Ceramic glaze pattern-glazed brick and production method thereof

A production method and technology for polishing glazed tiles, applied in the field of ceramic products, can solve the problems of the influence of color varieties, microcrystalline stone is not wear-resistant, and the color varieties are monotonous, etc., and achieves strong transparency, good wear resistance, and reduced glaze porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples, but not as a limitation to the present invention.

[0028] A kind of production method of glazed tile in porcelain glaze, comprising the following steps:

[0029] 1. Combined green body formula;

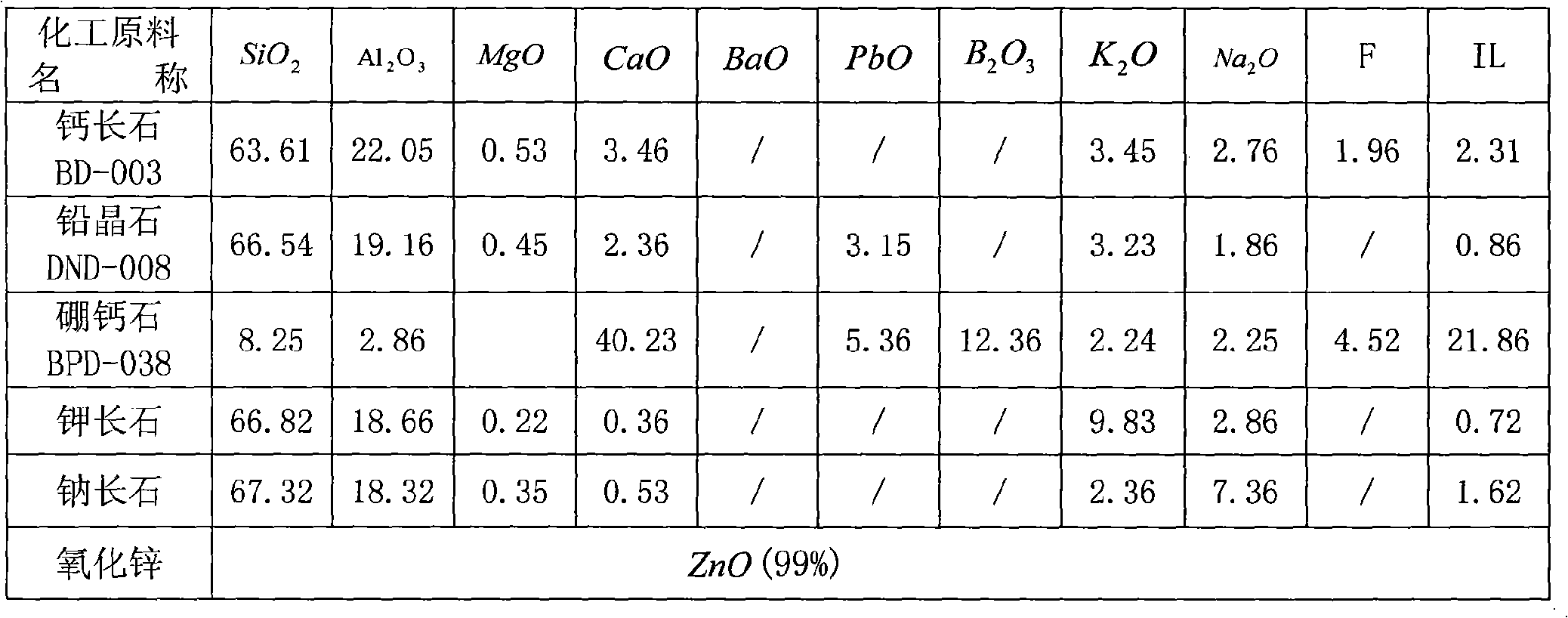

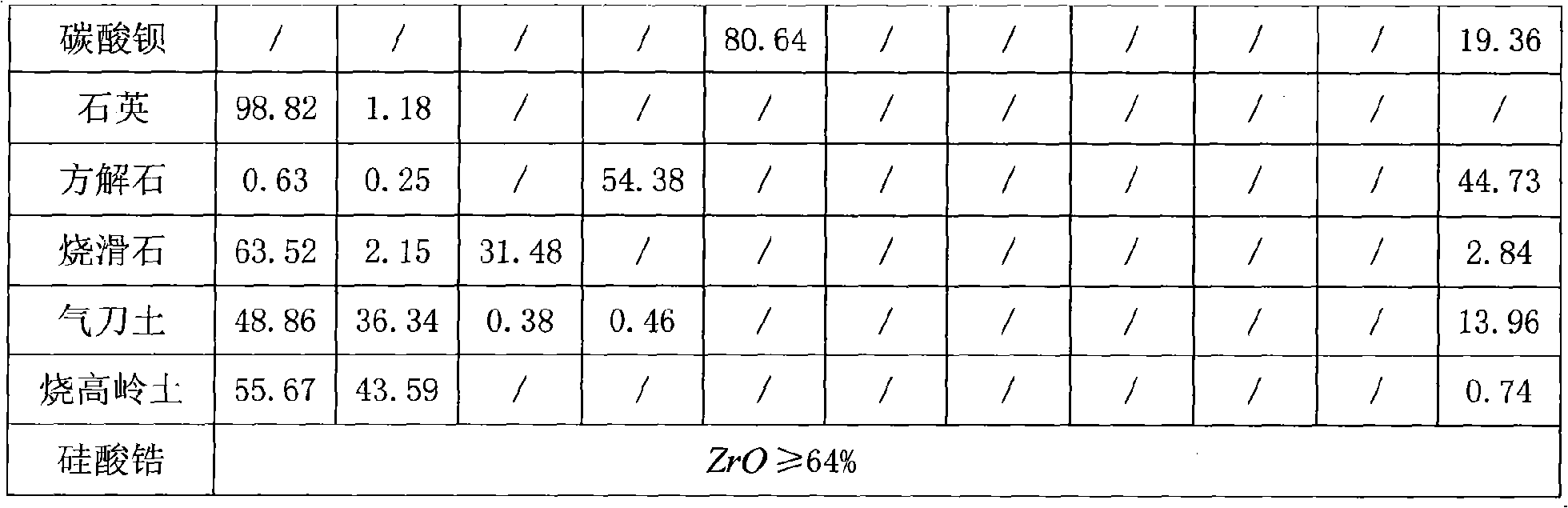

