Apparatus and methods for nanoparticle generation and process intensification of transport and reaction systems

A technology of reactants and microreactors, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as insufficient productivity, lack of scale and general applicability, and achieve high efficiency and cost-effectiveness. High flexibility performance, reducing component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

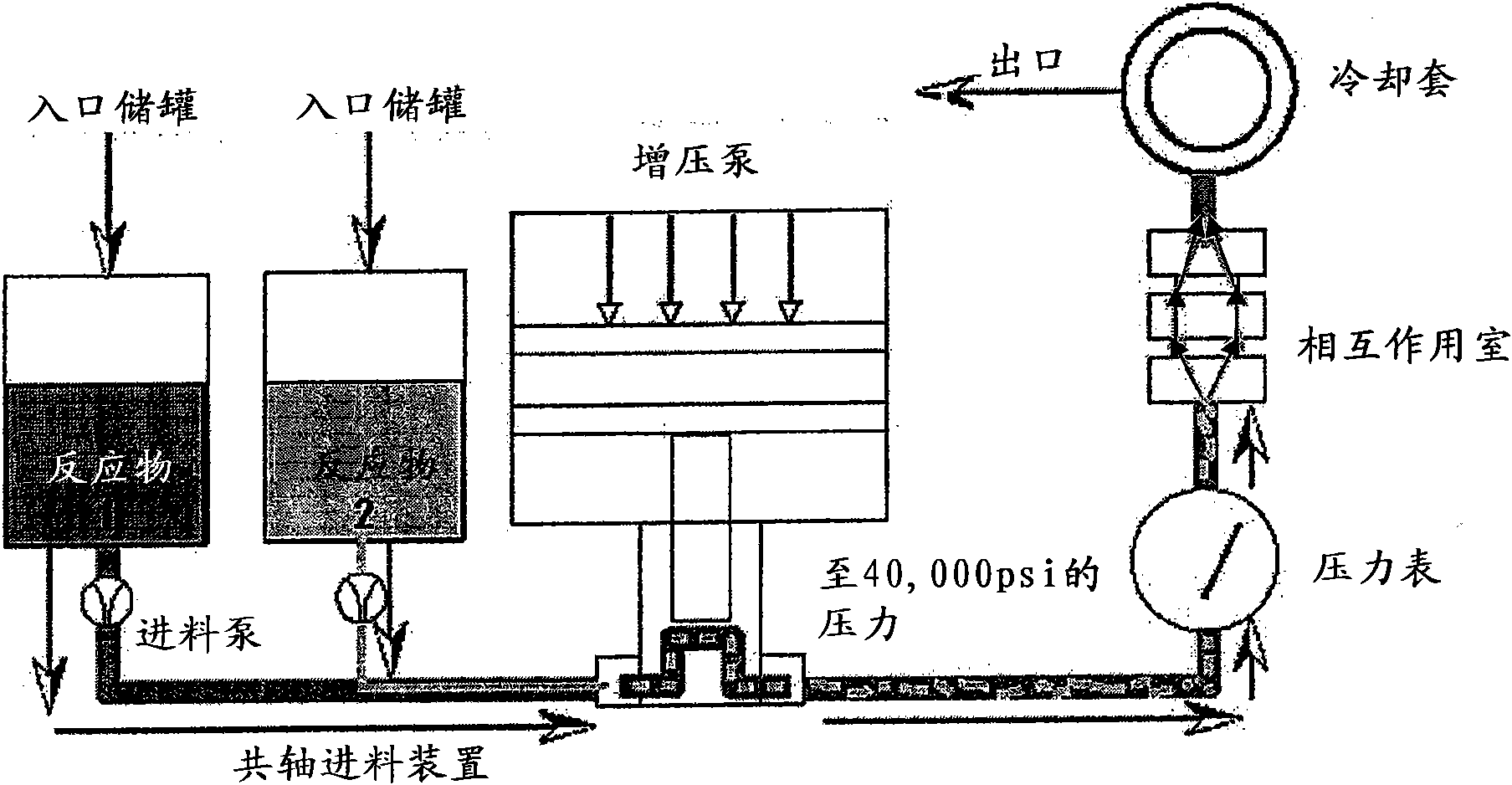

[0129] Example 1: Preparation of norfloxacin nanosuspensions using solvent / anti-solvent crystallization under high shear rate conditions

[0130] Overview: Hydrophobic active pharmaceutical ingredients (APIs) are often difficult to deliver effectively due to formulation constraints. Nanosuspensions of such drugs can be used to enhance bioavailability and provide multiple delivery options, including inhalation, oral, transdermal, and injection. The devices, systems and methods of the present disclosure have been used to reproducibly generate submicron API suspensions through a continuous process involving solvent-antisolvent crystallization. This technique of using miscible fluids to alter the solvent composition to create a supersaturated state is readily commercially implementable. It may also be the best economic choice due to its process-intensive nature that minimizes unit operations and energy requirements. Therefore, it may be the most environmentally friendly of the v...

