Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Marching cubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

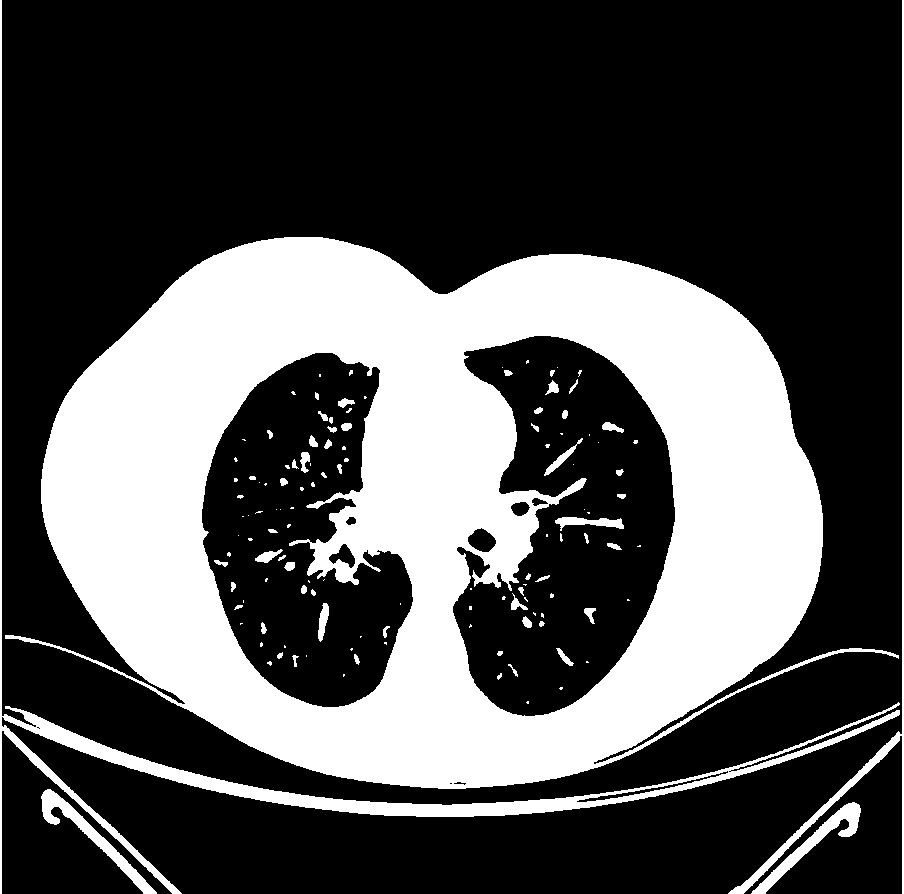

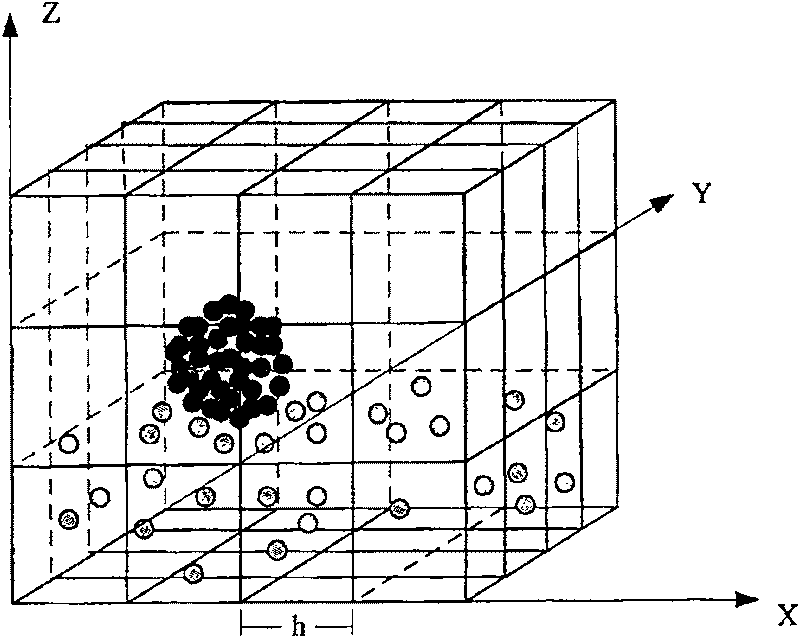

Marching cubes is a computer graphics algorithm, published in the 1987 SIGGRAPH proceedings by Lorensen and Cline, for extracting a polygonal mesh of an isosurface from a three-dimensional discrete scalar field (sometimes called a voxel). The applications of this algorithm are mainly concerned with medical visualizations such as CT and MRI scan data images, and special effects or 3-D modelling with what is usually called metaballs or other metasurfaces. An analogous two-dimensional method is called the marching squares algorithm.

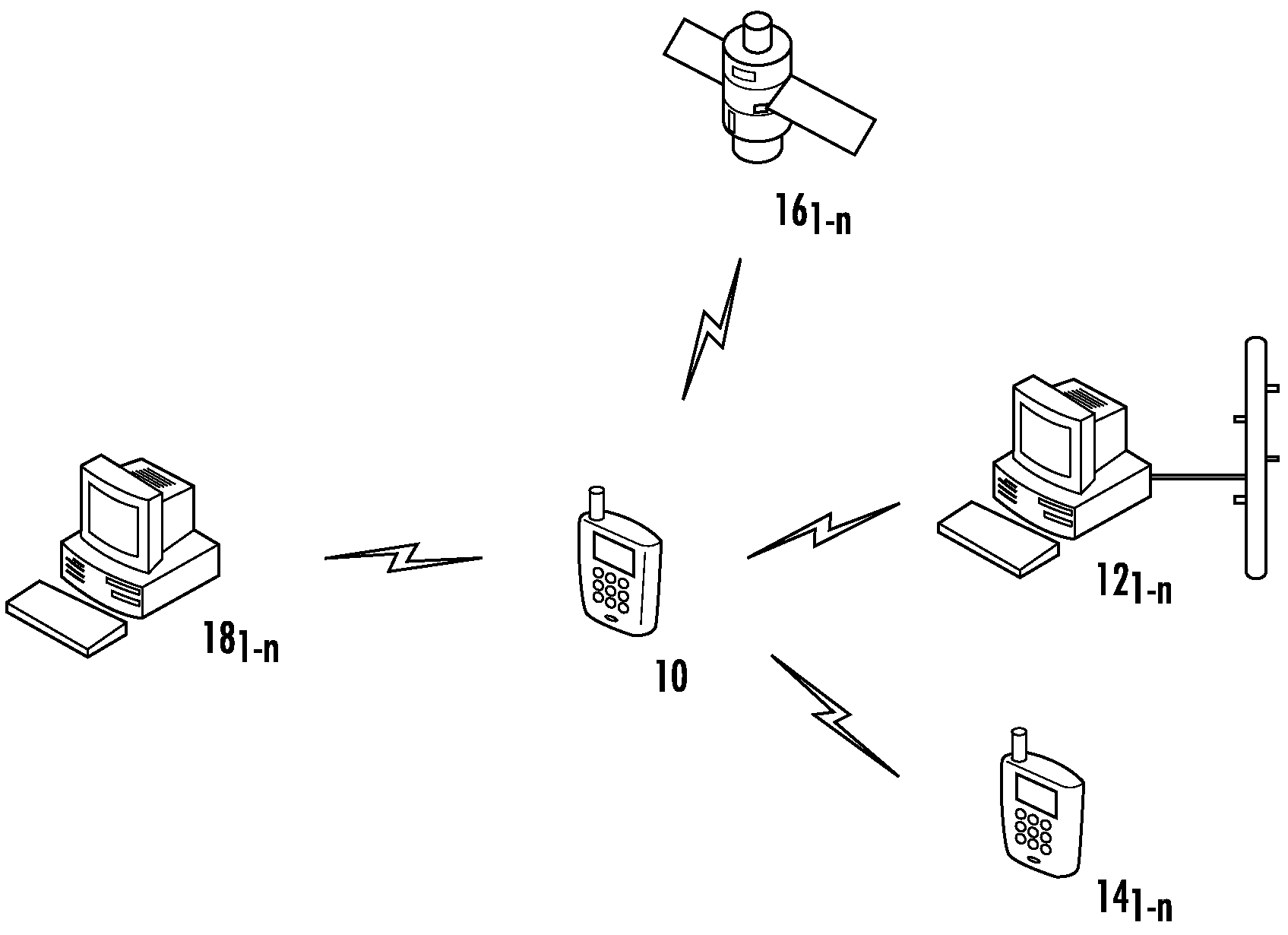

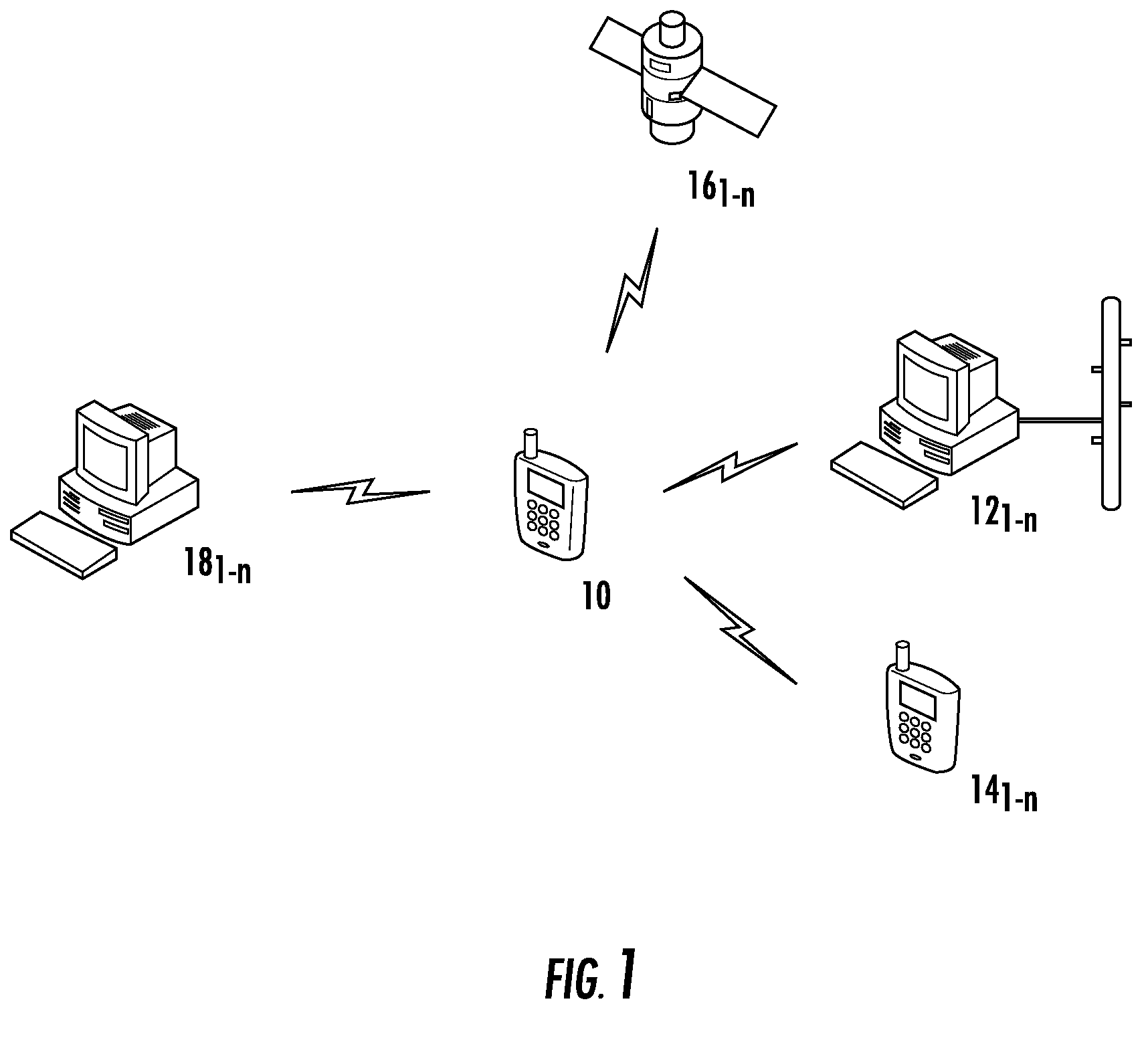

Systems and methods for providing location based services (LBS) utilizing WLAN and/or GPS signals for seamless indoor and outdoor tracking

ActiveUS20090196267A1Improve accuracyWide range of applicationsSatellite radio beaconingWireless commuication servicesApproximation algorithmPositioning system

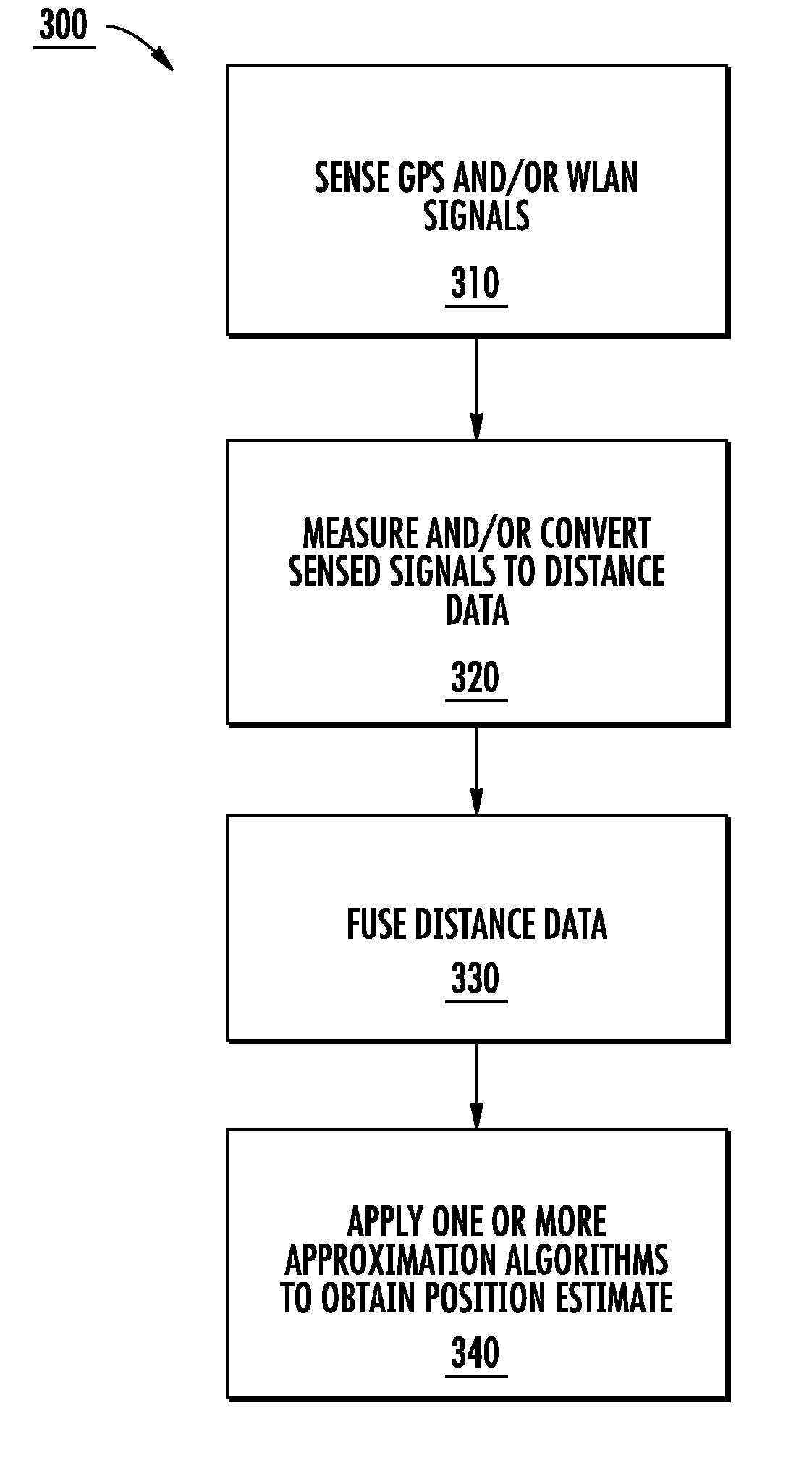

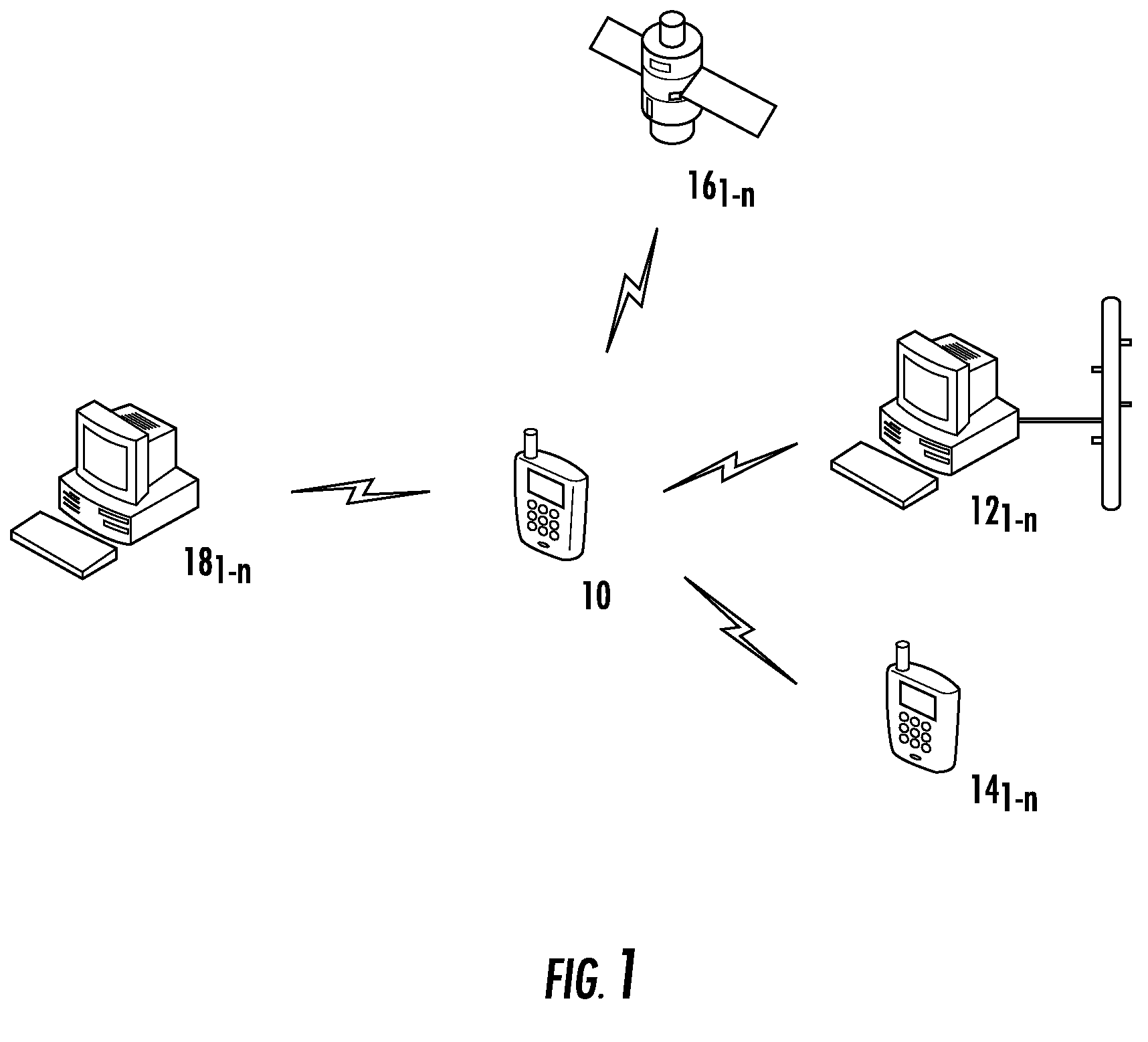

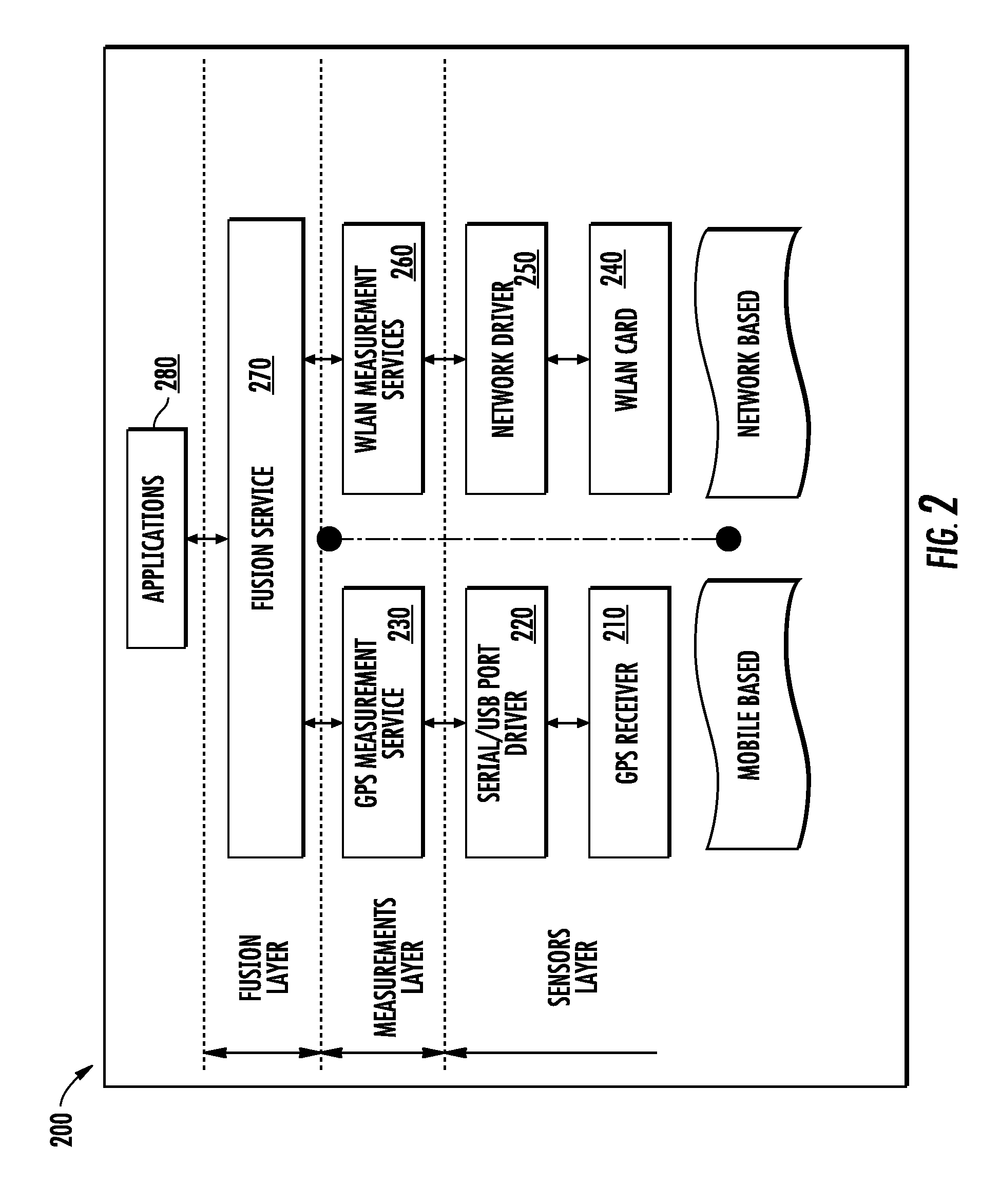

Systems and methods for tracking a wireless device are disclosed. According to one aspect, the wireless device includes a hybrid global positioning system (GPS) and wireless local area network (WLAN) circuit board for seamless indoor and outdoor tracking. In embodiments, GPS and WLAN data are combined to obtain a position estimate of the device. In other embodiments, the circuit board automatically switches between WLAN and GPS data for indoor and outdoor environments. A Location Based Services (LBS) algorithm for determining the position of a wireless device using WLAN and / or GPS signals is also disclosed. The LBS algorithm is implemented by way of method steps including: sensing GPS and / or WLAN signals, measuring and / or converting the sensed signals to obtain distance data, fusing the distance data, and applying one or more approximation algorithms to the distance data to obtain a position estimate of the wireless device. A method for rendering position data using a Marching Cubes algorithm is further disclosed.

