Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144 results about "Hydracrylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

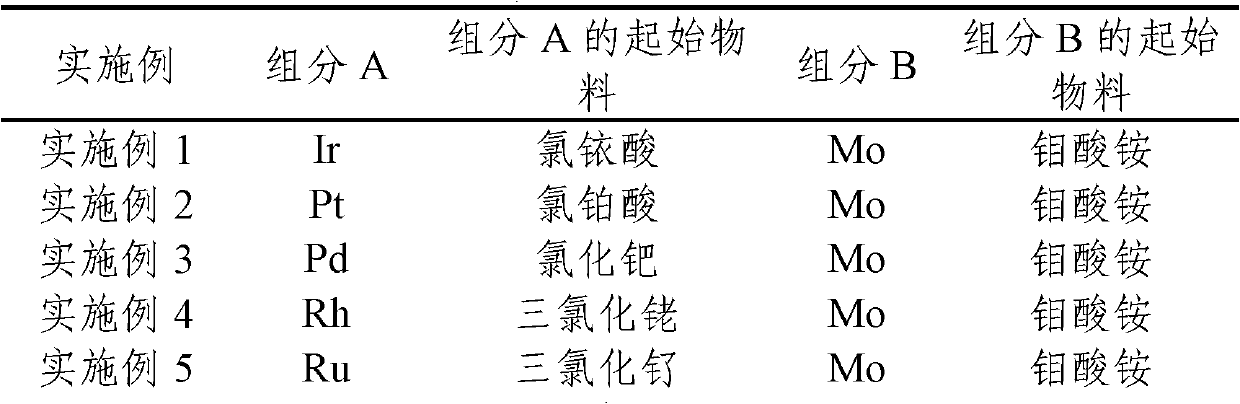

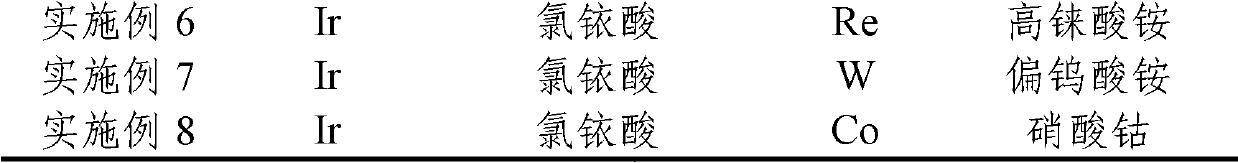

Method for preparing monohydric alcohol or dihydric alcohol through organic acid hydrogenation

ActiveCN103288596AOrganic compound preparationHydroxy compound preparation3-Hydroxypropionic acidPropanoic acid

The invention relates to a method for preparing monohydric alcohol or dihydric alcohol through organic acid hydrogenation. According to the method, any one of acetic acid, propionic acid, valeric acid, stearic acid, oleic acid, palmitic acid, levulinic acid, lactic acid, succinic acid, 3-hydracrylic acid and other organic acids is taken as a reactant, and an A-B / X supported catalyst is adopted, wherein the component A is any one or more than two from Ir, Pt, Pd, Rh and Ru, the assistant B is any one or more than two from Mo, Re and W, the carrier X is any one in SiO2, activated carbon, titanium oxide, zirconium oxide, SiO2-Al2O3 (the mass content of Al2O3 accounts for 17 percent) and molecular sieves, the mass load amount of A in the catalyst is 0.5-10 percent, the molar ratio of the assistant B to A is 0.01-1.0, the reaction pressure is 2-20 MPa, and the reaction temperature is 40-180 DEG C. The catalyst has the characteristics of mild reaction conditions, high reaction activity and good selectivity, and a novel effective way for preparing monohydric alcohol or dihydric alcohol from biomass is provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

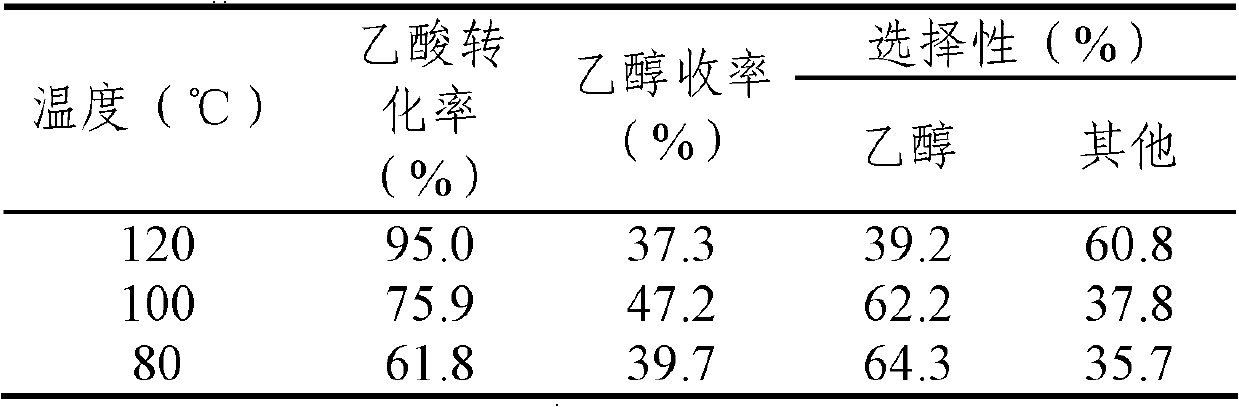

Asymmetric synthesis method of (+)-tanshinol

InactiveCN102924265ARaw materials are easy to getSimple and fast operationOrganic compound preparationCarboxylic compound preparationPropanoic acidCombinatorial chemistry

The invention relates to an asymmetric synthesis method of (+)-tanshinol, which comprises the following steps: carrying out Knoevenagel condensation on the raw material heliotropin, hydrolyzing for ring opening to obtain beta-(3,4-3,4-methylenedioxyphenyl)pyruvic acid, carrying out key asymmetric reduction reaction to obtain R-beta-(3,4-dibenzyloxyphenyl)-alpha-hydracrylic acid, and finally, deprotecting to obtain the (+)-tanshinol. The method has the advantages of accessible raw material and high optical purity of the product, is simple to operate, and can implement large-scale preparation.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Method for producing 1-propylene glycol with 3-hydracrylic acid methyl ester

InactiveCN101195558AHigh catalytic activityHigh selectivityOxygen-containing compound preparationOrganic compound preparationPropylene glycolMethyl propionate

The invention relates to a method for preparing 1, 3-propylene glycol reaction hydrogenated by 3-hydroxy methyl propionate, which adopts CuO-SiO2 as catalyst and can realize 1, 3-propylene glycol reaction hydrogenated by 3-hydroxy methyl propionate under milder conditions, wherein the highest conversion rate of 3-hydroxy methyl propionate is 97.8% and the highest selectivity of 1, 3-propylene glycol is 93.4%.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Amino acid anti-aging cream

InactiveCN101797213AImprove antioxidant capacityAnti-aging function is obviousCosmetic preparationsToilet preparationsLanolinAmino acid

The invention discloses an amino acid anti-aging cream which comprises three components A, B and C in parts by weight, the component A comprises the following materials in parts by weight: 18-25 parts of ozocerite, 4-7 parts of octadecanoic acid, 4-6 parts of stearyl alcohol, 2-5 parts of sp-60, 2-4 parts of Tween-60, 1-3 parts of hydrogenated lanolin, 1-2 parts of beewax and 0.1-0.3 part of propyl p-hydroxybenzoate; the component B comprises the following materials of 50-60 parts of distilled water, 3-8 parts of propylene glycol, 3-5 parts of cysteine, 1-3 parts of gamma-amino-beta-hydracrylic acid and 0.1-0.3 part of methyl parahydroxybenzoats; and the component C comprises the following material of 0.5-1 part of essence.

