System for desulfurization, white smoke elimination and deep waste heat recovery based on ammonia process, and application

A recovery system and ammonia desulfurization technology, applied in the field of ammonia desulfurization flue gas whitening waste heat deep recovery system, can solve problems such as equipment corrosion, and achieve the effects of easy control, high heat recovery rate and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0033] Structures, connections, etc. that are not described in detail in the present invention can be understood as conventional technical means in the art.

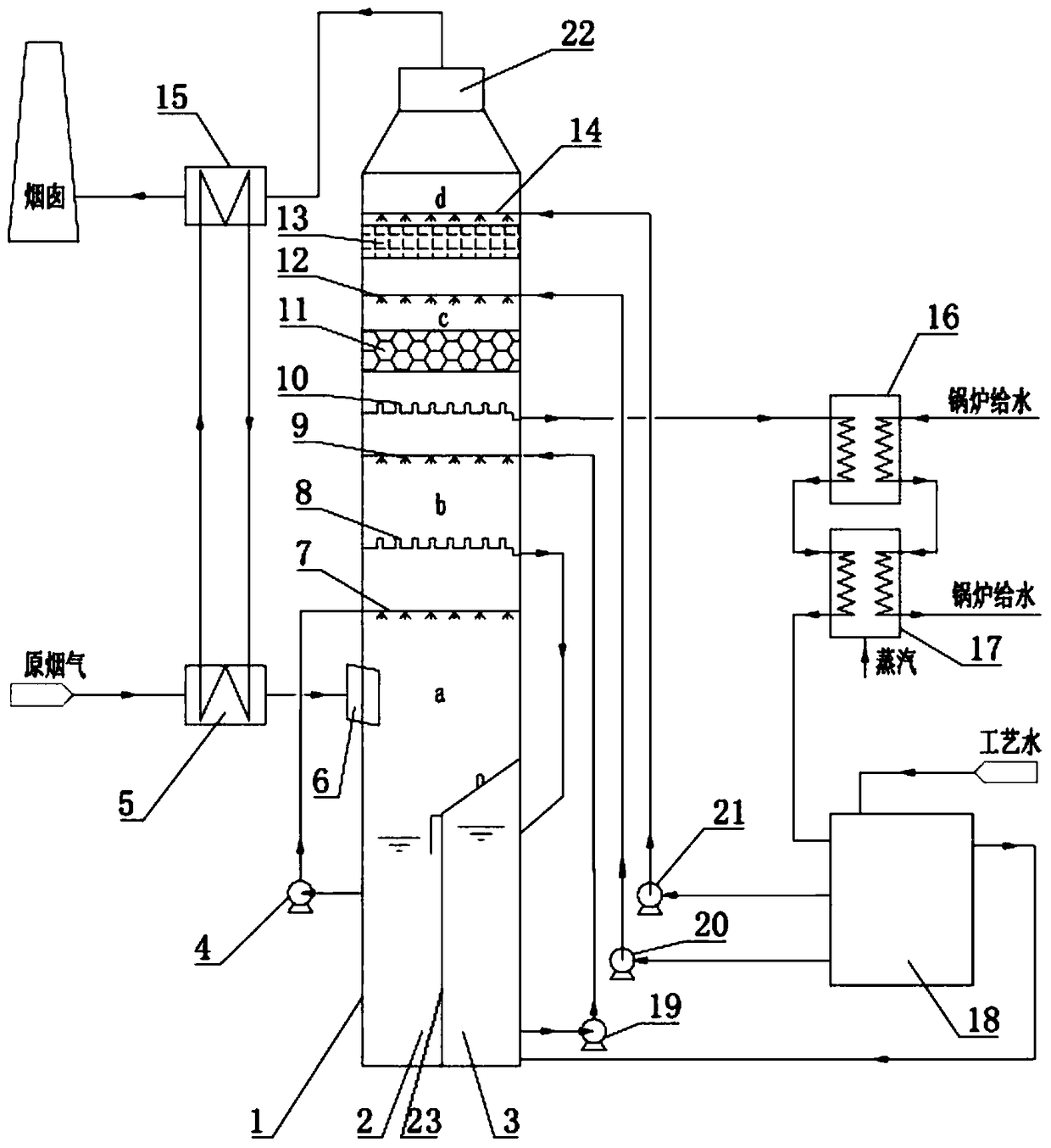

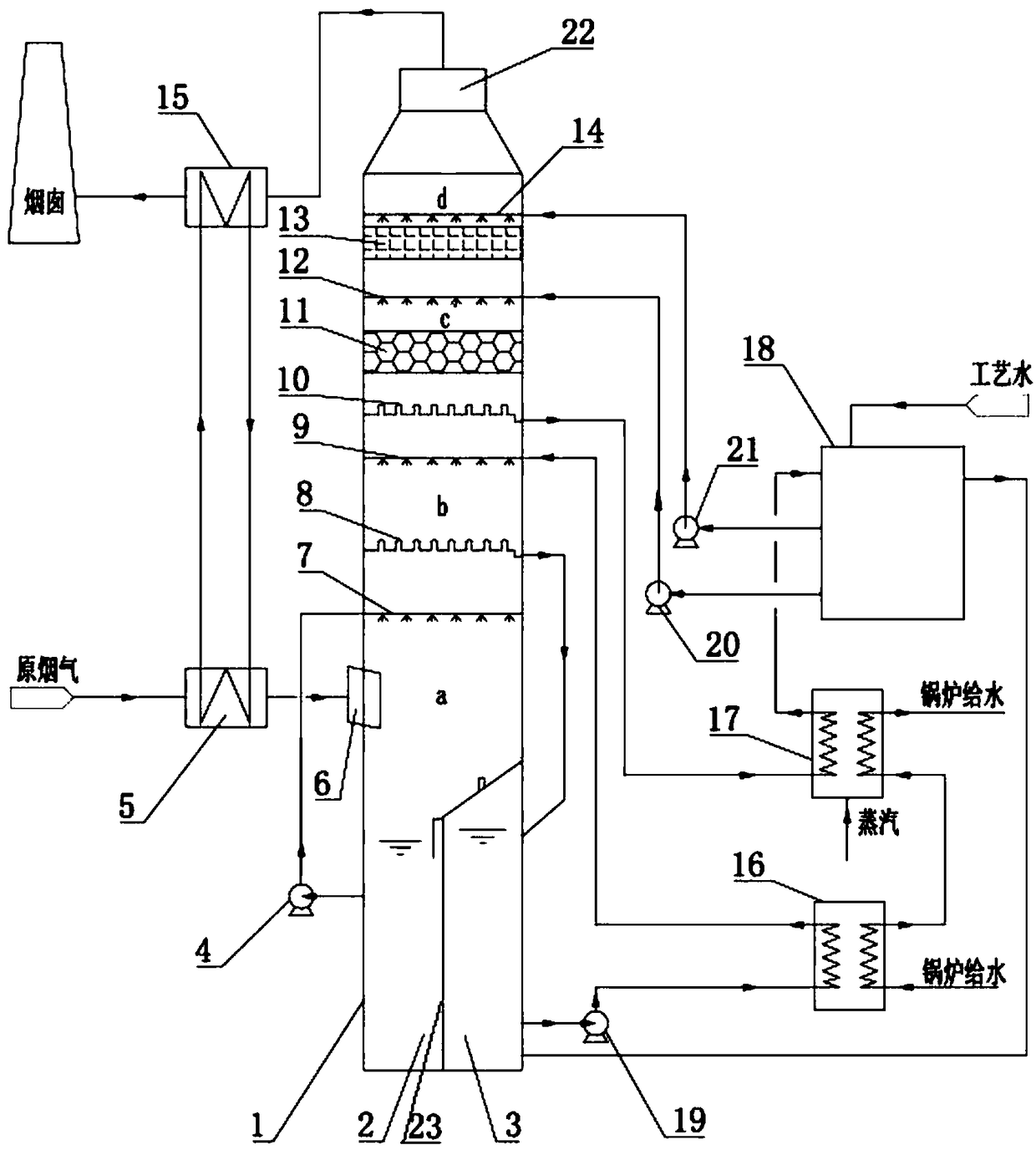

[0034] A deep recovery system for ammonia desulfurization flue gas whitening waste heat, such as figure 1 and figure 2 As shown, the system includes a desulfurization tower 1, a circulating water tank 18, a heat exchanger 16, an absorption heat pump unit 17, a flue gas cooling section 5, a flue gas heating section 15, an inlet flue 6 and an outlet flue 22. A concentration pool 2 and a desulfurization circulation pool 3 are arranged separately at the bottom of the desulfurization tower, and a concentration section a, a desulfurization section b, a water washing section c, and a demisting section d ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com