[0030] 1.1. The approximate chemical composition of the green body is calculated by weight percentage: SiO 2 : 69-72%, Al 2 o 3 : 18-20%, k 2 O+Na 2 O: 6-7.5%, CaO+MgO≤2.9%, Fe 2 o 3 +TiO 2 <1%, loss on ignition should be <4%, and the volatilization distribution in the material is: 26-33% of clay, 25-30% of sand, 35-40% of stone powder, and 2-3% of talc.

[0031] The selected green body formula: black mud 15% white mud 12%, high temperature sand 10%, medium temperature sand 11%, low temperature sand 16%, potassium stone powder 17% sodium stone powder 16%, raw talc 3%, with a size of 600×600mm as Example is 7.6kg.

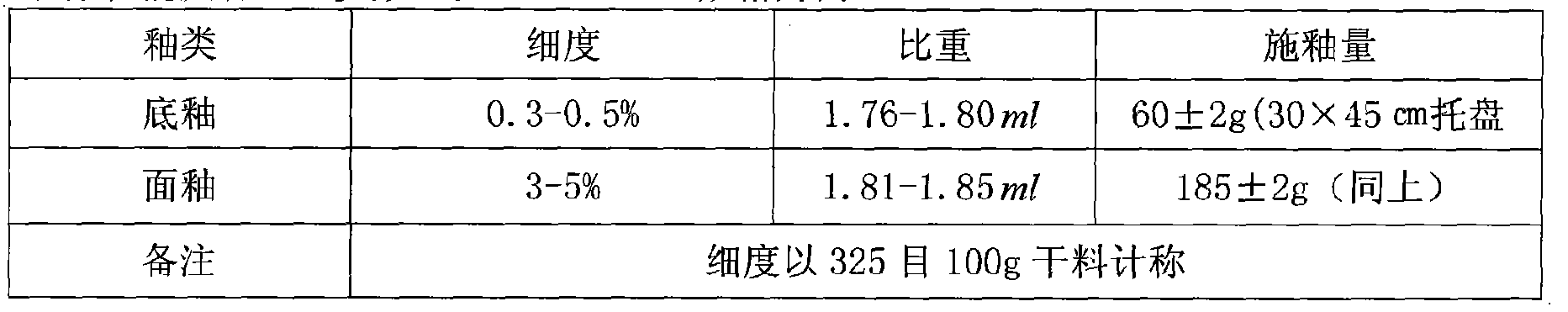

[0032] 1.2. The process parameter control of slurry and powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com