Toughened polylactic acid and preparation method thereof

A polylactic acid and toughening technology, applied in the field of toughened polylactic acid and its preparation, can solve the problems of weakening the advantages of polylactic acid, poor impact resistance, and low elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dehydration treatment of 1,10-sebacic acid: put a certain mass of 1,10-sebacic acid in a vacuum oven, and place it at 60° C. under vacuum for 24 hours to constant weight.

[0031] Synthesis of polyester elastomer: add a certain amount of lactic acid, 1,4-butanediol, 1,10-sebacic acid, itaconic acid in a three-necked flask, the molar ratio is 4:3:2.5:0.5, and It is a polymerization inhibitor 705 with 0.1% of the total mass of the above monomers. The reaction temperature of the control system is 130 ° C. After 1 hour of reaction, the temperature is raised to 180 ° C. After 2 hours of reaction, the temperature of the system is lowered to 100 ° C. Add 0.1 wt of the total mass of the above reaction monomers % tetrabutyl titanate catalyst, then heated up to 210° C., and reacted under vacuum conditions for 8 hours to obtain a polyester elastomer, which was placed in a sealed drying tower for later use.

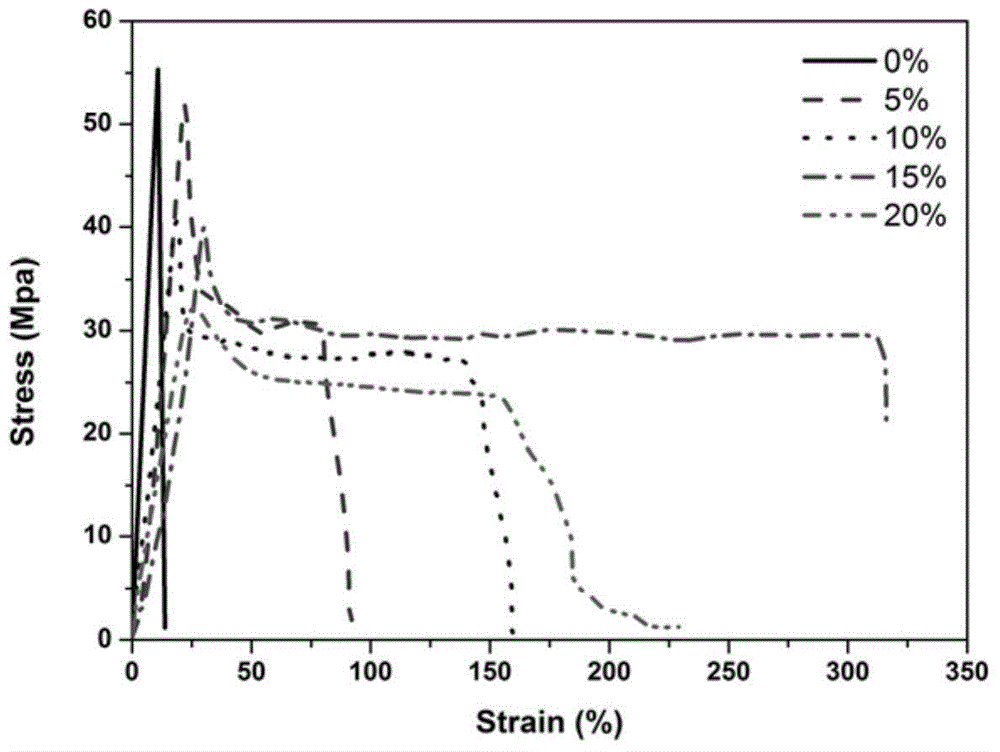

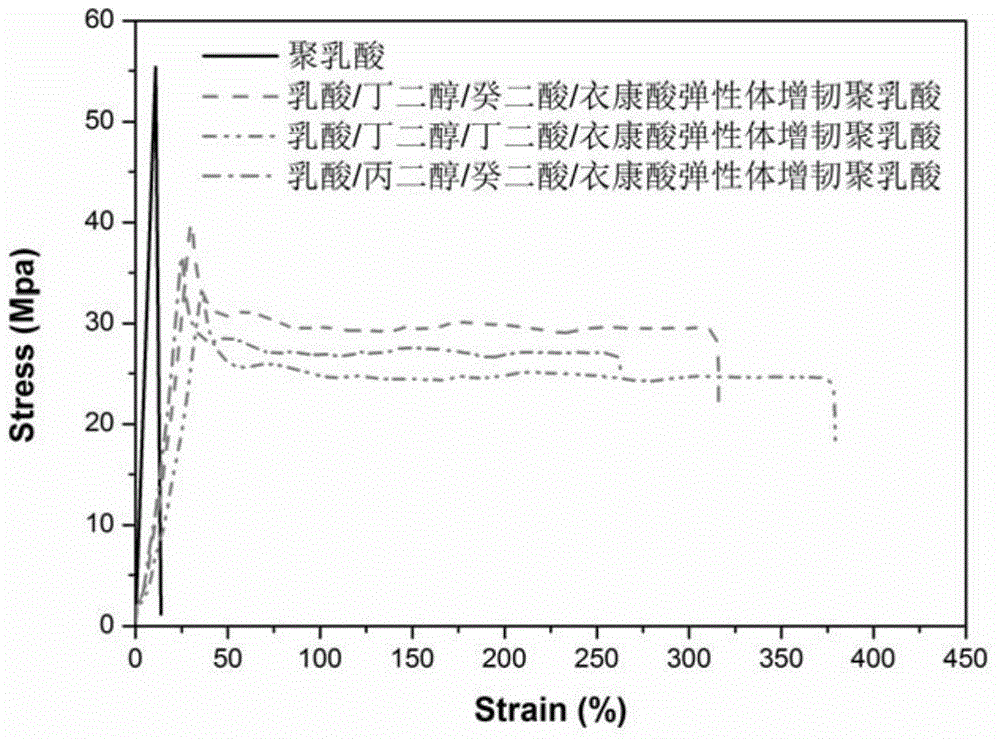

[0032] Blend ratio: Polylactic acid and polyester elastomer are melt blen...

Embodiment 2

[0037] The dehydration treatment of 1,10-sebacic acid: same as embodiment 1.

