Biodegradable polyester and preparation method thereof

A technology for degrading polyester and biology, applied in polyester coatings, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems affecting the thermodynamic properties of polyester products, lower melting point, low crystallinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

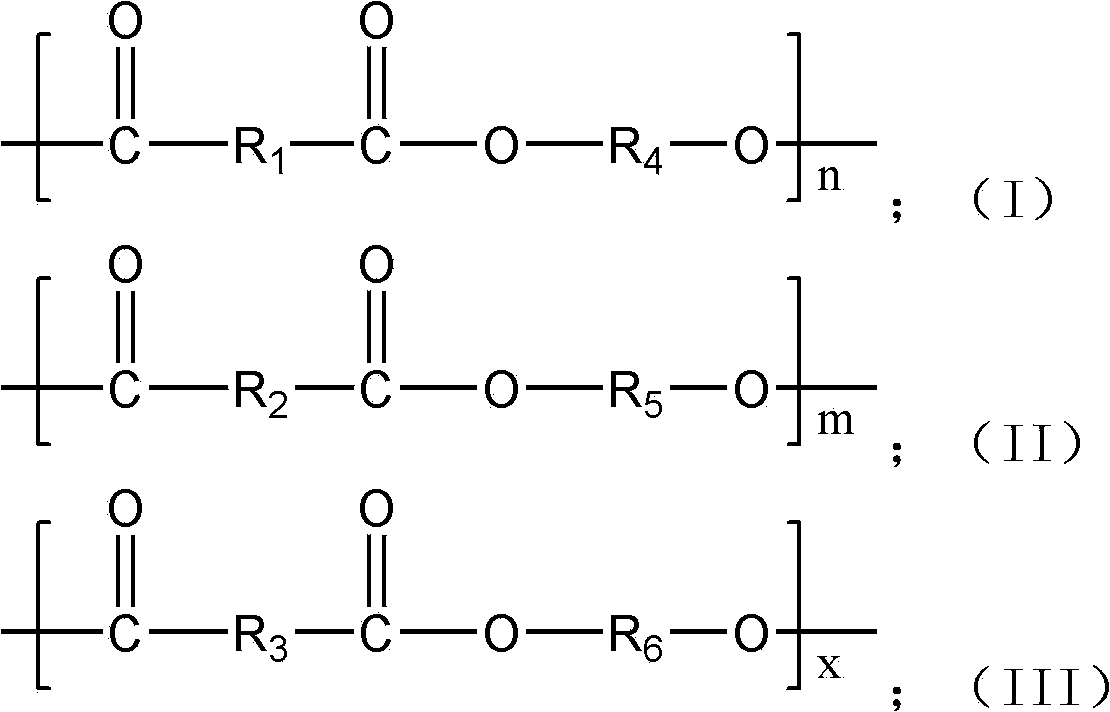

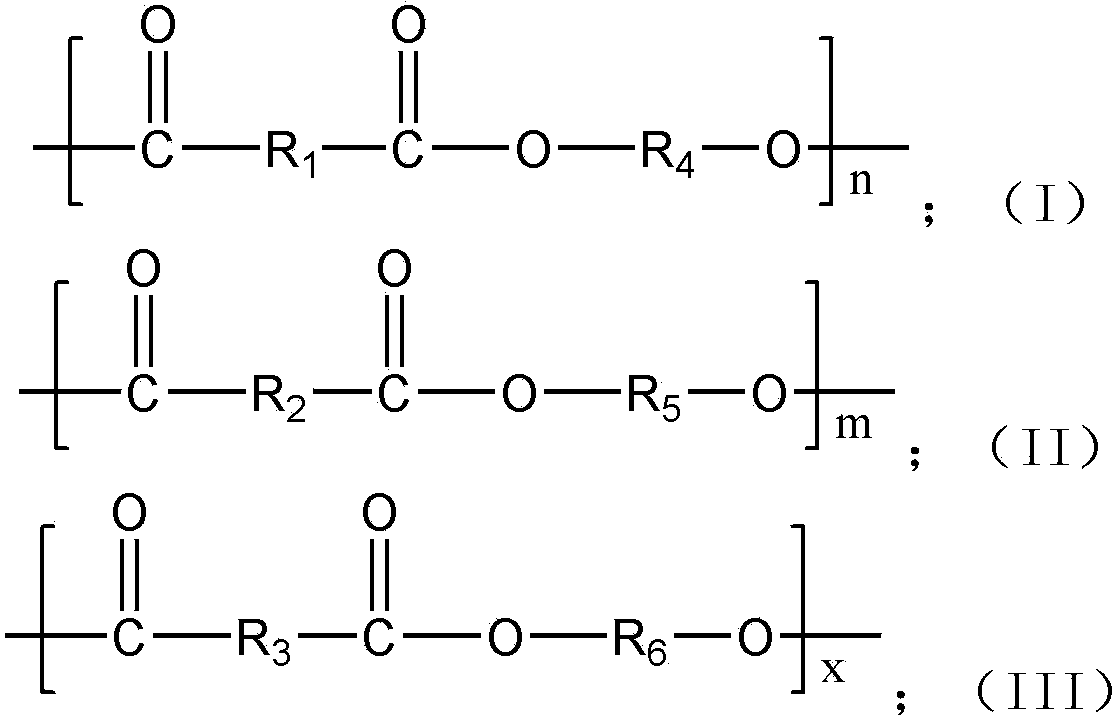

[0108] The preparation method of biodegradable polyester of the present invention comprises the steps:

[0109] The polyester is obtained by condensation of monomer a, monomer b, monomer c and monomer d,

[0110] Monomer a is selected from aliphatic dibasic acids, aliphatic dibasic esters or mixtures thereof;

[0111] Monomer b is selected from aromatic dibasic acids, aromatic dibasic esters or mixtures thereof;

[0112] Monomer c is aliphatic dihydric alcohol;

[0113] Monomer d is selected from 2,5-furandicarboxylic acid, 2,5-furandicarboxylic acid dibasic ester or mixtures thereof;

[0114] The mass ratio of monomer a to monomer b is 4:1 to 1:4; the mass ratio of the total mass of monomer a and monomer b to monomer c is 1:1 to 1:4; the mass ratio of monomer b to monomer The mass ratio of body d is 1000:1-2:1.

[0115] The present invention also provides a method for preparing the above-mentioned copolyester, the method comprising the following steps: subjecting monomer ...

Embodiment 1

[0177] Add 73g of adipic acid, 75g of terephthalic acid, 8g of 2,5-furandicarboxylic acid, 220g of 1,4-butanediol, and 0.10g of tetra-n-butyl titanate into a 500mL three-necked flask equipped with a mechanical stirring device . After all the materials have been added, equip the flask with a condensation