Water-based color ink-jet printing medium and production method thereof

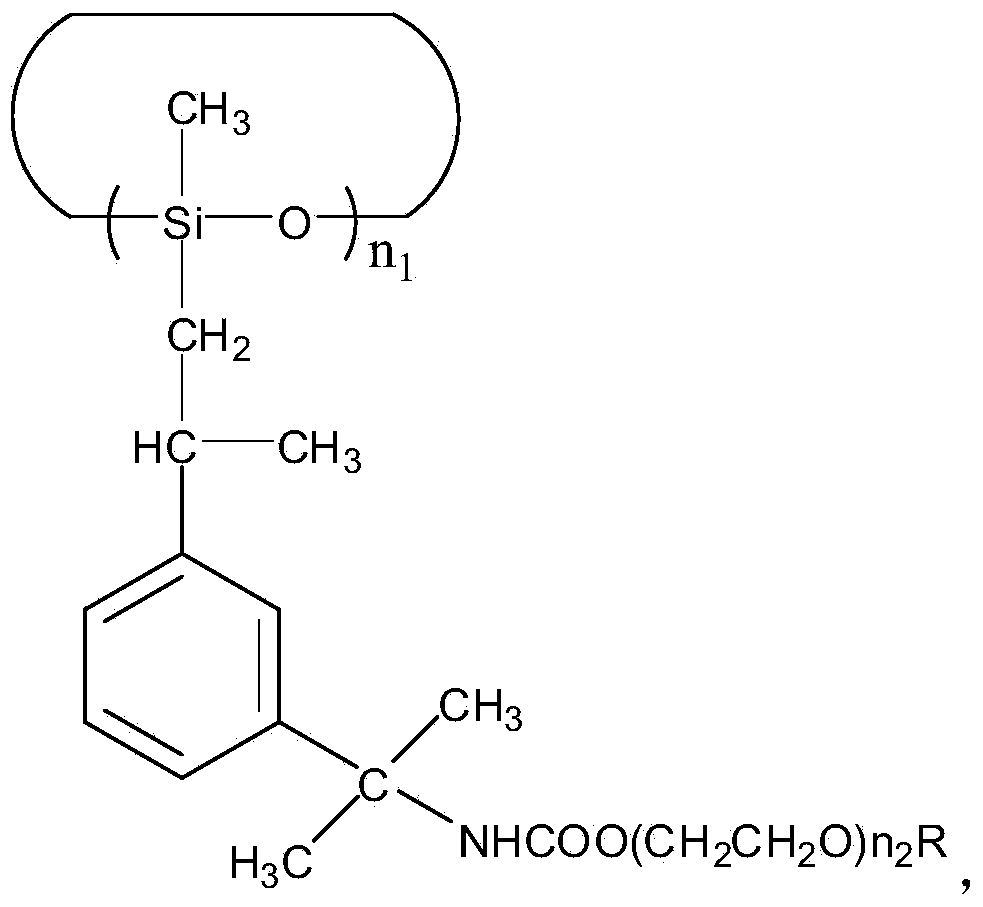

A color inkjet and printing media technology, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of easy peeling of layers, short storage time of printed products, blurred images, etc., to improve printing color density and water resistance performance, improved color fixation and water repellency, enhanced rheological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

