Weather-proof self-cleaning transparent material and preparation method thereof

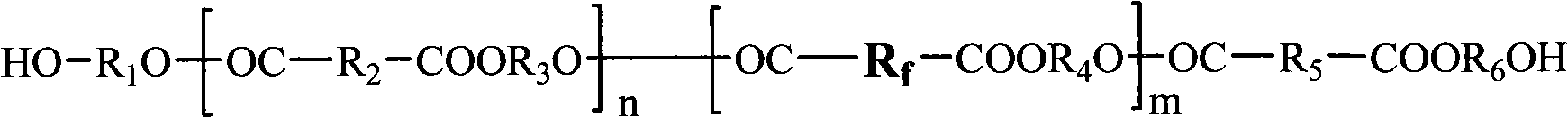

A transparent material and self-cleaning technology, applied in the field of weather-resistant self-cleaning transparent materials and their preparation, can solve the problems of poor mechanical strength, lack of processability of common polymers, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

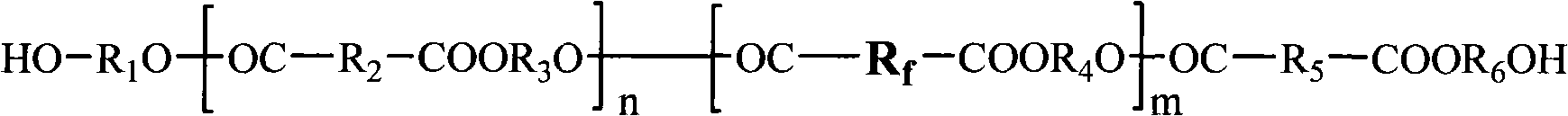

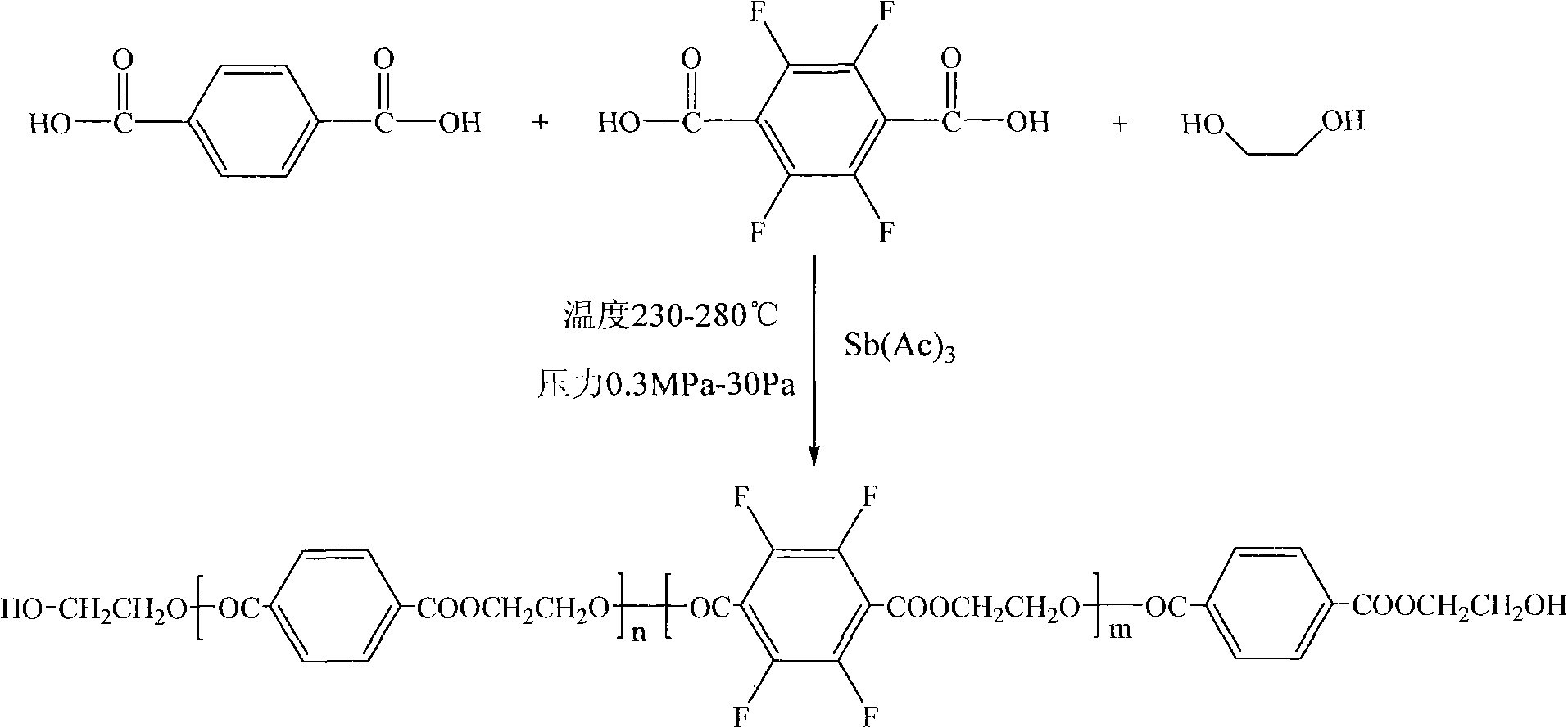

[0022] Example 1 Mix 0.1 mol of terephthalic acid, 0.16 mol of ethylene glycol and 0.01 mol of 2,3,5,6-tetrafluoroterephthalic acid into the reaction vessel, start stirring and heat up to 240-250 °C, and the system pressure is controlled At 0.3 MPa, the reaction time was 3 hours. After the esterification reaction is completed, add Sb(Ac) 3 , its concentration is about 400ppm, be warming up to 250~265 ℃, the system pressure is reduced to less than 1KPa, and the reaction time is 2 hours, and then the temperature is raised to 265~280 ℃, and the system pressure is reduced to less than 30Pa, and the reaction is performed for 2 hours. After finishing the reaction, when the reaction system is lowered to room temperature, the final product is extruded, diced and dried to prepare polyester chips, and heated and pressed in a vacuum laminator to prepare the final film material. The reaction formula is as follows:

[0023]

Embodiment 2