device, vacuumize and fill with nitrogen three times to remove the oxygen in the reaction vessel to ensure that the esterification reaction is carried out under nitrogen conditions. Heating to 225°C. After the reactants form a homogeneous system, control the reaction temperature so that the esterification reaction is stirred at 225°C for 3 hours. During this process, water is distilled from the reaction mixture as a by-product until the amount of the distillate reaches 92% of the theoretical calculation. (The theoretically calculated amount of water is twice the sum of the molar amounts of adipic acid, terephthalic acid and 2,5-furandicarboxylic acid).

[0178] 0.15 g of anti...

Embodiment 2

[0183] Add 70g dimethyl adipate, 93g dimethyl terephthalate, 22g dimethyl 2,5-furandicarboxylate, 230g 1,4-butanediol, 0.15g zinc acetate to a mechanical stirring device 500mL three-necked bottle. After all the materials have been added, equip the flask with a condensation device, vacuumize and fill with nitrogen three times to remove the oxygen in the reaction vessel to ensure that the transesterification reaction is carried out under nitrogen conditions. Heating to 205°C. After the reactants form a homogeneous system, control the reaction temperature so that the transesterification reaction is stirred at 205°C for 6 hours. During this process, methanol is distilled out from the reaction mixture as a by-product until the amount of the distillate reaches 92% of the theoretical calculation. (The theoretically calculated amount of methanol is twice the sum of the molar amounts of dimethyl adipate, dimethyl terephthalate and dimethyl 2,5-furandicarboxylate).

[0184] 0.15g of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com