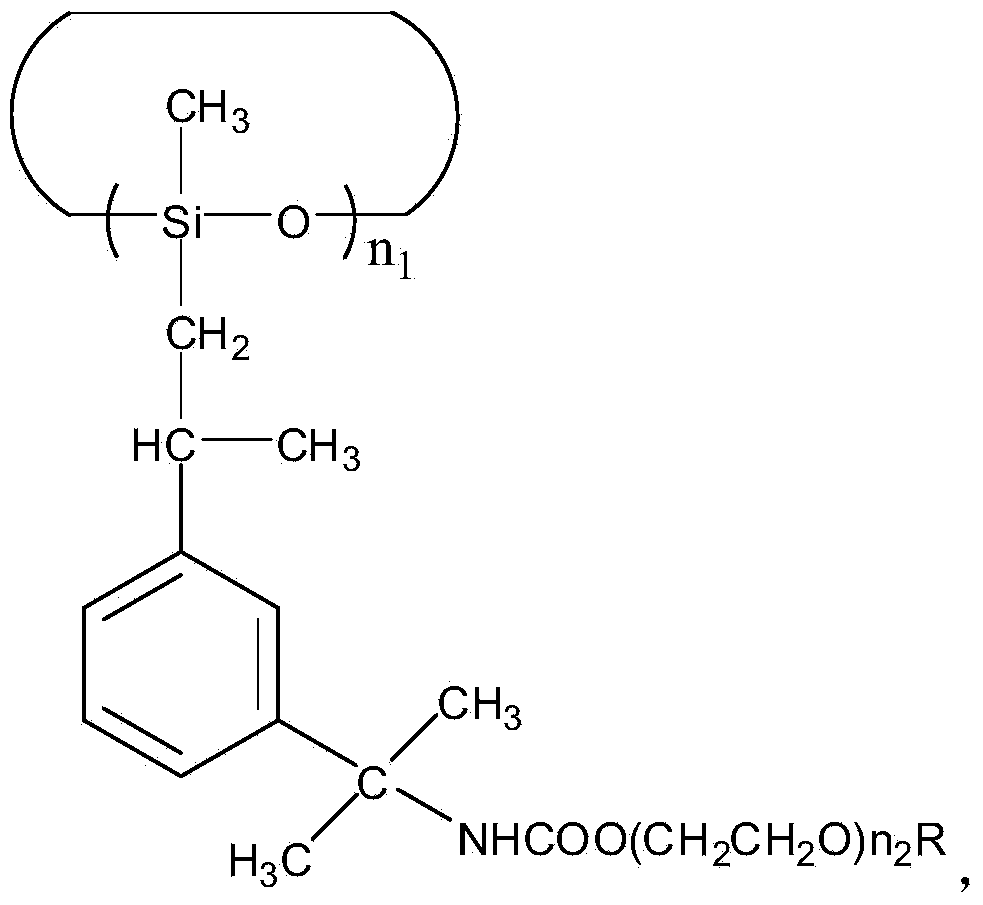

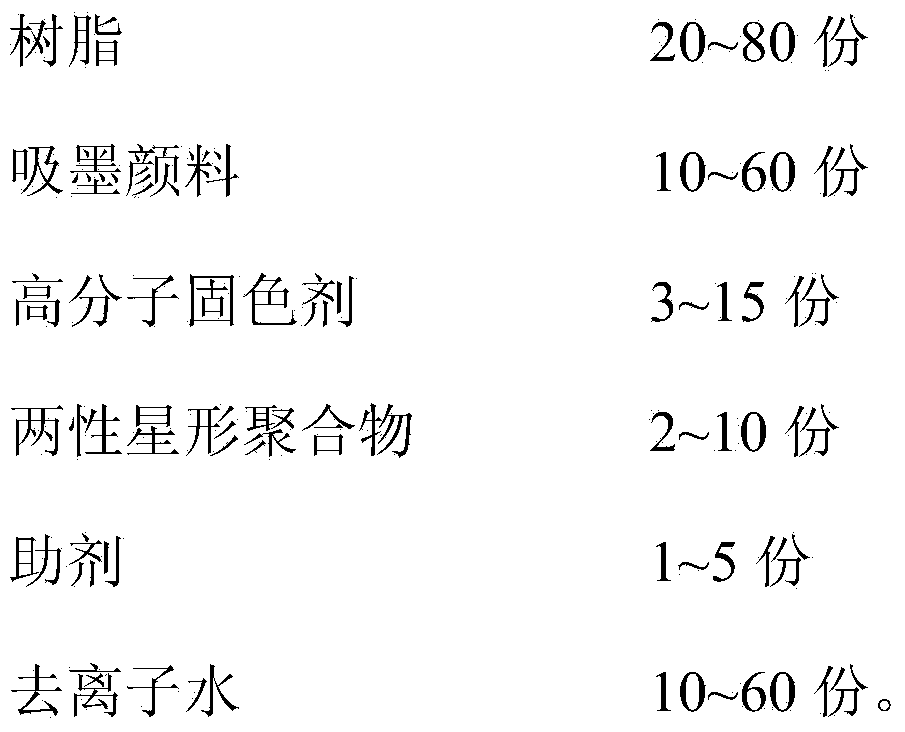

[0028] The material formula of the ink-absorbing layer is: 30 parts of 3-9 μm precipitated silica, 15 parts of 10-20 μm precipitated silica, 2 parts of polycarboxylate sodium salt ink-absorbing pigment dispersant, 10 parts of 2699 polyvinyl alcohol, vinyl acetate 30 parts of ester-ethylene copolymer, n 1 = 3, n 2 =10, 5 parts of amphoteric star-shaped polymers of R=CH2Cl, 8 parts of epichlorohydrin dimethylamine polymer color fixing agents and 15 parts of water;

[0029] The preparation process of the ink-absorbing layer material is as follows: add deionized water into the dispersion tank, turn the mixer to add the ink-absorbing pigment dispersant, increase the rotation speed to 800RPM, disperse for 10-20min, and increase the rotation speed to 2500RPM-3000RPM after adding the ink-absorbing pigment. Continue to disperse for 20-30 minutes, filter the dispersion liquid into the mixing tank and add polymer color fixing agent, surfactant and other additives, then add resin, contin...

Embodiment 2

[0032] The formula of the ink-absorbing layer material is: 30 parts of 3-9 μm precipitated silica, 15 parts of 10-20 μm silica, 2 parts of polycarboxylate sodium salt dispersant, 10 parts of 2099 polyvinyl alcohol, 30 parts of vinyl acetate-ethylene copolymer copies, n 1 = 4, n 2 =10, R=CH 2 CH 2 8 parts of COOH amphoteric star polymer, 8 parts of epichlorohydrin dimethylamine polymer fixing agent and 15 parts of water;

[0033] The ink-absorbing layer material preparation process of embodiment 2 is the same as embodiment 1;

[0034] The printing medium production process of Example 2: Corona is carried out on PVC, and the corona dyne value reaches 40-42. Use a scraper to coat a 15 μm acrylic resin primer on the substrate, and after drying in an oven at 90-100 ° C, continue Use a scraper to coat a 30μm ink-absorbing layer on the primer layer and dry it in an oven at 80-110°C.

Embodiment 3

[0036] The material formula of the ink-absorbing layer is: 30 parts of 3-9 μm precipitated silica, 15 parts of 10-20 μm silica, 2 parts of polycarboxylate sodium salt dispersant, 10 parts of 2499 polyvinyl alcohol, 25 parts of polyurethane resin, n 1 =5,n 2 =12, R=C 5 h 11 NH 2 10 parts of amphoteric star polymers, 8 parts of epichlorohydrin dimethylamine polymer fixing agent and 15 parts of water;

[0037] The preparation method of the ink-absorbing layer material is: add deionized water into the dispersion tank, turn the mixer to add sodium salt dispersant, increase the speed to 800RPM to disperse for 10-20min, add two kinds of silica pigments, increase the speed to 2500-3000RPM and continue to disperse for 20 minutes. ~30min, filter into the mixing tank, slow down and stir, add epichlorohydrin dimethylamine polymer color fixing agent, surfactant and other additives, add polyurethane resin, star polymer resin, continue to stir at 200~300RPM for 30min ;

[0038] Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com