A method of mineral fuel beneficiation with subsequent delivery to the consumer by pipeline transportation?

A beneficiation method and a technology for fossil fuels, which are applied in combustion methods, fuels, conveyors, etc., can solve the problems of negative temperature aggravating the continuous coil output of coal railway transportation, and achieve improved consumption performance, increased production, and reduced adverse effects on the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] figure 1 Flowchart showing the subterranean processing process for a portion of starting rock requiring additional size reduction under deep mining conditions where the rock is kept sufficiently heated throughout the year by internal heat regardless of climatic conditions and the coal produced Used in power plants.

[0060] The starting rock, which fraction is separated by sieving and requires additional size reduction to enhance waste rock separation, is ground in a drum 1 filled with a liquid having a density between that of the fossil fuel and the waste rock. The drum operates in a closed cycle with a three-product heavy-media hydrocyclone 2 .

[0061] The liquid expresses a density of 1.48g / cm 3 Aqueous solution of calcium nitrate / zinc chloride mixture.

[0062] The beneficiated product, leaving the hydrocyclone 2 still suspended in a heavy aqueous medium, first brings the product to the bottom of the well, then passes through a pump 3 and a surface pumping stati...

Embodiment 2

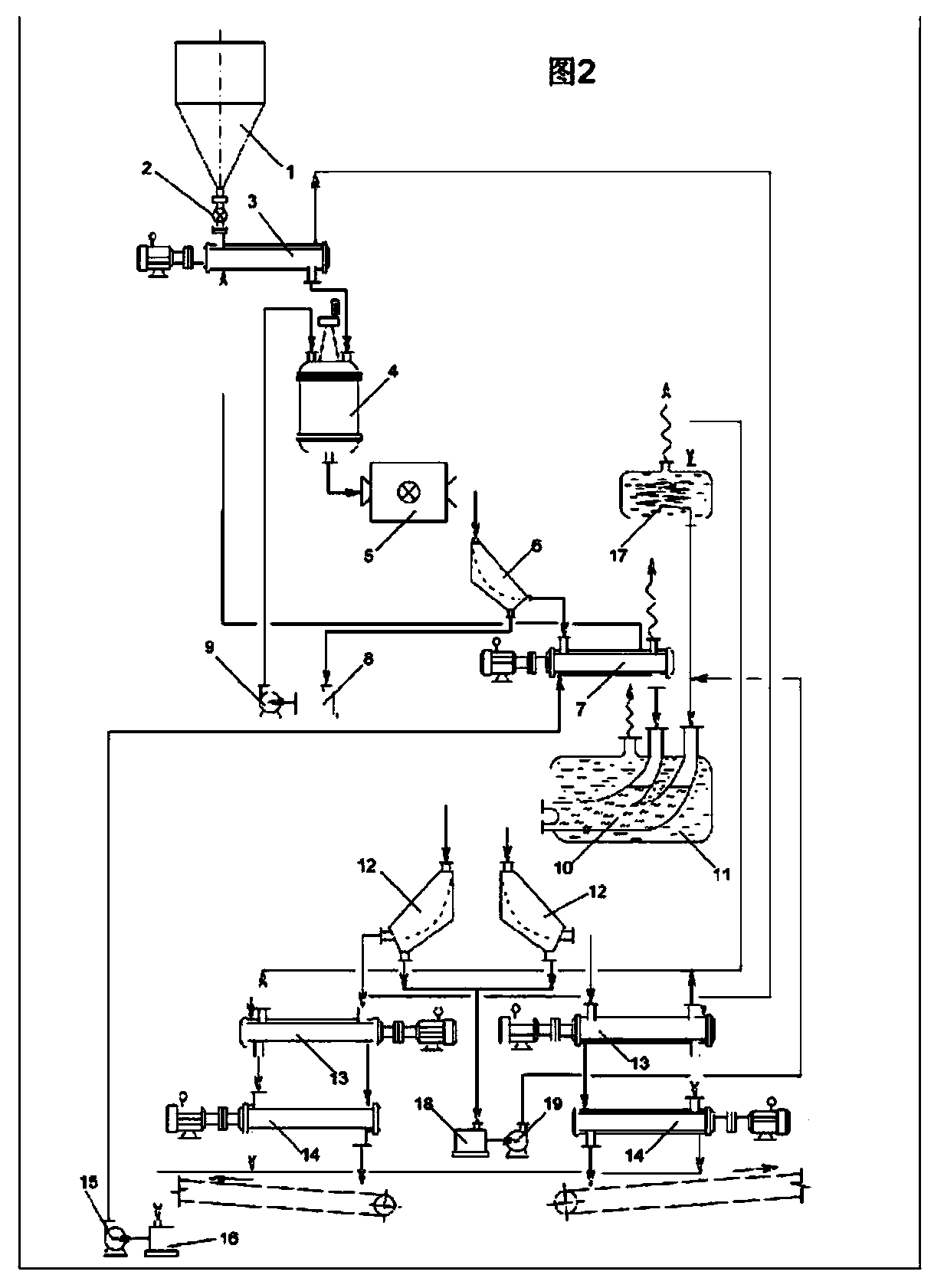

[0075] figure 2 Flow diagram showing underground beneficiation of pulverulent materials resistant to highly selective dry separation. Due to the increased influence of the rheological properties of the water-salt medium on the highly dispersed material, processing this part of the raw material in an aqueous solution of mineral salts leads to a decrease in separation efficiency, and the high humidity of the paste mineral processing product leads to a combination of dry coal and dry final tailings. Emissions-related increases in electricity consumption.

[0076] In this case, liquid argon, a non-aqueous cryogenic liquid with a density between that of fossil fuels and waste rock, is used as the separation medium. The boiling point of this liquid is so low that the irreversible boiling of the residual liquid phase due to contact with the environment, so that the discharge of the dry beneficiation product is carried out automatically.

[0077] To this end, the first pulverized r...

Embodiment 3

[0089] image 3 shows the basic technical scheme for co-transporting lump and pulverized coal from the mine to the ground when the user of the solid fuel is a thermal power station.

[0090] The coal conveyed in the main flow from the coal face to the bottom of the shaft is classified on the separator 1 into lumpy material and fine coal comprising small lumps of coal and all its pulverulent fractions.

[0091] The fine coal separated from lump and bulk coal is fed into screw feeder 2 equipped with heat exchange jacket, and extruded with extrusion die 3 . An appropriate amount of bitumen is introduced into the screw feeder 2 as a binding additive to reinforce the monolith made of fine coal in a cylindrical shape resembling a piston of a hydraulic device. The steam used to heat the coal mixture with bitumen prior to extrusion is fed into its heat exchange jacket.

[0092] Batches of lump coal and each briquette are alternately placed in the loading chamber 4 of the loading sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com