Owner:WALKER SR JONATHAN B

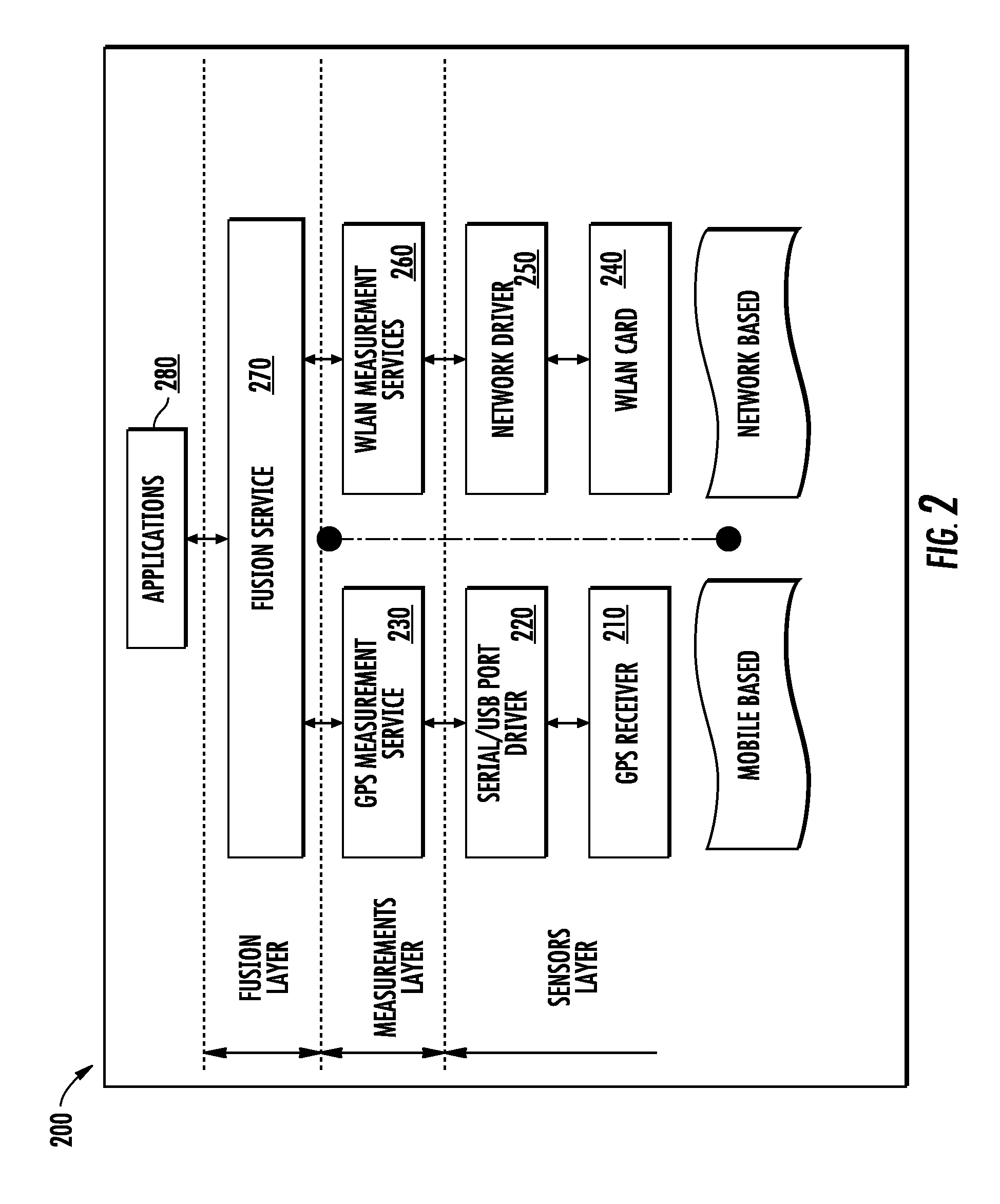

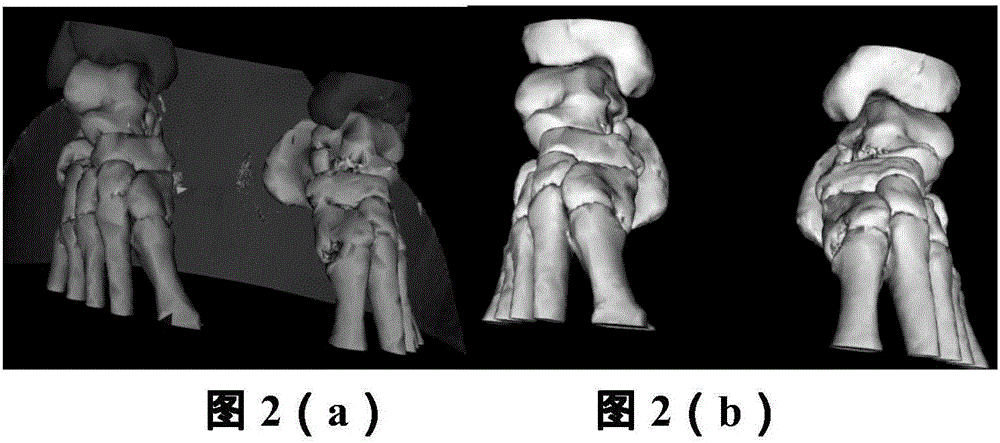

Medical image based segmentation and 3D reconstruction method and 3D printing system

The invention discloses a medical image based segmentation and 3D reconstruction method and a 3D printing system. The method comprises segmenting a medical image and carrying out 3D reconstruction. The 3D printing system carries out 3D printing on a reconstruction model by utilizing a fused decomposition modeling (FDM) method. In the image segmentation part, a unique segmentation algorithm based on medical image (DICOM) preprocessing is provided, and a segmentation task is completed effectively. In the reconstruction part, an MC (Marching Cubes) algorithm is optimized, and the model in the invention is improved greatly. In an interactive interface, a visualization tool enables interaction between a user and the model to certain extent. Finally, a 3D printer prints the obtained model and obtains a simulated entity of bones, and doctors can touch and make interaction with the simulated entity.

Owner:北京三体高创科技有限公司 +1

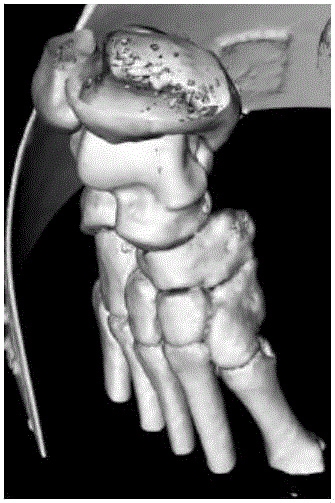

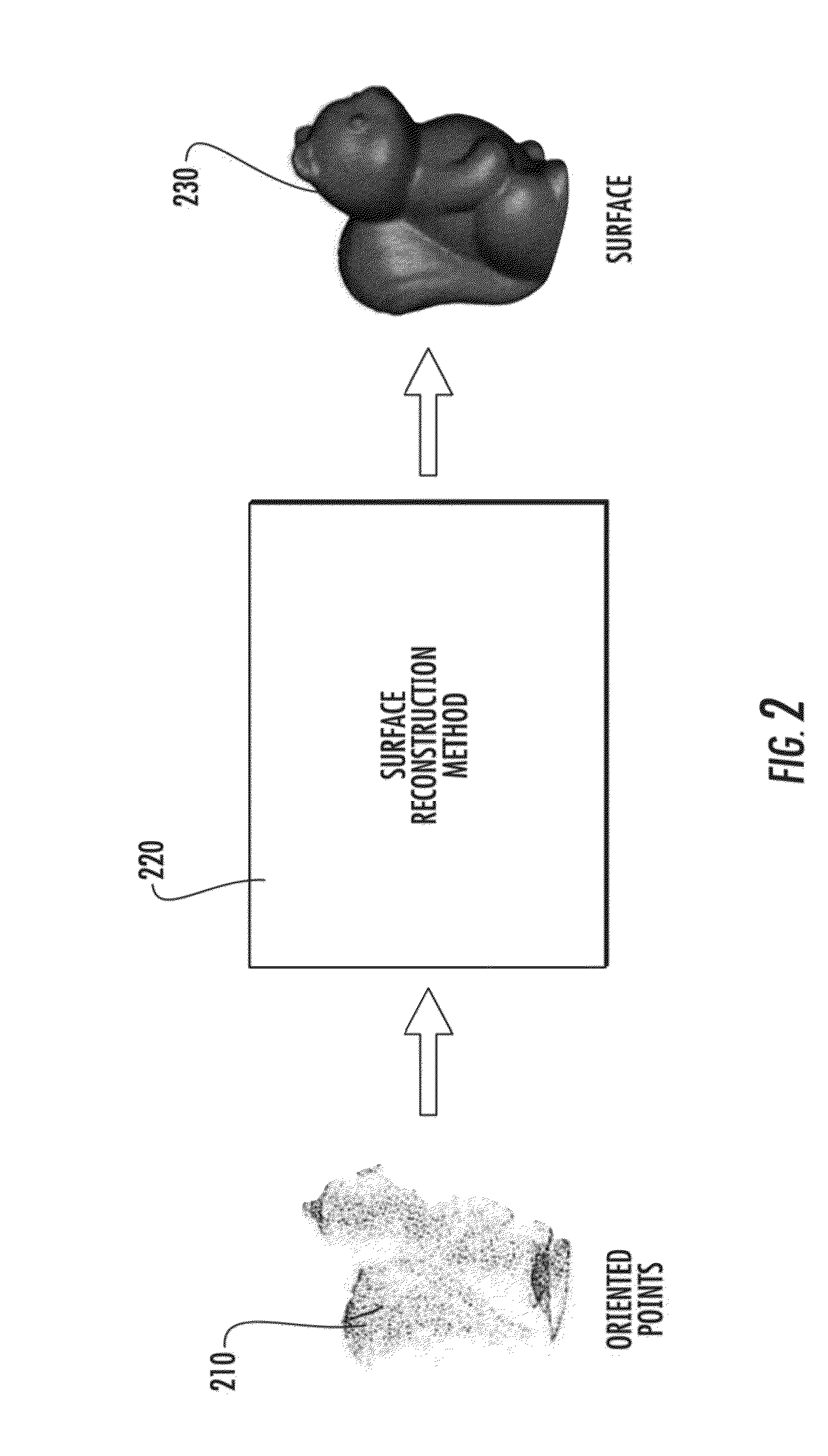

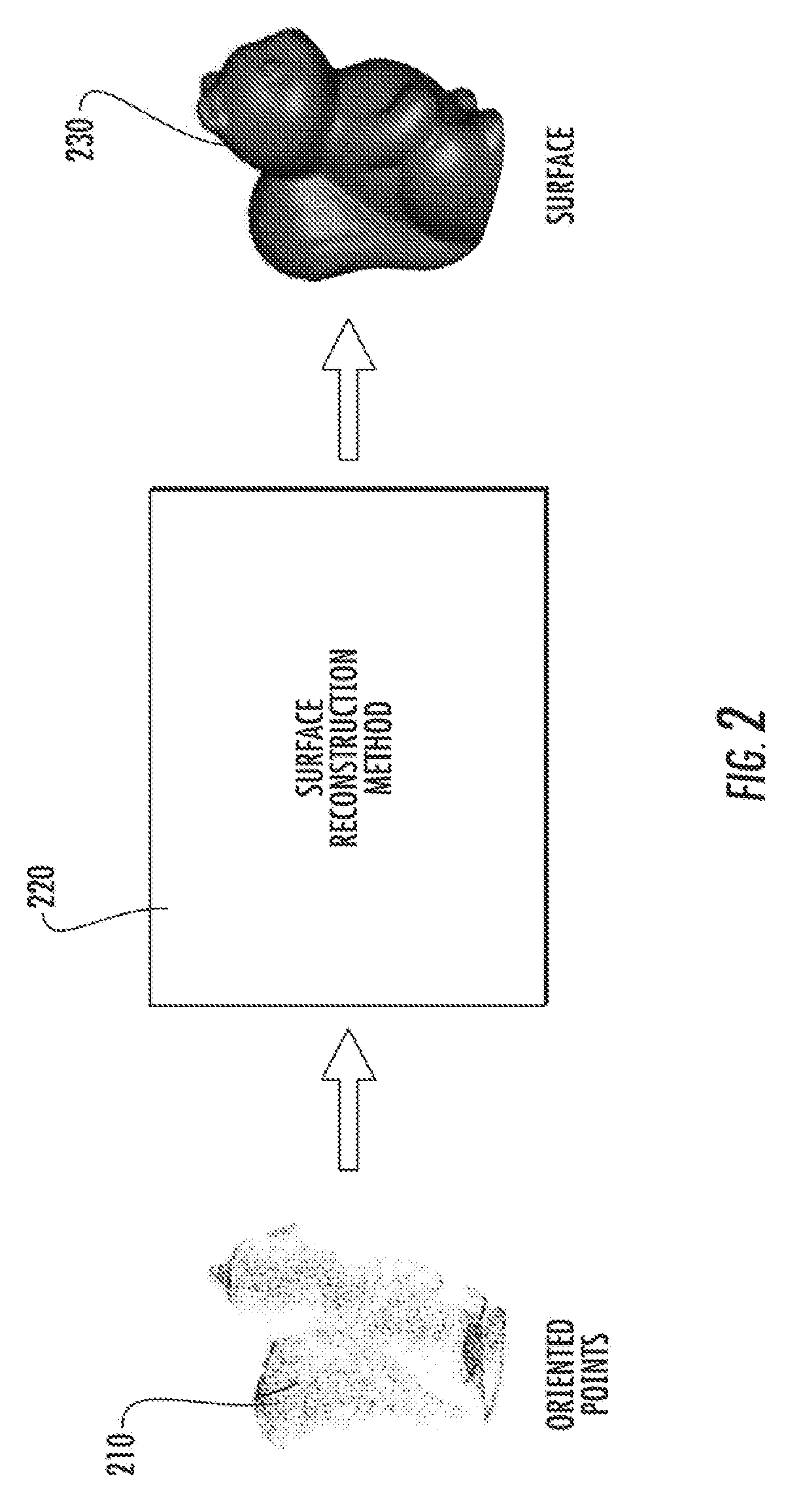

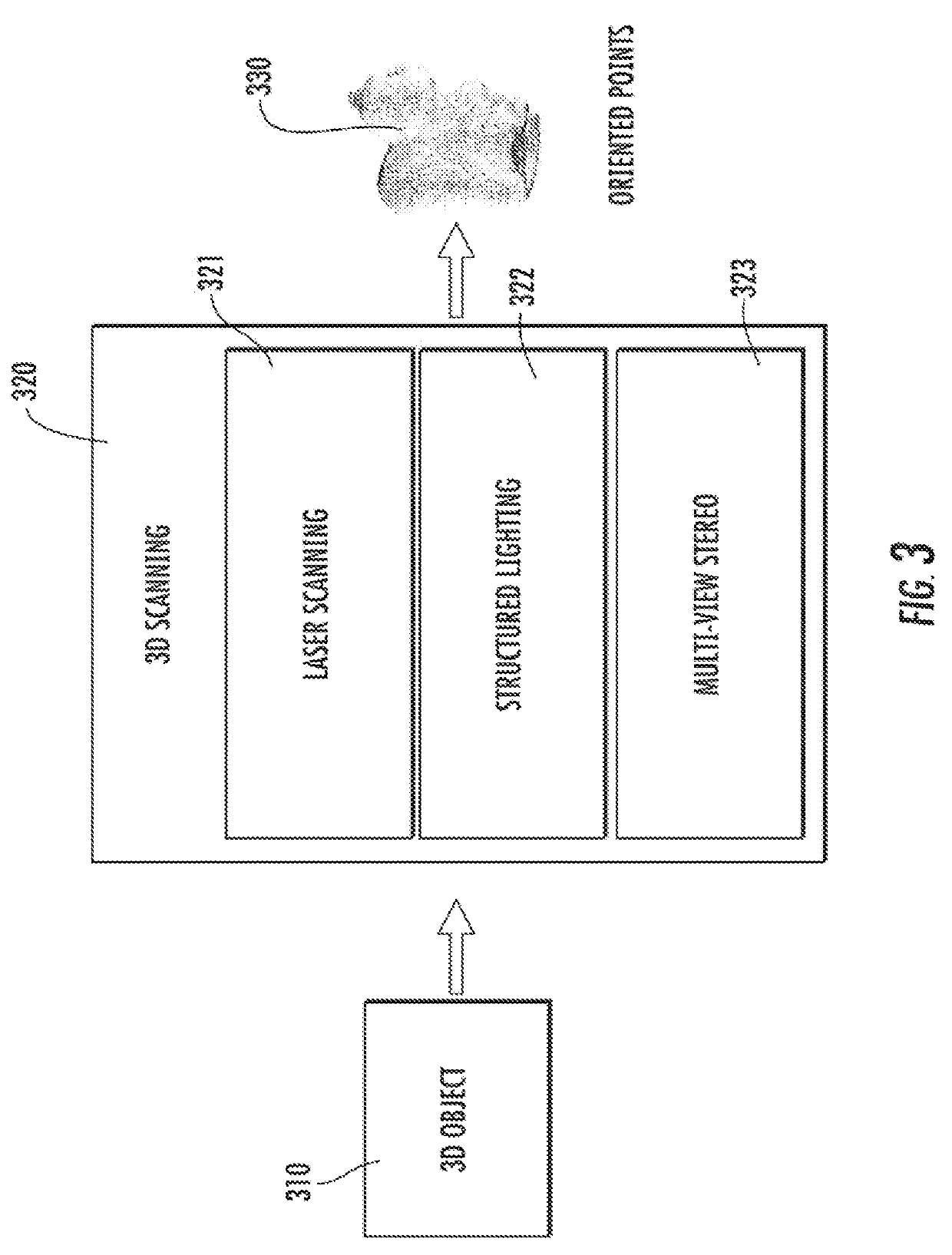

Method to reconstruct a surface from oriented 3-d points

InactiveUS20140172377A1Easy to implementQuality improvementSpecial data processing applicationsImage generationDiscretizationSymbol of a differential operator

A method for the problem of reconstructing a watertight surface defined by an implicit equation from a finite set of oriented points. As in other surface reconstruction approaches disctretizations of this continuous formulation reduce to the solution of sparse least-squares problems. Rather than forcing the implicit function to approximate the indicator function of the volume bounded by the surface, in the present formulation the implicit function is a smooth approximation of the signed distance function to the surface. Then solution thus introduced is a very simple hybrid FE / FD discretization, which together with an octree partitioning of space, and the Dual Marching Cubes algorithm produces accurate and adaptive meshes.

Owner:BROWN UNIVERSITY

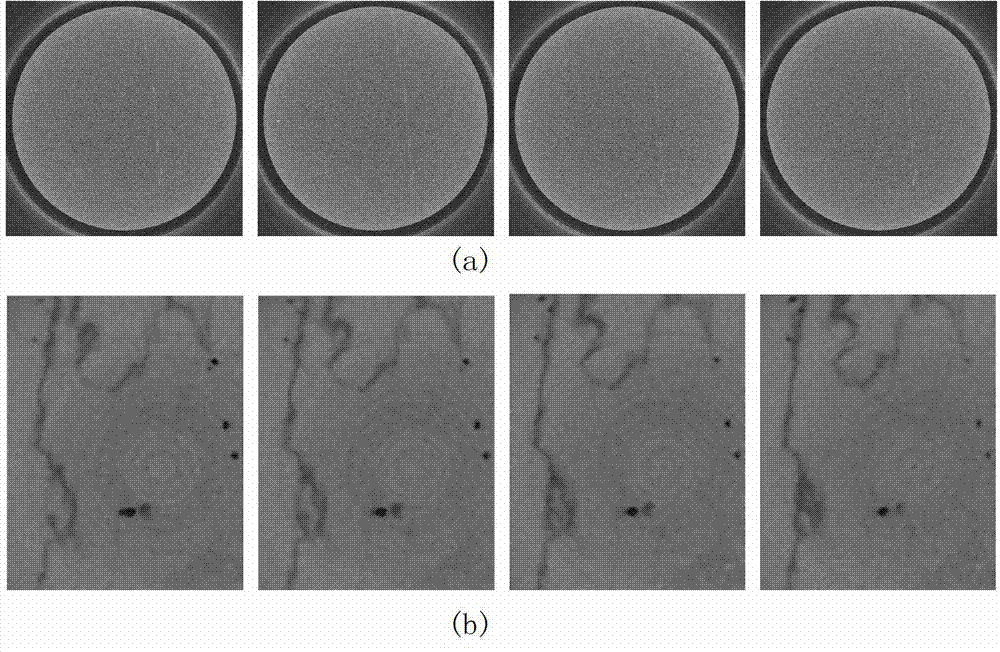

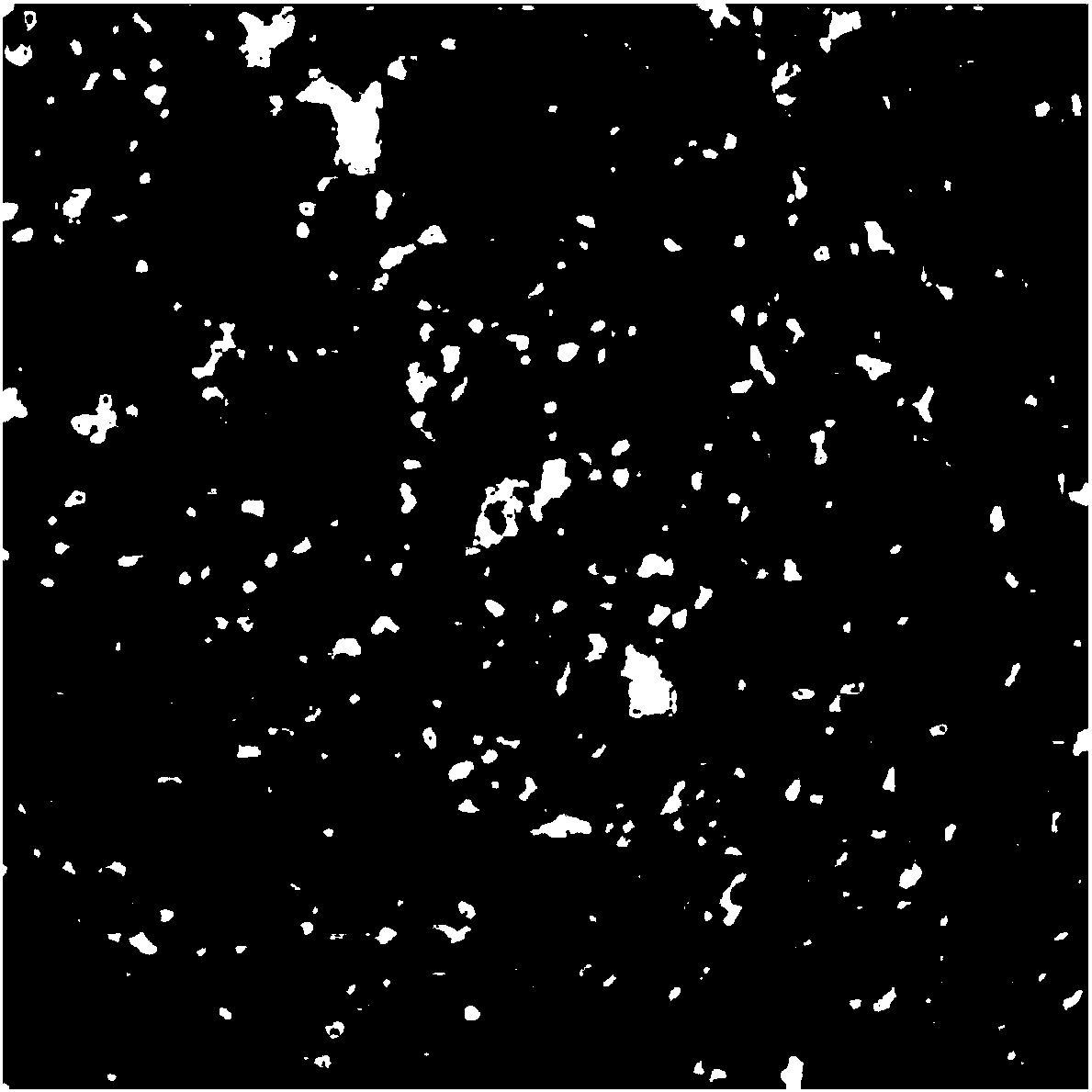

Core fracture identification method based on three-dimensional image information processing

ActiveCN102867302AAccurate identificationQuick identificationImage analysis3D modellingInformation processingMobile Cube

The invention relates to a core fracture identification method based on three-dimensional image information processing, belonging to the technical field of image segmentation. The method comprises the following steps of: scanning a core to be processed by using a CT (computerized tomography) machine, storing a scanned core CT sequence image in a computer, reading the well scanned core CT sequence image by using core three-dimensional image fracture identification software, performing three-dimensional image reconstruction on the core CT sequence image by utilizing a marching cubes algorithm, and performing a series of calculation, getting and screening processed by utilizing the differences among pores, random noise and fracture in morphological features in a three-dimensional data field to achieve the purpose of identifying a core fracture. According to the method provided by the invention, the core fracture can be fast and accurately identified; and the problems of causing error and even mistake due to negligence of communication information of the core fracture between layers in the existing isolate analysis of each core CT sequence image can be solved.