Owner:任芳芳

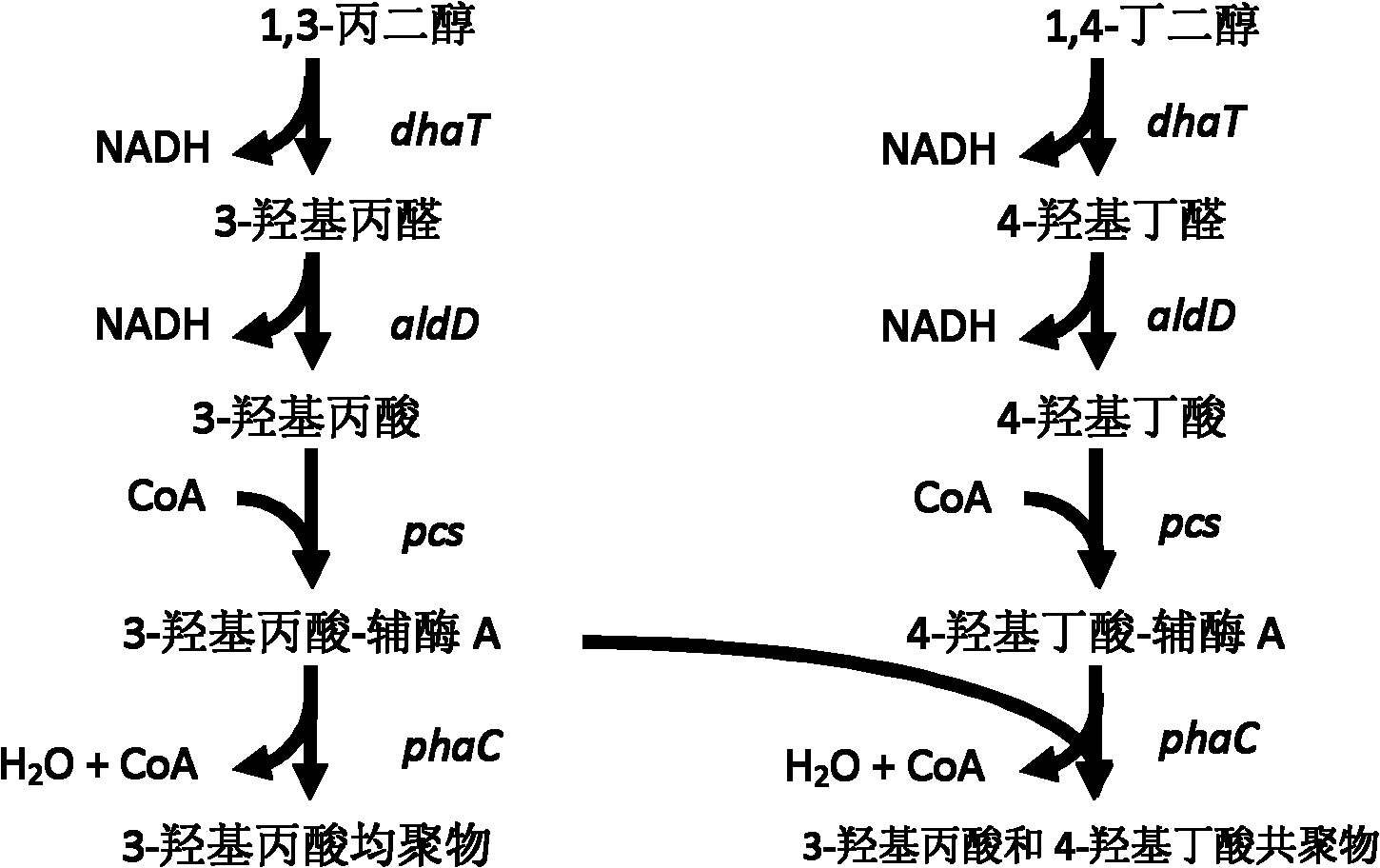

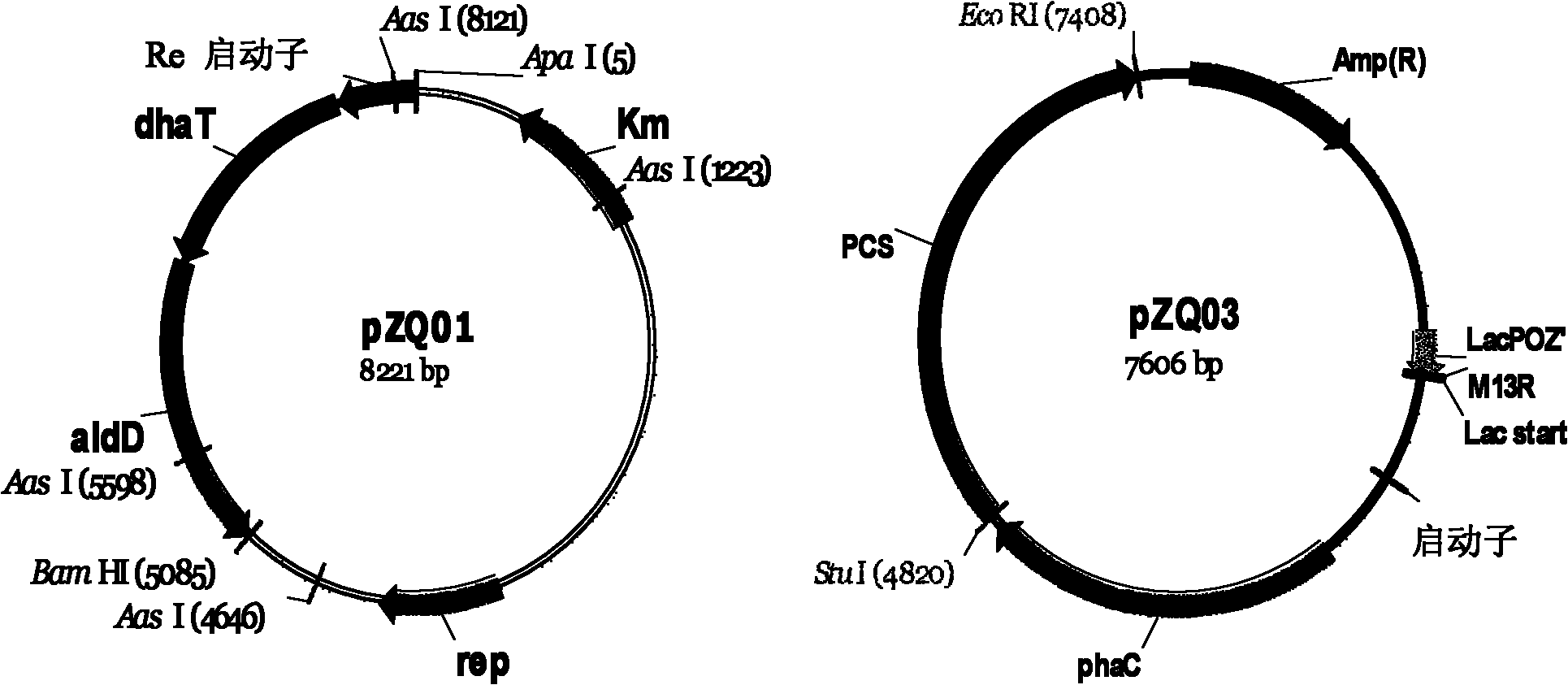

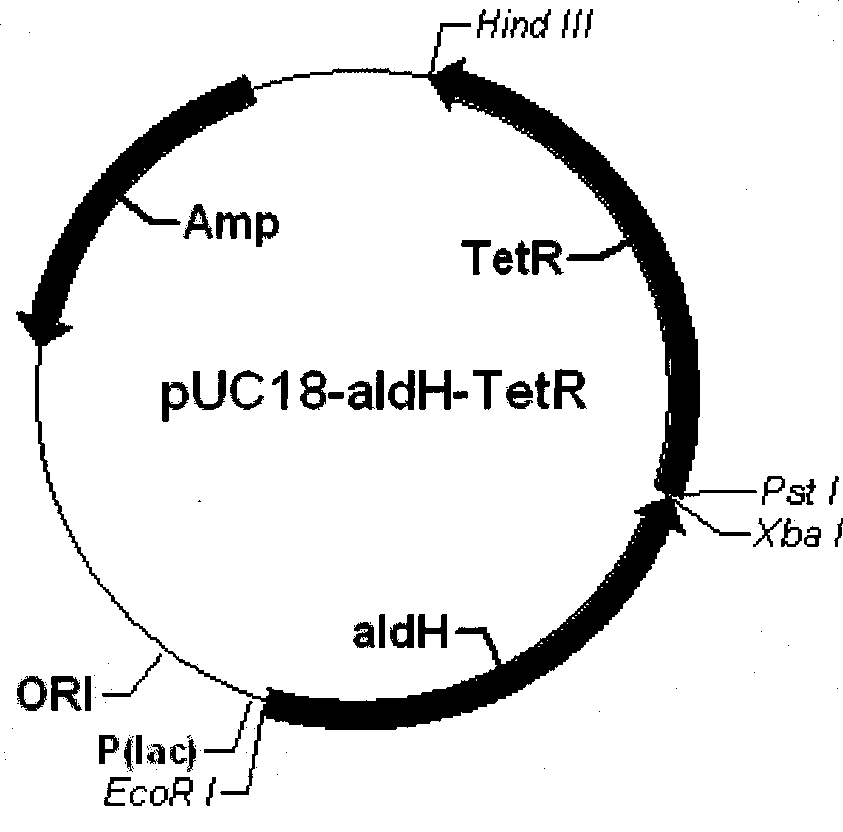

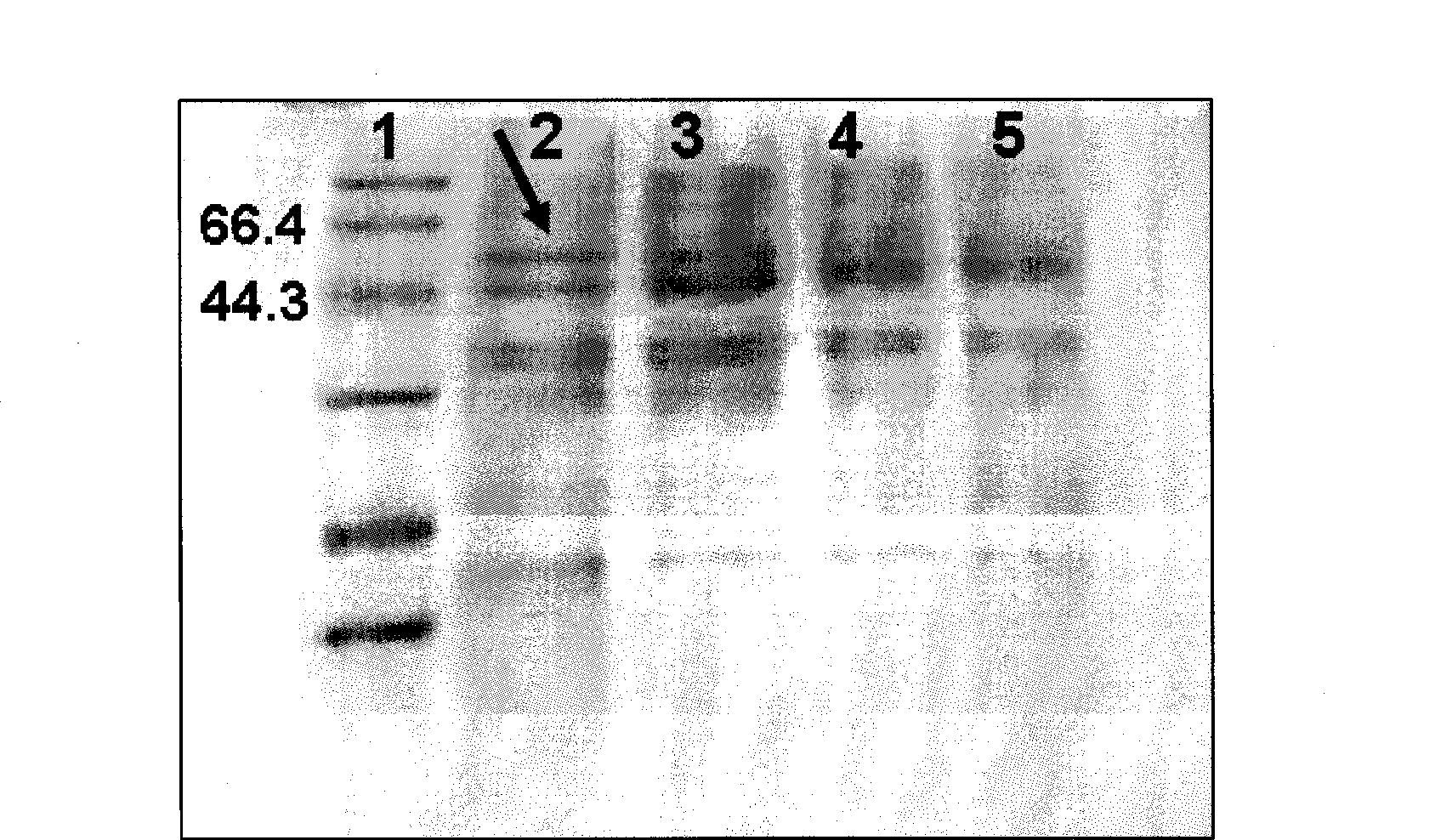

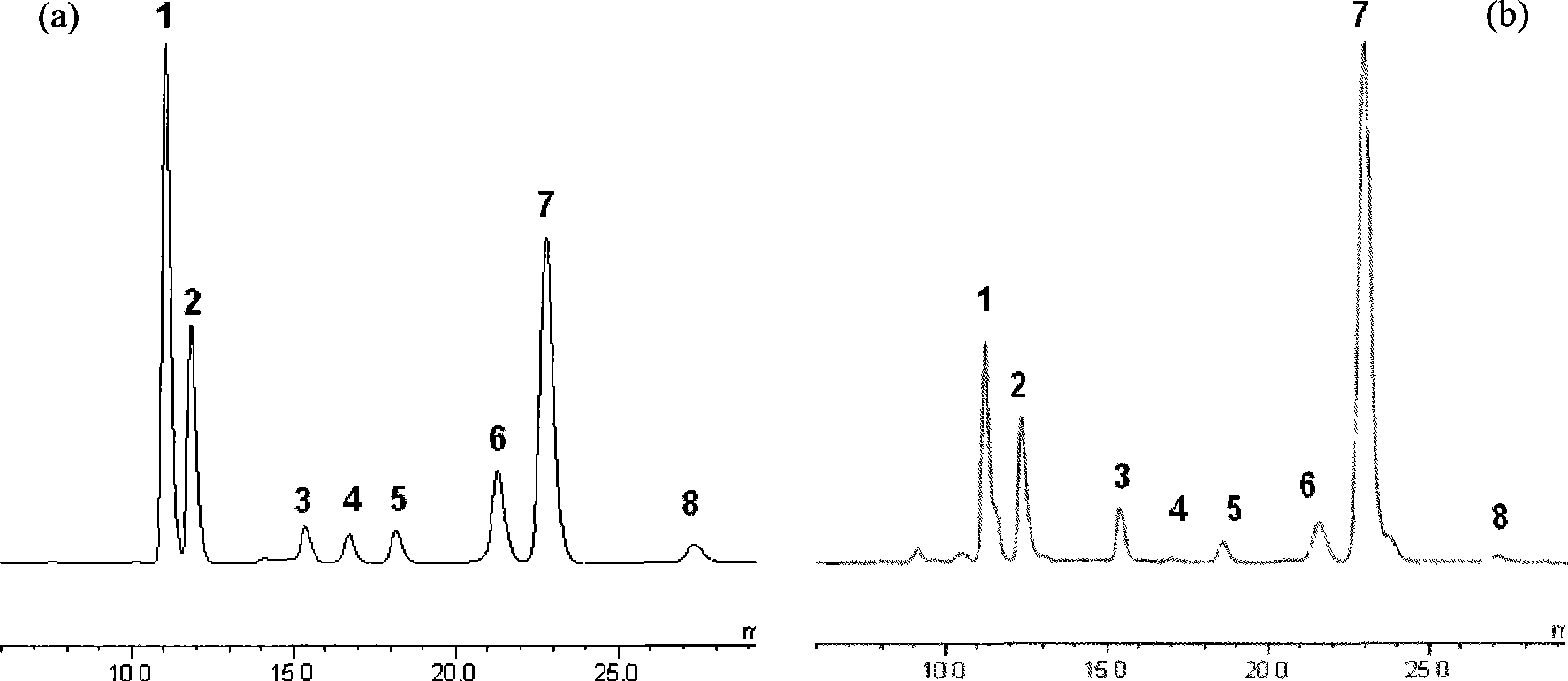

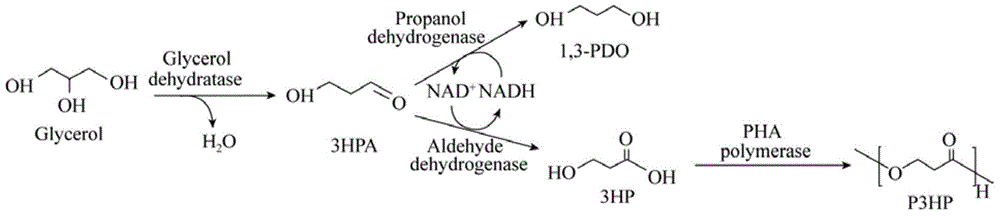

Recombinant strain for producing 3-hydracrylic acid homopolymer and/or 3-hydracrylic acid copolymer and application thereof

ActiveCN102174542AImprove conversion efficiencySimple production processBacteriaMicroorganism based processes3-Hydroxypropionic acidPolymerase L

The invention discloses a recombinant strain for producing a 3-hydracrylic acid homopolymer and / or a 3-hydracrylic acid copolymer and an application thereof. The construction method of the recombinant strain comprises the following steps: leading 1,3-Propanediol dehydrogenase coded genes, aldehyde dehydrogenase coded genes, 3-hydracrylic acid coenzyme A ligase coded genes and PHA (Polyhydroxyalkanoates) polymerase coded genes into a starting strain to obtain the recombinant strain. The experiments in the invention prove that the engineering bacteria can efficiently express 3-hydracrylic acid coenzyme A ligase coded genes and PHA polymerase coded genes and enable the 3-hydracrylic acid to be finally polymerized into 3-hydracrylic acid homopolymer (P(3HP)) from the 3-hydracrylic acid coenzyme A. Minitype fermentation tank experiments show that the engineering bacteria provided by the invention can have a maximum P (3HP) output of 8.9g / L after being fermented in a 6L fermentation tank and the P (3HP) can account for a maximum 91.5% of cell dry weight. In addition, the recombinant strain provided by the invention has the advantages of simple production process, low costs and broad application prospects.

Owner:TSINGHUA UNIV

Catalyzer for preparing 1, 3-trimethylene glycol from 3-hydracrylic acid ester through hydrogenation and preparation method thereof

ActiveCN101176848AEasy to prepareRaw materials are cheap and easy to getOrganic chemistryPhysical/chemical process catalystsFour componentSalt solution

The invention relates to the technical field of catalysts, in particular to a catalyst for hydrogenating 3-hydroxypropionate to prepare 1,3-propanediol and a preparation method thereof. The catalyst of the present invention is composed of CuO, ZnO, P and SiO2 four components, and the weight percentage of each component is CuO 25%~60%, ZnO 1%~30%, P 0.01%~10%, SiO2 30%~60% %, the total amount of the four components satisfies 100%. The preparation method of the catalyst is to first complex the copper salt and the ammonium salt and then blend them with a salt solution containing a certain amount of Cu and Zn, then add ammonium hypophosphite and silica sol in turn, and undergo aging, filtration, drying, molding, and high-temperature roasting. The obtained catalyst can be used to hydrogenate 3-hydroxy propionate to prepare 1,3-propanediol after being reduced in a reactor. The catalyst preparation method of the invention is simple and convenient, has long service life, good stability and high selectivity of 1,3-propanediol.

