Composite material of polyetheretherketone/organizing montmorillonite and method of producing the same

A technology of organic montmorillonite and polyether ether ketone, applied in the field of special engineering plastics, can solve the problems of reducing the price of polyether ether ketone, etc., and achieve the effects of low production cost, stable processing performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

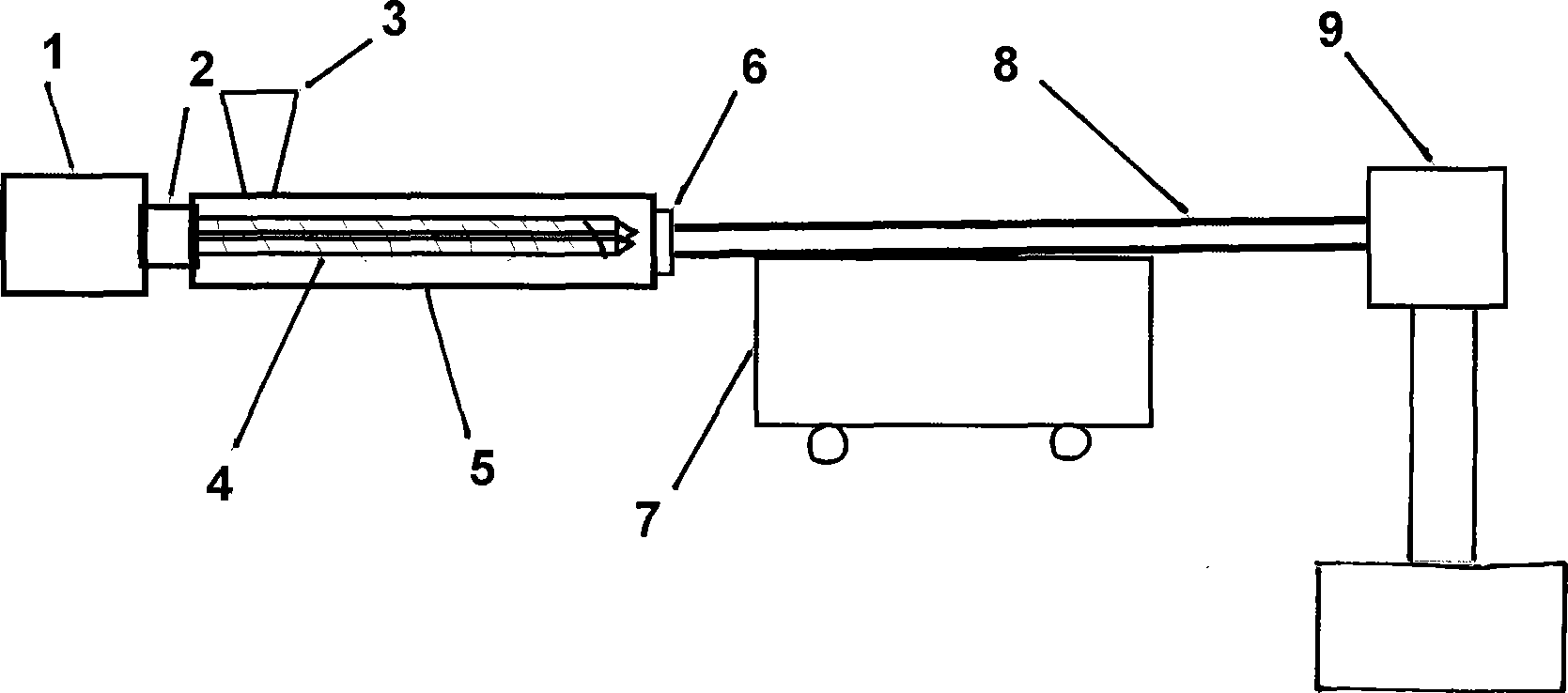

Method used

Image

Examples

Embodiment 1

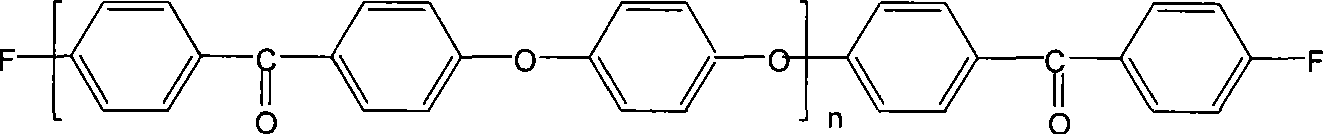

[0024] Example 1: Preparation of polyether ether ketone / organized montmorillonite composite material

