Method for reducing sensitivity by elastomer and graphene double coating of HMX

A double-coating, octogold technology, applied in the direction of non-explosive/non-thermal agent components, non-explosive desensitizers/passivators, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., It can solve the problems of reducing the friction sensitivity and mechanical sensitivity of octogold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

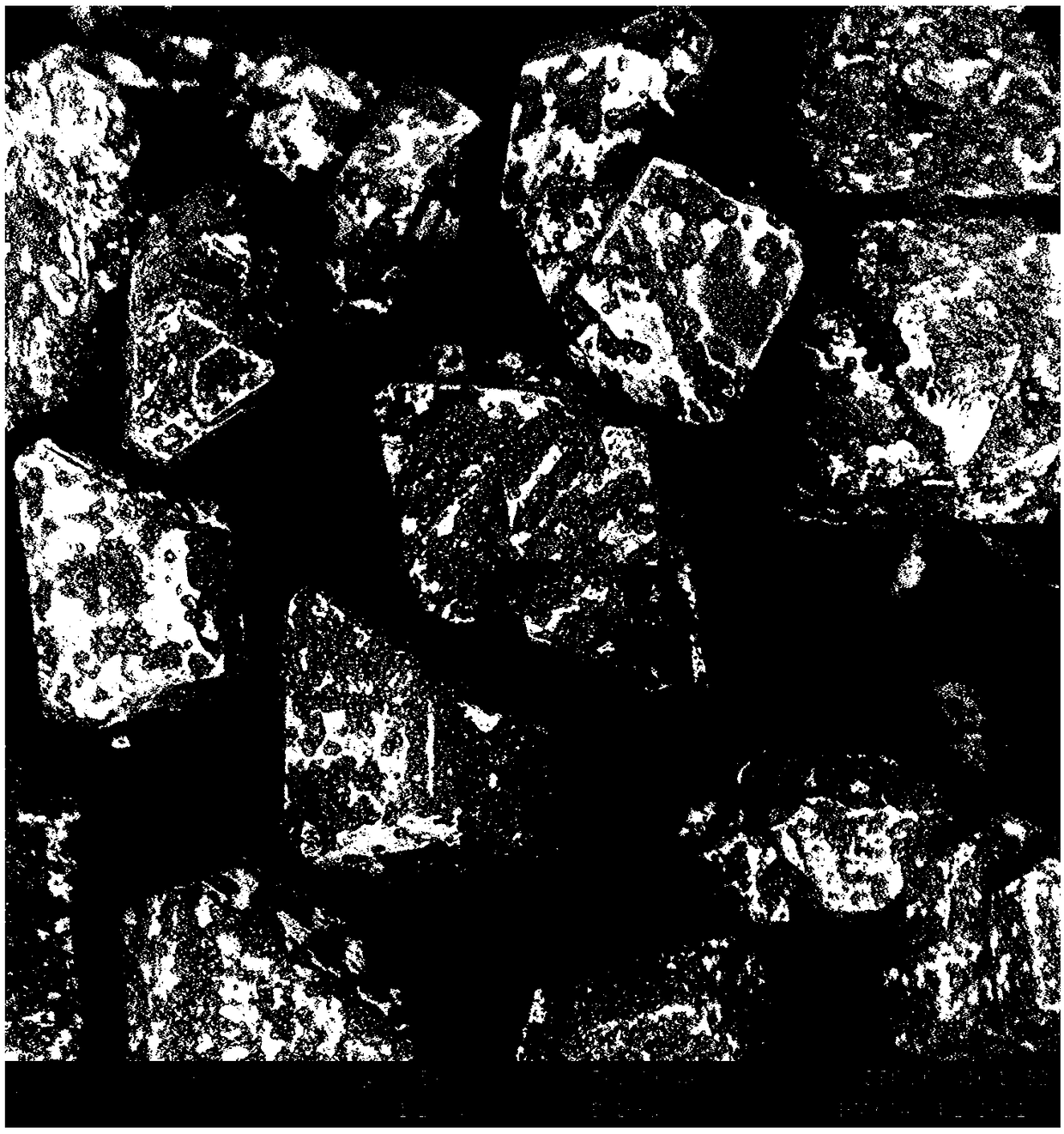

[0022] A kind of method for the elastic body of octogold, graphene double-layer coating to drop the sense, comprises the following steps: (1) octokine cleaning: take by weighing 50g of octogen, add to certain 1000ml anhydrous Soak in ethanol for 5h, then filter and dry the Octogold after cleaning; (2). Add the Octogold after drying into the beaker, then weigh 0.9g Hydroxybutane (HTPB), 0.2g Add dioctyl sebacate, 0.1g curing agent TDI, 0.1g dilaurate-dibutyltin 50g ethyl acetate, etc. into the above beaker and stir and mix together for 15min; (3) Weigh 0.2g graphene, add Add 0.1g of surfactant KH560 to 50g of absolute ethanol, and then place it in an ultrasonic device for 10 minutes; (4). Mix the Octogold mixed solution with the graphene solution and keep stirring until the solvent evaporates completely , and then placed in an oven to dry, the elastomer and graphene double-layer coated octogold can be prepared.

Embodiment 2

[0024] A kind of elastic body of octogold, the method for graphene double-layer coating to drop the sense, comprises the following steps: (1) octogold cleaning: take by weighing 100g such as figure 1 The Octogold shown is added to certain 1200mL of dehydrated ethanol and soaked for 6h, then the Octogold after cleaning is filtered and dried; (2) the Octogold after drying is added to the beaker, Then weigh 50-100g of ethyl acetate, 1.8g of hydroxybutyrate (HTPB), 0.2g of plasticizer dioctyl sebacate, 0.2g of curing agent TDI, 0.2g of catalyst dilaurate-dibutyltin, etc. Stir and mix together in the above-mentioned beaker for 30min; (3) weigh 0.3g of graphene in addition, add it to 100g of absolute ethanol, add 0.1g of surfactant KH560, and then place it in an ultrasonic device for ultrasonication for 15min; (4) put The mixed solution of octogold is mixed with the graphene solution, and continuously stirred until the solvent is completely evaporated, and then placed in an oven to ...

Embodiment 3

[0026] A kind of elastic body of octogold, the method for double-layer coating of graphene to reduce the sensitivity comprises the following steps: (1) octogold cleaning: take by weighing 80g of octogen, add to certain 1500mL anhydrous Soak in ethanol for 6h, then filter and dry the Octogold after cleaning; (2) Add the Octogold after drying into a beaker, then weigh 100g of ethyl acetate, 0.9g123 resin, 0.2g Add plasticizer dioctyl sebacate and 0.02g diethyl sulfate into the above-mentioned beaker and stir and mix together for 15min; (3) weigh 0.2g of graphene in addition, join in 50g of absolute ethanol, add 0.05g of Surfactant KH560, and then placed in an ultrasonic device for 10 minutes of ultrasonication; (4) Mix the mixed solution of octogold and graphene solution, and keep stirring until the solvent is completely evaporated, and then put it in an oven to dry, and the product can be prepared Obtained elastomer, graphene double-layer coated octogold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com