Owner:SHANGHAI HUAYI ENERGY CHEM

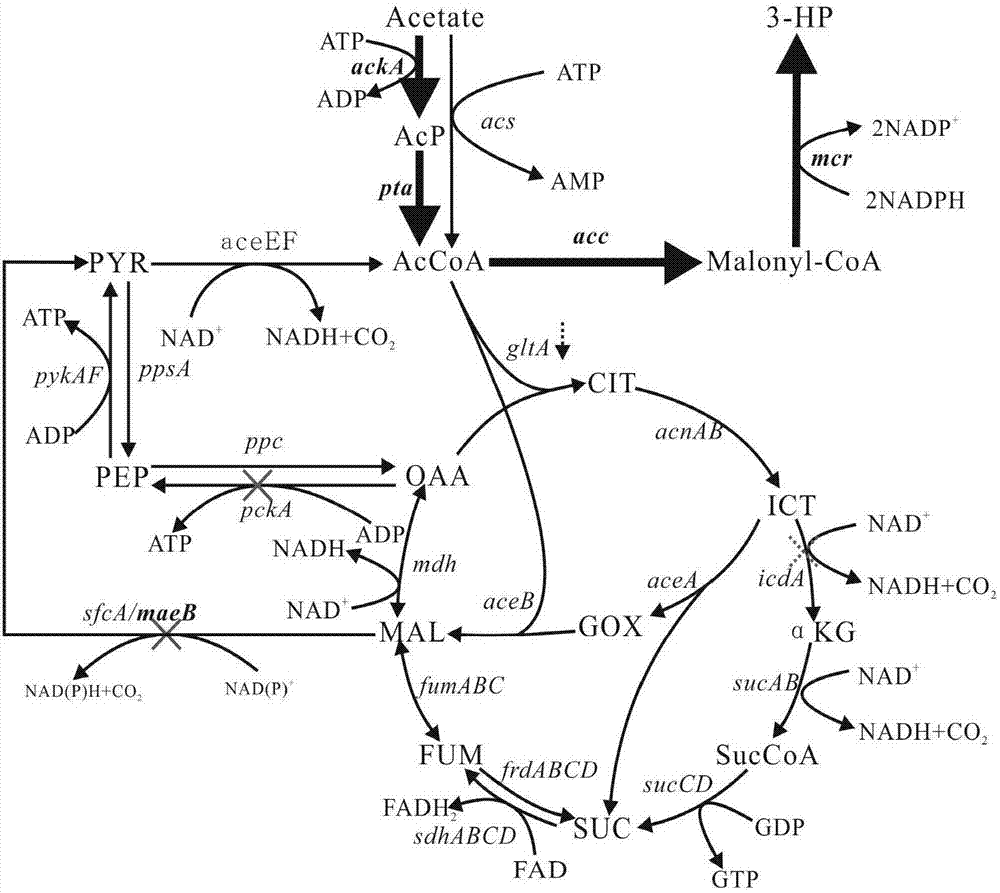

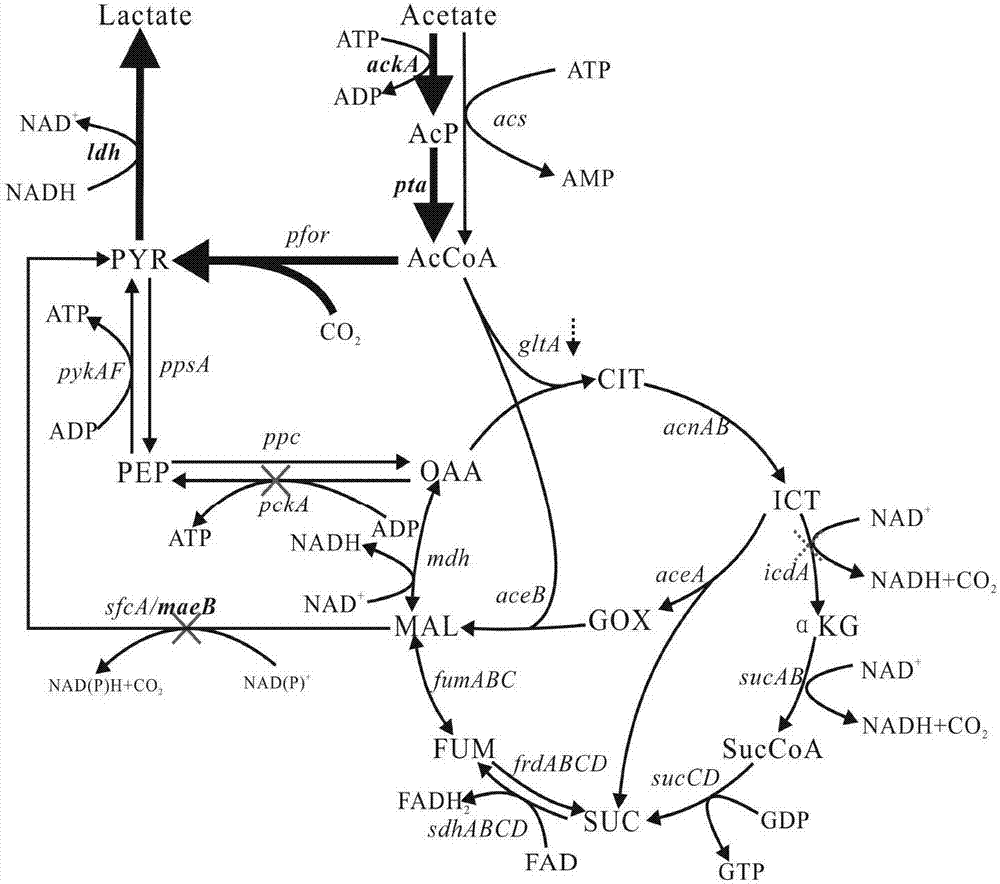

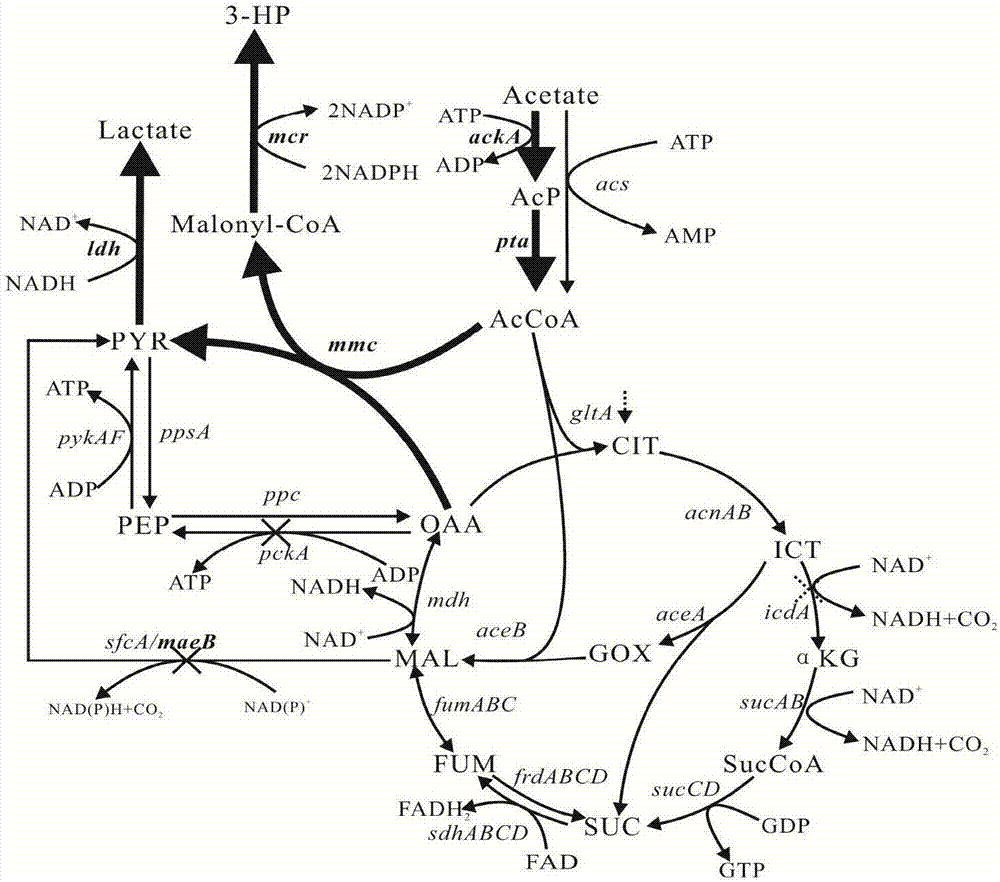

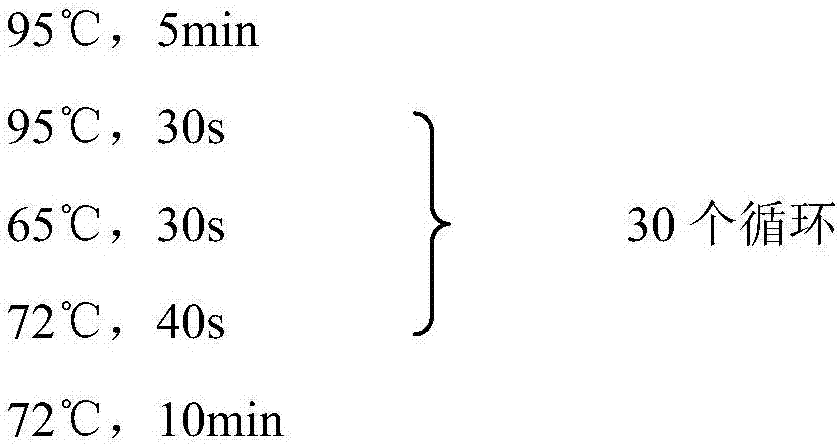

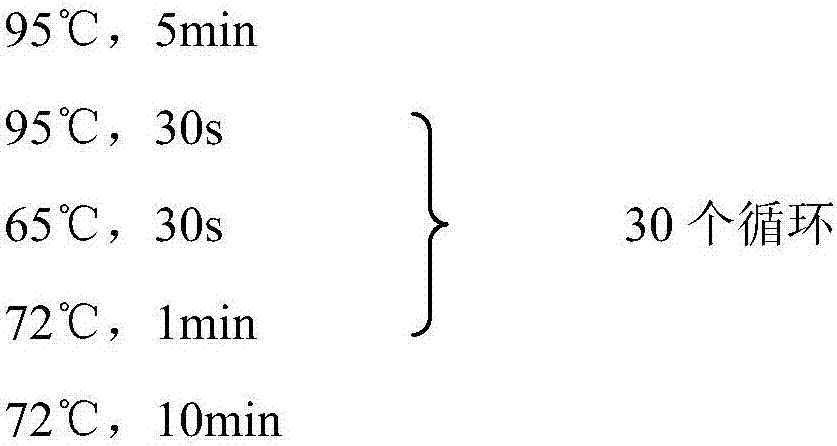

Construction method and application of metabolic engineering escherichia coli strain for producing hydracrylic acid from acetic acid

The invention discloses a construction method of a metabolic engineering escherichia coli strain for producing hydracrylic acid from acetic acid. Escherichia coli reformed by metabolic engineering isutilized for producing hydracrylic acid by fermenting acetic acid; and construction ways are as follows: constructing a metabolic way for producing hydracrylic acid from acetyl CoA, and / or over-expressing relevant genes of an acetic acid intake way so as to increase the transmission rate of acetic acid, and / or blocking or decreasing TCA circle so as to increase metabolic flow of acetyl CoA flowingtowards a target metabolite, and / or reducing decarboxylic reaction between malic acid or oxaloacetic acid so as to delete a byproduct generation way, and / or deleting key genes in an alcohol production way so as to regulate metabolic flow of an acetyl CoA node and / or regulating intracellular oxidation reduction balance through coenzyme engineering. According to the construction method, a production way for exogenously expressing hydracrylic acid is constructed, the metabolic ways, the adjustment and control are analyzed, and escherichia coli is reformed by virtue of a metabolic engineering measure, so that the prepared strain can be utilized for producing hydracrylic acid in a culture medium taking acetic acid as a carbon source.

