A kind of high color fastness environmental protection ecological board and preparation method

A high color fastness, ecological board technology, applied in the field of decorative materials, can solve the problems of low environmental protection level, poor light fastness and other problems, and achieve the effect of improving light fastness, reducing irradiance, and improving light fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

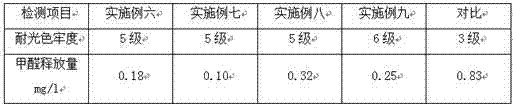

Examples

Embodiment 1

[0049] The preparation method of the environmental protection ecological board with high color fastness comprises the following steps:

[0050] (1) Disperse the hindered amine light stabilizer in the melamine modified resin, and then carry out the first impregnation treatment, the first drying, the second impregnation treatment, and the second drying of the wood grain paper in it. High color fastness finish layer; hindered amine light stabilizer is a liquid hindered piperidinyl compound, the dosage is 5% of the mass of melamine modified resin;

[0051] Wherein, the process of dispersing the light stabilizer in the melamine modified resin includes: 1. Weigh 100 parts of the melamine modified resin and 5 parts of the light stabilizer in parts by mass; 2. Add the light stabilizer while stirring in the melamine modified resin, Stirring speed ≥ 1000 rpm, evenly disperse the light stabilizer in the resin;

[0052] The preparation of melamine-modified resin includes first two additi...

Embodiment 2

[0060] The preparation method of the environmental protection ecological board with high color fastness comprises the following steps:

[0061] (1) Disperse the hindered amine light stabilizer in the melamine modified resin, and then carry out the first impregnation treatment, the first drying, the second impregnation treatment, and the second drying of the wood grain paper in it. Obtain a high color fastness finish layer; hindered amine light stabilizer is a liquid hindered piperidinyl compound, the dosage is 20% of the mass of melamine modified resin;

[0062] Wherein, the process of dispersing the light stabilizer in the melamine modified resin comprises: 1. Weigh 100 parts of the melamine modified resin and 20 parts of the light stabilizer in parts by mass; 2. Add the light stabilizer while stirring in the melamine modified resin, Stirring speed ≥ 1000 rpm, evenly disperse the light stabilizer in the resin;

[0063] The preparation of melamine-modified resin includes firs...

Embodiment 3

[0071] Same as Example 1, except that the hindered amine light stabilizer in step (1) is UV-765, and the dosage is 8% of the mass of the melamine-modified resin.

[0072] Step (2) after hot pressing and step (3) between applying environmental protection glue also includes dyeing treatment, in which ternary compound dyes are used; ternary compound dyes are liquid hindered piperidinyl compounds, flame retardants and azo The dye is a ternary compound dye compounded according to the mass ratio of 1:25:300. Azo dyes have a molecular weight of 500-600 Daltons and a cubic crystal structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com