Owner:SICHUAN UNIV

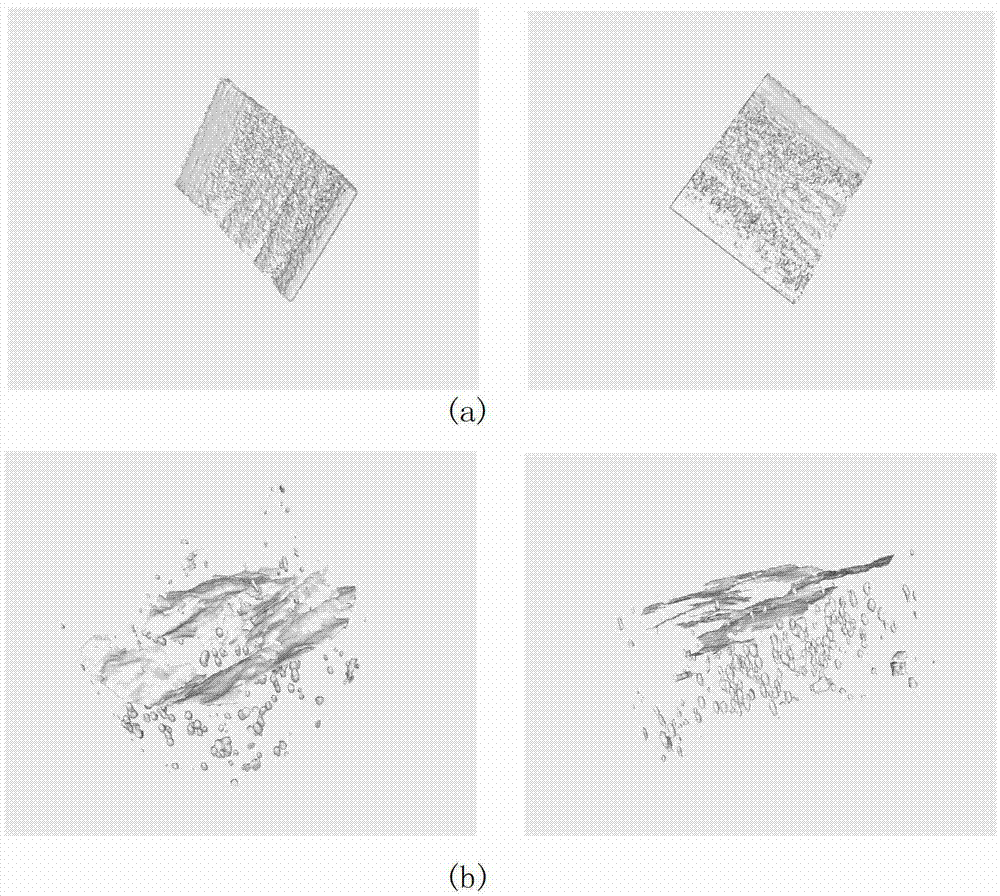

Micro-CT technology-based reservoir core three-dimensional entity model reconstruction method

ActiveCN105261068AValid descriptionEffective Digital Management3D modellingFractographyReconstruction method

The invention relates to a micro-CT technology-based reservoir core three-dimensional entity model reconstruction method. The method includes the following steps that: a micro-CT technology is utilized to scan a reservoir core, so that a sectional scanning image of the reservoir core can be obtained, so that a CT image of a real reservoir core can be obtained, and a watershed algorithm is adopted to perform image segmentation on the CT image, so that the three-dimensional data of the image can be obtained; a Marching Cubes algorithm is adopted to generate a three-dimensional surface model of the reservoir core; and with the three-dimensional surface model of the reservoir core adopted as constraints, a constrained Delaunay tetrahedralization algorithm is utilized to generate the three-dimensional entity model of the reservoir core. According to the method of the invention, the three-dimensional entity model of the real reservoir core is established based on the sectional scanning image of the reservoir core, so that the obtained three-dimensional entity model of the reservoir core is more approximate to the structure of a real reservoir core. The method of the invention has the advantages of high accuracy and high efficiency. With the method adopted, defects of poor accuracy and low efficiency in the reconstruction of the three-dimensional entity model of a reservoir core in the prior art can be eliminated, and an effective guarantee can be provided for reservoir core simulation characteristic research.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

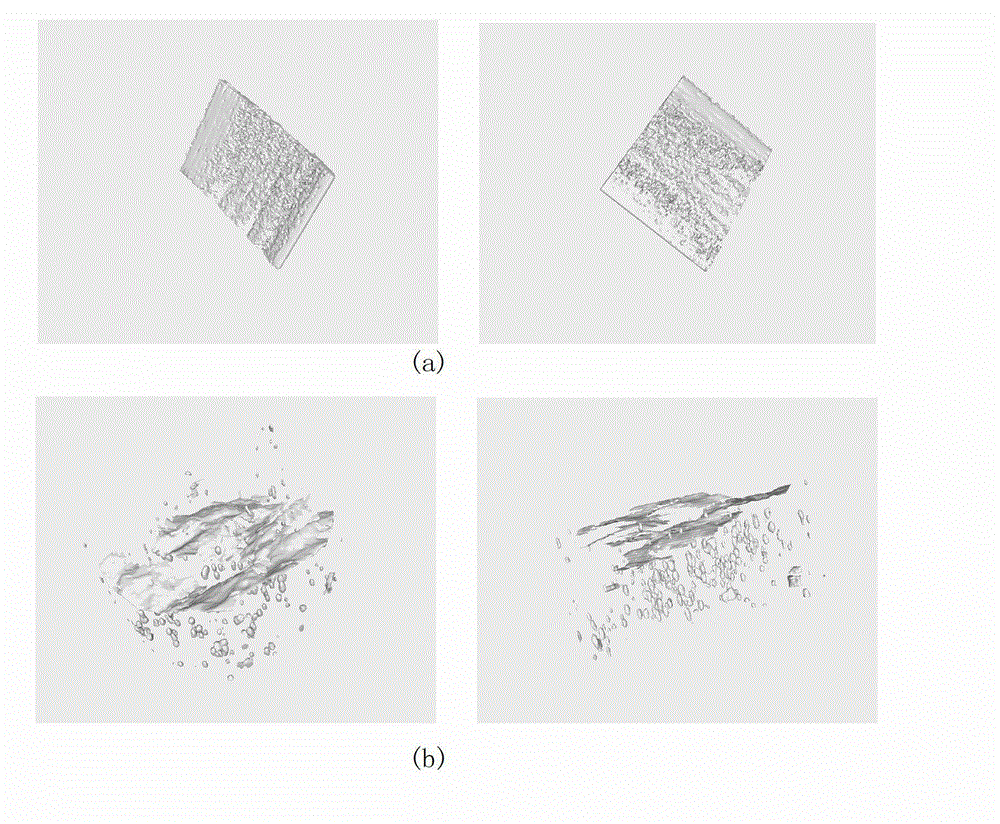

Method to reconstruct a surface from partially oriented 3-d points

InactiveUS20190259202A1Easy to implementQuality improvementImage generation3D modellingDiscretizationSmoothing approximation

Owner:BROWN UNIVERSITY

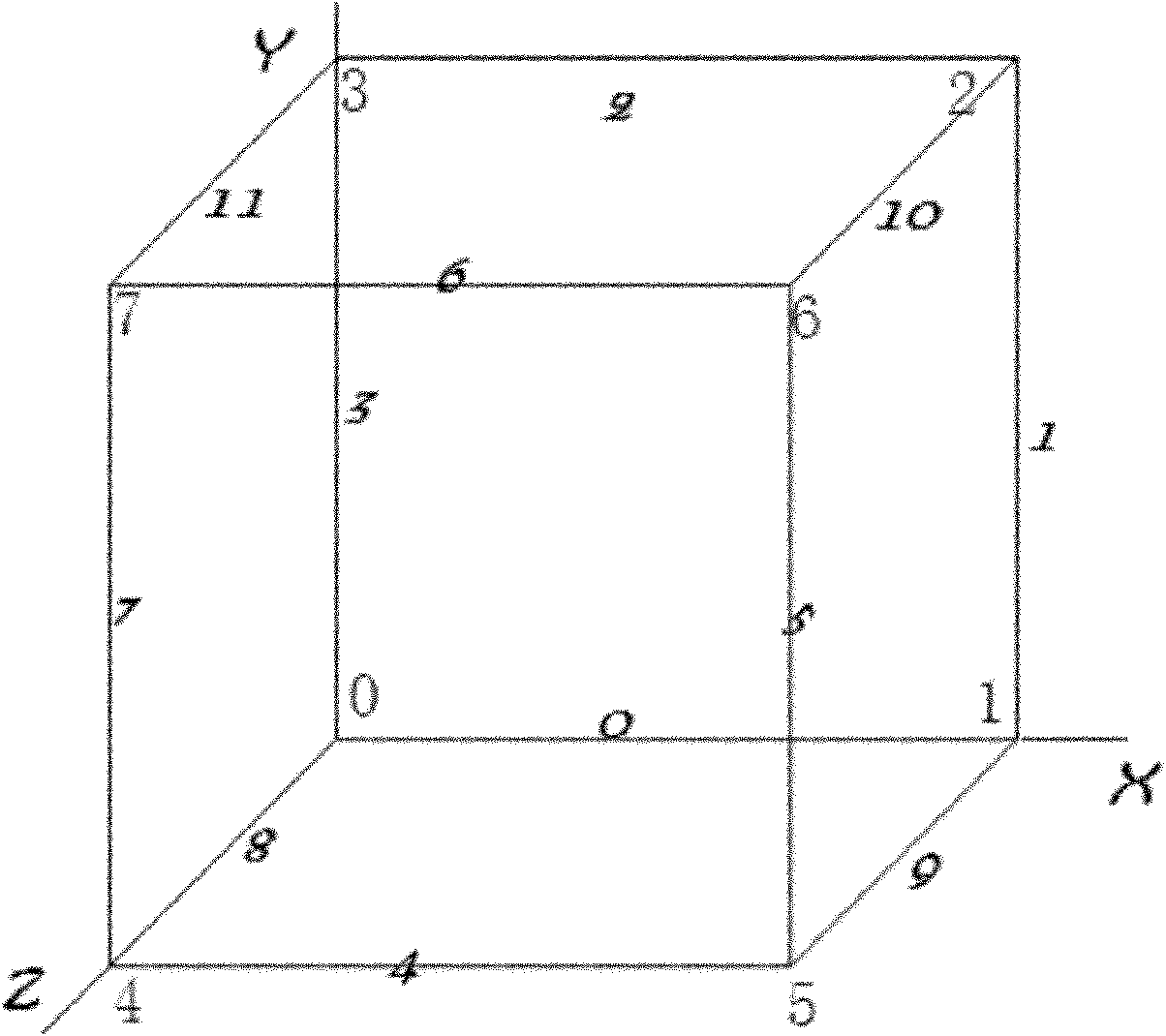

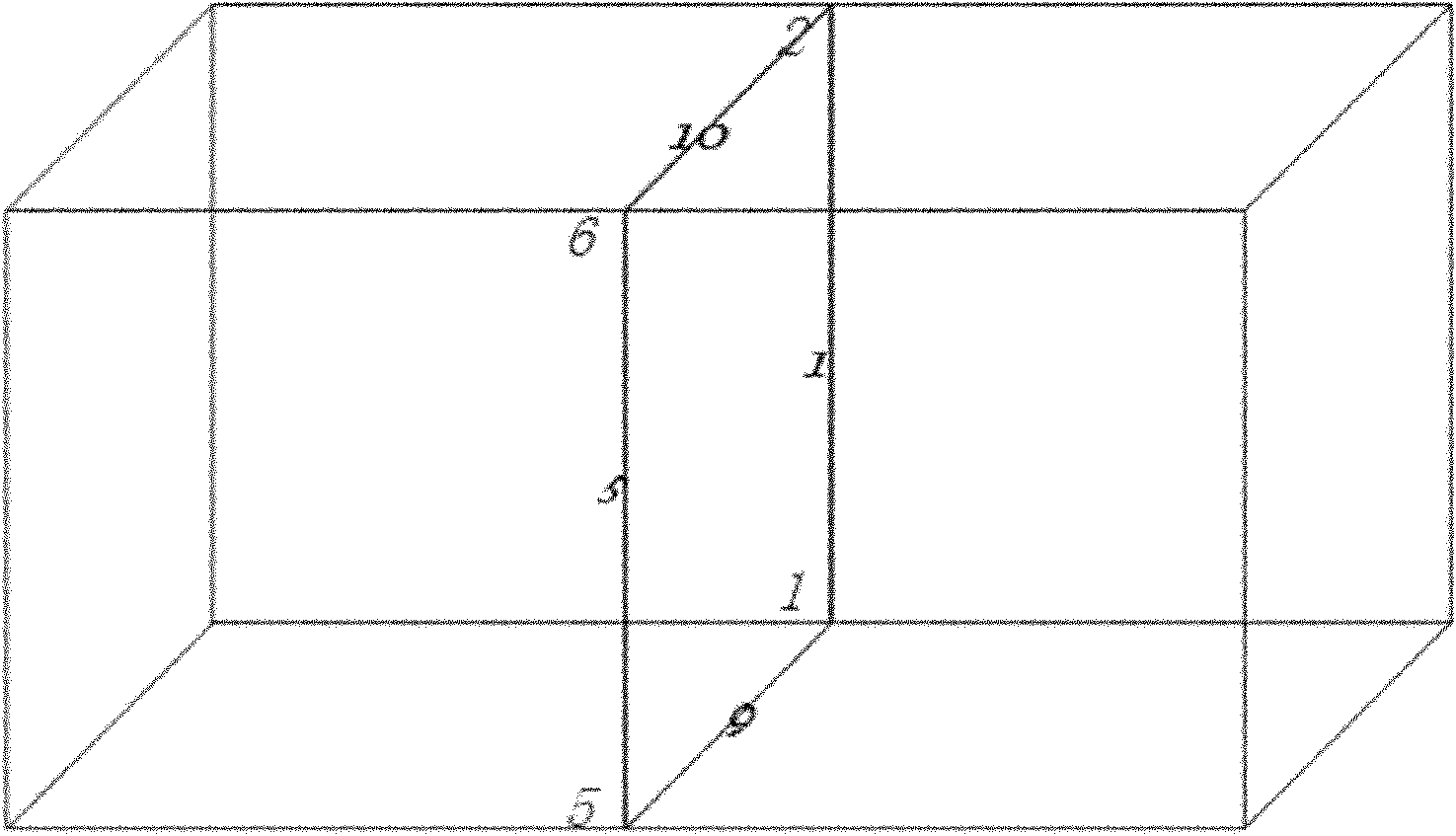

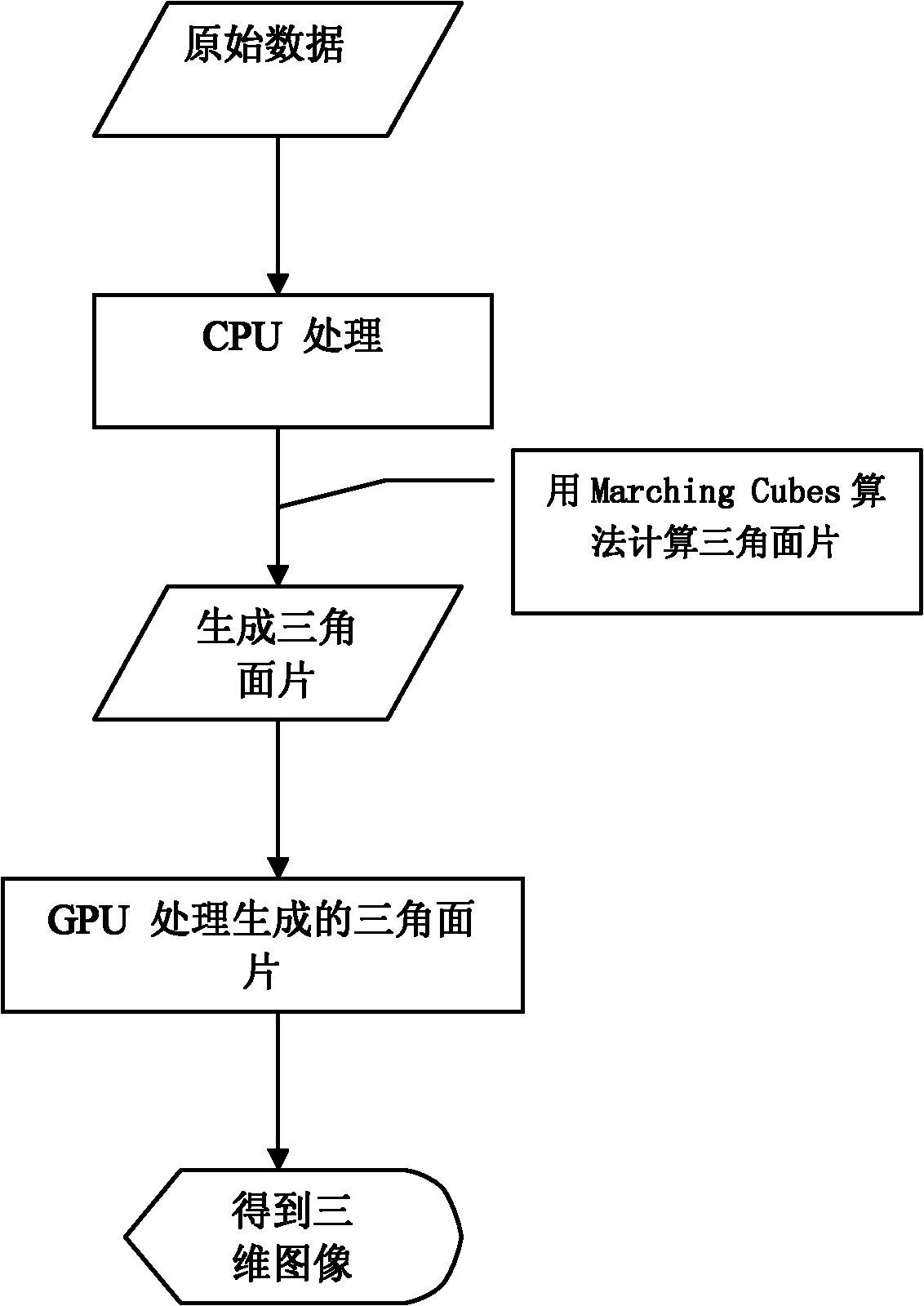

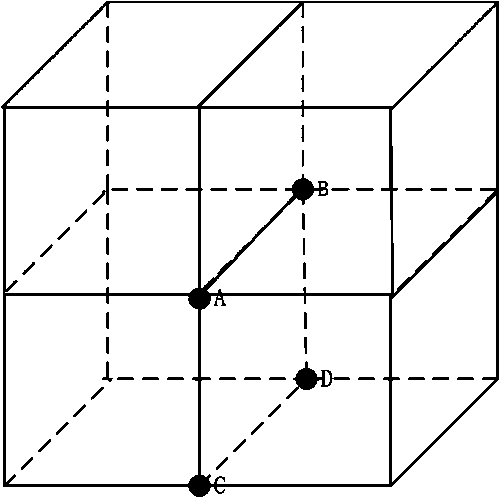

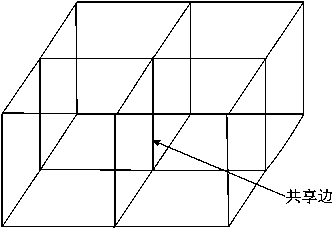

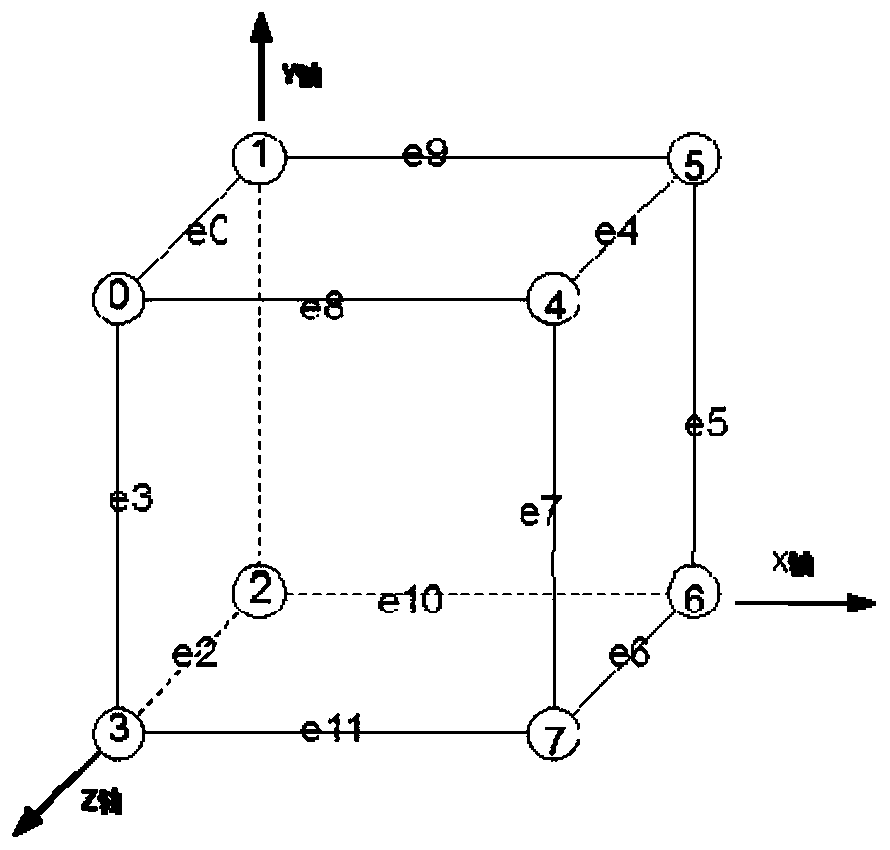

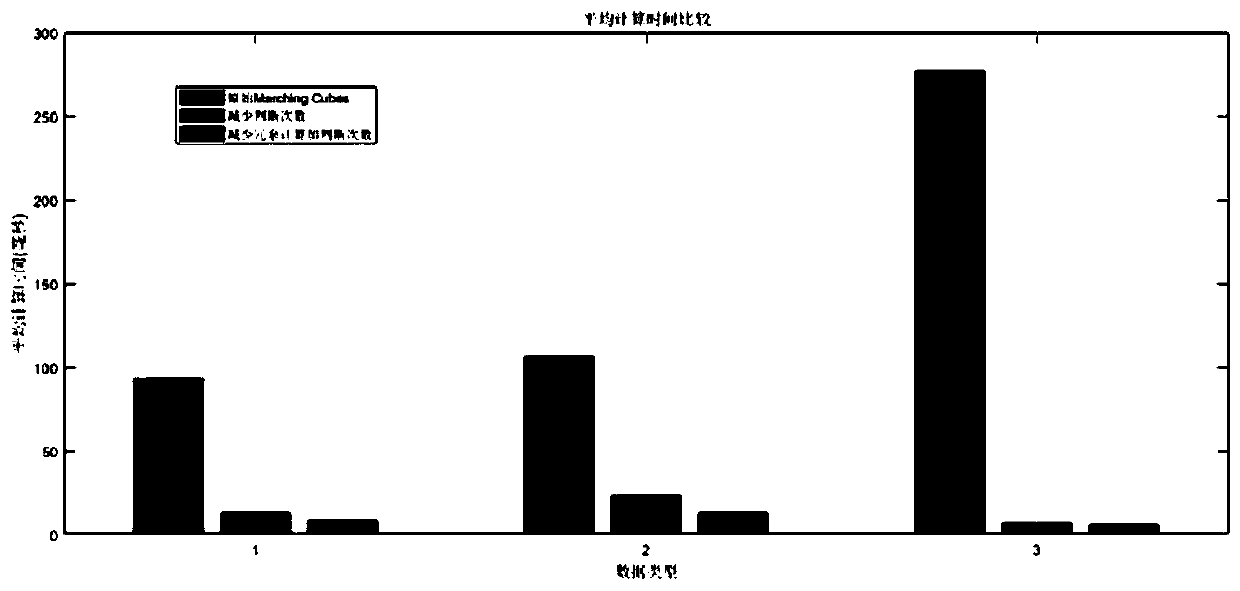

Acceleration improvement algorithm based on cube edge sharing equivalent point

The invention relates to an acceleration improvement algorithm based on cube edge sharing an equivalent point which comprises the following steps of: (1) storing related information of each edge of a cube by using a global array variable; (2) calculating equivalent point coordinates: before the equivalent point is calculated, firstly judging whether the edge is provided with the equivalent point or not , if so, extracting data stored in an array, wherein the data are used for calculating a triangular patch; if not, calculating coordinates and a normal vector of the equivalent point through linear interpolation; and recording the equivalent point of the edge of a current voxel, and giving an assignment for the equivalent point of the edge of other voxels sharing the edge; and (3) calculating the triangular patch by using a Marching Cubes algorithm, and processing the generated triangular patch through GPU (Ground Power Unit) acceleration image processing software to obtain a three-dimensional graph. By utilizing the method of the cube edges sharing the equivalent point, the algorithm efficiency can be improved and the three-dimensional reconstruction problem of medical images is effectively solved.