Owner:EAST CHINA UNIV OF SCI & TECH

Recombinant bacterium of synthesizing 3-hydracrylic acid, construction method and application of recombinant bacterium

The invention provides a recombinant bacterium of synthesizing 3-hydracrylic acid, and a construction method and preparation of the recombinant bacterium and belongs to the fields of gene engineering and fermentation engineering. A host bacterium of the recombinant bacterium is escherichia coli, and the recombinant bacterium expresses and codes gene clpP of an ATP (adenosine triphosphate) dependent protease hydrolysis subunit, and codes a gene accABCD of acetylcoenzyme A carboxylase and a gene mcr of malony-coA reductase. A preparation method comprises the steps of obtaining and transforming recombinant vectors pETDuet-clpP-mcr, and pACYCDuet-accADBC into a host competent cell. The recombinant bacterium solves the problem that the increase of a concentration of 3-hydracrylic acid in a microbial fermentation process inhibits microbial growth to influence a yield; a fermentation level is increased by 116% compared with that of strains of the ATP dependent protease hydrolysis subunit without expression and coding; and the level is the highest known shake flask fermentation level.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

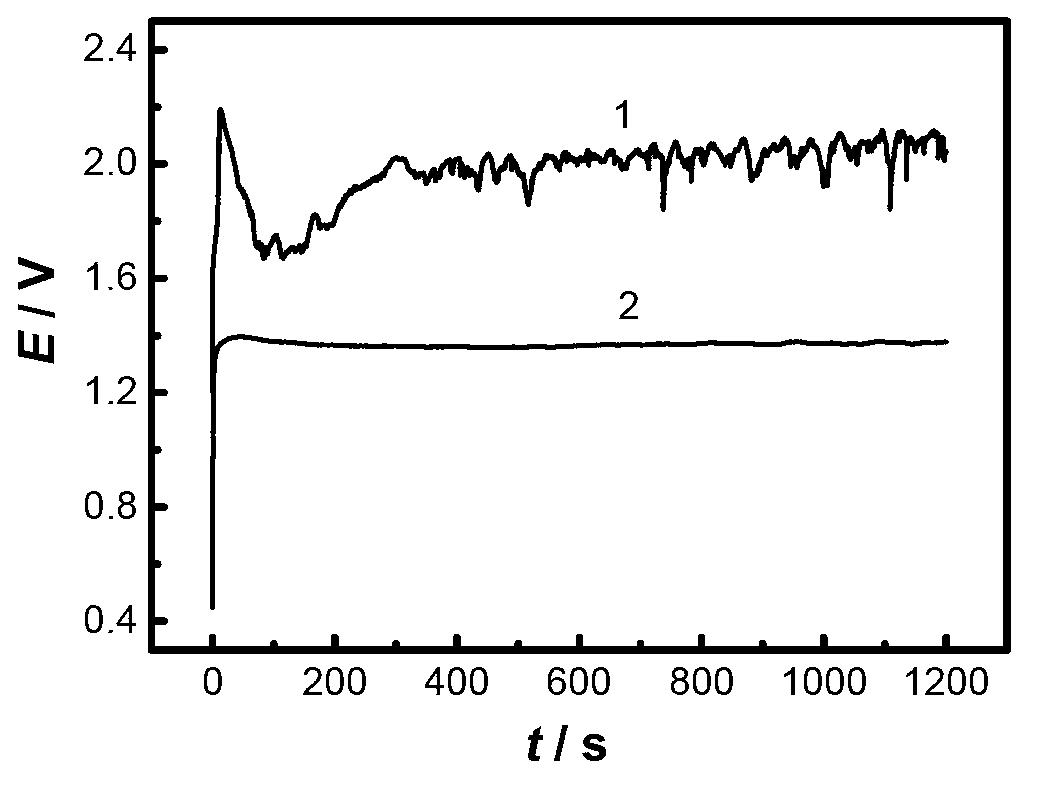

Electroplating additive and its preparation method

ActiveCN1733977ASuppress generationEliminate compressive stressSoldering apparatusSynthesis methodsPhenol

The invention relates to synthesis method for leadless pure tin electroplating additive. Wherein, mixing lauryl phenol polyoxydivinyl ether, polyoxyethylene aniline ether, N, N-diethylm toluidine, hydracrylic acid, acetylglycine acid, naphthalene sulfonic acids, polyoxyethylene polyoxyprophylene propylene, and hydroquinone, and deionized water evenly by turns on given physical conditions; adjusting the constituents to eliminate compressive stress, control crystal process, and form perfect, normal crystallization structure; controlling particle size, thickness of plating layer and tin expansibility to solve generation problem of tin whisker. This invention is also easy to maintenance and needs low consumption.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Transformation microbe generating 3-hydracrylic acid, construction method and application thereof

InactiveCN101519635AImprove stabilityReduce bacterial contaminationBacteriaMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a transformation microbe containing a recombinant vector, wherein the recombinant vector contains protein expressed by a nucleotide sequence shown by a gene code SEQ ID NO.1. A method for preparing the transformation microbe comprises introducing the nucleotide sequence shown by the gene code SEQ ID NO.1 into a host. The transformation microbe containing the recombinant vector is applied to generating 3-hydracrylic acid. A plasmid has high stability in a host strain, and is quite suitable for generating a strain; the final concentration of a product has competitiveness; in addition, trace tetracycline can be added during fermentation so as to achieve the aim of inhibiting part hybrid bacteria, greatly reduce the phenomenon of easily dyeing the hybrid bacteria during industrialization, shorten the fermentation time and lay a good foundation for industrialization production of the 3-hydracrylic acid by a microbe fermentation method.

Owner:NANJING UNIV OF TECH

Method for producing 3-hydracrylic acid

InactiveCN101445813AReduce manufacturing costBacteriaMicroorganism based processesAldehyde oxidaseMicroorganism

The invention discloses a method for producing 3-hydracrylic acid. The method is characterized by taking 1,3-propylene glycol as a raw material, and producing the 3-hydracrylic acid by microbes which express 1,3-propylene glycol dehydrogenase and aldehyde oxidase. The microbes which express the 1,3-propylene glycol dehydrogenase and the aldehyde oxidase are microbes which naturally express the 1,3-propylene glycol dehydrogenase and the aldehyde oxidase, or recombinant microbes which can express the 1,3-propylene glycol dehydrogenase and the aldehyde oxidase and are obtained by transferring coding gene of 1,3-propylene glycol dehydrogenase and coding genes of the aldehyde oxidase into a microbe host. By the method, the 1,3-propylene glycol is taken as the raw material, content of the 3-hydracrylic acid per liter of a culture medium is up to 0.24-12.1g.

Owner:TSINGHUA UNIV

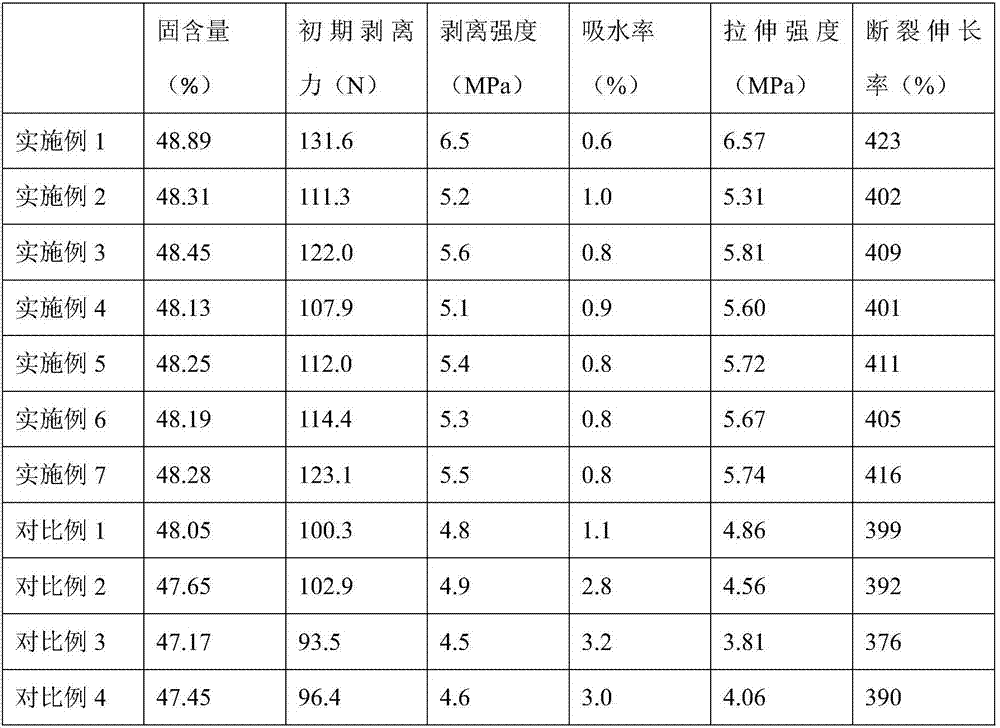

Polyurethane adhesive composition for shoes and preparation method thereof

ActiveCN107236511ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySulfonate

The invention provides a polyurethane adhesive composition for shoes. The polyurethane adhesive composition for shoes is prepared from raw materials including, by weight part, 10-50 parts of polyhydric alcohols, 20-60 parts of isocyanate compounds, 15-25 parts of chain extender, 5-16 parts of modified epoxy resin, 3-10 parts of modified octa (aminophenyltrioxysilane), 1-10 parts of cross-linking agent and 60 parts of deionized water, wherein the chain extender is composed of sodium 2, 4-diaminophenylsulfonate and dimethylolpropionic acid, the modified epoxy resin is organic clay-modified epoxy resin, and organic clay is a compounded composition of 2, 4, 6-trihydroxybenzoic acid grafted with sodium dodecyl sulfonate, and acrylic acid attapulgite; the modified octa (aminophenyltrioxysilane) is octa (aminophenyltrioxysilane) grafted with 3, 4', 5-trihydroxyl-diphenyl; the cross-linking agent is obtained by reacting triethanolamine with 2-hydracrylic acid.