[0038] Synthesis of polyester elastomer: Synthesis of polyester elastomer: add a certain amount of lactic acid, 1,4-butanediol, 1,10-sebacic acid, itaconic acid in a three-necked flask, the molar ratio is 4: 3:2.5:0.5, and the polymerization inhibitor 705 which is 0.1% of the total mass of the above-mentioned monomers, the reaction temperature of the control system is 150°C, the temperature is raised to 200°C after 1 hour of reaction, and the temperature of the system is lowered to 100°C after 2 hours of reaction, adding the above A tetrabutyl titanate catalyst with a total monomer mass of 0.1 wt% was heated up to 230° C., and reacted under vacuum for 8 hours to obtain a polyester elastomer, which was placed in a sealed drying tower for later use.

[0039] The proportioning of blend: with embodiment 1.

[0040] Preparation of blend: same as Example 1.

[0041] Preparation of test sample: same as E...

Embodiment 3

[0043] The dehydration treatment of 1,10-sebacic acid: same as embodiment 1.

[0044] Synthesis of polyester elastomer: Synthesis of polyester elastomer: add a certain amount of lactic acid, 1,4-butanediol, 1,10-sebacic acid, itaconic acid in a three-necked flask, the molar ratio is 4: 3:2.5:0.5, and the polymerization inhibitor 705 which is 0.1% of the total mass of the above-mentioned monomers, the reaction temperature of the control system is 140°C, the temperature is raised to 190°C after 1 hour of reaction, and the temperature of the system is lowered to 100°C after 2 hours of reaction, adding the above A tetrabutyl titanate catalyst with a total monomer mass of 0.1 wt% was heated up to 220° C., and reacted under vacuum conditions for 8 hours to obtain a polyester elastomer, which was placed in a sealed drying tower for later use.

[0045] The proportioning of blend: with embodiment 1.

[0046] Preparation of blend: same as Example 1.

[0047] Preparation of test sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com