Preparation method of non-migratory rubber plasticizer based on ricinoleic acid homopolymerisation

A technology of ricinoleic acid and plasticizer, which is applied in the field of preparation of general-purpose rubber plasticizer ricinoleic acid homopolymer, can solve the problems of low molecular weight, low migration, poor plasticizing effect, etc., and achieves simple preparation method and low raw material Easy to get, cheap results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

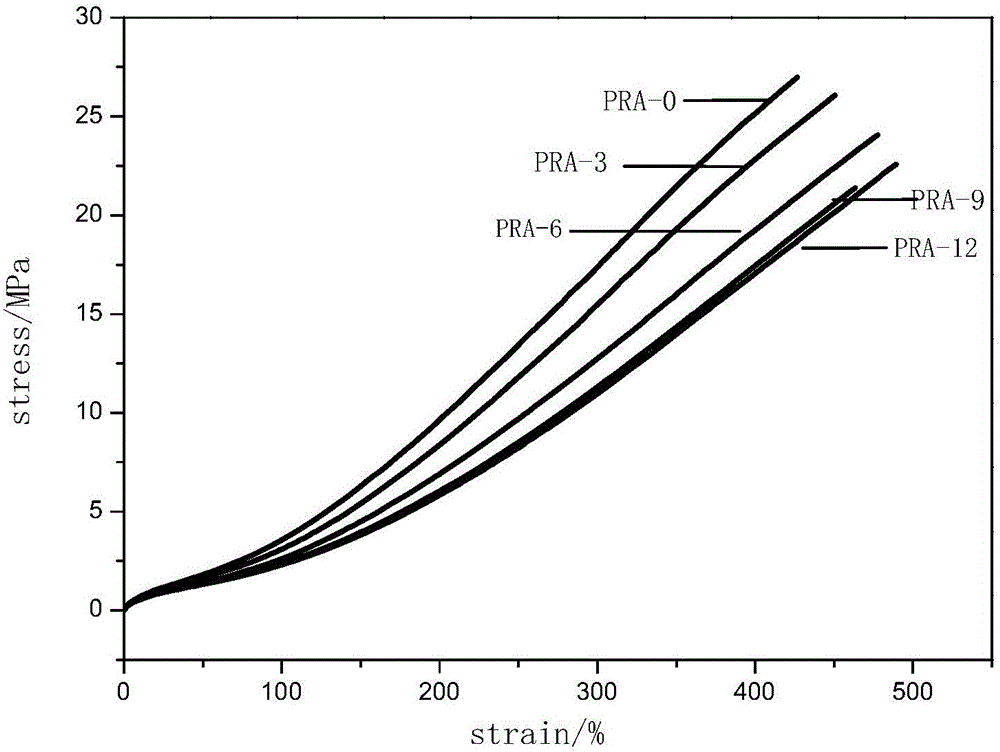

[0028] The ingredients were weighed in parts by mass as follows: 100 parts of natural rubber, 50 parts of carbon black, 5 parts of zinc oxide, 2 parts of stearic acid, 2 parts of antioxidant 4010NA, 0.6 part of accelerator NS, and 2.5 parts of sulfur. Mixing process: In order to prevent the natural rubber from being over-mixed and thus affect the test results of each system, the entire rubber mixing time on the open mill is controlled within 15 minutes. The order of feeding: in order to shorten the mixing time, and to make small materials and carbon black To be able to disperse evenly, first add zinc oxide, stearic acid and anti-aging agent for mixing, then add carbon black, add sulfur when the carbon black is uniformly dispersed, and finally add accelerator, and then vulcanize after one day of mixing. The vulcanization temperature is selected at 145°C, and the vulcanization time is set at 25 minutes. After vulcanization, samples are cut to test performance.

Embodiment 3

[0030] Except for adding 3 parts of ricinoleic acid homopolymer together with carbon black during mixing, other conditions are the same as in Example 2, vulcanization is carried out one day after the mixing is completed, the vulcanization temperature is selected at 145°C, and the vulcanization time is set at 25min , After vulcanization, cut the sample and test the performance.

Embodiment 4

[0032] Except adding 6 parts of ricinoleic acid homopolymer together with carbon black during mixing, other conditions are the same as in Example 2, vulcanization is carried out one day after the mixing is completed, the vulcanization temperature is selected at 145°C, and the vulcanization time is set at 25min , After vulcanization, cut the sample and test the performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com