Preparation method for blocked waterborne polyurethane and application of blocked waterborne polyurethane to preparation of digital printing waterborne paint ink

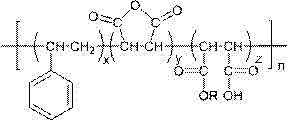

A water-based polyurethane, end-capped technology, used in dyeing, textiles and papermaking, etc., can solve the problems of dry and wet friction, poor washing fastness, affect the hand feel, and hard film formation, and improve the friction resistance and washing fastness. , The effect of high washing fastness and easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The end-capped water-based polyurethane emulsion of the SME modification of the present embodiment, its specific preparation process is as follows:

[0048] S1. Heat and stir 14.3g of SME (Mn=2800, SMA 17352 of Crayville Chemical Co., Ltd.), 1.7g of 1,4-butanediol, 0.6g of p-toluenesulfonic acid and 83.4g of methyl ethyl ketone, and heat up to 80°C , heat preservation reaction for 4h, and post-treatment to obtain SME solid with hydroxyl groups;

[0049] S2. Prepolymerize 60.61g of dehydrated polypropylene glycol (Mn=2000), 18.53g of isophorone diisocyanate, and 0.01g of stannous octoate at 85°C for 2 hours, and add the hydroxyl SME9.21g, continue to react for 2 hours, then add 2.00g of 1,4-butanediol, chain extension reaction for 1 hour, to obtain polyurethane prepolymer;

[0050] S3. Cool down and add 5.88g of 3,5-dimethylpyrazole for capping, then raise the temperature to 70°C for 2 hours;

[0051] S4. down to room temperature, add acetone to reduce viscosity, add 3...

Embodiment 2

[0059] The end-capped water-based polyurethane emulsion of the SME modification of the present embodiment, its specific preparation process is as follows:

[0060] S1. Heat and stir 17.5g of SME (Mn=2800, SMA 17352 of Crayville Chemical Co., Ltd.), 2.5g of 1,4-butanediol, 0.7g of p-toluenesulfonic acid and 79.3g of methyl ethyl ketone, and heat up to 85°C , heat preservation reaction for 6h, and post-treatment to obtain SME solid with hydroxyl groups.

[0061] S2. Prepolymerize 24.99g of dehydrated polypropylene glycol (Mn=2000), 35.70g of polytetramethylene ether glycol, 18.68g of isophorone diisocyanate, and 0.01g of stannous octoate at 85°C After reacting for 2 hours, add 9.49 g of SME with hydroxyl groups obtained from S1, continue the reaction for 2 hours, then add 2.00 g of 1,4-butanediol, and perform a chain extension reaction for 1 hour to obtain a polyurethane prepolymer;

[0062] S3. Lower the temperature and add 5.68g of 3,5-dimethylpyrazole for capping, then raise...

Embodiment 3

[0071] The end-capped water-based polyurethane emulsion of the SME modification of the present embodiment, its specific preparation process is as follows:

[0072] S1. Heat and stir 14.3g SME (Mn=3600, SMA 2625 from Craigville Chemical Co., Ltd.), 1.7g 1,4-butanediol, 0.6g p-toluenesulfonic acid and 83.4g butanone, and heat up to 85°C , heat preservation reaction for 5h, and post-treatment to obtain SME solid with hydroxyl groups.

[0073] S2. 34.83g of dehydrated polypropylene glycol (Mn=2000), 26.79g of polybutylene adipate, 14.54g of hexamethylene diisocyanate, and 0.02g of dibutyltin dilaurate were carried out at 85°C. Prepolymerization reaction for 2 hours, add 11.96g of SME with hydroxyl obtained from S1 (dissolved in a proper amount of acetone), continue the reaction for 2 hours, then add 2.00g of 1,4-butanediol, and perform chain extension reaction for 1 hour to obtain a polyurethane prepolymer;

[0074] S3. Lower the temperature and add 6.10g of 3,5-dimethylpyrazole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com