Oil penetration-preventing polymer-bonded explosive containing paraffin microcapsules and preparation method of explosive

A technology of paraffin microcapsules and bonded explosives is applied in the directions of explosives, ammonium perchlorate compositions, non-explosive/non-thermal agent components, etc., and can solve the problems of hindering the development of insensitive explosives, poor compatibility, uneven distribution, etc., To achieve the effect of reducing oil leakage, reducing shock wave sensitivity and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

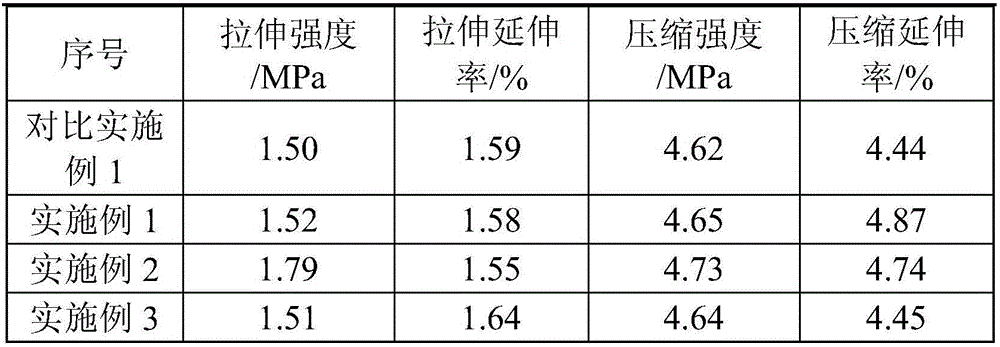

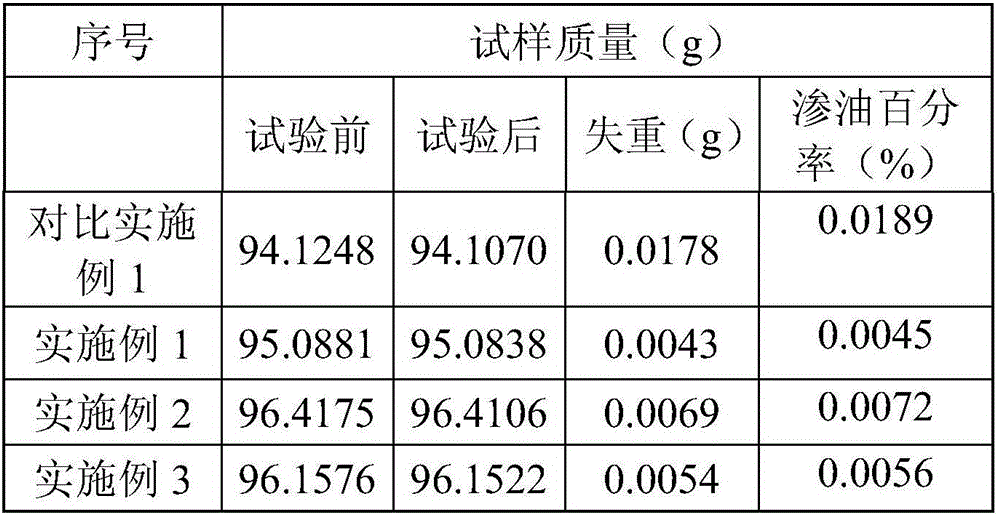

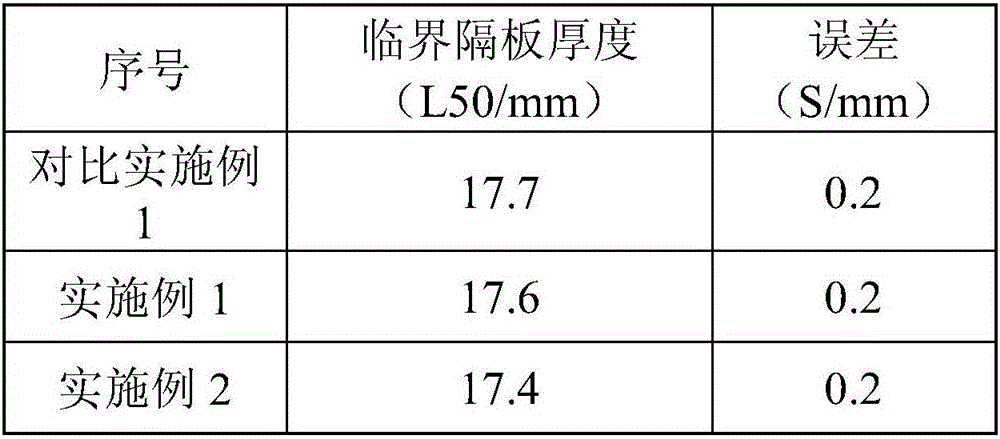

Embodiment 1

[0030] Take by weighing 30g RDX, 10gAl, 5g ammonium perchlorate, 8g hydroxyl-terminated polybutadiene, 2g paraffin (fusing point is 50°C), 3g of paraffin microcapsules with melamine resin as the capsule wall, these materials are added to the pre-prepared Heat it into a kneader at 70°C, stir for 25 minutes, mix well, add 0.5g of TDI, mix and react for 12 minutes, pour it into a mold that has been preheated to 70°C at a constant temperature of 70°C, and put it in a vacuum oven at 60°C , Reaction 3d, take out and cool to room temperature to obtain the product.

Embodiment 2

[0032] Take by weighing 50g HMX, 20gAl, 30g ammonium perchlorate, 15g hydroxyl-terminated polybutadiene, take polystyrene as the paraffin microcapsule 5g of capsule wall, these materials join in the kneader that has been preheated to 80 ℃, Stir for 30 minutes, after mixing evenly, add 1g of TDI, mix and react for 30 minutes, pour it into a mold preheated to 70°C at a constant temperature of 80°C, put it in a vacuum oven at 80°C, react for 5 days, take it out and cool it to room temperature to obtain the product .

Embodiment 3

[0034] Get 90g RDX, 35gAl, 20g ammonium perchlorate, 20g hydroxyl-terminated polybutadiene, 5g paraffin (fusing point is 50 DEG C), take melamine resin as the paraffin microcapsule 0.5g of capsule wall, these materials are added to pre-prepared Heat it into a kneader at 65°C, stir for 25 minutes, mix well, add 0.8g of TDI, mix and react for 25 minutes, pour it into a mold that has been preheated to 65°C at a constant temperature of 65°C, and put it in a vacuum oven at 65°C , Reaction 7d, take out and cool to room temperature to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com