Owner:ZHEJIANG UNIV

Systems and methods for providing location based services (LBS) utilizing WLAN and/or GPS signals for seamless indoor and outdoor tracking

ActiveUS8279840B2Improve accuracyReduce computational overheadSatellite radio beaconingWireless commuication servicesApproximation algorithmPositioning system

Systems and methods for tracking a wireless device are disclosed. According to one aspect, the wireless device includes a hybrid global positioning system (GPS) and wireless local area network (WLAN) circuit board for seamless indoor and outdoor tracking. In embodiments, GPS and WLAN data are combined to obtain a position estimate of the device. In other embodiments, the circuit board automatically switches between WLAN and GPS data for indoor and outdoor environments. A Location Based Services (LBS) algorithm for determining the position of a wireless device using WLAN and / or GPS signals is also disclosed. The LBS algorithm is implemented by way of method steps including: sensing GPS and / or WLAN signals, measuring and / or converting the sensed signals to obtain distance data, fusing the distance data, and applying one or more approximation algorithms to the distance data to obtain a position estimate of the wireless device. A method for rendering position data using a Marching Cubes algorithm is further disclosed.

Owner:WALKER SR JONATHAN B

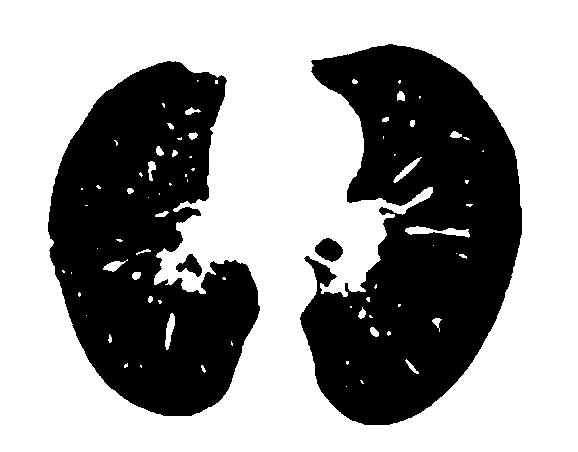

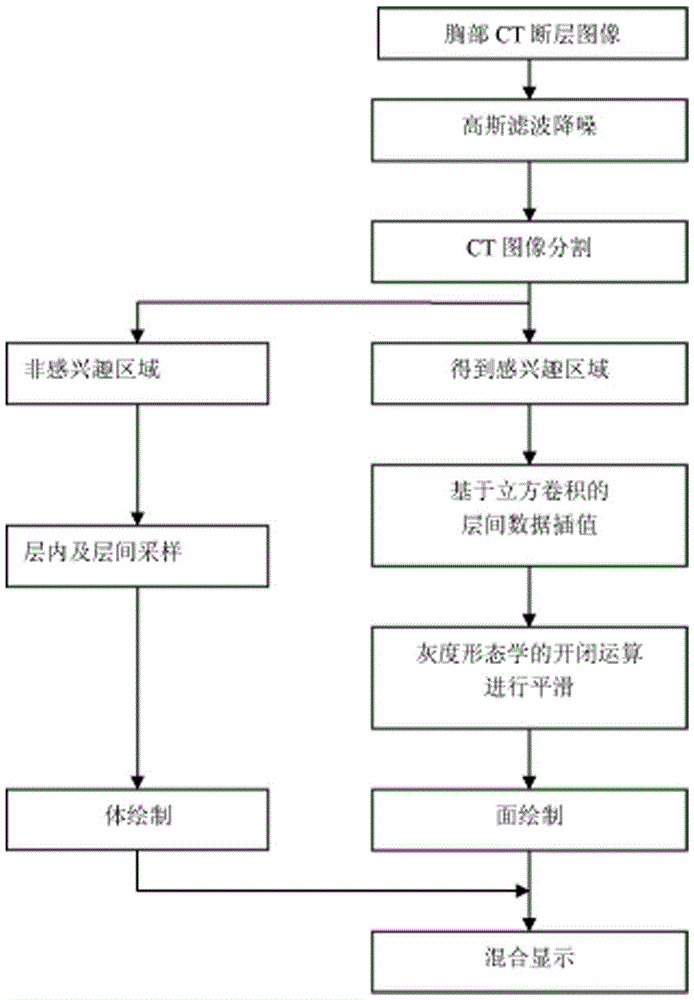

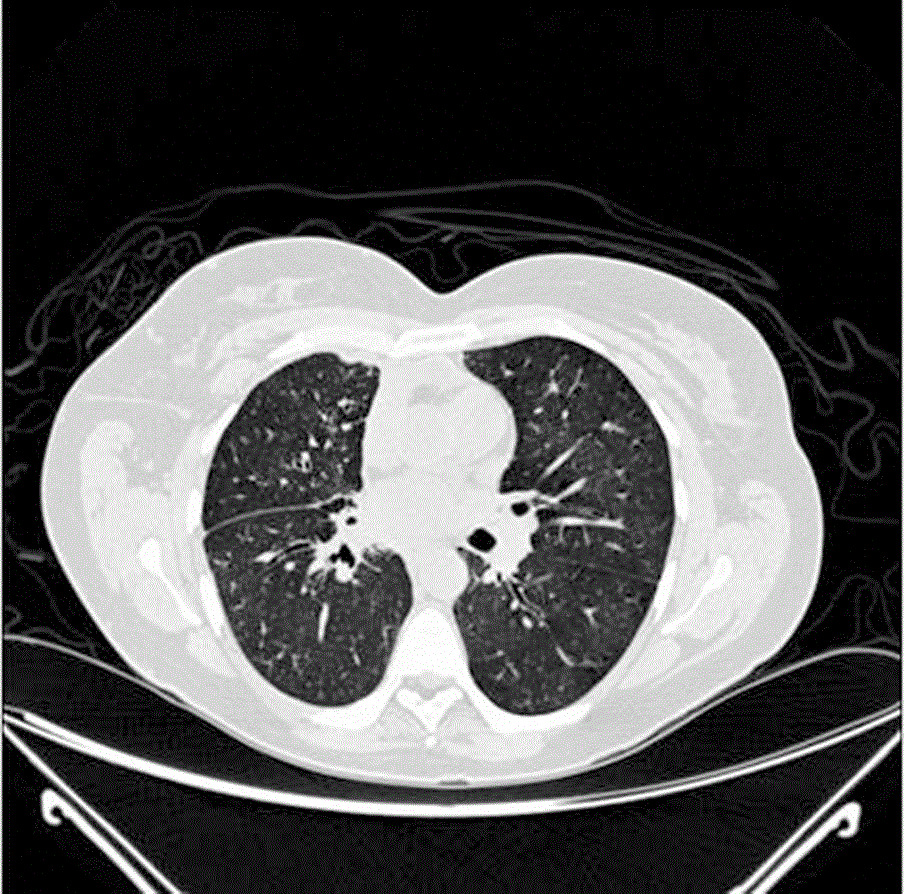

Adaptive hierarchical chest large data display implementation method

InactiveCN103077557AIncrease local resolutionImprove surface drawing clarityImage analysis3D modellingData displayMobile Cube

The invention discloses an adaptive hierarchical chest large data display implementation method, which comprises the following steps: dividing a CT (computed tomography) sectional image into a target layer image sequence and a background layer image sequence; performing interlayer cubic convolution interpolation on the divided target layer image sequence to form volume data of which each axial resolution is appropriate; making a clear surface drawing by a marching cubes algorithm; performing intraformational and interlayer sampling on the data of the background layer sequence to obtain uninteresting region data of which the resolution is reduced; making a rough body drawing for the data by a ray casting algorithm; displaying the drawing results of the clear surface drawing and the rough body drawing at the same time, and performing hybrid three-dimensional visualization. By the method, the local resolution in the interesting region is increased, and the anisotropic resolution of the uninteresting region is reduced, so that a user is facilitated to know the structure information of a local interesting region, the data volume is decreased and drawing can be implemented on an ordinary computer.

Owner:HEBEI UNIVERSITY

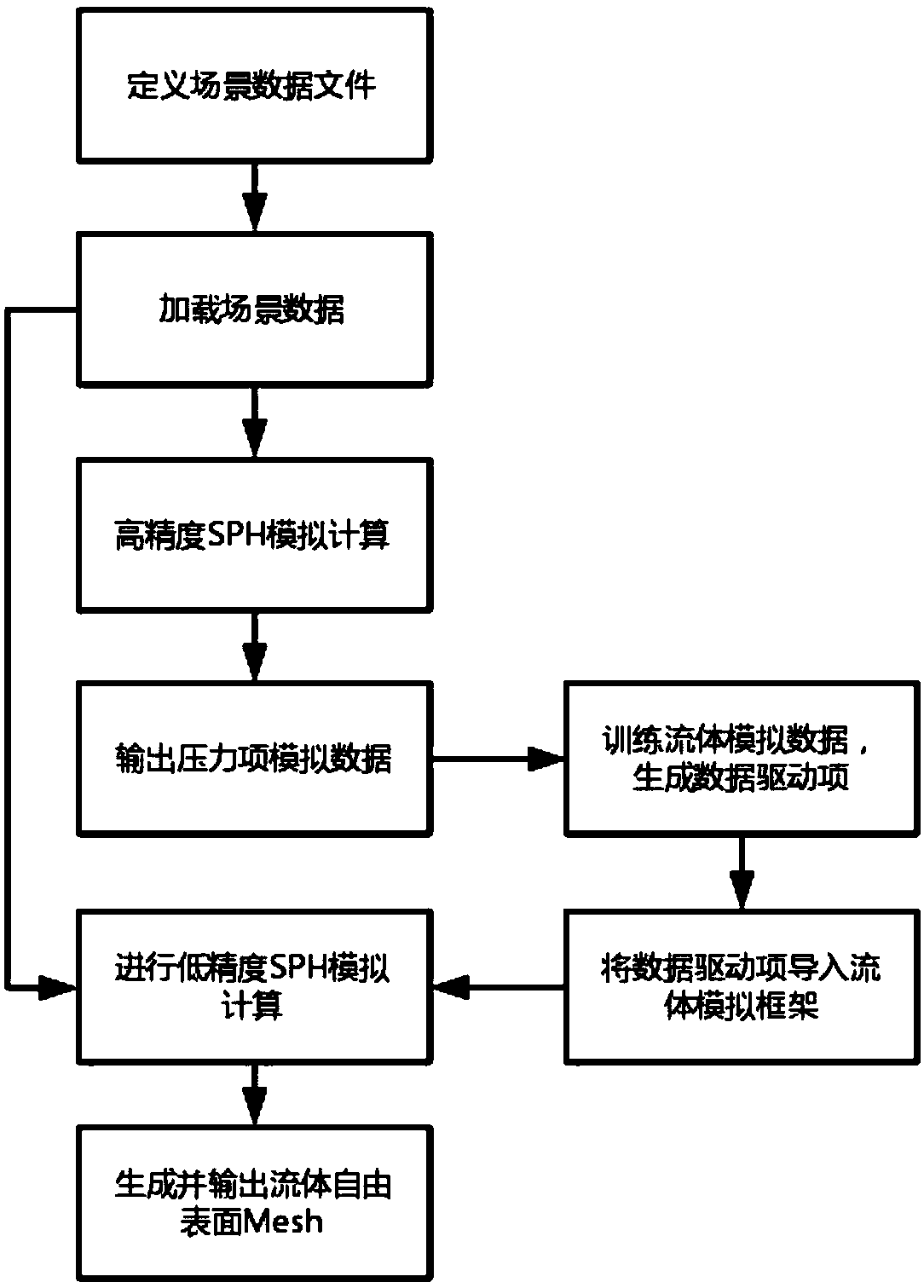

Fluid animation generation method and device based on deep learning and SPH framework

InactiveCN108717722AImprove computing efficiencyQuality improvementImage enhancementImage analysisData setAnimation

The invention discloses a fluid animation generation method and device of deep learning and an SPH framework. The method includes: constructing a deep-learning model, and carrying out training on fluid simulation data to generate a data drive item based on the neural network; constructing a neural network model according to features of a data set, setting relevant hyperparameters, then reading thedata set for preprocessing, and carrying out training of the network model; importing the trained neural network model into the SPH fluid simulation framework to replace a pressure item in a fluid simulation step with the same as the data drive item; importing the data drive item into low-precision fluid scene data, and then carrying out SPH fluid simulation calculation; and using a Marching Cubes algorithm to construct a fluid surface model, extracting a fluid surface mesh, outputting the same, storing a fluid mesh of each frame as a data file, and using the same for offline rendering. High-detail showing of fluid under a low-precision SPH simulation scene is realized, and calculation efficiency of a large-scale fluid simulation scene is improved.

Owner:TIANJIN UNIV

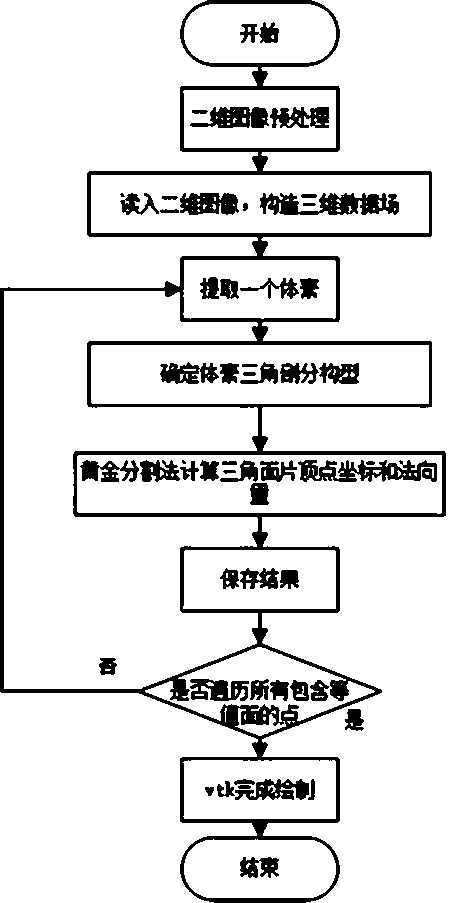

Vertebra CT image three-dimensional visualization method

InactiveCN108510580AImprove execution efficiencyDoes not affect the drawing effect3D modellingVoxelFinite difference method

The invention discloses a vertebra CT image three-dimensional visualization method and belongs to the medical field. In order to solve the problem that a large quantity of voxels and equivalent pointsare processed in the process of performing three-dimensional reconstruction visualization through a traditional Marching Cubes algorithm, the vertebra CT image three-dimensional visualization methodmakes improvement on the theoretical basis of the traditional Marching Cubes algorithm, wherein when subdivision configuration of triangular patches in the voxels is determined, a golden section method is utilized to calculate intersection points of an isosurface and voxel edges, the triangular patches are fitted into the isosurface, normal vectors of the triangular patches are calculated, a central difference method is adopted to solve gradient values of eight vertexes inside the voxels, and display, rotation, scaling and other interactive operation are completed through a VTK (VisualizationToolkit). In this way, transparent and semi-transparent visual function setting is realized, it is convenient for doctors and researchers to perform observation and analysis from arbitrary angles, andthe method provides a theoretical basis and technical support for observation of vertebra internal and external structure information and treatment and research in a later period.

Owner:HARBIN UNIV OF SCI & TECH

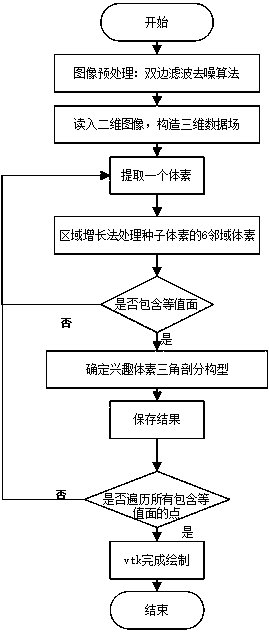

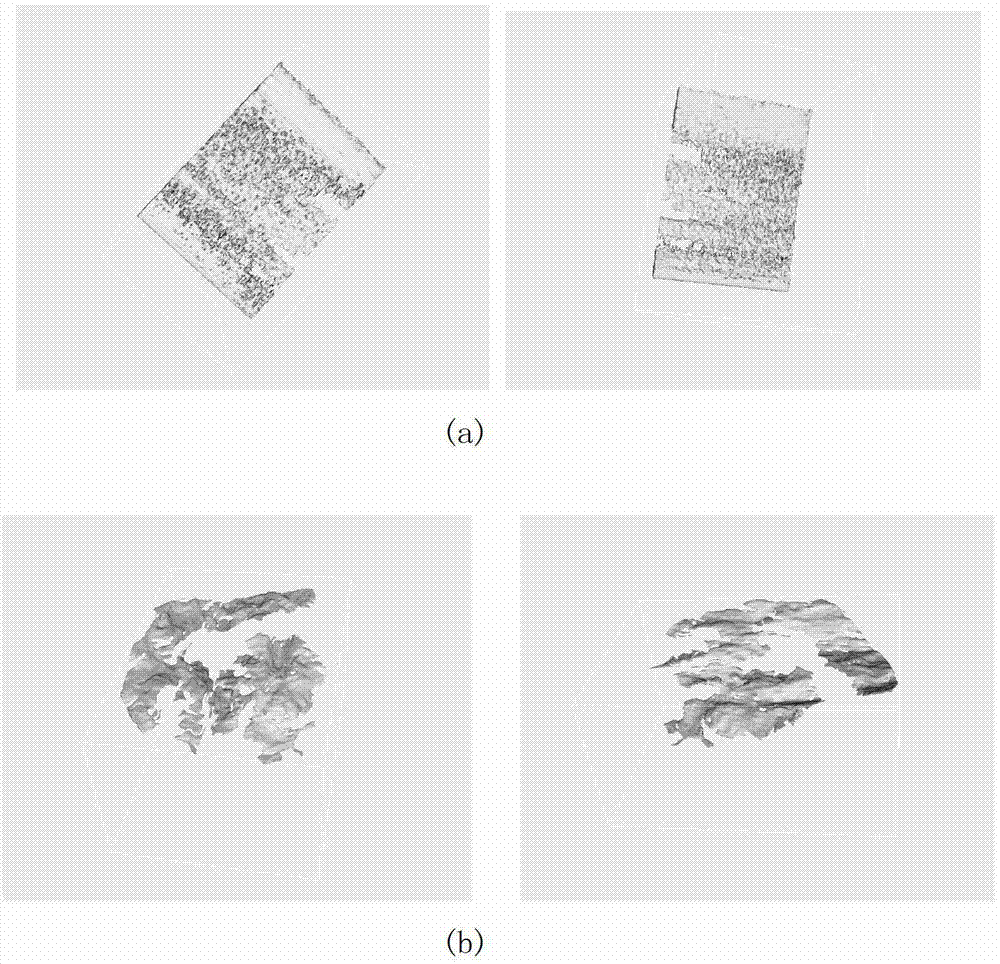

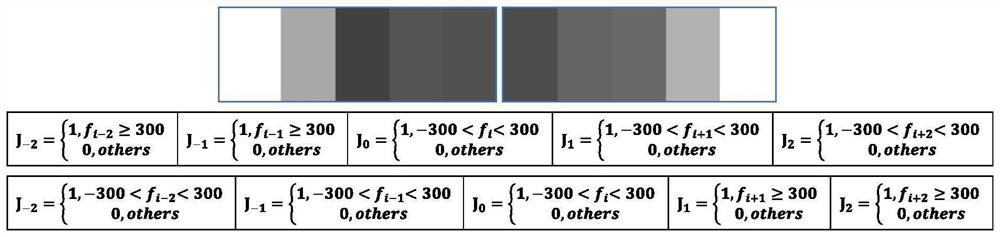

Fast three-dimensional reconstruction method for spinal CT image

InactiveCN108537750AReduce the number of traversal voxelsLower edgeImage enhancement3D-image renderingMobile CubeVoxel

The invention discloses a fast three-dimensional reconstruction method for a spinal CT image, belongs to the medical field, and aims at solving problems that a spinal model is long in three-dimensional reconstruction time and is not sufficient in smoothness in the actual operation and teaching and research of the clinical medicine, especially in a screw implantation operation of vertebral pedicle.The invention provides the fast three-dimensional reconstruction method for the spinal CT image, and the method comprises the steps: performing preprocessing according to a three-dimensional reconstruction surface drawing theory through employing a characteristic selection bilateral filtering denoising algorithm, performing the improvement on the basis of a conventional MC (Marching Cubes) algorithm, selecting a seed voxel, extracting all voxels comprising a contour surface through the regional growth idea, determining a triangulation configuration of the contour surface in the voxels, carrying out the parallel processing through a visualization toolkit VTK and Open GL with the help of a GPU, and completing the fast and precise three-dimensional reconstruction of the spinal CT image. Themethod is of great significance to the analysis, research, actual operation and operation scheme formulating of spinal diseases.

