One-step paper deacidification strengthening and enhancing agent and method

A technology of reinforcing agent and paper, applied in the post-processing of waste paper, etc., to achieve the effect of improving bursting resistance, short processing time, and slowing down corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

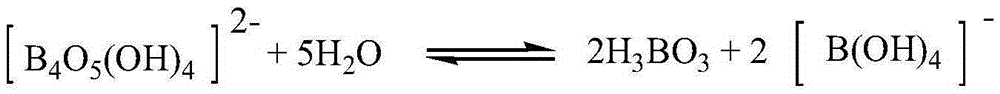

Method used

Image

Examples

Embodiment 1

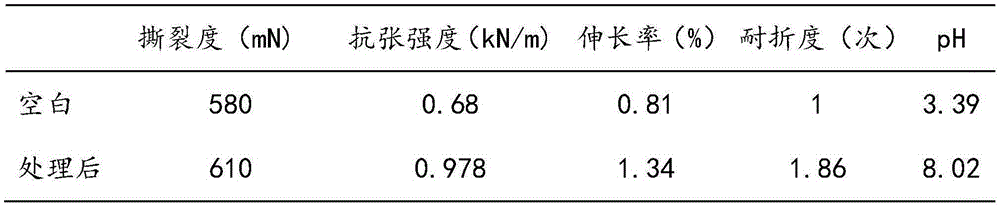

[0035] Cut about 30g of the 1986 newspaper ("Mei Xing Daily") for later use, weigh 0.3g of cationic etherified starch and mix with 2.1g of sodium tetraborate, add 80mL of deionized water and heat to 90°C, add water to 500mL, and keep at 30°C spare. Pour the deacidification and strengthening agent into the deacidification and strengthening tank, then add the newspapers cut above into the deacidification and strengthening tank, soak for 30 minutes for deacidification. After the paper is dried, let it stand under constant temperature and humidity conditions, and measure the mechanical strength and acidity of the paper after 72 hours.

[0036] The results are shown in the table below:

[0037]

Embodiment 2

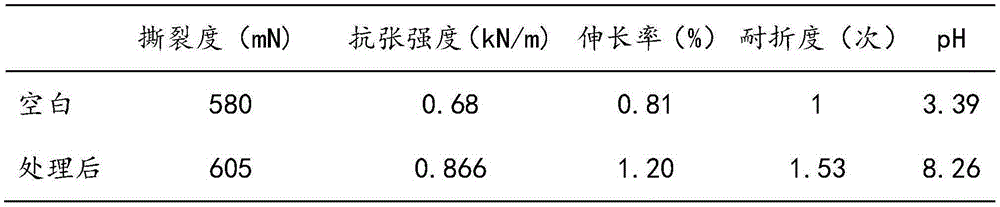

[0039] Cut out about 30g of the 1986 newspaper ("Mei Xing Daily") for later use, weigh 0.09g of cationic etherified starch, 3.0g of potassium tetraborate and mix, add a small amount of deionized water and heat to 90°C, add water to 500mL, and keep at 25°C spare. Pour the deacidification and strengthening agent into the deacidification and strengthening tank, then add the newspapers cut above into the deacidification and strengthening tank, soak for 30 minutes for deacidification. After the paper is dried, let it stand under constant temperature and humidity conditions, and measure the mechanical strength and acidity of the paper after 72 hours.

[0040] The results are shown in the table below:

[0041]

Embodiment 3

[0043] Cut out about 30g of the 1986 newspaper ("Mei Xing Daily") for later use, weigh 0.1g of cationic etherified starch and 2.3g of lithium tetraborate and mix, add a small amount of deionized water and heat to 90°C, add water to 500mL, and keep at 60°C spare. Pour the deacidification and strengthening agent into the deacidification and strengthening tank, then add the newspapers cut above into the deacidification and strengthening tank, soak for 30 minutes for deacidification. After the paper is dried, let it stand under constant temperature and humidity conditions, and measure the mechanical strength and acidity of the paper after 72 hours.

[0044] The results are shown in the table below:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com