Embodiment 2

[0185] Example 2: Preparation of Stable Drug Nanosuspensions According to the Disclosure (Extension of Example 1)

[0186] Several active pharmaceutical ingredients (APIs) were tested to further demonstrate the efficacy of the disclosed devices, systems and methods. The median particle size of the suspension produced by the device / system of the present disclosure is in the range of 50-767 nm. The suspensions were stable with one exception. For some APIs, the process efficiency exceeds 80%.

[0187] In contrast to the conventional "top-down" approach to preparing nanosuspensions, which primarily relies on reducing the particle size of drug powders in dry or wet formulations, exemplary embodiments of the present disclosure employ crystallization with solvent and anti-solvent "Bottom-up" processing to generate drug nanosuspensions. The disclosed "bottom-up" process enables the formation and stabilization of nanosuspensions without the need for size reduction. More specificall...

Embodiment 3

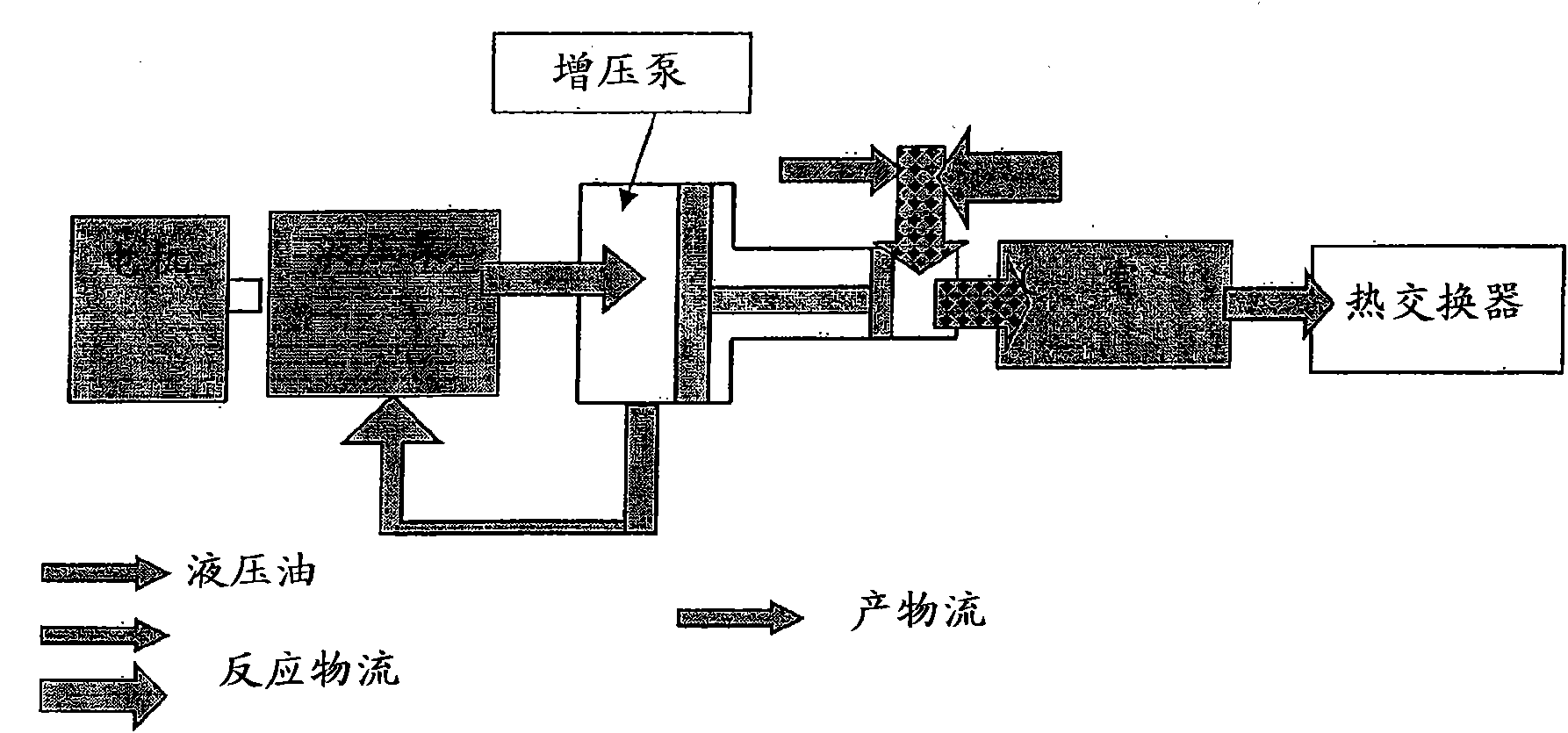

