Nonporous moisture permeable and water-repellent modified polyether ester functional film material and preparation method thereof

A moisture-permeable waterproof and film material technology, which is applied in the non-porous moisture-permeable waterproof modified polyether ester functional film material and its preparation field, can solve the problems of high raw material cost and poor heat resistance stability, and achieve the effect of reducing raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

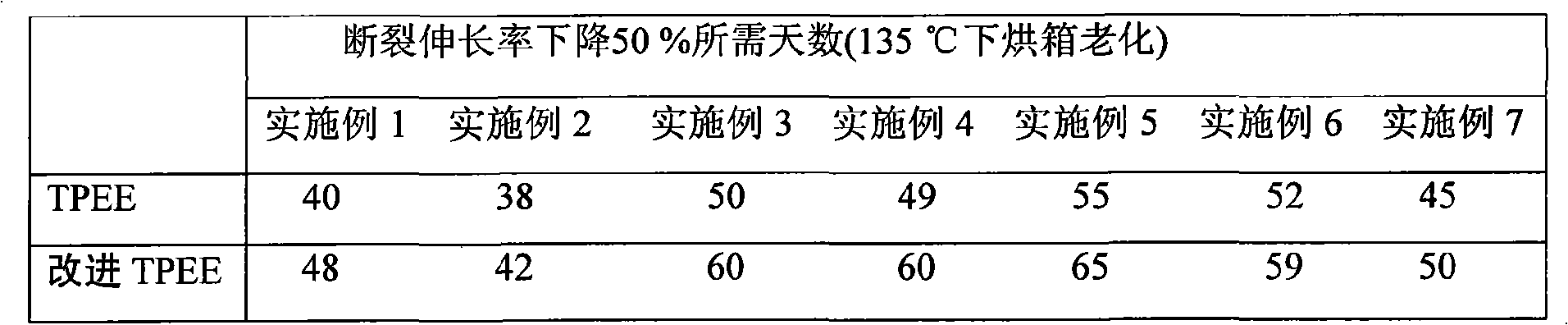

Examples

Embodiment 1

[0025] The number average molecular weight of 900g PA6 and 240g is 2×10 3 After dispersion and mixing of polyethylene glycol and 3g of antioxidant B215, melt through a twin-screw extruder, knead, extrude, cool, pelletize, and dry to obtain moisture-permeable PA6. The temperature of each zone of the twin-screw extruder barrel used is: Section I: 200°C; Section II: 240°C; Section III: 240°C; Section IV: 235°C; Section V: 230°C; Section VI Segment: 225°C.

[0026]The 500g polyether segment is made of polyethylene oxide, the number average molecular weight is 600, and the mass percentage is 50% TPEE, 381g moisture-permeable PA6, 80g EVA (wherein the VA mass percentage content is 20%), 30g nano silver antibacterial Masterbatch (Shanghai Huzheng Nano Technology Co., Ltd., the same below), 4g novolac epoxy resin, 2g light stabilizer 944, 3g antioxidant B215 are dispersed and mixed, melted, kneaded, extruded by twin-screw extruder, After cooling, pelletizing and drying, a non-porous...

Embodiment 2

[0028] The number average molecular weight of 700g PA6 and 350g is 2×10 4 After dispersion and mixing of polyethylene glycol and 2g of antioxidant B215, melt through a twin-screw machine, knead, extrude, cool, pelletize, and dry to obtain moisture-permeable PA6. The temperature of each zone of the twin-screw extruder barrel used is: Section I: 200°C; Section II: 240°C; Section III: 240°C; Section IV: 235°C; Section V: 230°C; Section VI: 225°C.

[0029] The 700g polyether segment is composed of polypropylene oxide with a number average molecular weight of 2.8×10 3 , 20% TPEE by mass percentage, 150g moisture-permeable PA6, 100g EVA (wherein VA mass percentage content is 30%), 38g nano-silver antibacterial masterbatch, 5g novolak epoxy resin, 1g ultraviolet absorber UV-531, 4g phenol Antioxidant 1010, after dispersion and mixing of 2g silicone release agent, the modified TPEE was obtained after melting, kneading, extruding, cooling, pelletizing, and drying through a twin-screw...

Embodiment 3

[0031] The number average molecular weight of 700g PA6 and 350g is 4×10 3 After dispersion and mixing of polyethylene glycol and 2g of antioxidant B215, melt through a twin-screw extruder, knead, extrude, cool, pelletize, and dry to obtain moisture-permeable PA6. The temperature of each section of the twin-screw extruder barrel used is: Section I: 200°C; Section II: 240°C; Section III: 240°C; Section IV: 235°C; Section V: 230°C; Section VI: 225°C.

[0032] The 600g polyether segment is composed of 1:1 polyethylene oxide and polypropylene oxide, and the number average molecular weight is 1×10 3 , TPEE with a mass percentage of 35%, 300g moisture-permeable PA6, 50g EVA (wherein the VA mass percentage is 25%), 30g nano-silver antibacterial masterbatch, 10g novolac epoxy resin, 3g ultraviolet absorber UV-329, 4g sub- Phosphate antioxidant 168, after dispersing and mixing 2g of dioctyl phthalate, melted, kneaded, extruded, cooled, pelletized, and dried through a twin-screw extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com