Owner:HARBIN UNIV OF SCI & TECH

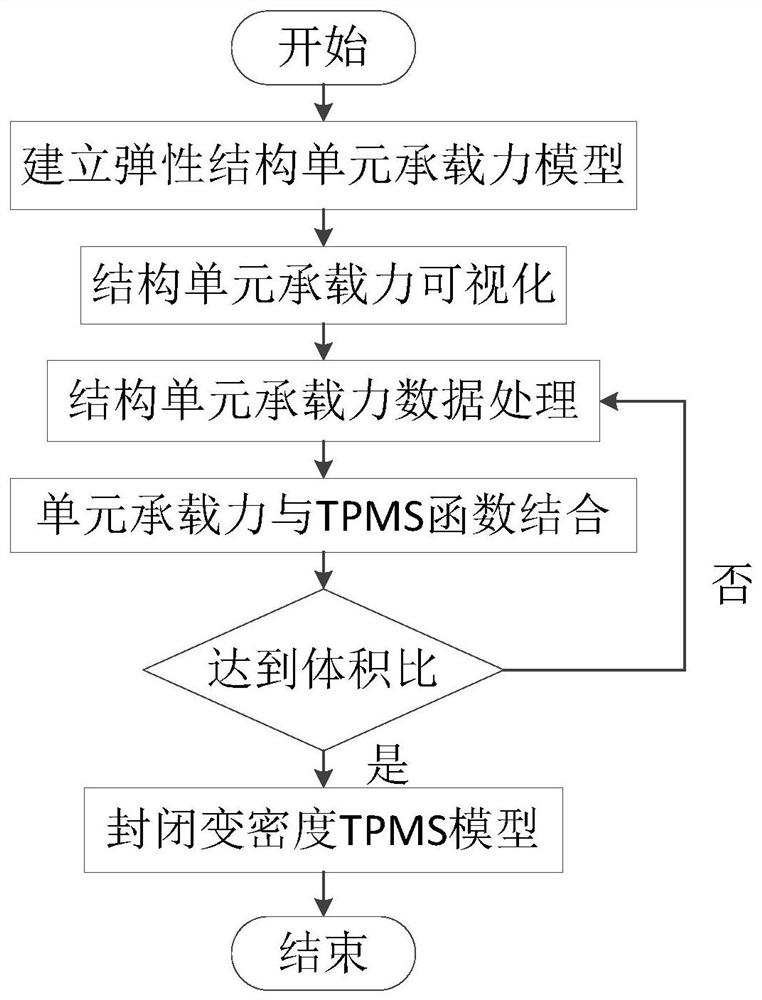

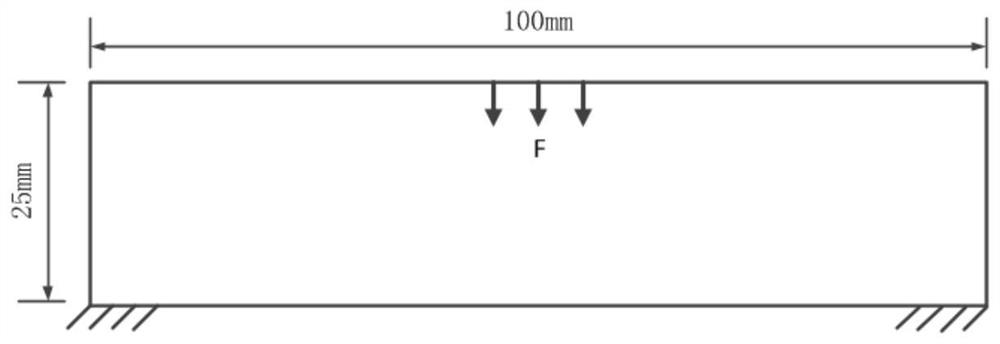

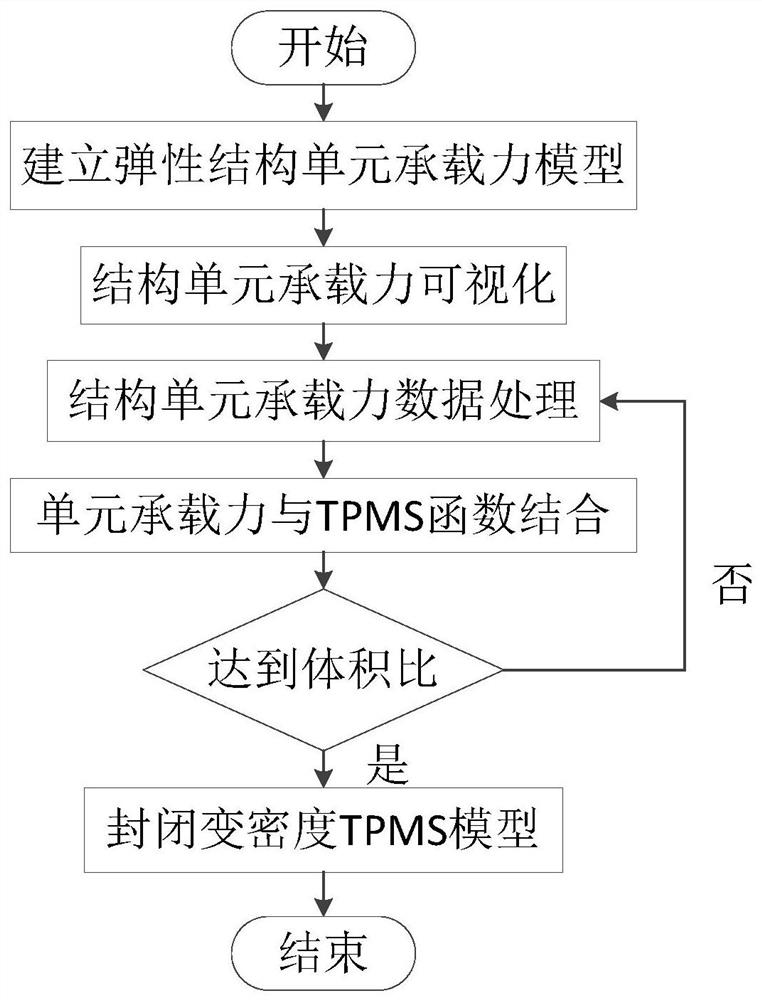

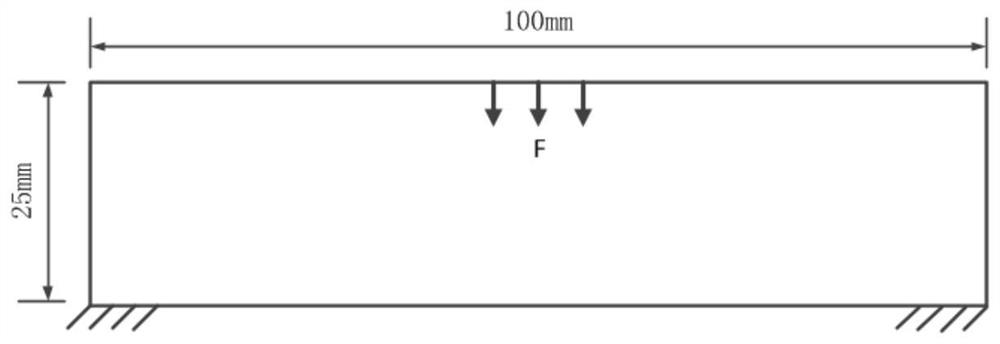

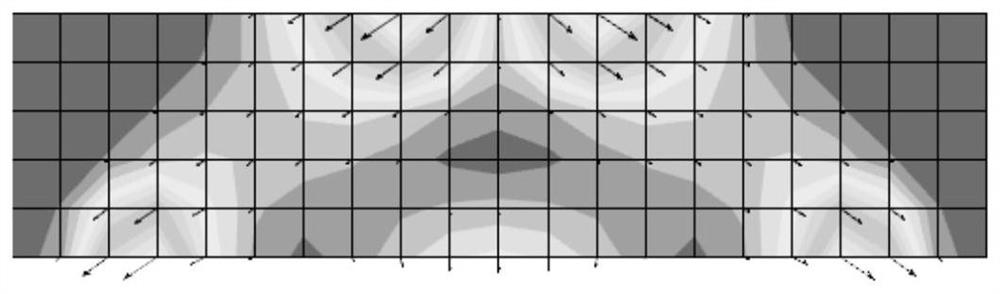

Three-period minimal curved surface variable density lattice structure design method for additive manufacturing

ActiveCN112036063AImprove structural strengthImprove structural rigidityDesign optimisation/simulationConstraint-based CADElement modelEngineering

The invention provides a three-period minimal curved surface variable density lattice structure design method for additive manufacturing. The method comprises the following steps: firstly, establishing an elastic structure finite element model based on an elastic structure static balance theory and a unit 'birth and death' technology, and designing a structure unit bearing capacity extraction method; then, obtaining structural unit bearing capacity vector data and structural finite element model unit node data through calculation, and giving a structural unit bearing capacity cloud chart; then, processing the bearing capacity data of the structural unit, including curved surface interpolation, spline interpolation and normalization, and combining the processed bearing capacity data of thestructural unit with a TPMS function; then, serving the porosity of the TPMS porous structure as an evaluation index of the variable density lattice structure, and achieving TPMS variable density curved surface modeling through a March cubes algorithm; and finally, performing Boolean operation on the TPMS variable-density curved surface model and the original structure model to realize curved surface sealing. According to the invention, the problems of unstable topological structure numerical value, low efficiency and the like in the traditional lattice structure design are solved.

Owner:YANSHAN UNIV

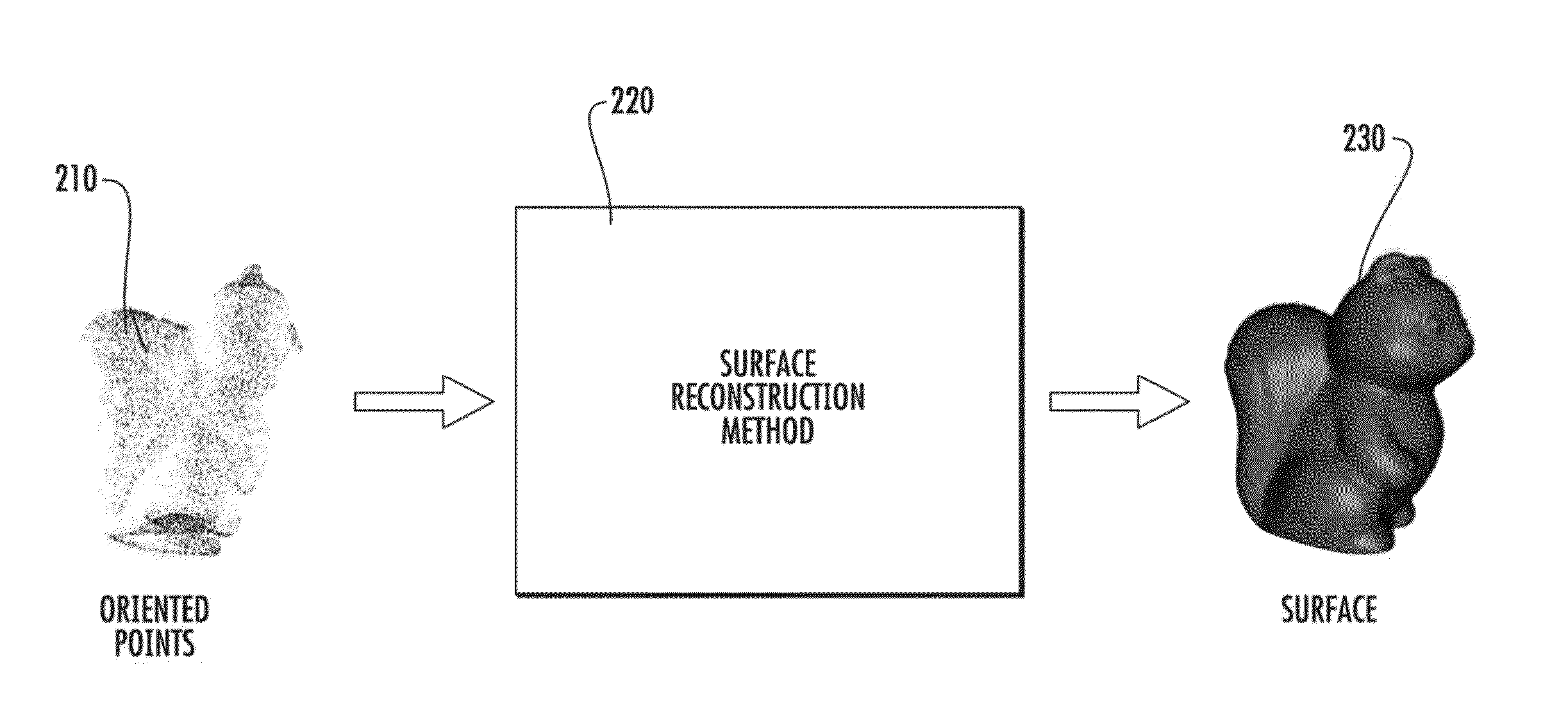

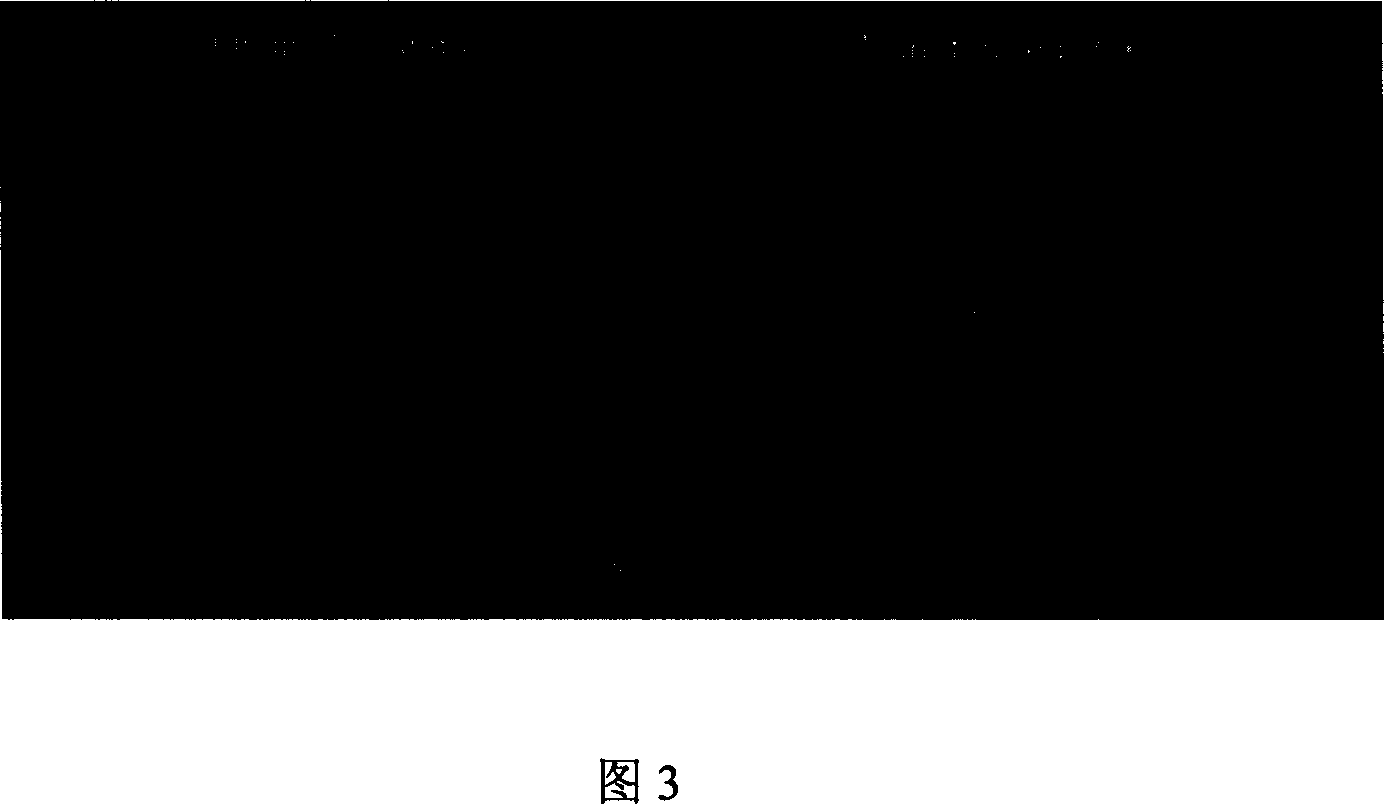

Analysis of sea-horse quantitative shape in magnetic resonance image

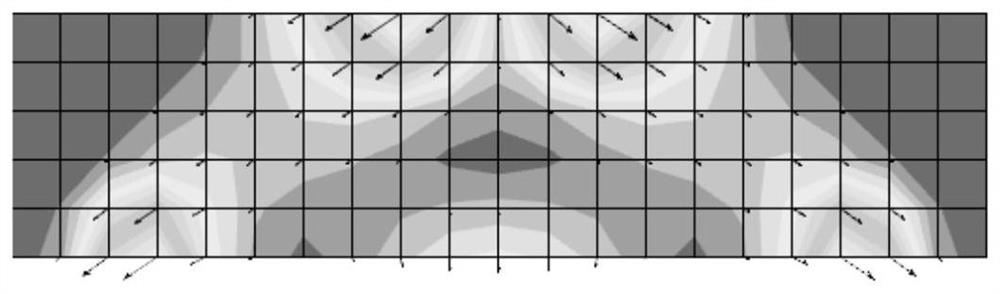

A method for quantitatively analyzing the hippocampal shape in magnetic resonance image includes such steps as acquiring the data of magnetic resonance image, pre-processing, manually dividing the hippocampus, extracting the coordinates of the dots on the hippocampal surface by marching cube method, creating a parameterized curved surface model of hippocampus, finding out the central axis of hippocampus, using the area of relative parallel coil for registration to the central axis to obtain better tissue correspondency, and significant statistical analyzing by arranging-testing method.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

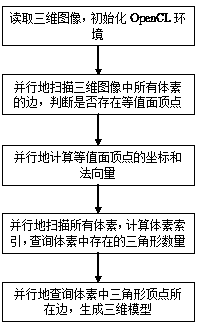

OpenCL (Open Computing Language)-based marching cube method

The invention discloses an OpenCL (Open Computing Language)-based marching cube method, belonging to the technical field of three-dimensional reconstruction. The OpenCL-based marching cube method runs on a computer provided with OpenCL calculation equipment. The method comprises the following steps: reading a three-dimensional image, and initializing an OpenCL environment; scanning the edges of all voxels in the three-dimensional image in parallel, and judging whether contour surface vertexes exist or not; calculating the coordinates and normal vectors of the contour surface vertexes in parallel; scanning all the voxels in parallel, calculating voxel indexes, and inquiring the number of triangles existing in the voxels; inquiring the edges of triangle vertexes in the voxels in parallel to generate a three-dimensional model. Parallel acceleration is performed on an algorithm based on an OpenCL technology; the edges in the voxels are traversed to generate vertexes, and the voxels are traversed to generate the three-dimensional model, so that memory redundancy is eliminated.

Owner:NORTHEASTERN UNIV

Core fracture identification method based on three-dimensional image information processing

ActiveCN102867302BAccurate identificationQuick identificationImage analysis3D modellingInformation processingMobile Cube

The invention relates to a core fracture identification method based on three-dimensional image information processing, belonging to the technical field of image segmentation. The method comprises the following steps of: scanning a core to be processed by using a CT (computerized tomography) machine, storing a scanned core CT sequence image in a computer, reading the well scanned core CT sequence image by using core three-dimensional image fracture identification software, performing three-dimensional image reconstruction on the core CT sequence image by utilizing a marching cubes algorithm, and performing a series of calculation, getting and screening processed by utilizing the differences among pores, random noise and fracture in morphological features in a three-dimensional data field to achieve the purpose of identifying a core fracture. According to the method provided by the invention, the core fracture can be fast and accurately identified; and the problems of causing error and even mistake due to negligence of communication information of the core fracture between layers in the existing isolate analysis of each core CT sequence image can be solved.

Owner:SICHUAN UNIV

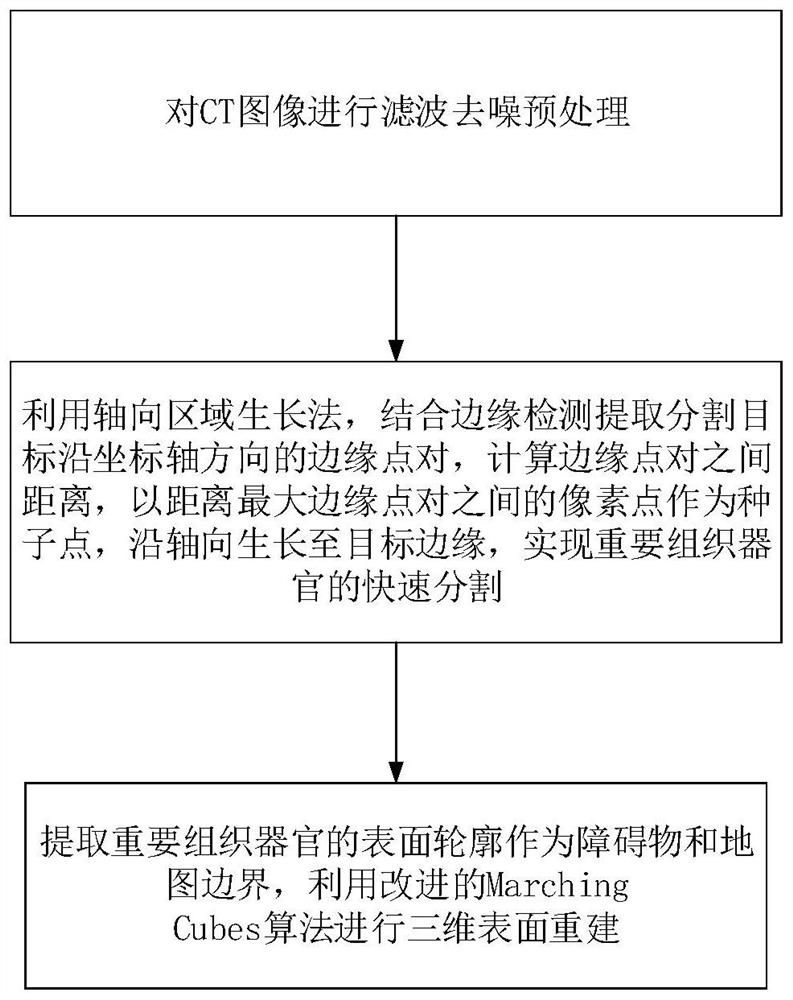

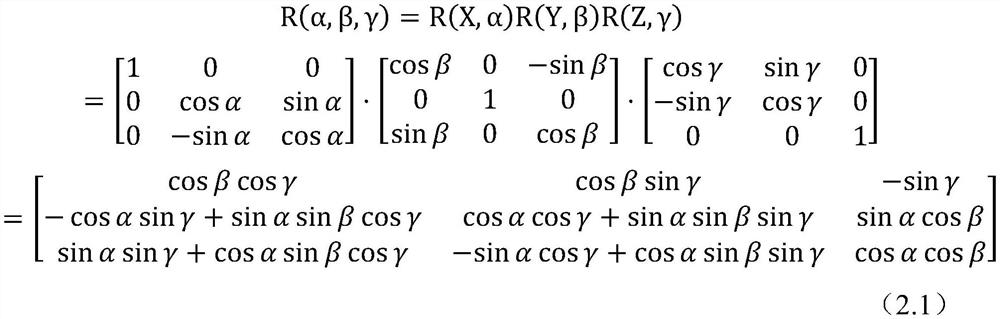

Route planning nose environment modeling method and device

PendingCN113706687AQuick splitBuild accuratelyMedical simulationImage enhancementPattern recognitionComputer graphics (images)

According to the path planning nose environment modeling method and device, accurate construction of a nose environment map can be achieved. The method comprises the following steps: (1) carrying out filtering and denoising preprocessing on a CT image; (2) extracting edge point pairs of a segmentation target along the coordinate axis direction by using an axial region growing method and combining edge detection, calculating the distance between the edge point pairs, and growing to the edge of the target along the axial direction by taking a pixel point between the edge point pair with the maximum distance as a seed point, so as to realize rapid segmentation of important tissues and organs; and (3) extracting surface contours of important tissues and organs as obstacles and map boundaries, and performing three-dimensional surface reconstruction by using an improved Marching Cubes algorithm.