[0024] Example 2 Mix 0.1mol succinic acid, 0.18mol butanediol and 0.02mol 3,4,5,6-tetrafluorophthalic acid into the reaction vessel, start stirring and heat up to 230-240°C, the system pressure is controlled at 0.3MPa, the reaction time is 4 hours. After the esterification reaction, add Sb(Ac) 3 , its concentration is about 400ppm, be warming up to 240~255 ℃, the system pressure is reduced to less than 1KPa, and the reaction time is 3 hours, and then the temperature is raised to 255~270 ℃, and the system pressure is reduced to less than 30Pa, and the reaction is performed for 3 hours. After finishing the reaction, when the reaction system is lowered to room temperature, the final product is extruded, diced and dried to prepare polyester chips, and heated and pressed in a vacuum laminator to prepare the final film material. The reaction formula is as follows:

[0025]

Embodiment 3

[0026] Example 3 Mix 0.1 mol of terephthalic acid, 0.2 mol of ethylene glycol and 0.03 mol of 4-(trifluoromethyl)phthalic acid into the reaction vessel, start stirring and heat up to 240-250 °C, and control the system pressure at 0.3 MPa, the reaction time was 3 hours. After the esterification reaction finishes, add tetraisopropyl titanate, its concentration is about 50ppm, be warming up to 250~265 ℃, the system pressure is reduced to less than 1KPa, and the reaction time is 3 hours, and then the temperature is raised to 265~280 ℃, The system pressure was reduced to less than 30Pa, and the reaction was carried out for 3 hours. After finishing the reaction, when the reaction system is lowered to room temperature, the final product is extruded, diced and dried to prepare polyester chips, and heated and pressed in a vacuum laminator to prepare the final film material. The reaction formula is as follows:

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com