Owner:上海都昱新材料科技有限公司

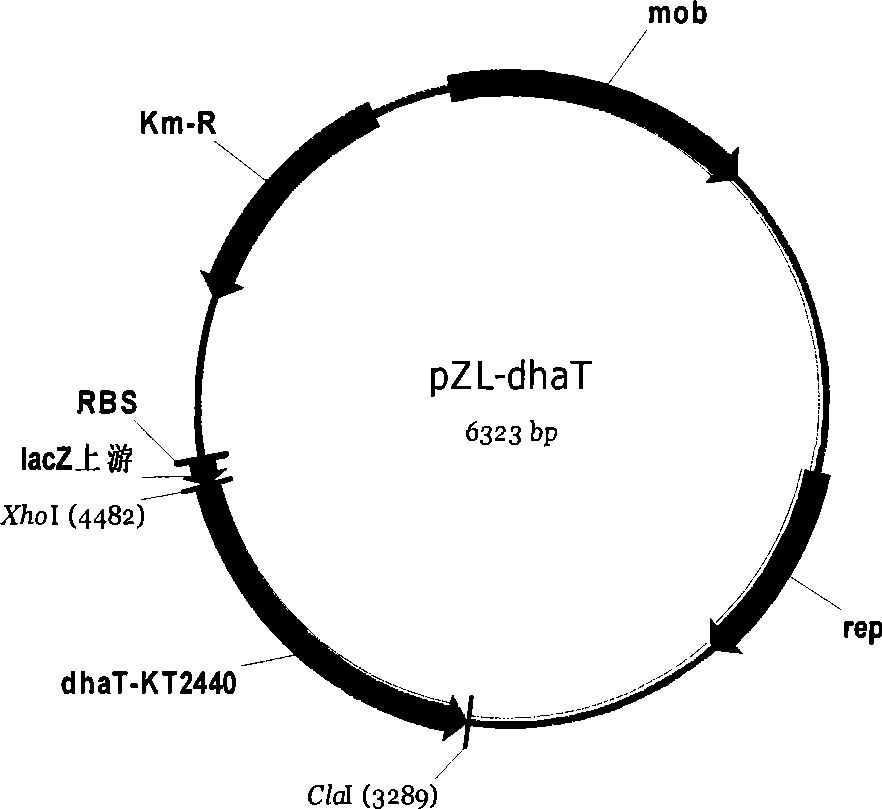

3-hydracrylic-acid-producing recombinant Corynebacterium glutamicum strain, and construction method and application thereof

ActiveCN105950529ASolving Tolerance IssuesAddress biosecurityBacteriaMicroorganism based processes3-Hydroxypropionic acidGlycerol

The invention relates to a 3-hydracrylic-acid-producing recombinant Corynebacterium glutamicum strain, and a construction method and application thereof. The construction method of the recombinant Corynebacterium glutamicum strain comprises the following steps: in a Corynebacterium glutamicum strain, overexpressing an endogenous dihydroxyacetone phosphate phosphatase gene hdpA, and overexpressing a glyceroldehydrogenase gene gldA, a glycerol anhydrase and activating factor gene pduCDEGH and a 3-hydroxypropylaldehyde dehydrogenase gene aldH. When the recombinant strain is used for producing 3-hydracrylic acid by fermentation, the Corynebacterium glutamicum strain can perform fermentation by using different cheap raw materials, thereby further lowering the raw material cost. The 3-hydracrylic-acid-producing recombinant Corynebacterium glutamicum strain solves the problems of biosafety and acid tolerance. The strain in the fermentation process can be used in a feed additive as a product. The method can generate fewer byproducts, so that the separation process of the end product 3-hydracrylic acid is simplified.

Owner:GUANGDONG TSINGDA SMART BIOTECH CO LTD

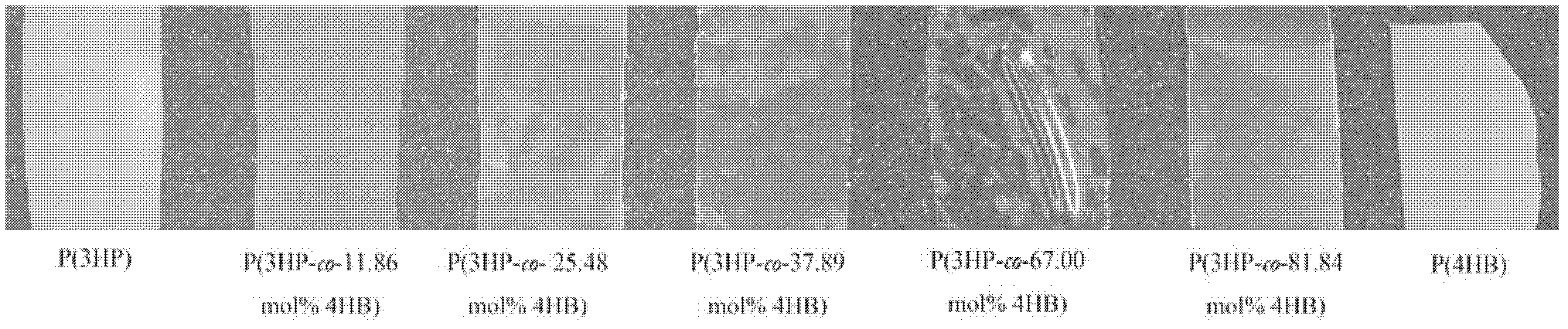

Recombinant bacteria for producing copolymer of 3-hydracrylic acid and 4-hydroxybutyric acid and application thereof

InactiveCN102676567AExcellent thermodynamic propertiesBacteriaMicroorganism based processesHydroxybutyric acid3-Hydroxypropionic acid

The invention discloses recombinant bacteria for producing a copolymer of 3-hydracrylic acid and 4-hydroxybutyric acid and application thereof. According to a method for constructing the recombinant bacteria, a 1,3-propanediol dehydrogenase encoding gene, an aldehyde dehydrogenase encoding gene, 3-hydracrylic acid coenzyme A ligase encoding gene, 4-hydroxybutyric acid coenzyme A transferase encoding gene and a polyhydroxyalkanoate polymerase encoding gene are imported into starting bacteria to obtain the recombinant bacteria. After engineering bacteria are produced in a 500-mL shake flask, the yield of P(3HP-co-4HB) can reach 6.2 g / L, and the maximum P(3HP-co-4HB) reaches 63 percent of the dry weight of cells. According to the recombinant bacteria, a production process is simple, and the thermodynamic property of the produced polymer can be changed by regulating the ratio of 3HP and 4HB, so the recombinant bacteria has bright application prospect.