Owner:THE EYE HOSPITAL OF WENZHOU MEDICAL UNIV +1

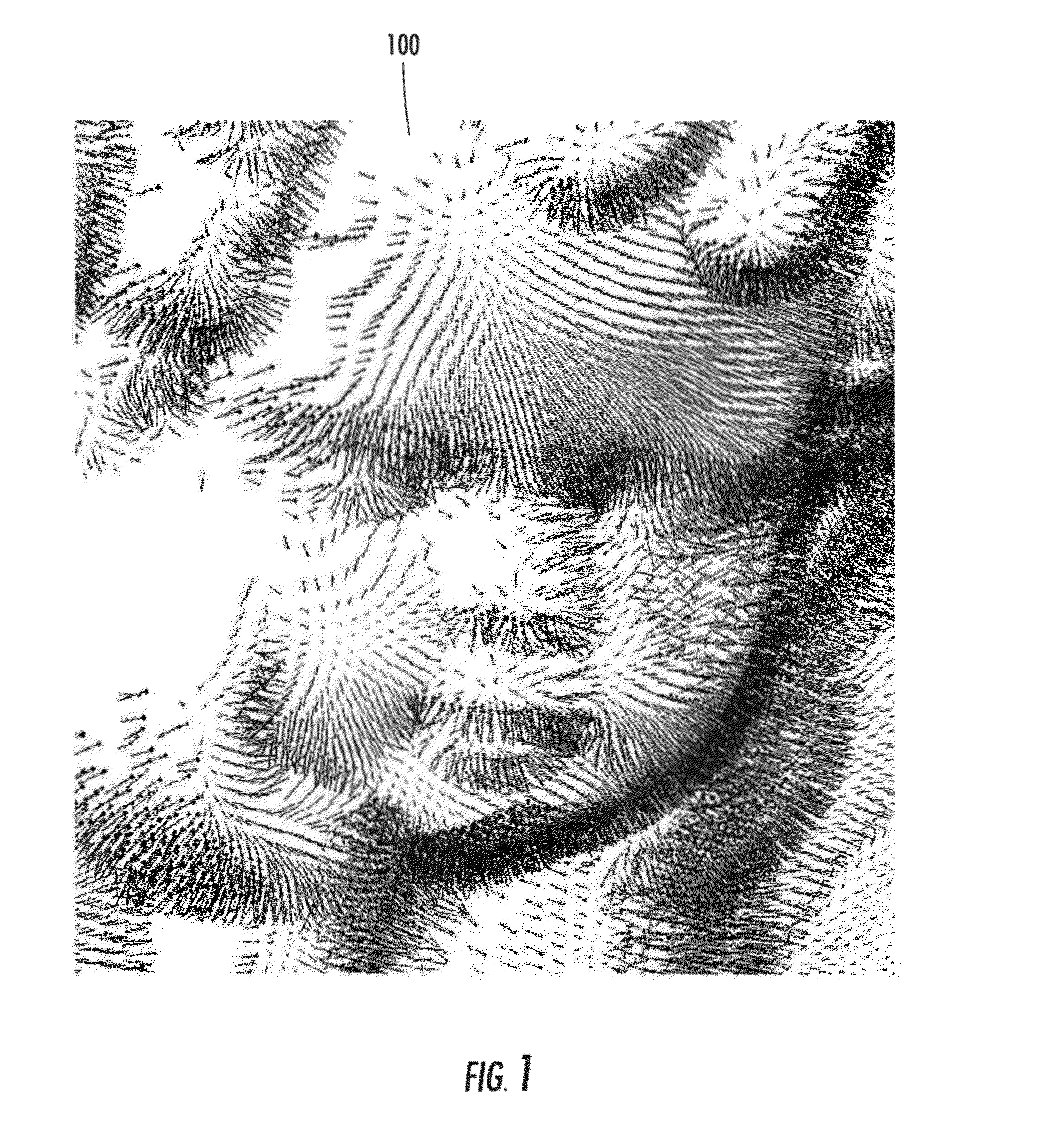

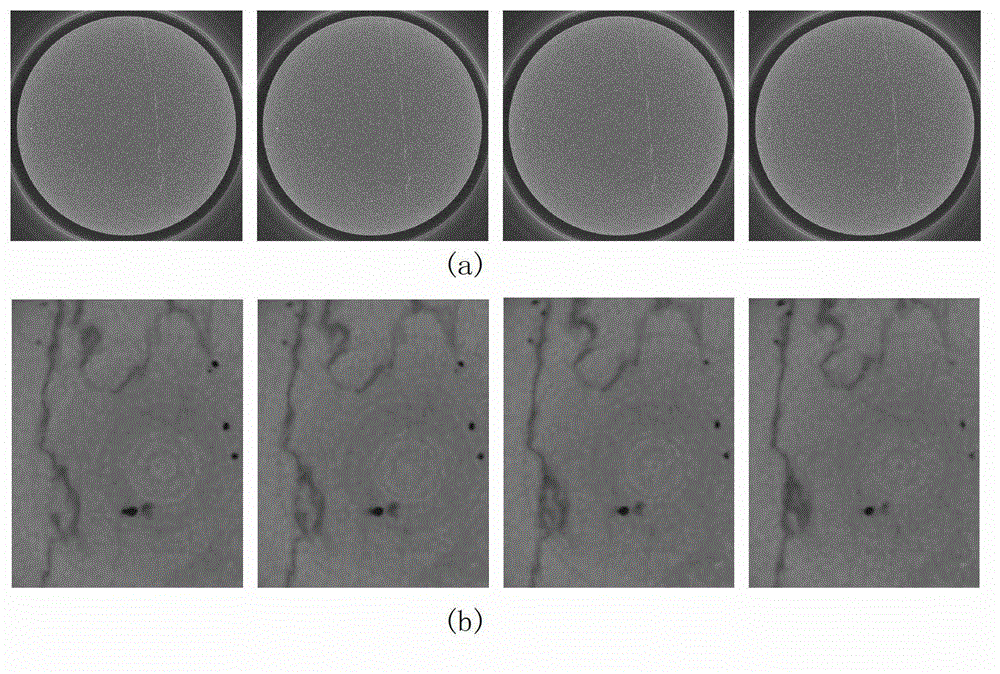

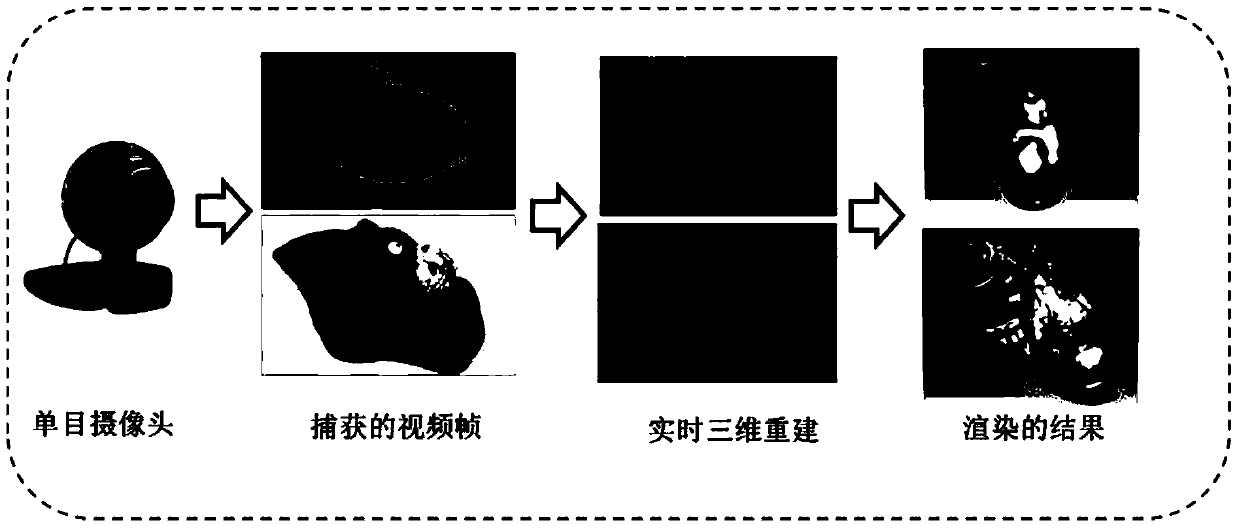

Robust real-time 3D reconstruction method based on consumer-grade camera

ActiveCN105654492BReal-time reconstructionQuality improvementImage enhancementImage analysisImaging processingVoxel

Owner:HARBIN INST OF TECH

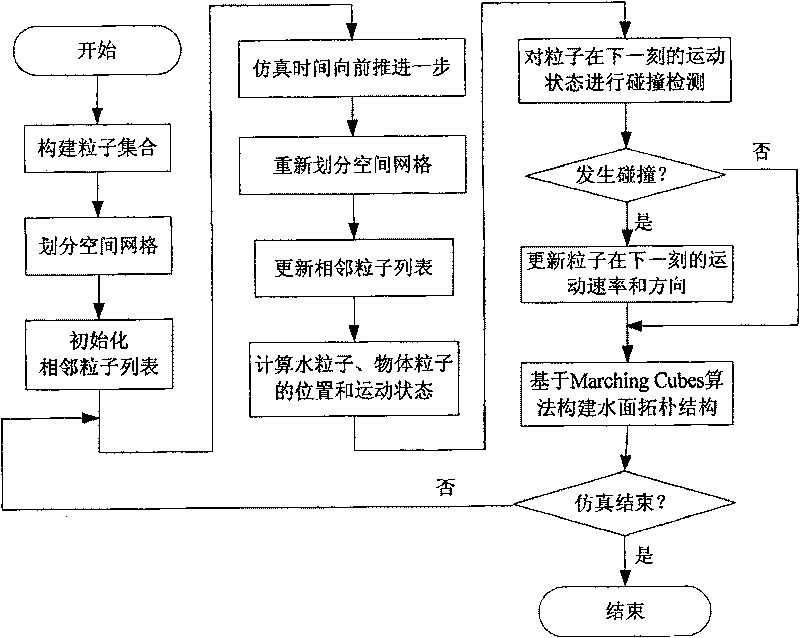

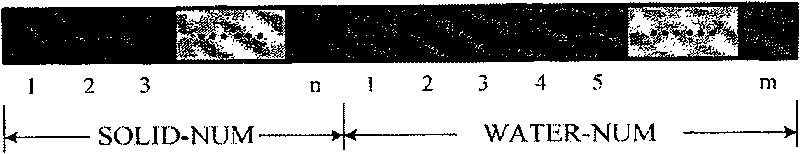

Emulation modelling method interacted with movable object and water based on SPH

InactiveCN101329772BReal simulation resultsAchieve real-time simulation effect3D modellingWater basedComputer graphics

The invention relates to a simulated modeling method of the interaction of moving objects and water based on SPH, which pertains to the computer graphics and the virtual reality field. The method of the invention comprises the following steps: 1. the simulation is initialized, and the initialization comprises the initial configuration of particle properties and the establishment of a neighboring particle list of the particles; 2. neighboring particle lists of water particles are updated; 3. the positions and states of movements of the water particles at the next time step are calculated; 4. the positions and states of movements of object particles at the next time step are calculated; 5. whether the particles collide with the obstacles is judged, if the collision happens, the movement rates and directions of the particles are altered, or the sixth step is directly executed; 6. a water surface topological structure is constructed on the basis of marching cubes algorithm; 7. a graph drawing language is adopted to draw and display the water surface and the object; 8. whether the simulation is stopped is judged. The method of the invention can be utilized to simulate the interactions of moving objects and water and obtain comparatively true simulation results.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

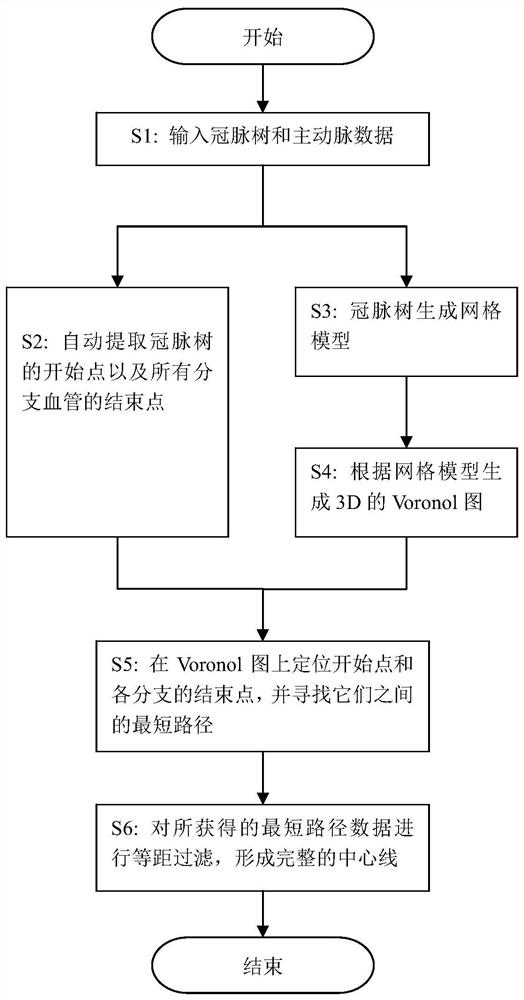

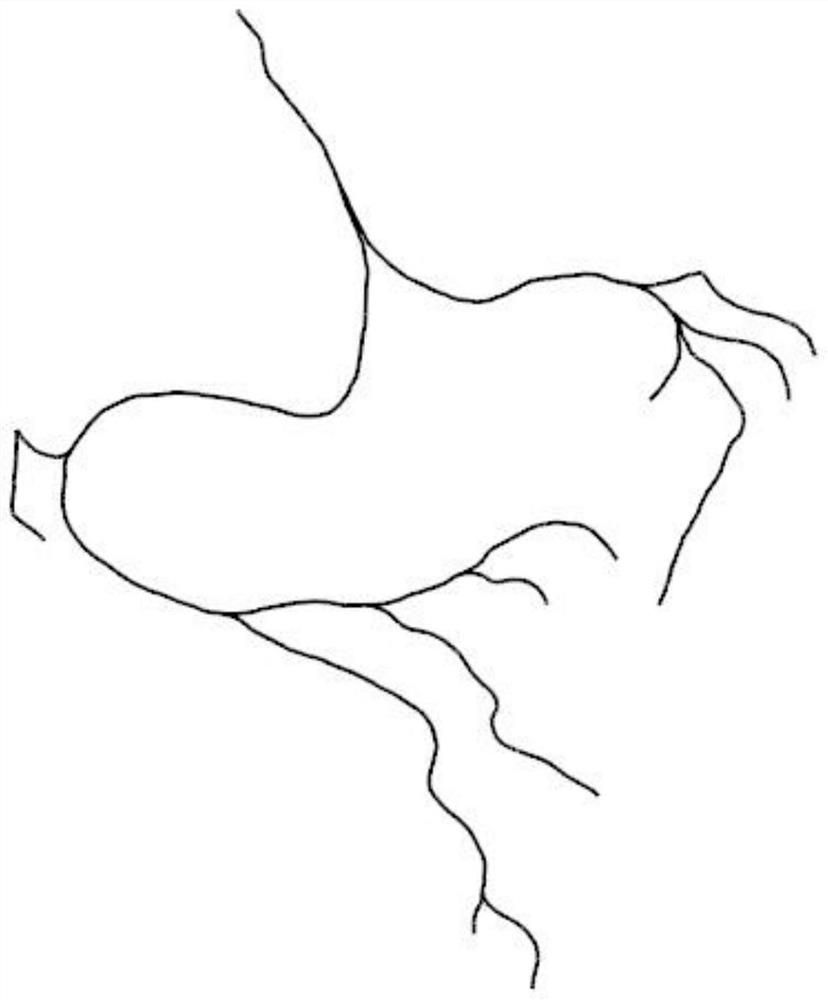

A method for extracting coronary artery centerline

ActiveCN108133478BGuaranteed accuracyEasy to handleImage enhancementImage analysisAorta aorticBlood vessel

The invention discloses a method for extracting the centerline of coronary artery blood vessels, comprising the following steps: Step S1: input the data of coronary artery tree and aorta; Step S2: automatically extract the starting point of coronary artery tree and the end of all branch vessels point; step S3: use the Marching Cubes algorithm to generate grid model data from the coronary tree data; step S4: carry out Delaunay triangulation processing to all points on the grid and generate a three-dimensional Voronol diagram; step S5: on the Voronoi diagram Locate the start point and the end points of all branch vessels, and calculate the shortest path between the start point and the end point to obtain several corresponding curves; step S6: perform equidistant filtering on the obtained curves to form a complete centerline data; its advantage is to automatically obtain the start point and end point of the coronary artery, which ensures the accuracy of the centerline and makes full use of the powerful processing power of the computer, eliminating the steps of obtaining the start point and end point by manual interaction, which greatly Improve the efficiency of doctors' diagnosis.

Owner:SUZHOU RAINMED MEDICAL TECH CO LTD

Design method of variable-density lattice structure with three-period minimal curved surface for additive manufacturing

ActiveCN112036063BImprove structural strengthImprove structural rigidityDesign optimisation/simulationConstraint-based CADElement modelDot matrix

The invention provides a method for designing a three-period minimum curved surface variable-density lattice structure for additive manufacturing. Firstly, based on the elastic structure static balance theory and unit "life and death" technology, the finite element model of the elastic structure is established, and the extraction method of the structural unit bearing capacity is designed; then, the vector data of the structural unit bearing capacity and the unit node data of the structural finite element model are calculated, And give the bearing capacity cloud diagram of the structural unit; then, process the bearing capacity data of the structural unit, including surface interpolation, spline interpolation and normalization, combine the processed bearing capacity data of the structural unit with the TPMS function; then, combine the TPMS The porosity of the porous structure is used as the evaluation index of the variable density lattice structure, and the Marching cubes algorithm is used to realize the modeling of the TPMS variable density surface; finally, the Boolean operation is performed on the TPMS variable density surface model and the original structure model to realize the surface closure. The invention solves the problems of numerical instability and low efficiency of the topological structure existing in the design of the traditional lattice structure.

Owner:YANSHAN UNIV

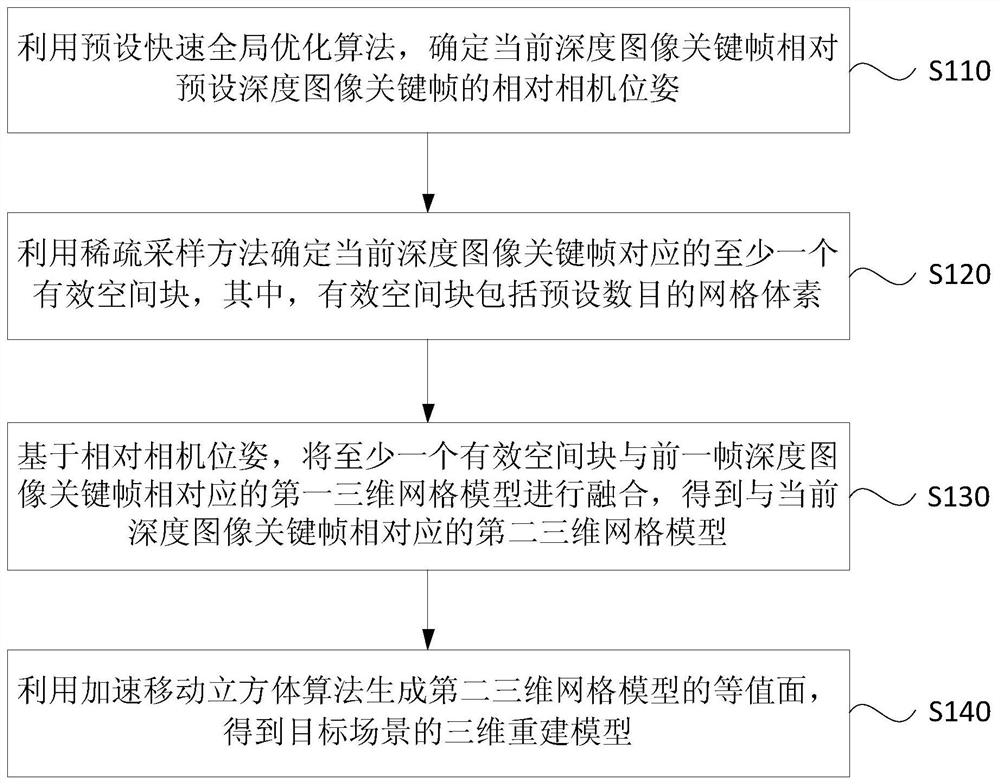

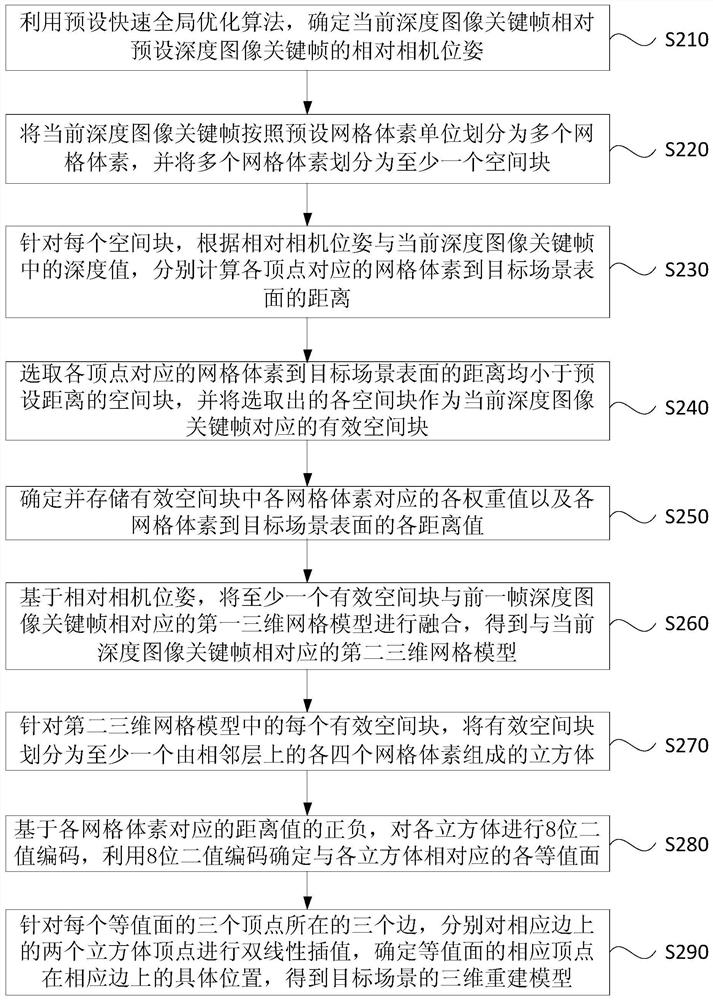

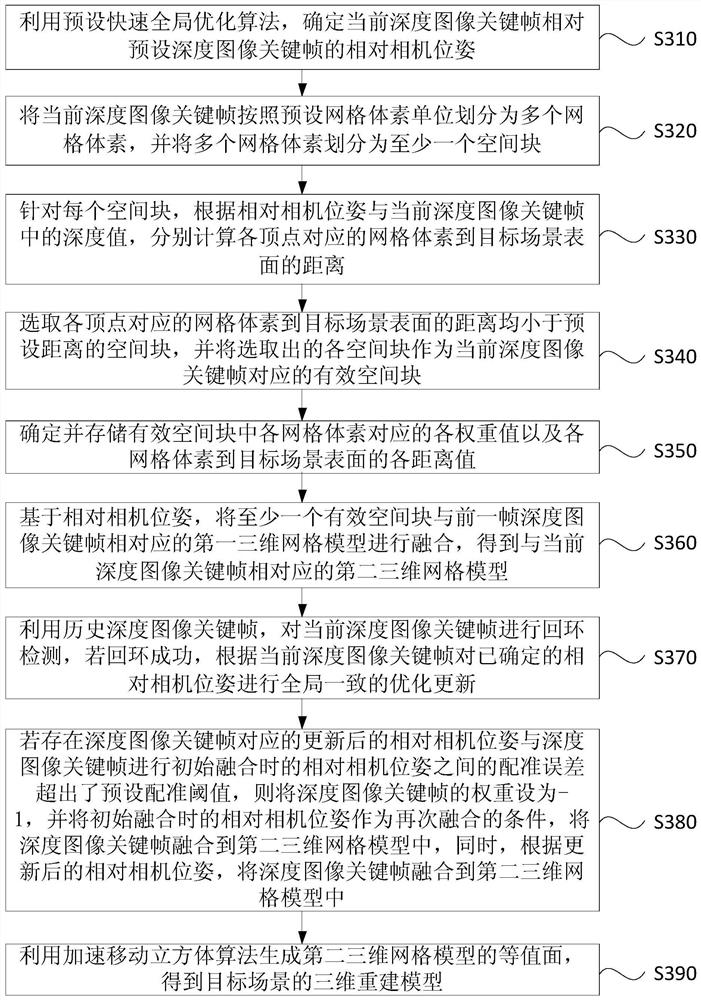

A three-dimensional reconstruction method, apparatus, device and storage medium

ActiveCN108898630BImprove portabilityOvercoming the inability to achieve portabilityImage enhancementImage analysisAlgorithmReconstruction method

