Preparing method of thermally-driven self-repairing elastomer based on hydrogen-bond interaction

A hydrogen bonding, thermally driven technology, applied in the field of preparation of thermally driven self-healing elastomers based on hydrogen bonding, can solve the problems of low elongation, only one-time repairing ability, low repairing efficiency, etc., and achieve high tensile strength and the effect of elongation at break, excellent self-healing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

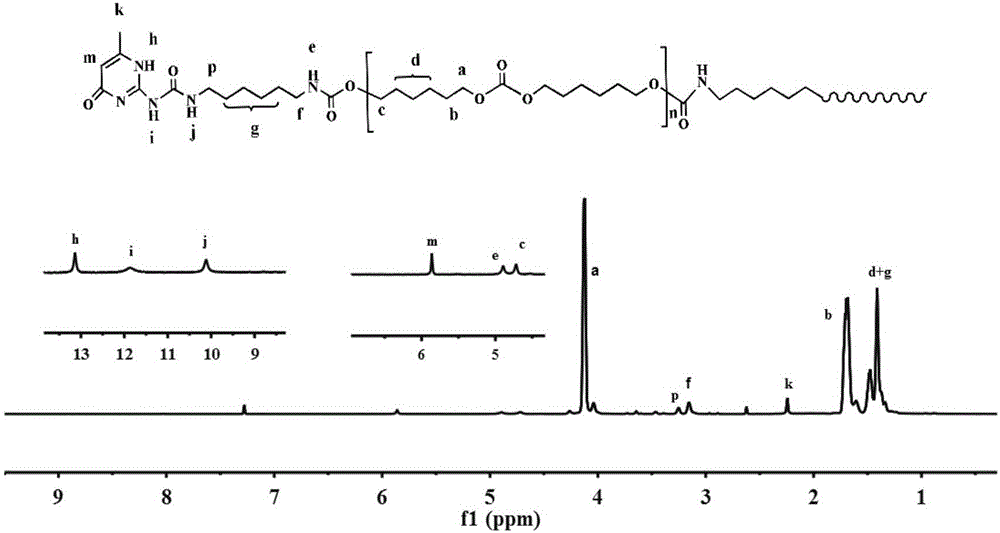

[0038] Take 40 g of vacuum-dried polycarbonate diol (PCDL) with a molecular weight of 2000 and 1 drop of catalyst (dibutyltin dilaurate) in a three-necked flask equipped with a reflux condenser, raise the temperature to 50 ° C under nitrogen protection, and slowly drop Add measured hexamethylene diisocyanate diluted with 10ml of anhydrous toluene, under mechanical stirring until the -NCO absorption peak in the infrared spectrum disappears, then add 150ml of anhydrous toluene and heat up to 100°C; add Upy-NCO (system residual 1.5 times the number of moles of hydroxyl groups), reacted for about 16 hours under mechanical stirring, and stopped the reaction when the hydroxyl proton peak disappeared under the detection of proton nuclear magnetic spectrum. After cooling to room temperature, the polymer solution was added dropwise to 200 ml of n-hexane to obtain a white precipitate, which was washed and dried several times to obtain a transparent elastic solid. Adjust the molar ratios...

Embodiment 2

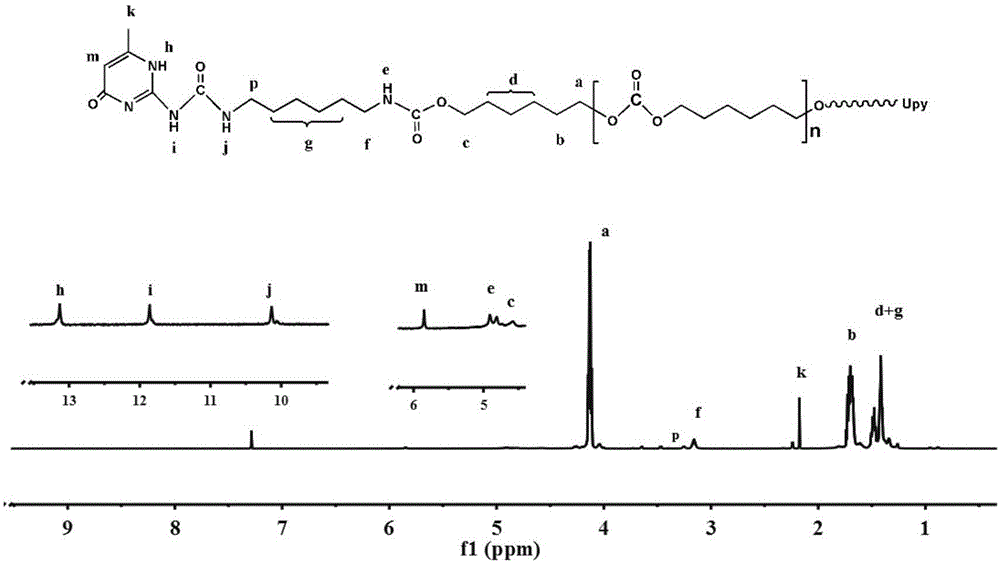

[0041] Take 40 g of vacuum-dried polycarbonate diol (PCDL) with a molecular weight of 2000 and 1 drop of catalyst (dibutyltin dilaurate) in a three-necked flask equipped with a reflux condenser, raise the temperature to 60 ° C under nitrogen protection, and slowly drop Add NCO-Upy-NCO dissolved in 100ml of anhydrous toluene, and stop the reaction under mechanical stirring until the -NCO absorption peak in the infrared spectrum disappears. Volatilize in a polytetrafluoroethylene tank at room temperature to obtain a transparent elastic film. Adjust the molar ratio of PCDL and NCO-Upy-NCO to be 1.2 respectively to obtain polyurethane elastomer HPU 1.2 -Upy.

[0042] To characterize the elastomer prepared above, figure 2 for HPU 1.2 -Upy's NMR spectrum, the repair efficiency is shown in Table 1, the results show that HPU 1.2 -Upy has a repair efficiency of 71% at 80°C for 2 hours, a repair efficiency of 91% after repair for 4 hours, and even 95% repair efficiency for 6 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com