High-weather-resisting type green recombined decorative veneer and preparation method thereof

A technology of reorganized decoration and high weather resistance, applied in the field of decorative materials, can solve the problems of poor light fastness, low environmental protection level, etc., and achieve the effects of improving bonding force, improving wear resistance and weather resistance, and good bactericidal and bacteriostatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with examples, and the present invention is not limited by the following examples.

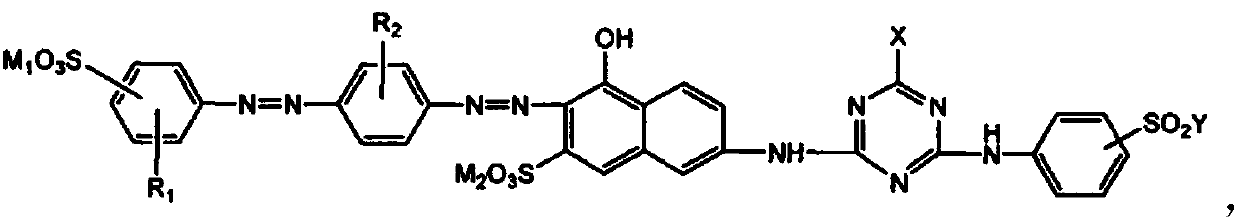

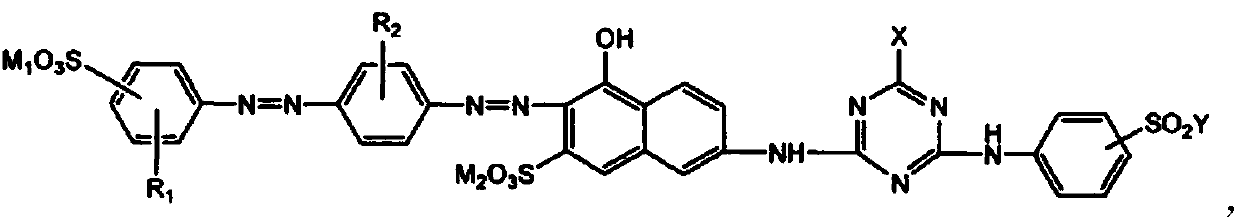

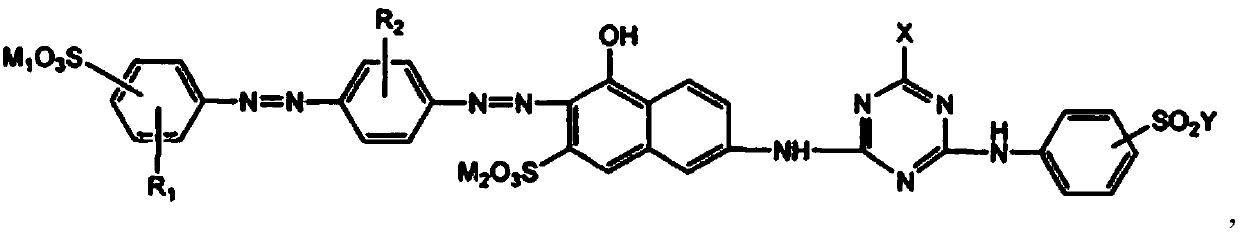

[0051] A high-weather-resistant green recombined decorative veneer, which sequentially includes a transparent wear-resistant adhesive film paper layer, a high color fastness recombined decorative veneer layer and a flexible reinforcing material layer from top to bottom; the high color fastness recombined decorative veneer The thickness of the layer is 0.15-1.0mm, made of environmentally friendly toughened glue, the formaldehyde emission is below 0.3mg / l, and dyes with high color fastness are used for dyeing, and the color fastness to light is above grade 5; the flexible reinforcing material The thickness of the layer is 0.05-0.15mm, and it is bonded with the recombined decorative veneer layer with high color fastness through environmentally friendly formaldehyde-free glue; the transparent wear-resistant adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com