Owner:TSINGHUA UNIV

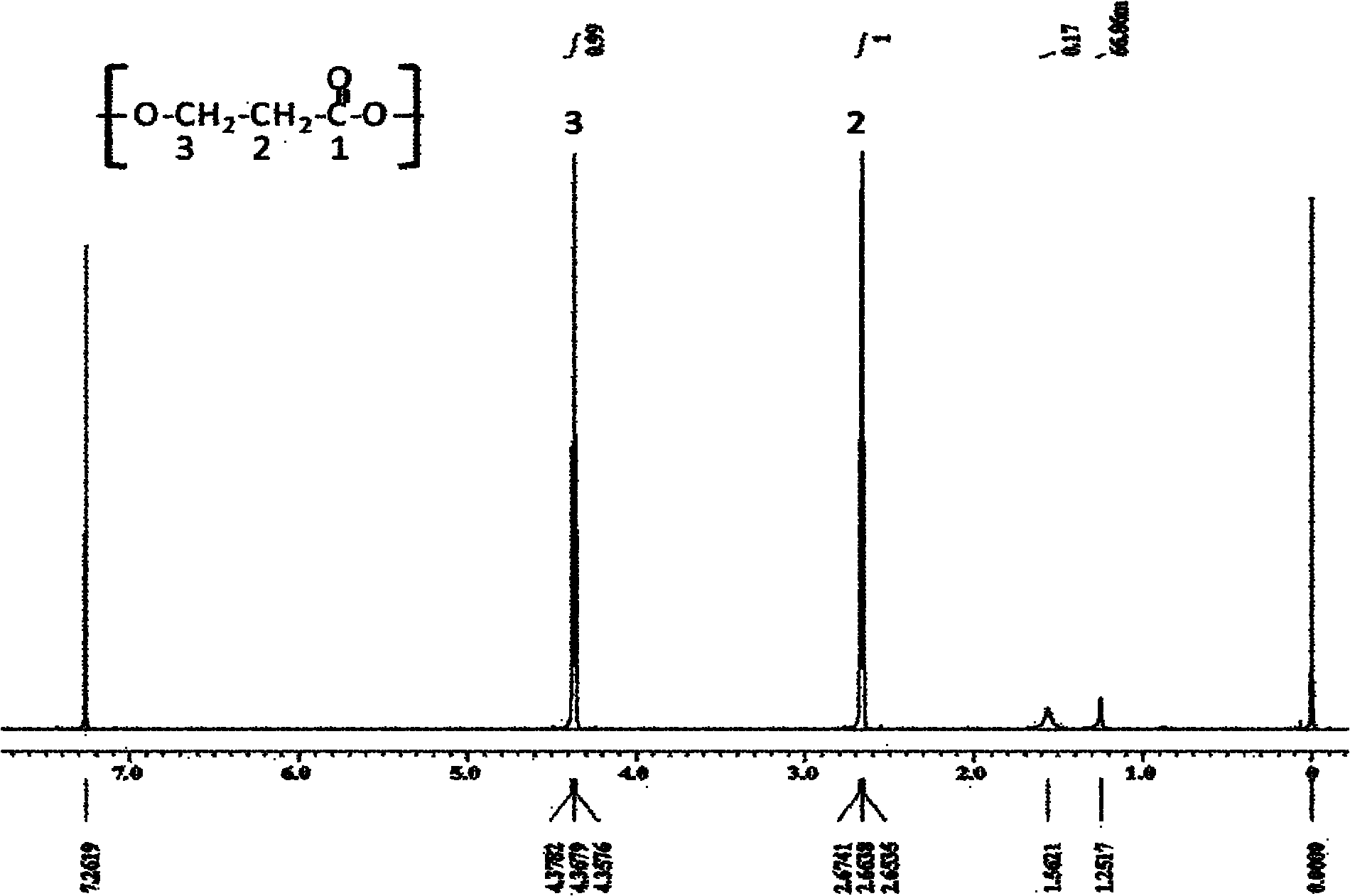

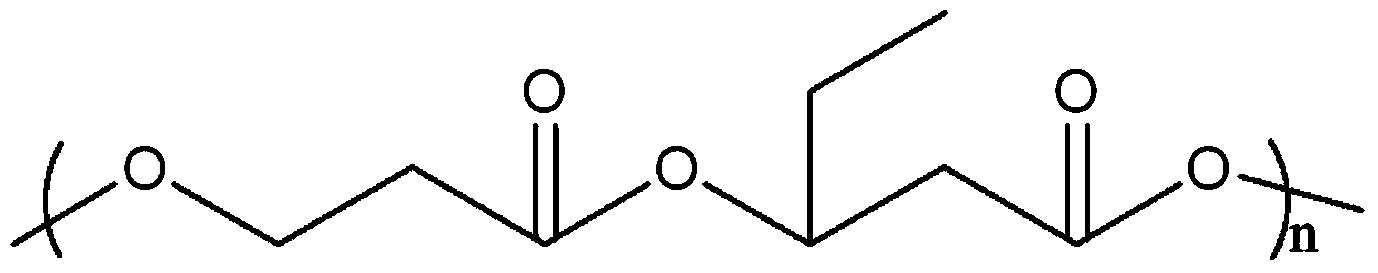

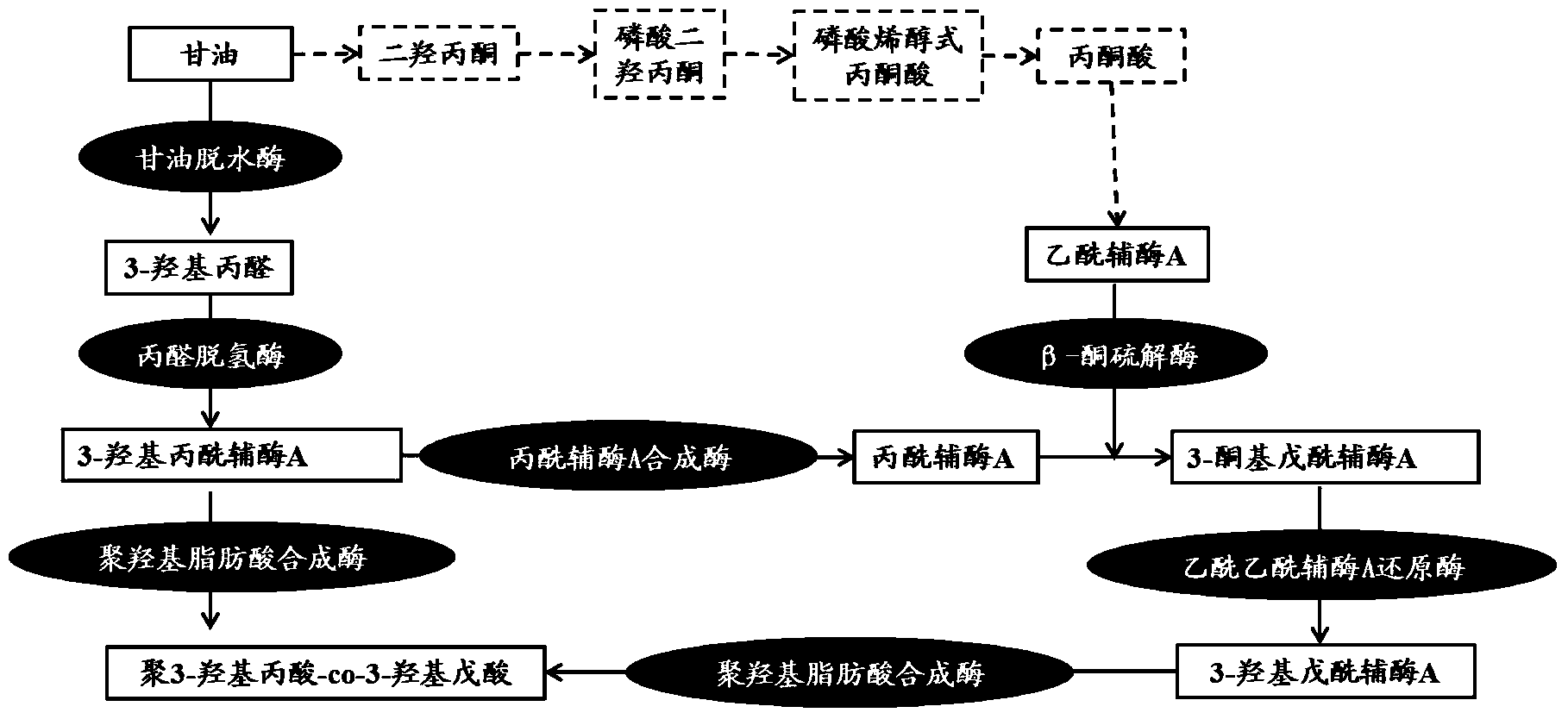

Poly-3-hydroxy propionic acid copolymer and production method thereof

ActiveCN104046659AHigh melting pointReduce crystallinityBacteriaMicroorganism based processes3-Hydroxypropionic acidPropanoic acid

The invention discloses a poly-3-hydroxy propionic acid copolymer and a production method thereof and belongs to the technical field of genetic engineering. According to the poly-3-hydroxy propionic acid copolymer and the production method thereof, a glycerol dehydratase gene and a glycerol dehydratase re-activating enzyme gene are integrated with a host strain genome by a gene integration technology, a polyhydroxy fatty acid synthase gene, a propionaldehyde dehydrogenase gene, a beta-ketoacyl coenzyme A thiolase gene, an acetoacetyl coenzyme A reductase gene and a propionyl coenzyme A synthetase gene are introduced, and a recombinant gene engineering strain has the ability of biologically synthesizing poly-3-hydracrylic acid-co-3-hydroxyvaleric acid. According to the poly-3-hydroxy propionic acid copolymer and the production method thereof, the poly-3-hydracrylic acid-co-3-hydroxyvaleric acid is obtained in a biosynthesis manner for the first time; compared with poly-3-hydracrylic acid, the obtained poly 3-hydracrylic acid-co-3-hydroxyvaleric acid has a higher melting point and lower crystallinity, has good degradability and can serve as a packaging material, a medical implant material, a drug sustained-release material and an electrochemical material.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Catalytic agent for preparing 1,3-PDO by performing hydrogenization on 3-hydracrylic acid methyl ester, and preparation and application of catalytic agent

ActiveCN103721734AHigh selectivityLow selectivityPhysical/chemical process catalystsOrganic compound preparationOrganic acid3-Hydroxypropionic acid

The invention relates to a catalytic agent for preparing 1,3-PDO by performing hydrogenization on 3-hydracrylic acid methyl ester. The catalytic agent consists of the following components in percentage by weight: 55 to 80 wt% of CuO, 2 to 5 wt% of MnO2, 0.1 to 2 wt% of MoO3, 0.1 to 2 wt% of P2O5 and 15 to 40 wt% of SiO2. The catalytic agent prepared by the invention is used for the technology of preparing the 1,3-PDO by performing hydrogenization on the 3-hydracrylic acid methyl ester, the reaction condition is mild, the requirement on the content of organic acid and moisture in the raw material of the 3-hydracrylic acid methyl ester is low (less than 0.5 wt%), the selectivity of the 1,3-PDO is improved, the selectivity of the 1,3-PDO and ester exchange products is reduced, and meanwhile the catalytic agent is suitable for preparing the 1,3-PDO by performing hydrogenization on the 3-hydracrylic acid methyl ester in high concentration; the conversion rate of the 3-hydracrylic acid methyl ester is larger than 99%, and the yield coefficient of the 1,3-PDO is larger than 85%.

Owner:SHANGHAI HUAYI ENERGY CHEM

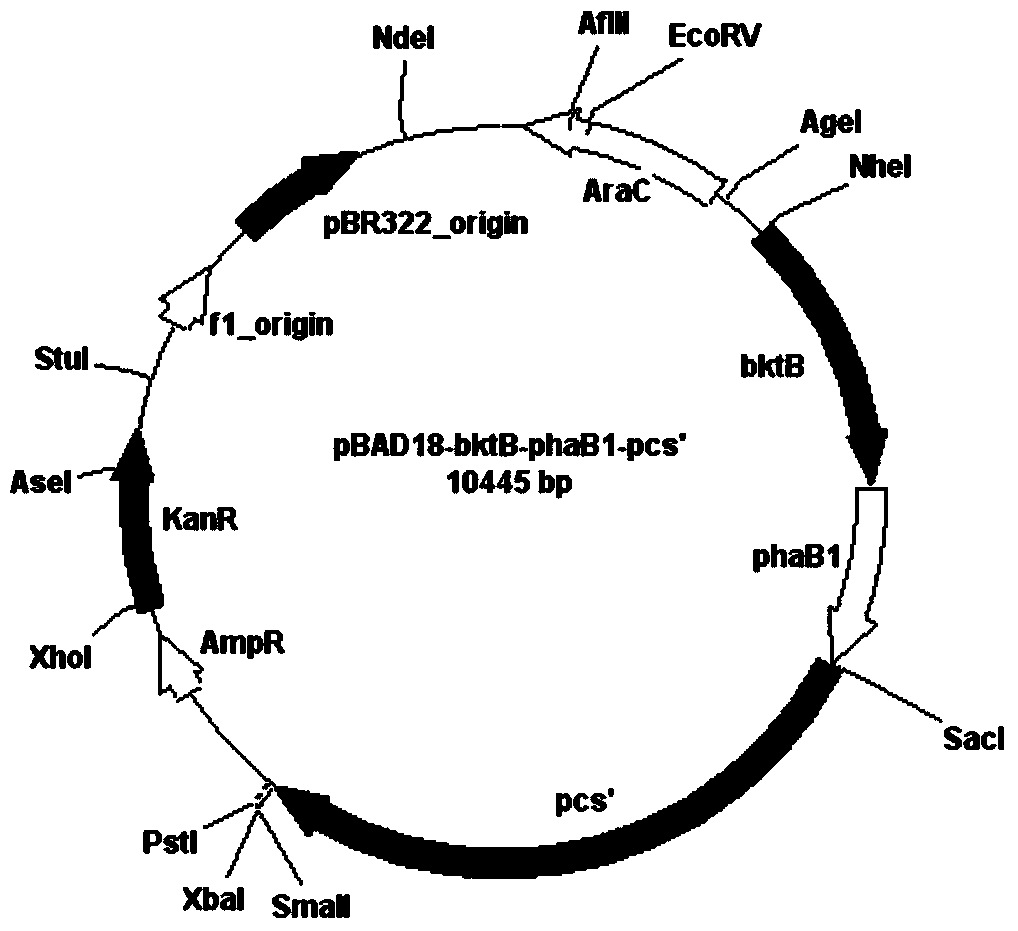

Method of synthesizing poly 3-hydracrylic acid by utilizing recombinant Escherichia coli

