Polyether-ether-ketone composite material containing gadolinium oxide and preparation method of composite material

A technology for sulfonating polyether ether ketone and polyether ether ketone is applied in the field of gadolinium oxide-containing polyether ether ketone composite material and its preparation field, and achieves the effects of good dispersion effect, good adhesion and rich rare earth resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

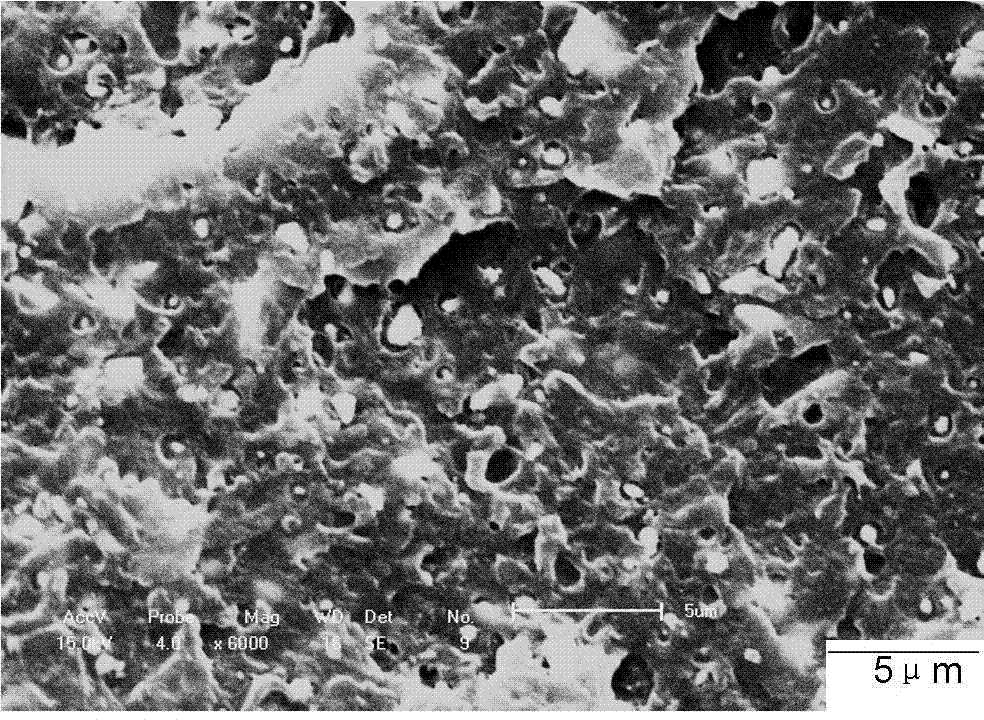

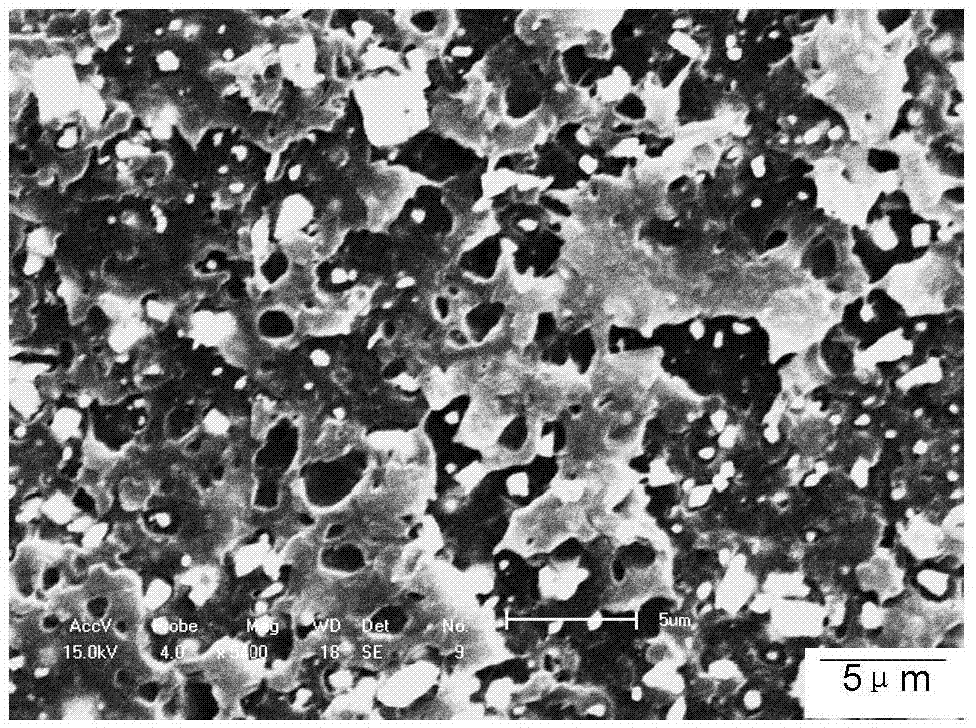

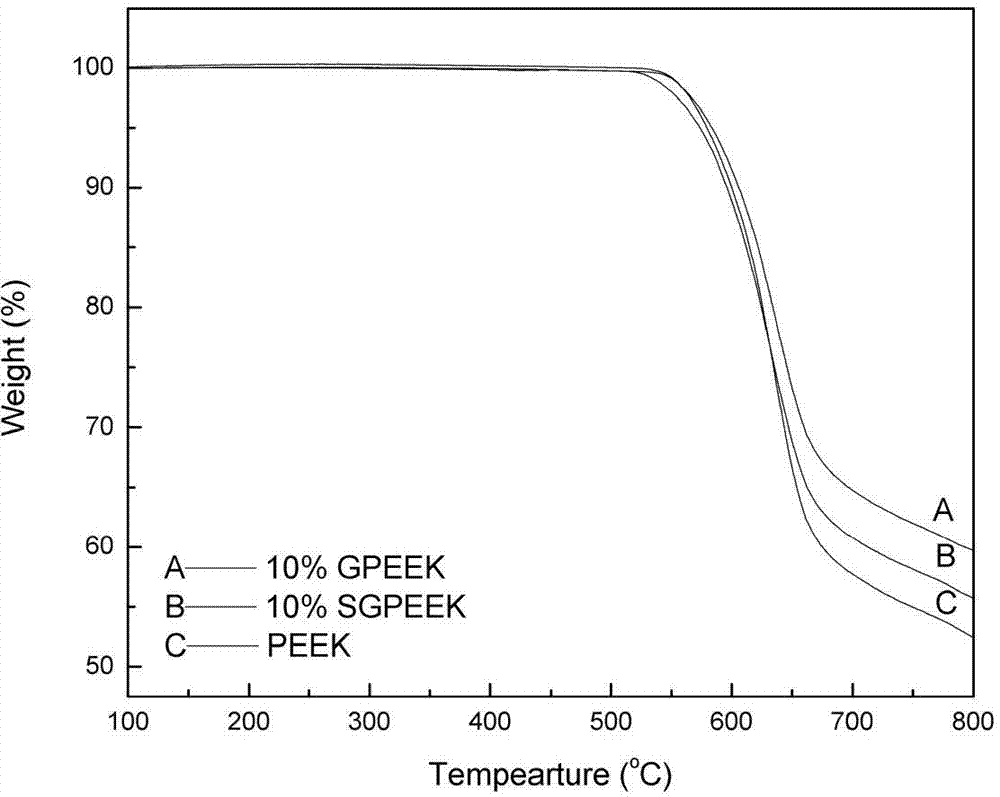

[0042] Example 1: Preparation of polyether ether ketone / gadolinium oxide composite material

[0043] Composition of the composite material: PEEK, sulfonated PEEK, gadolinium oxide.

[0044] First, prepare sulfonated polyetheretherketone: 30g polyetheretherketone is dispersed in 300ml concentrated sulfuric acid, mechanically stirred in a water bath at 40°C for 8 hours for sulfonation, and the whole experiment is under a nitrogen environment; the polymer is poured into ice water to form The product is in the form of filaments, crushed and washed with distilled water until the filtrate becomes neutral, and then baked in an oven at 80°C for 24 to 36 hours to obtain sulfonated polyether ether ketone with a sulfonation degree of 73%.

[0045] Next, prepare modified gadolinium oxide: take 4 g of sulfonated polyether ether ketone and dissolve it in distilled water at 80 ° C, disperse 200 g of gadolinium oxide in the sulfonated polyether ether ketone solution, stir mechanically for 4 h...

Embodiment 2

[0050] Example 2, change the addition amount of sulfonated polyether ether ketone to 2 g in Example 1, and change the addition amount of polyetherether ketone to (100-1.01X) parts, and the polyether ether ketone / gadolinium oxide composite can also be prepared Materials, composite materials have good mechanical properties and good thermal stability.

Embodiment 3

[0051] Example 3, changing the addition amount of sulfonated polyetheretherketone to 8g in Example 1, and changing the addition amount of polyetheretherketone to (100-1.04X) parts, the same can prepare polyetheretherketone / gadolinium oxide composite Materials, composite materials have good mechanical properties and good thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com