Poly-cation color fixing agent and preparation method thereof

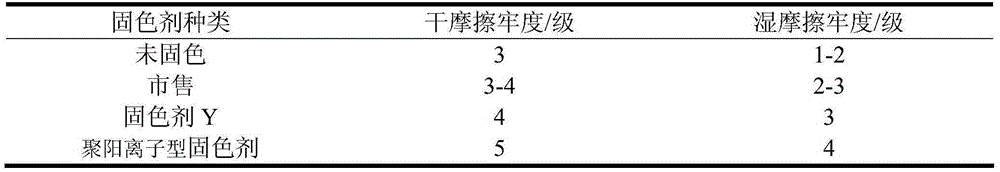

A technology of polycation and color-fixing agent, which can be used in dyeing, textiles and papermaking, and can solve the problems of poor color fastness to wet rubbing and washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add water and diethylenetriamine (AE) into the reaction vessel, heat up to 50°C while stirring, add epichlorohydrin (EP) dropwise, continue the reaction for 2 hours after the dropwise addition, and obtain a pH value of 8 , Adjust to 6 with glacial acetic acid and continue heating to 70°C, add dimethyl diallyl ammonium chloride (DMDAAC) dropwise, react for 4 hours after the dropwise addition, obtain the pH value of the reaction solution 7.5, cool to At room temperature, the finished product can be obtained after discharging. In the reaction, the materials are fed in the following proportions. The molar ratio of the monomers of diethylenetriamine, epichlorohydrin and dimethyldiallylammonium chloride (DMDAAC) is 2:2:1. The prepared fixing agent is The solid content is 10%.

Embodiment 2

[0021] Add water and diethylenetriamine (AE) into the reaction vessel, heat to 40°C while stirring, add epichlorohydrin (EP) dropwise, continue the reaction for 2 hours after the dropwise addition, and obtain the pH value of the reaction solution 6.5 , Continue to heat up to 80°C, add dimethyl diallyl ammonium chloride (DMDAAC) dropwise, react for 2 hours after the dropwise addition is complete, the pH value of the reaction solution obtained is 7.0, cooled to room temperature, and the finished product is obtained after discharge . In the reaction, the materials are fed in the following proportions. The molar ratio of the monomers of diethylenetriamine, epichlorohydrin and dimethyldiallylammonium chloride (DMDAAC) is 3:2:1. The prepared fixing agent The solid content is 15%.

Embodiment 3

[0023] Add water and diethylenetriamine (AE) into the reaction vessel, heat up to 45°C while stirring, add epichlorohydrin (EP) dropwise, and continue the reaction for 1 hour after the dropwise addition. The pH of the reaction solution is 8 , Adjust to 6 with glacial acetic acid, continue heating to 60℃, add dimethyl diallyl ammonium chloride (DMDAAC) dropwise, react for 4 hours after the dropwise addition, obtain the pH value of the reaction solution 7.5, cool to At room temperature, the finished product will be obtained after discharging. In the reaction, the materials are fed in the following proportions. The molar ratio of the monomers of diethylenetriamine, epichlorohydrin and dimethyldiallylammonium chloride (DMDAAC) is 4:2:1. The prepared fixing agent is The solid content is 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com