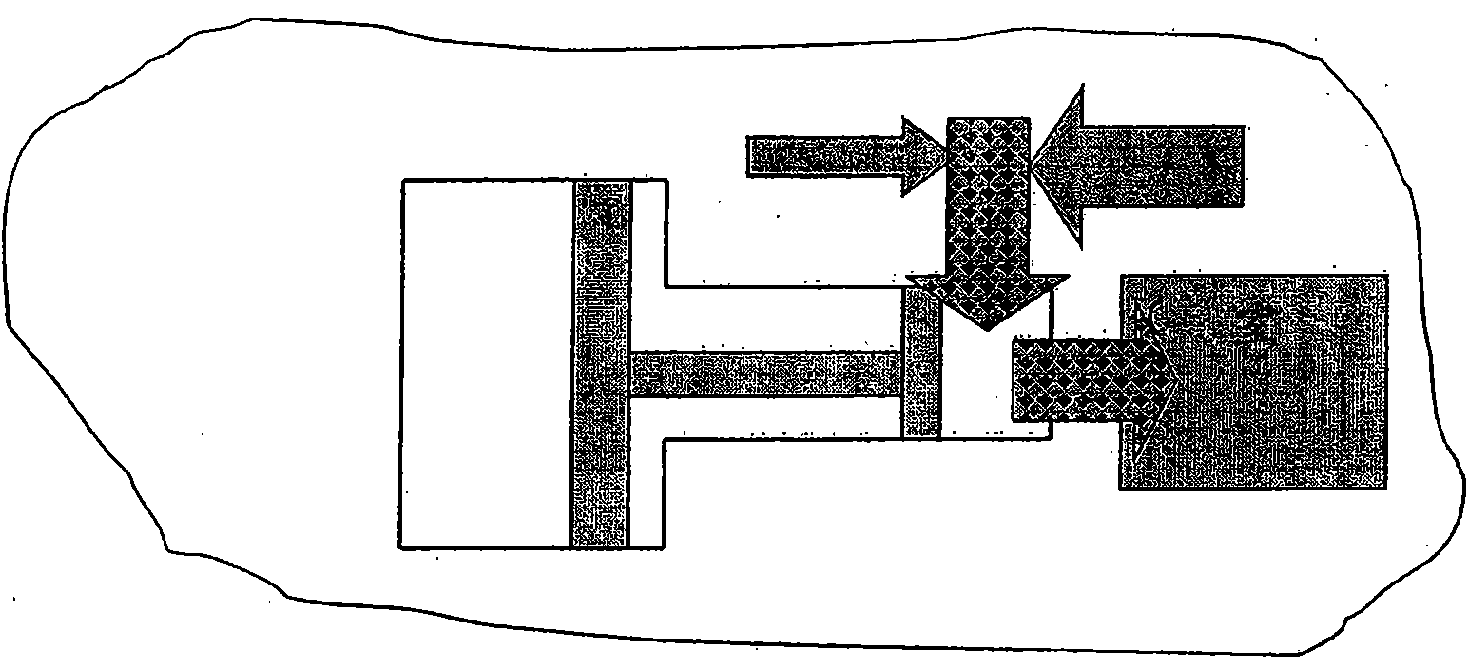

[0211] Example 3: Proposed system dynamics for biodiesel synthesis

[0212] Biodiesel can be produced by transesterification of vegetable oils. The most commonly used vegetable oils are soybean oil and canola oil. The reaction is a three-step catalytic reversible reaction. For every mole of triglyceride (TG) reactant (i.e. three fatty acid side groups), three moles of methanol are required to produce three moles of specific fatty acid methyl esters (FAME, referred to as "biodiesel") and one mole of glycerol (G, by-product). However, the reaction was carried out in an excess of methanol (6:1 molar ratio of methanol and vegetable oil) to push the reaction forward. The main reaction scheme is in Figure 17 shown in .

[0213] Typically, the catalyst is sodium hydroxide or sodium methoxide. In either case, the ion responsible for the catalysis is the methoxy ion. When sodium hydroxide is used, the methoxyl ion is generated in situ by reaction with methanol. The reaction me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com