Preparation method of spandex with reactive dye easy-dying function

A reactive dye and spandex technology, which is applied in the field of polyurethane elastic fiber material manufacturing, can solve the problems of spandex fiber damage, uneven dyeing of cloth surface, low dye uptake rate, etc., and achieve enhanced reactivity, improved dye uptake effect and color fixation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

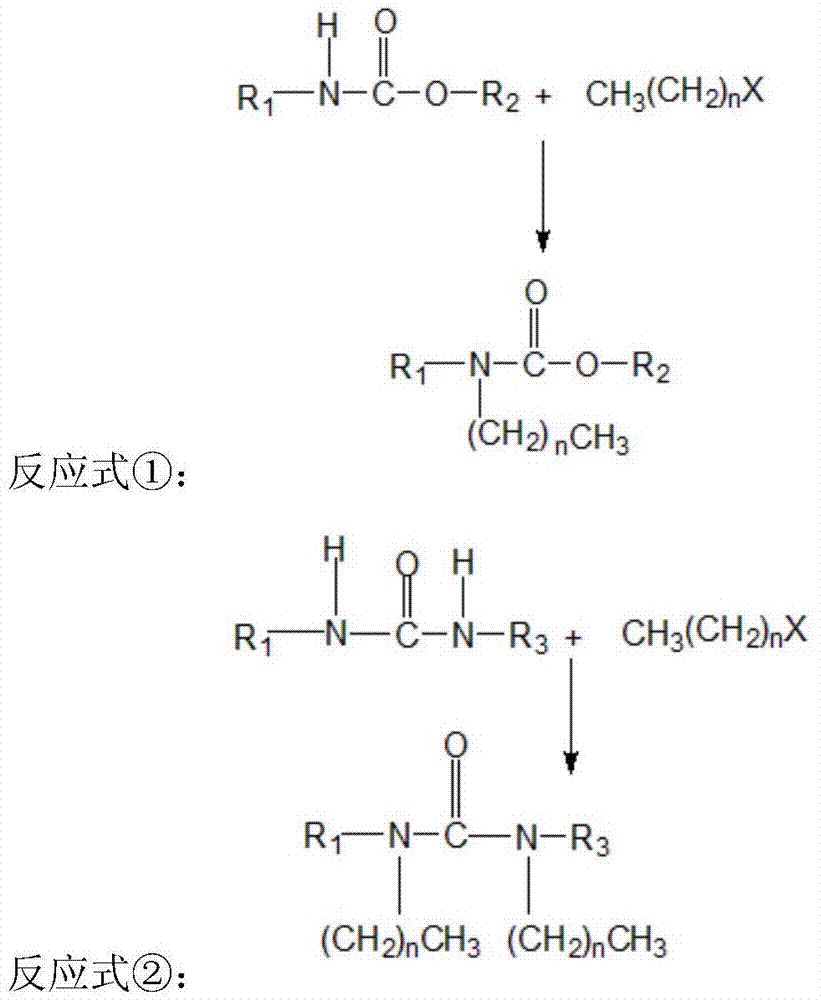

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of reactive dye easily dyeable spandex of the present invention comprises the following steps:

[0027] 1) Add the modification additive to N,N-dimethylacetamide DMAC, stir well for 1 hour, make it uniformly dispersed in the solvent, and form a stable solution for use;

[0028] 2) In the prepolymerization tank, add DMAC and polytetramethylene ether glycol PTMG in sequence, and then add 4,4-diphenylmethane diisocyanate 4,4-MDI according to the set NCO / OH ratio, and fully carry out prepolymerization reaction;

[0029] 3) Transfer the prepolymerization product to the chain extension tank, stir evenly, and at low temperature, control dropwise the mixed amine DMAC solution containing diamine chain extender and monoamine terminator to carry out chain extension and chain termination, and finally obtain polyurethane Urea solution;

[0030] 4) Add a certain proportion of modification aid / DMAC solution to the prepared polyurethane urea solution, per...

Embodiment example 1

[0044] Step 1. Add 5.71kg of hexadecane bromide to 13.32kg of N,N-dimethylacetamide (DMAC) at 40°C, and stir thoroughly for 1 hour to form a stable solution for use.

[0045] Step 2. Add 5kg N,N-dimethylacetamide and 10kg polytetramethylene ether glycol (molecular weight 1800) into the prepolymerization tank, stir and mix well, and when the temperature reaches about 25°C, follow the NCO / Add 2.281kg of 4,4-diphenylmethane diisocyanate to an OH of 1.65, raise the temperature to 45°C, and the reaction time is 120min to obtain a prepolymerized product;

[0046] Step 3. Cool the chain extension tank to 0-10°C, and add chain extension amine solution (including 29.22g propylenediamine, 213.21g ethylenediamine, 37.2g diethylamine, 4851.2gN, N-dimethylethylene Amide), under the condition of rapid stirring, carry out chain extension reaction, obtain polyurethane urea solution;

[0047] Step 4. Add the hexadecane bromide / DMAC solution configured in step 1 to the prepared polyurethane u...

Embodiment example 2

[0051] Step 1. Add 5.45 kg of chlorooctadecane to 11.6 kg of N,N-dimethylacetamide (DMAC) at 45° C. and stir thoroughly for 1 hour to form a stable solution for use.

[0052] Step 2. Add 5kg N,N-dimethylacetamide and 10kg polytetramethylene ether glycol (molecular weight 1800) into the prepolymerization tank, stir and mix well, and when the temperature reaches about 25°C, follow the NCO / Add 2.281kg of 4,4-diphenylmethane diisocyanate to an OH of 1.65, raise the temperature to 45°C, and the reaction time is 120min to obtain a prepolymerized product;

[0053] Step 3. Cool the chain extension tank to 0-10°C, and add chain extension amine solution (including 29.22g propylenediamine, 213.21g ethylenediamine, 37.2g diethylamine, 4851.2gN, N-dimethylethylene Amide), under the condition of rapid stirring, carry out chain extension reaction, obtain polyurethane urea solution;

[0054] Step 4. Add the chlorooctadecane / DMAC solution configured in step 1 to the prepared polyurethane ure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com