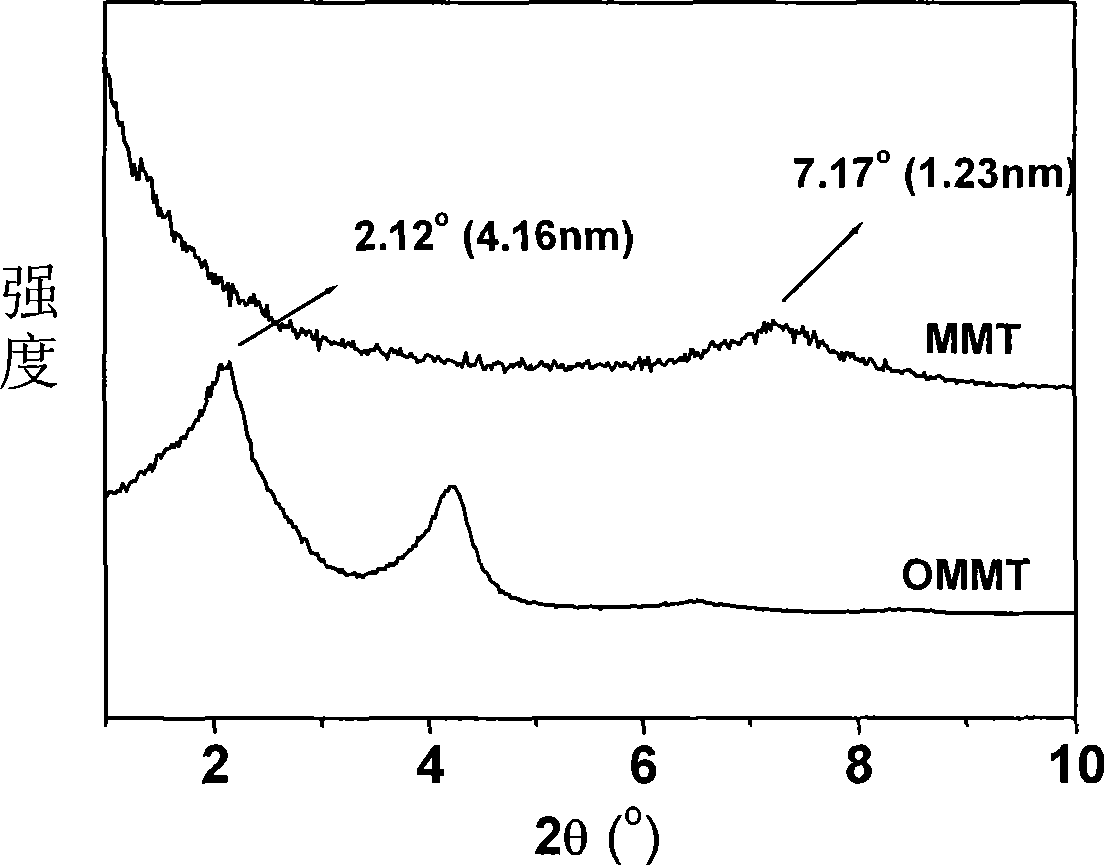

[0025] First prepare organic montmorillonite: 50 grams of sodium montmorillonite is dispersed in 1000 ml of distilled water, stirred, and left to stand for 24 hours; organically modified in a water bath at 40 ° C, adding monooctadecyl trimethyl Ammonium chloride 55.85 g, stirred for 1 hour using an electric stirring paddle; the product was cooled to room temperature, washed with distilled water until AgNO was added dropwise 3 Until the solution does not precipitate; use a high-speed centrifuge to separate the organic montmorillonite from water, then dry it in an oven at 120° C., crush it, and pass it through a 200-mesh sieve to obtain the organic montmorillonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com