Disclosed are a three-dimensional reconstruction method, apparatus, and device, and a storage medium. The three-dimensional reconstruction method comprises: determining a relative camera pose of a current depth image key frame with respect to a preset depth image key frame by using a preset fast global optimization algorithm; determining at least one effective space block corresponding to the current depth image key frame by using a sparse sampling method; fusing the at least one effective space block with a first three-dimensional grid model corresponding to a previous depth image key frame on the basis of the relative camera pose, to obtain a second three-dimensional grid model corresponding to the current depth image key frame; and generating an equivalent contour surface of the second three-dimensional grid model by using an accelerated marching cubes algorithm, to obtain a three-dimensional reconstruction model of a target scene.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

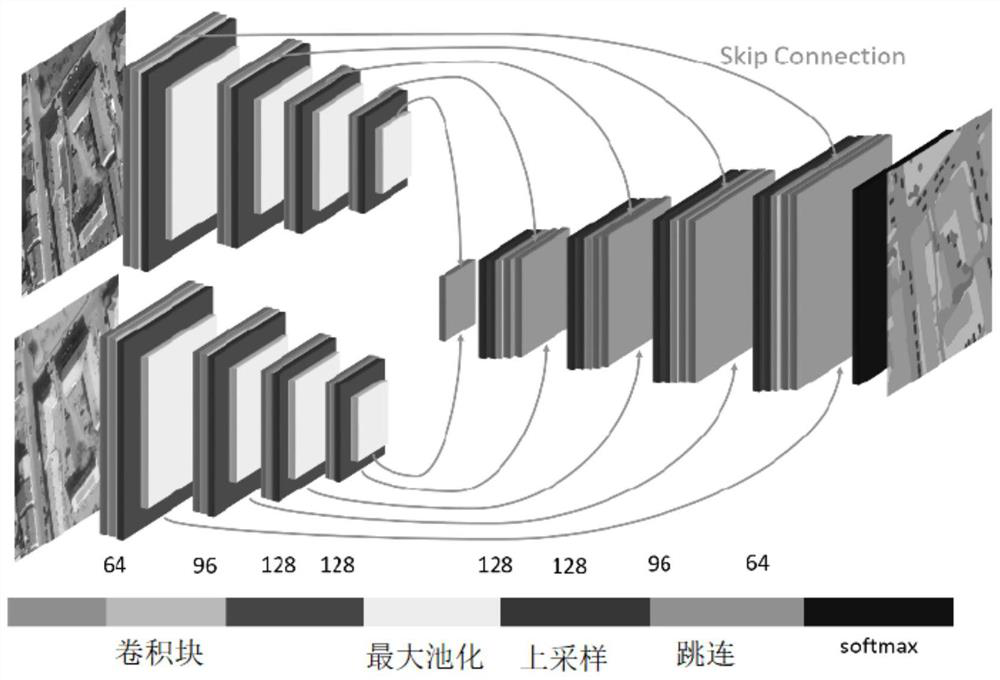

Method for generating multi-scale house detection vector diagram

The invention relates to the technical field of multi-scale house detection vector diagrams, in particular to a method for generating a multi-scale house detection vector diagram, which comprises the following steps of: 1, classifying earth surface targets by utilizing an earth surface coverage segmentation network, and performing network jump connection by utilizing skip-connection; 2, generating a house vector diagram by using a house vector diagram generation network, and processing training data according to different scale proportions in order to implicitly learn multi-scale information; 3, carrying out polygon extraction and shape simplification of the house vector diagram by using a Marching Cubes algorithm and a Regulation Building Footprint module provided in an arcpy library of ArcGIS10.4, and meanwhile, solving the problems that corners of a building are incomplete and opposite sides are not parallel. According to the method, multi-scale processing can be carried out on an existing map, multi-scale information is implicitly learned through the neural network, and a multi-scale vector diagram with a good effect is obtained.

Owner:杭州高斯洪堡科技有限公司

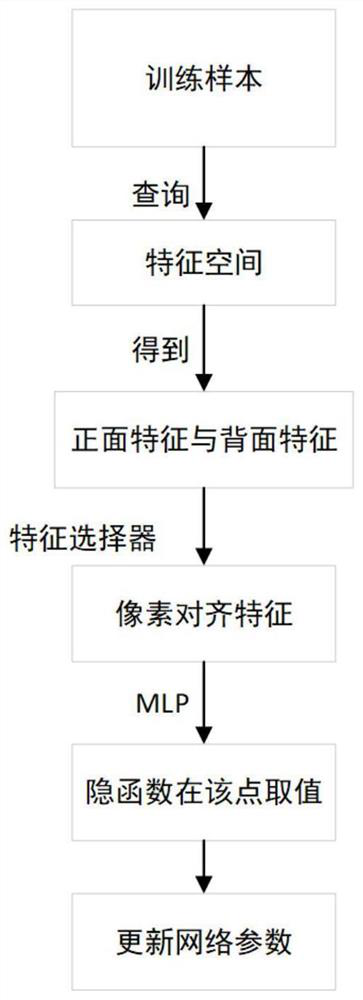

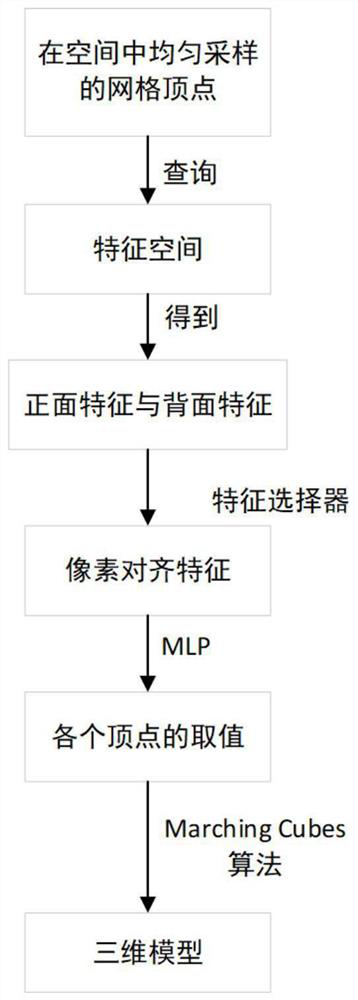

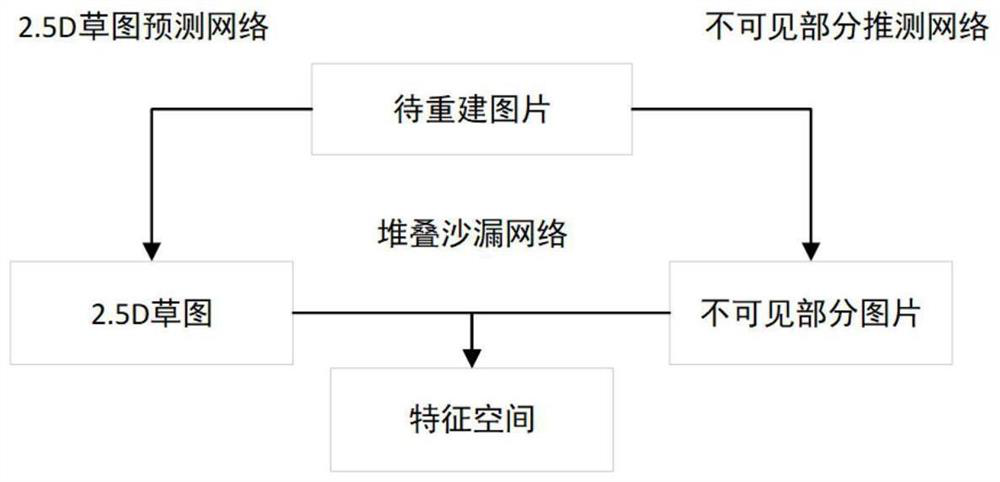

Three-dimensional reconstruction method based on single image

PendingCN114299227AImprove the problem of severe lack of prior conditionsGood detailsNeural architectures3D modellingAlgorithmSingle image

The invention discloses a three-dimensional reconstruction method based on a single image. The method comprises a training stage, wherein a training sample comprises sampling points on a three-dimensional model, actual implicit function values corresponding to the sampling points and the single image corresponding to the three-dimensional model; a feature space is generated through a single input picture, sampling points of the three-dimensional model are used as query points, implicit function values of the query points are predicted, loss is calculated according to the predicted implicit function values and actual implicit function values, and fitting of an implicit function field is completed; in the reconstruction stage, after the training stage is completed, a feature space is generated for a single input picture, a plurality of points are sampled in an observation space, and the points form query points; predicting an implicit function value of a query point; and inputting the query point and the prediction implicit function value into a marching cubes algorithm, and reconstructing to obtain a three-dimensional model. According to the method, the problem of serious lack of prior conditions in single image reconstruction is solved, and fine details can be obtained in a visible part.

Owner:JIANGSU TIANHONG MACHINERY IND

Reconstruction method of 3D solid model of reservoir core based on micro-ct technology

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

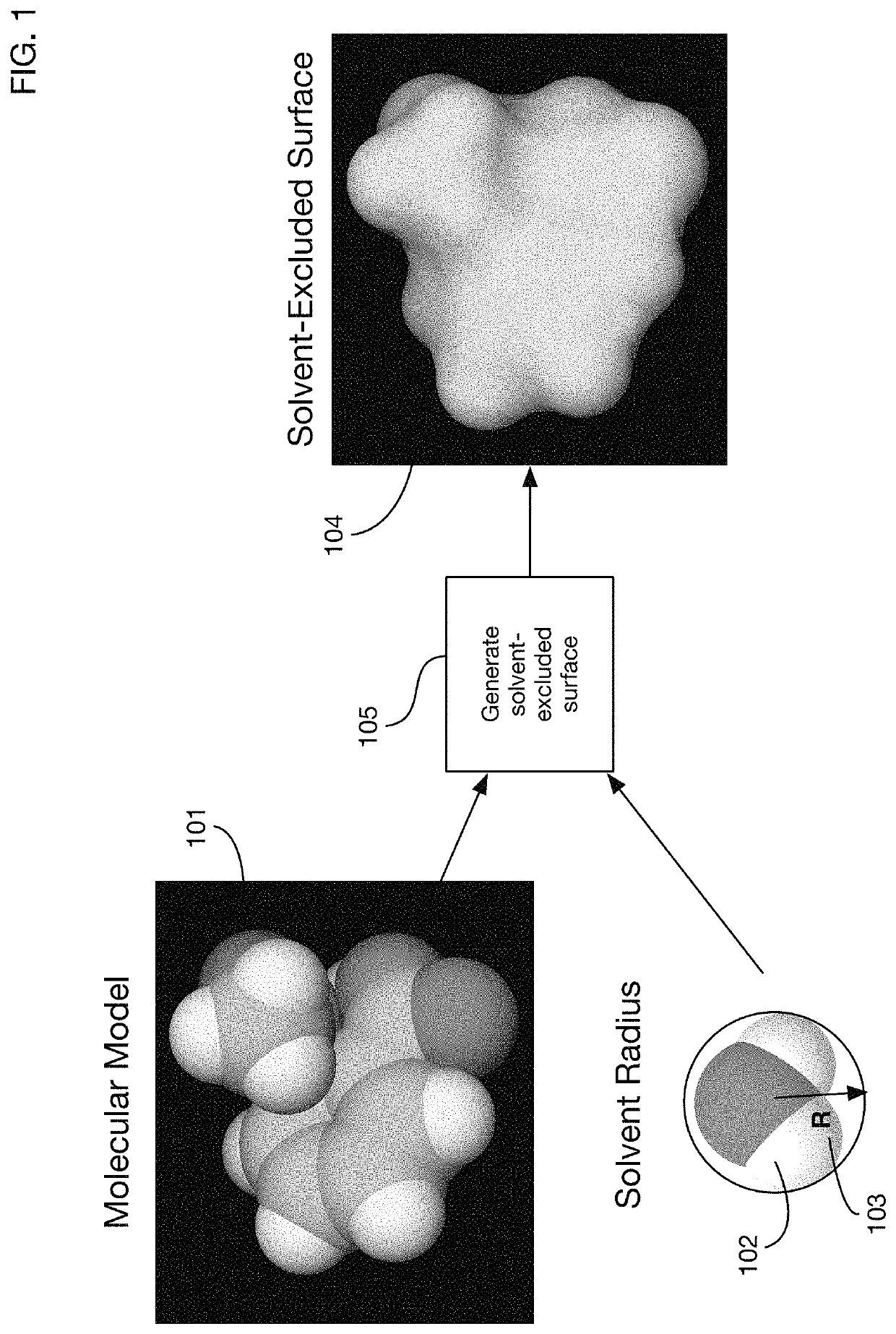

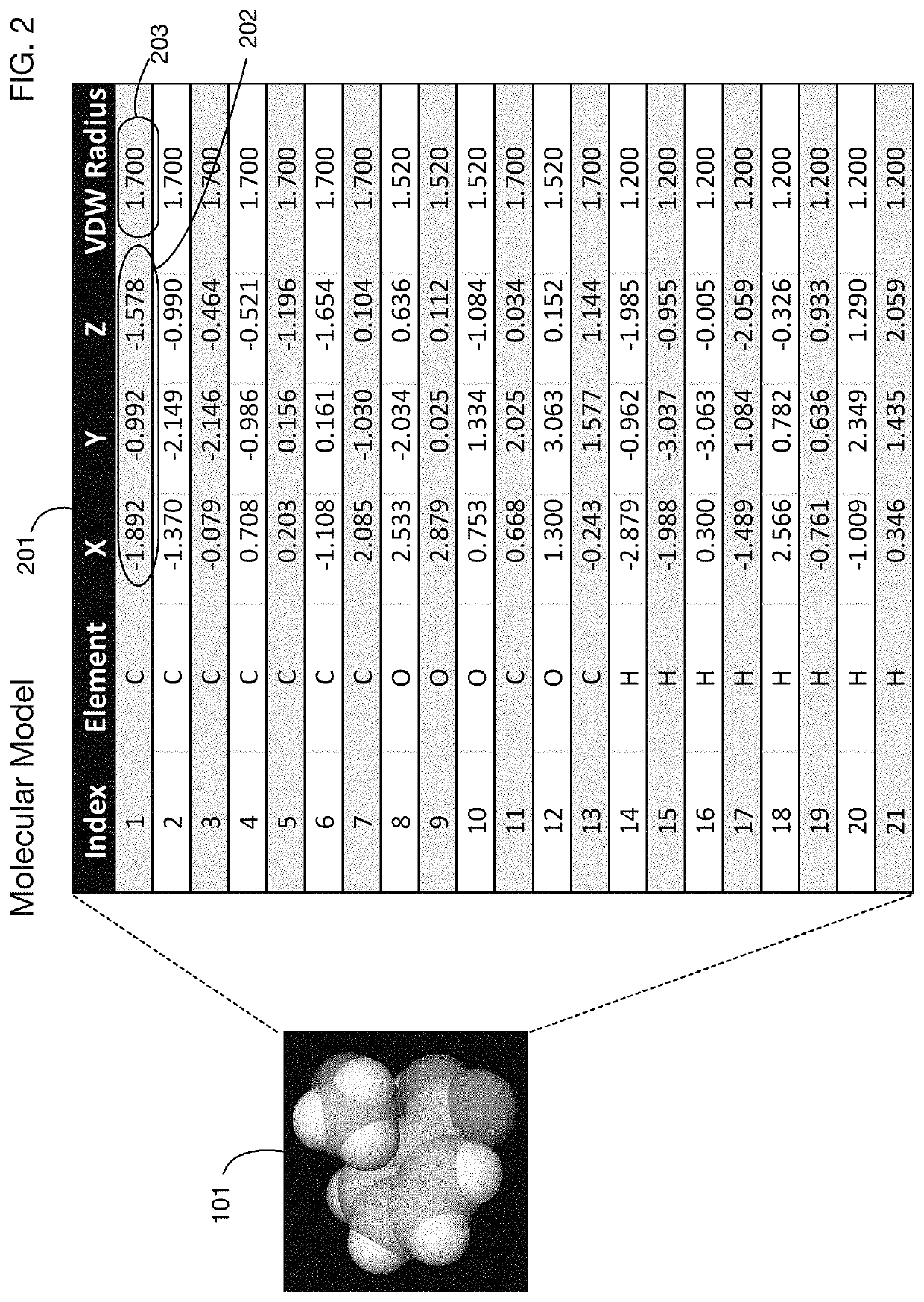

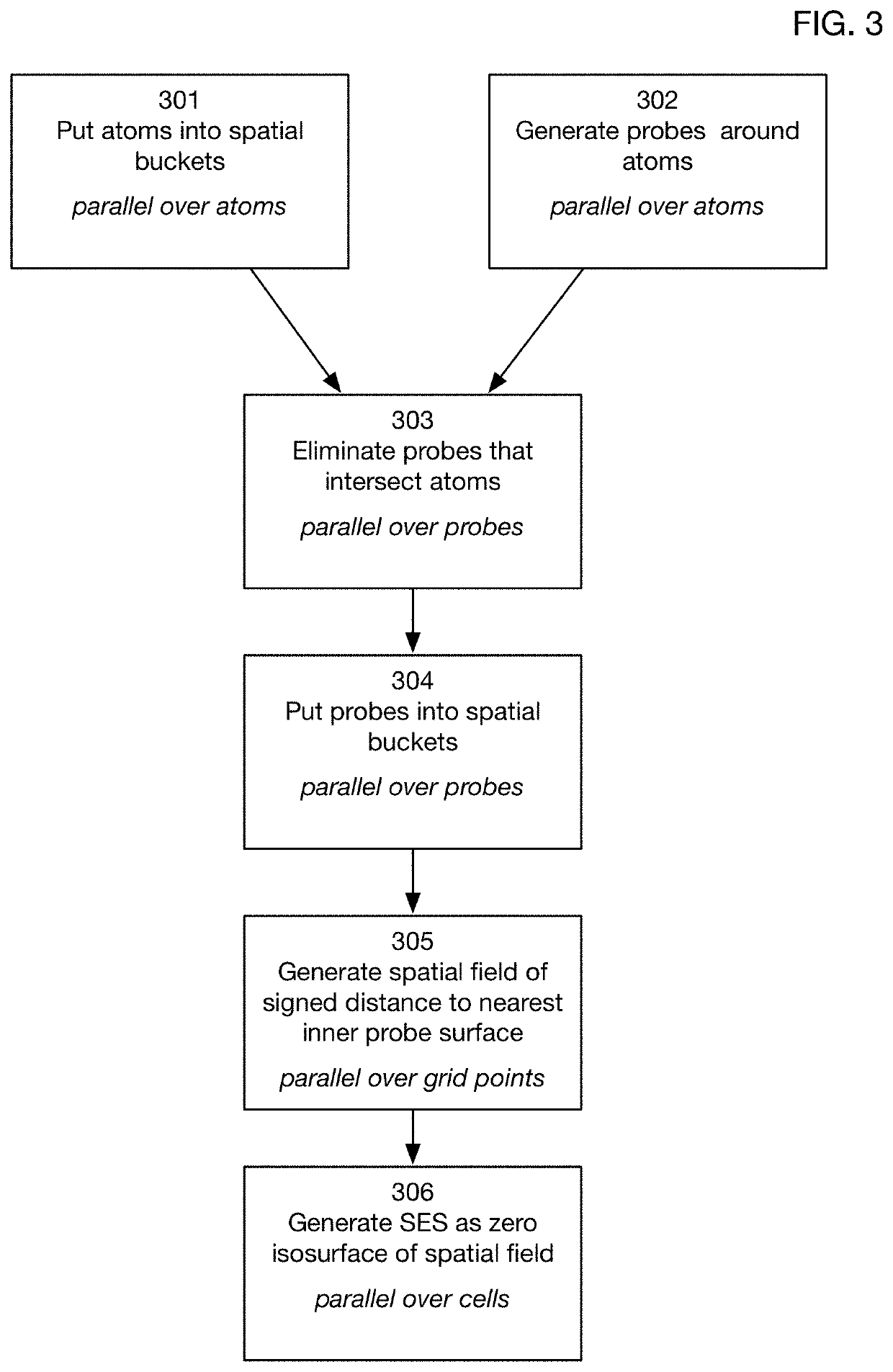

System that rapidly generates a solvent-excluded surface

ActiveUS10529444B1Quick buildImprove efficiencyData visualisationCheminformatics data warehousingParallel algorithmComputational physics

System that generates the solvent-excluded surface (SES) of a molecule using a parallel algorithm that may execute on a GPU. Parallel execution allows a SES to be created in seconds even for a large protein, or to be recreated rapidly when exploring modifications to molecular structure. The algorithm calculates a spatial field that represents a signed distance between an atom-facing surface of a probe and each point in 3D grid. Spatial field calculations for different grid points may be performed in parallel. The SES is then obtained as the zero isosurface of the spatial field, using for example marching cubes. Atoms and probes may be placed into spatial buckets and indexed by bucket to improve efficiency by limiting calculations to atoms and probes in the proximity of a point.

Owner:NANOME INC

A Realization Method of Adaptive Hierarchical Big Data Display of Chest

InactiveCN103077557BIncrease local resolutionImprove surface drawing clarityImage analysis3D modellingData displayMobile Cube

The invention discloses an adaptive hierarchical chest large data display implementation method, which comprises the following steps: dividing a CT (computed tomography) sectional image into a target layer image sequence and a background layer image sequence; performing interlayer cubic convolution interpolation on the divided target layer image sequence to form volume data of which each axial resolution is appropriate; making a clear surface drawing by a marching cubes algorithm; performing intraformational and interlayer sampling on the data of the background layer sequence to obtain uninteresting region data of which the resolution is reduced; making a rough body drawing for the data by a ray casting algorithm; displaying the drawing results of the clear surface drawing and the rough body drawing at the same time, and performing hybrid three-dimensional visualization. By the method, the local resolution in the interesting region is increased, and the anisotropic resolution of the uninteresting region is reduced, so that a user is facilitated to know the structure information of a local interesting region, the data volume is decreased and drawing can be implemented on an ordinary computer.

