103]In this technical solution, the translation and lifting functions are combined, and the push-pull box mechanism drives the box body 1 to move to realize the docking between the feeding port 4 of the box body 1 and the pusher silo 2, and the lifting mechanism adjusts the height position of the pusher silo 2. Adjustment, it is convenient to realize the docking with the feeding port 4 and the detachment from the feeding port 4. After the feeding port 4 is docked with the pusher silo 2, it is convenient to feed materials. After the feeding port 4 is separated from the pusher silo 2, it is convenient to push and pull. The box mechanism moves the box body 1 out horizontally. Since the horizontal movement is used to realize the docking and removal, it avoids t...

Embodiment 3

[0106] This embodiment is optimized on the basis of the above-mentioned Embodiment 1 or 2.

[0107] In order to facilitate the transfer of the box 1 to make room, the feeding mechanism is a mobile feeding mechanism.

[0108] Specifically, the bottom of the mobile feeding mechanism is provided with four walking wheels 7, which facilitates the overall movement of the mobile feeding mechanism. After the mobile feeding mechanism completes the feeding operation of the box 1 at the station, the lifting mechanism drives the pusher. The silo 2 is moved up to realize the separation of the pusher silo 2 and the feed port 4 of the box body 1, and then the driving device drives the box body 1 to move horizontally along the box body guide 3 to make the box body 1 detach from the feeding mechanism, and push the head material. Below the bin 2 is the box channel, that is, the driving device drives the box 1 to move out of the box channel below the pusher bin 2, and then the mobile feeding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com