Energy-saving decorative plate and preparation method thereof

A decorative board and decorative surface layer technology, applied in the field of wood processing, can solve the problems of energy saving and environmental protection to be improved, the service life is not long, and the light fastness and color fastness are poor. The effect of high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

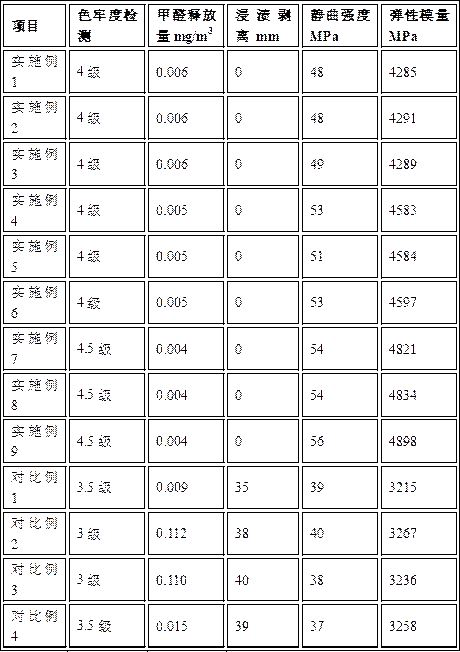

Examples

Embodiment 1

[0054] A method for preparing an energy-saving decorative board, comprising the following steps:

[0055] 1) Prepare the decorative surface layer: first prepare the PVC skin layer, and then sequentially press the color film layer and the transparent skin layer on the PVC skin layer to obtain the decorative surface layer;

[0056] 2) Prepare the substrate layer;

[0057] 3) hot pressing the decorative surface layer and the substrate layer, and then coating the UV light-resistant paint on the transparent skin layer.

[0058] The preparation method of PVC skin layer comprises

[0059] S21, Raw material ratio: In parts by weight, it includes polyvinyl chloride resin powder 80, calcium carbonate 160, calcium titanate 10, internal lubricant 0.6, polyethylene wax 1.0, chlorinated polyethylene 2, acrylate 0.8, composite lubricant 0.6 , liquid barium zinc stabilizer 2 and dioctyl phthalate 3;

[0060] Wherein, the internal lubricant is polyethylene wax and stearic acid mixed accordi...

Embodiment 2

[0075] A method for preparing an energy-saving decorative board, comprising the following steps:

[0076] 1) Prepare the decorative surface layer: first prepare the PVC skin layer, and then sequentially press the color film layer and the transparent skin layer on the PVC skin layer to obtain the decorative surface layer;

[0077] 2) Prepare the substrate layer;

[0078] 3) hot pressing the decorative surface layer and the substrate layer, and then coating the UV light-resistant paint on the transparent skin layer.

[0079] The preparation method of PVC skin layer comprises

[0080] S21, Raw material ratio: In parts by weight, it includes polyvinyl chloride resin powder 90, calcium carbonate 180, calcium titanate 30, internal lubricant 0.8, polyethylene wax 1.2, chlorinated polyethylene 4, acrylate 1.5, composite lubricant 0.9 , liquid barium zinc stabilizer 3 and dioctyl phthalate 3;

[0081] Wherein, the internal lubricant is polyethylene wax and stearic acid mixed accordi...

Embodiment 3

[0095] A method for preparing an energy-saving decorative board, comprising the following steps:

[0096] 1) Prepare the decorative surface layer: first prepare the PVC skin layer, and then sequentially press the color film layer and the transparent skin layer on the PVC skin layer to obtain the decorative surface layer;

[0097] 2) Prepare the substrate layer;

[0098] 3) hot pressing the decorative surface layer and the substrate layer, and then coating the UV light-resistant paint on the transparent skin layer.

[0099] The preparation method of PVC skin layer comprises

[0100] S21, raw material ratio: by weight, including polyvinyl chloride resin powder 80-90, calcium carbonate 170, calcium titanate 20, internal lubricant 0.7, polyethylene wax 1.1, chlorinated polyethylene 3, acrylate 1.3, compound lubrication Agent 0.8, liquid barium zinc stabilizer 2.5 and dioctyl phthalate 2;

[0101] Wherein, the internal lubricant is polyethylene wax and stearic acid mixed accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com