Owner:HEBEI UNIVERSITY

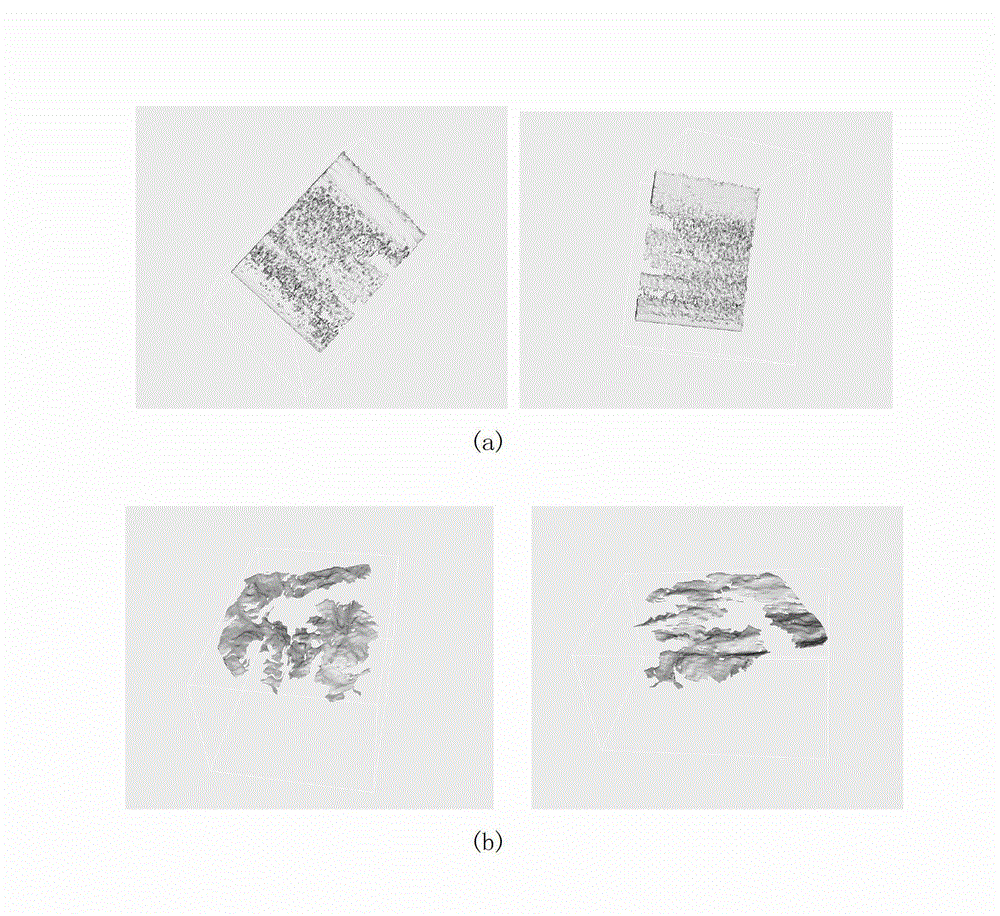

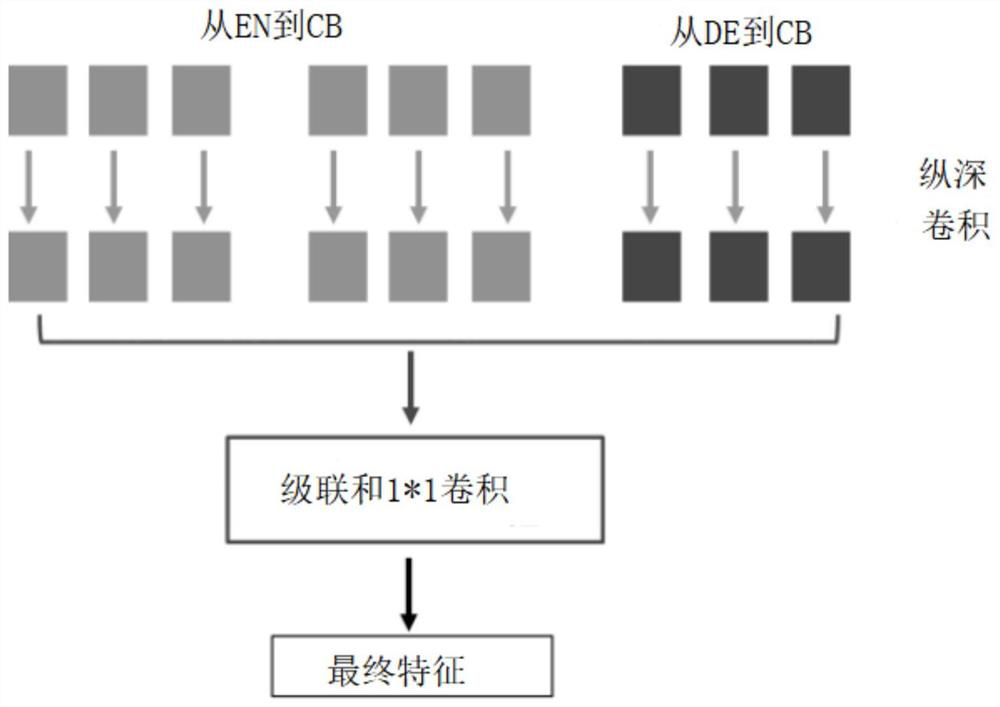

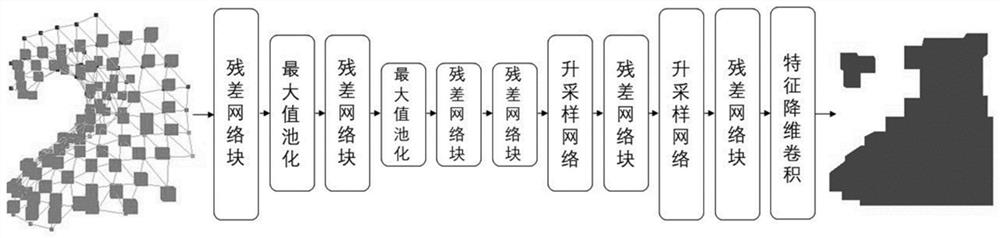

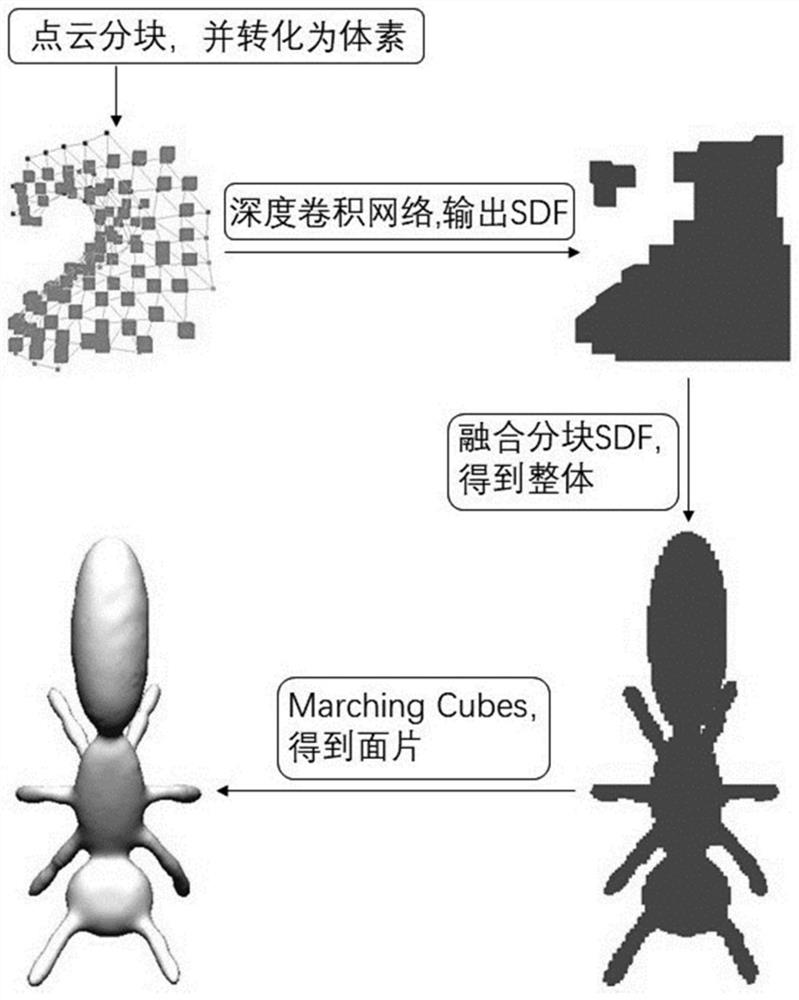

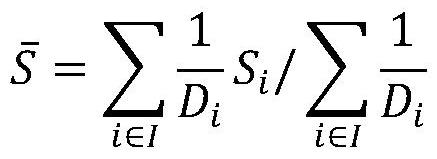

A block patch reconstruction method for point cloud data based on deep learning

ActiveCN111028335BImprove reliabilityAvoid complex geometry operationsNeural architecturesNeural learning methodsAlgorithmComputer-aided

The invention presented in this paper is called a block-based surface reconstruction method from point cloud data based on deep learning. The invention discloses a method for reconstructing a surface model from a point cloud based on deep learning. The method utilizes point cloud data in three-dimensional space to generate SDF (Signed Distance Field, directed distance field) in blocks and integrates each block to obtain a complete SDF, and finally use the Marching Cubes algorithm to get the final patch data. The present invention can still perform robustly in the presence of noise in the point cloud data, especially in the case of normal information deviation, greatly reducing the requirement for the direction accuracy of the collected point cloud data; during operation, the present invention can also process in parallel ,efficient. As for the application of the present invention, it mainly focuses on the field of three-dimensional object reconstruction, and has wide application space in three-dimensional modeling in digital entertainment, computer-aided design and the like.

Owner:ZHEJIANG UNIV

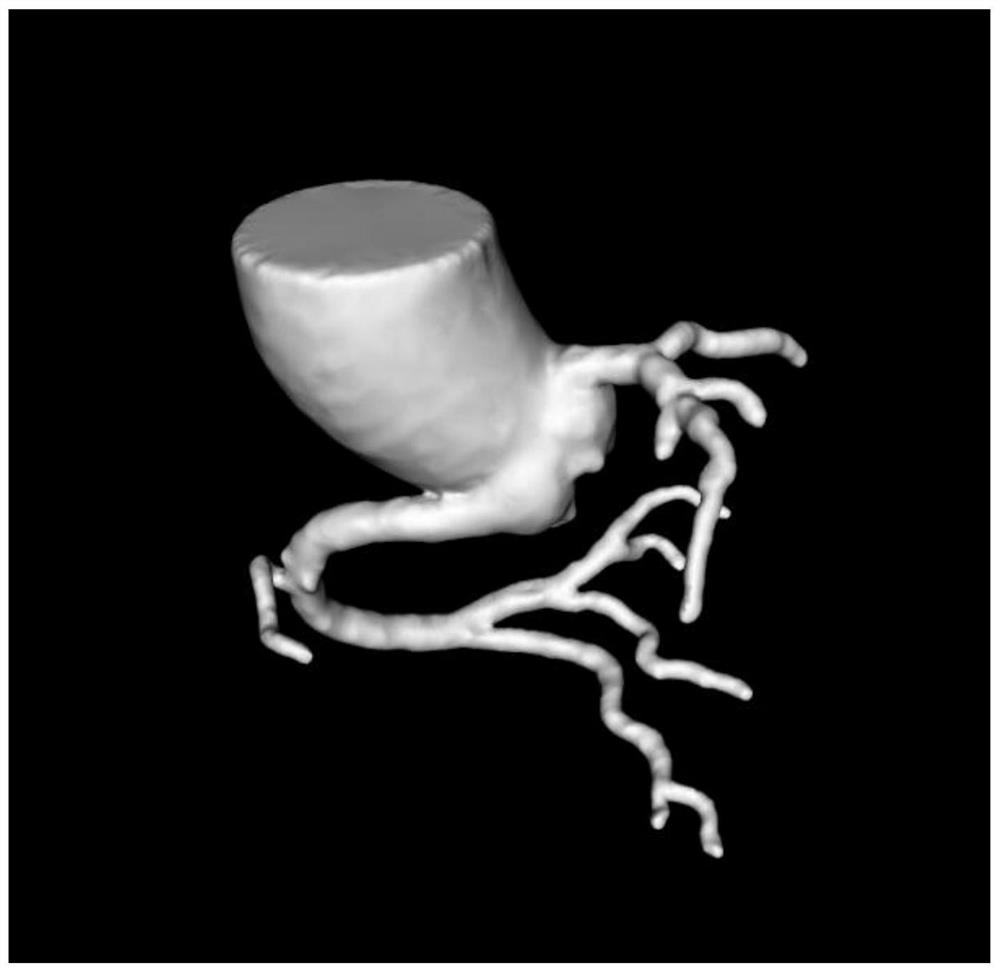

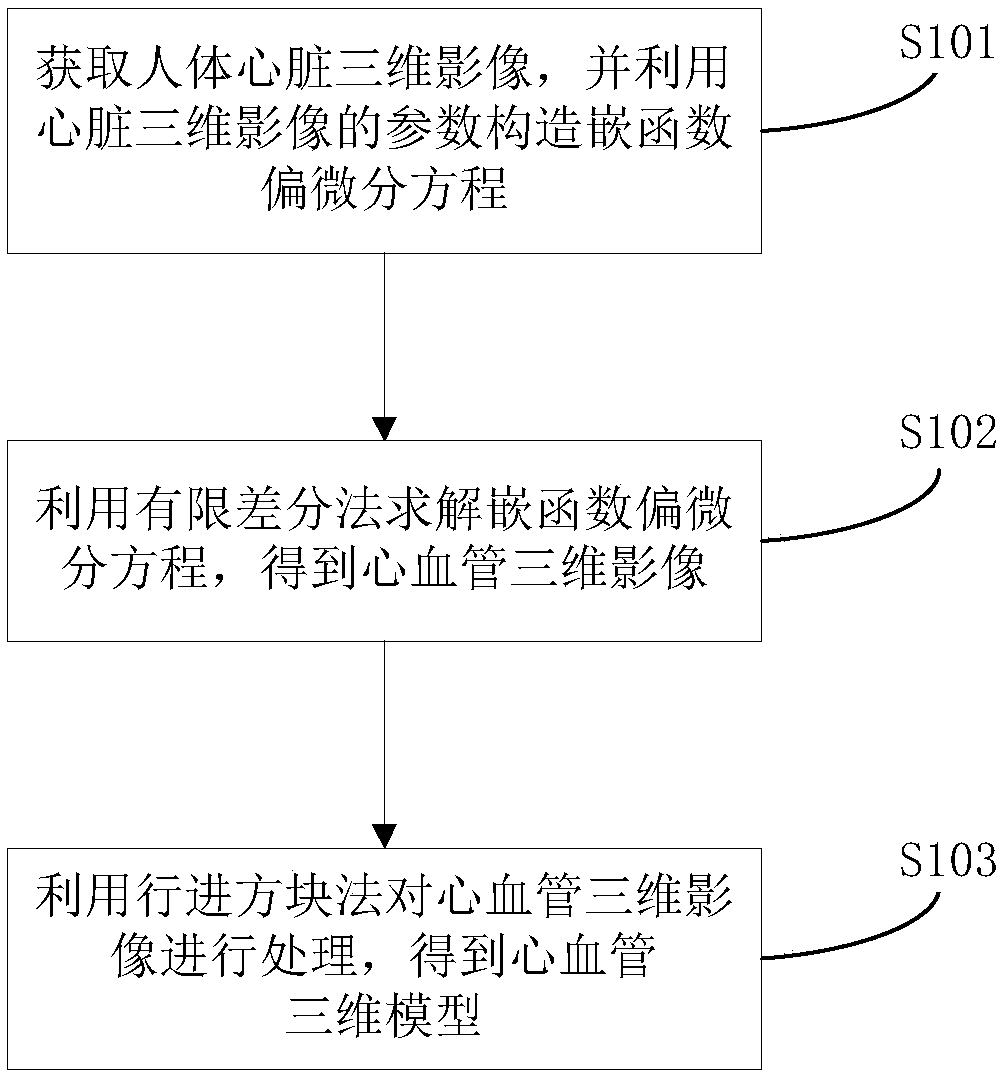

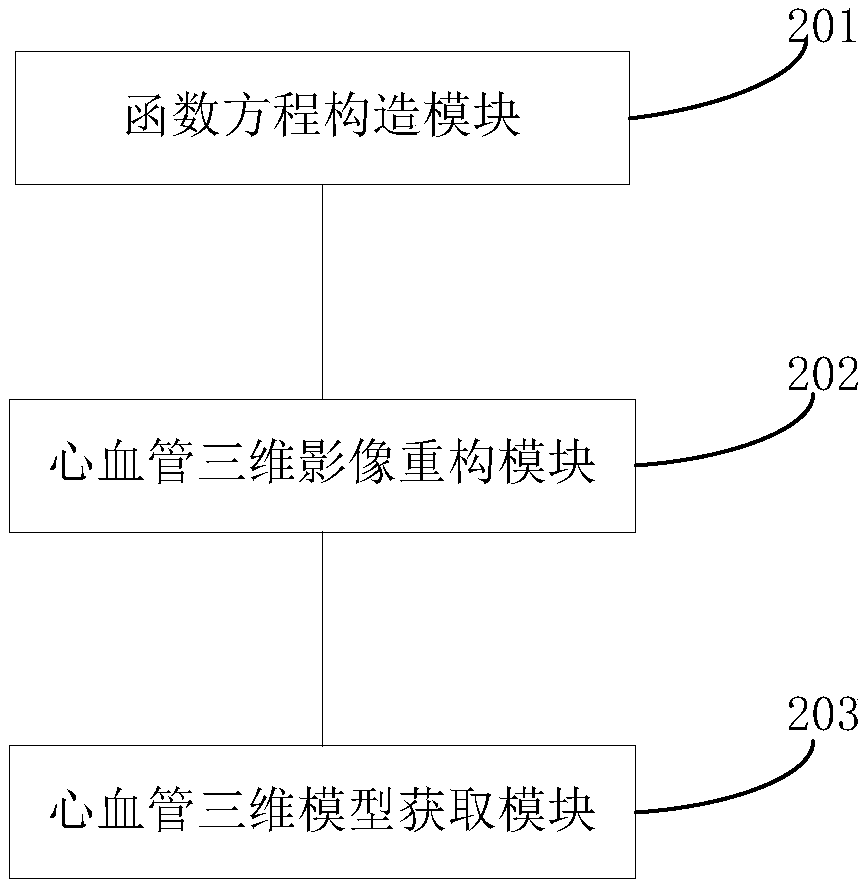

Angiocarpy image reconstruction method and system based on implicit deformable model

ActiveCN108765543AAccurate segmentationSimple methodImage generationComplex mathematical operationsHuman bodyPartial differential equation

The present invention provides an angiocarpy image reconstruction method and system based on an implicit deformable model. The method comprises the steps of: obtaining a human body heart three-dimensional image, and employing the parameters of the human body heart three-dimensional image to construct a nested function partial differential equation; employing a combination mode of a fast marching method and a collision forward method to initialize angiocarpy aorta images and coronary artery images, perform swelling, smoothing and convection processing, solve the nested function partial differential equation and obtain a reconstructed angiocarpy three-dimensional image; and employing marching cubes to perform processing of the reconstructed angiocarpy three-dimensional image to obtain an angiocarpy three-dimensional model. The method and the system solve the problem that the calculation stability is poor in a current angiocarpy image reconstruction method, achieve rapidly and accuratelysegment required areas on the premise of ensuring the calculation result stability, are simple to operate and facilitate later calculation of the hydromechanics analysis.

Owner:HANGZHOU ARTERYFLOW TECH CO LTD

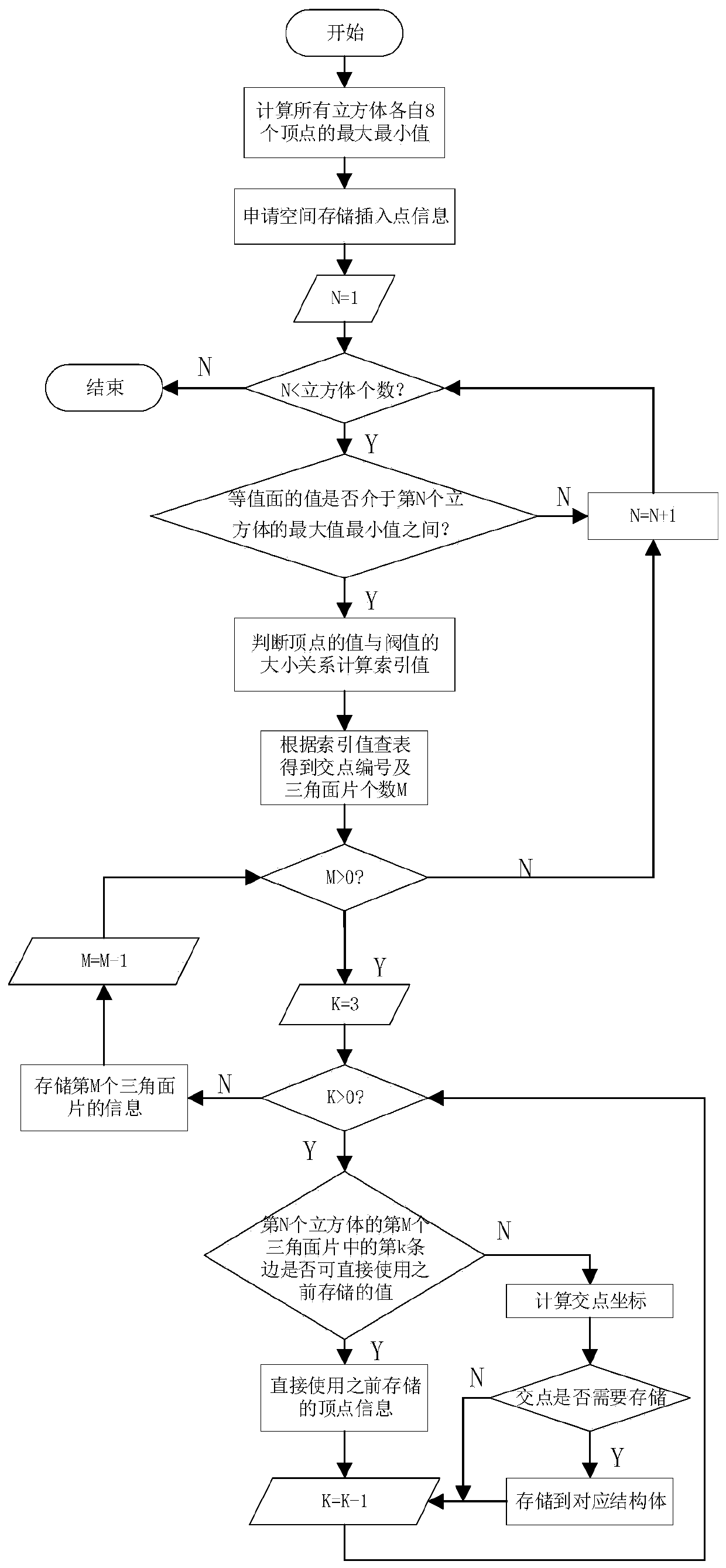

Efficient Marching Cubes equivalent surface extraction method and system without redundancy calculation

ActiveCN110021059AIncrease profitHigh speed3D-image rendering3D modellingComputational scienceAlgorithm

The invention provides an efficient Marching Cubes equivalent surface extraction method and system without redundancy calculation. Coordinates of inserting vertexes on the edges capable of being repeatedly used in the extra data structure storage cube are facilitated, the maximum and minimum values of the eight vertexes in the array storage cube are used, and the relation between the maximum and minimum values and the value of an equivalent surface is firstly compared in the comparison process. The speed is high, redundant computing is reduced, the insertion points of the same sides of the adjacent cubes are only calculated once; direct removal is carried out in the second time, the utilization rate of the cpu is greatly improved; the storage spce is small, the insert point information andthe contour surface are stored separately, the specific information of the same insert point is only stored once, the same vertex information is directly utilized by the same insert point of different contour surfaces when the contour surface is drawn, the storage space is reduced, and meanwhile, the speed of outputting the information into a file is increased. The method is applied to the fieldof data visualization processing.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com