InactiveCN104480055AIncrease productionReduce loss rateBacteriaMicroorganism based processes3-Hydroxypropionic acidLoss rate

Owner:天津申宗科技有限公司

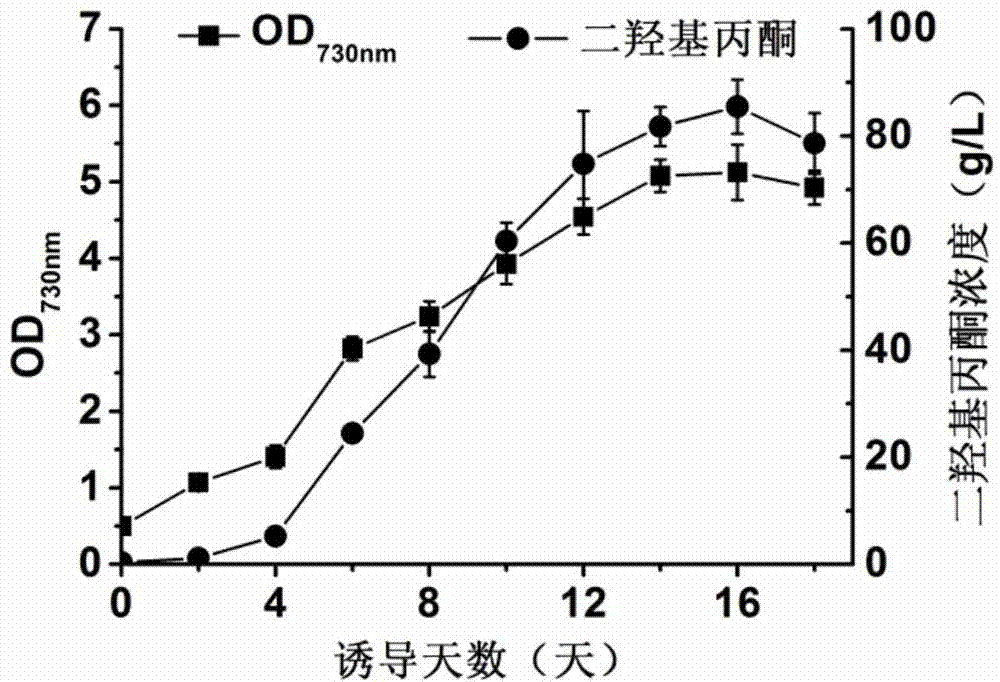

Method for producing three-carbon compounds by using gene engineering cyanobacteria

InactiveCN104726505AAvoid consumptionLow costProductsReagentsPhylum Cyanobacteria3-Hydroxypropionic acid

The invention discloses a method for producing three-carbon compounds by directly using gene engineering cyanobacteria to transform CO2. Thee method is characterized in that related genes in a synthesis approach of the three-carbon compounds are transformed to cyanobacteria, and gene engineering cyanobacteria is prepared, and subjected to enlarged culture for producing the three-carbon compounds such as dihydroxy acetone, 3-hydracrylic acid, 1,3-propylene glycol, d-glyceric acid and hydroxypyruvic acid. The method avoids high-cost collection, treatment and decomposition processes of a biomass resource, directly uses the low-cost raw material CO2 as a carbon source, produces the widely applied chemicals and fuels, can reduce the emission of CO2 in atmosphere, and has popularization and application values.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of tea dyed costume fabric

InactiveCN106367957AImprove permeabilitySpeed up entryDyeing processVegetal fibresHigh resistanceBenzoic acid

The invention discloses a preparation method of a tea dyed costume fabric. By the use of fatty alcohol-polyoxyethylene ether, sodium citrate, hydroxypropyl methylcellulose, ethyl maltol and 2-hydracrylic acid, permeation of water is accelerated, so that tea polyphenol can quickly enter water, and the extraction time is shortened; 2-phosphonic acid butane-1,2,4-tricarboxylic acid sodium salt, sodium tetraphenylboron, 1,2,3,4,5,6-cyclohexanehexacarboxylic acid, sorbitol, ethanediol di(2-aminoethyl ether)quadrol enhance tea even dyeing, so that the dyeing is uniform and consistent, and the resistance to wet rubbing fastness of tea leaves is improved; hydroxypropyl guar gum trimethyl ammonium chloride, trehalose, glucosamine sulfate, 2,4,6-trichlorine benzoic acid and 4-hydroxy phenethylamine enhance the antibacterial property of chitosan, and the dyeing firmness is facilitated; ethylene diamine tetraacetic acid, L-cysteine, 4-hydroxyphenyl boronic acid, methoxyphenylboronic acid and hexamethylol melamine enhance the fixation effect of a tea dye, and the color fastness is enhanced; the costume fabric has high resistance to washing fastness, antibacterial property and resistance to dry and wet rubbing fastness.

Owner:SICHUAN VOCATIONAL COLLEGE OF SICHUAN

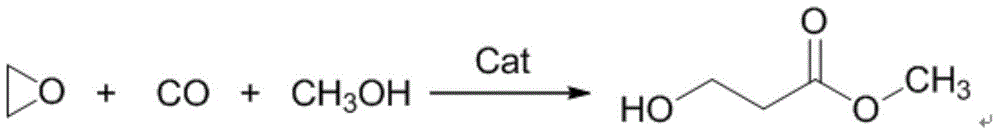

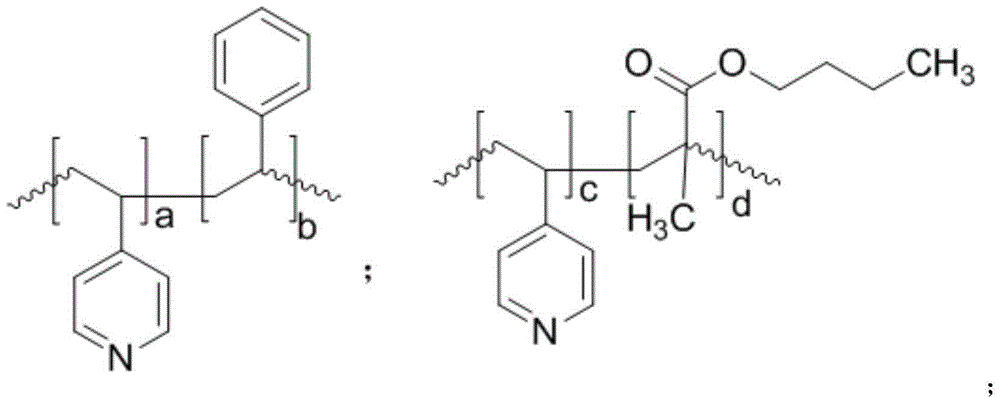

Method for synthesizing 3-hydracrylic acid ester

ActiveCN106431926AAvoid easy separationEasy to separateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reaction3-Hydroxypropionic acidAlcohol

The invention relates to a method for synthesizing 3-hydracrylic acid ester. The method mainly solves the problem that in the prior art, catalysts in a homogeneous system are difficult to separate. The method for synthesizing 3-hydracrylic acid ester includes the following steps that firstly, a ligand and cobalt carbonyl are subjected to a coordination reaction in an alcohol solvent to obtain turbid liquid of a catalyst; secondly, ethylene oxide and carbon monoxide are added, and a reaction is conducted to obtain 3-hydracrylic acid ester. According to the technical scheme, the ligand is selected from 4-vinylpyddine homopolymers or copolymers containing 4-vinylpyddine monomeric units, the technical problem is well solved, and the method can be used in industrial production of 3-hydracrylic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microorganism converting method

The invention relates to a method for producing R-(+)-3-(4-hydroxyphenyl)-2-hydracrylic acid by converting L-tyrosine with Providencia microorganisms. The method is simple in process and has significant industrial application value.

Owner:卓虹超源生物科技(郑州)有限公司

Method for using glyceric acid to prepare 3-hydroxypropionic acid

ActiveCN108329203AHigh selectivitySimple post-processingOrganic compound preparationCarboxylic compound preparation3-Hydroxypropionic acidPropanoic acid

The invention provides a method for using glyceric acid to prepare 3-hydroxypropionic acid. The method comprises the following steps that in a wild reaction condition, hydroiodic acid and glyceric acid are used for generating 3-iodopropionic acid in water; then 3-iodopropionic acid is extracted by using an organic solvent; and finally, a basic catalyst is used for catalyzing and hydrolyze 3-iodopropionic acid to be 3-hydracrylic acid. The reactants used in the method are cheap and easy to obtain, and the sources are green; the reaction time is short, efficient and energy saving effects are achieved; the amount of by-products is less, the yield rate of the first-step product 3-iodopropionic acid can reach 99%, and the yield rate of the second-step product 3-hydracrylic acid can reach 99%. The first-step product is separated by using the extraction method, and the extraction method is directly used in a two-phase system hydrolysis reaction in the second step. The product selectivity in the method is high, post-treatment is easy, and the method is easy to industrialize. The reaction system is simple, the reaction cost is low, and the preparation method has very important application value.

Owner:NANCHANG UNIV

Tetramethyl guanidine hydroxy-acid salt composite desulfurizing agent and preparation method thereof

ActiveCN101979128AHigh recycling valueImprove desulfurization efficiencyDispersed particle separationHydroxybutyric acidGluconic acid

The invention discloses a tetramethyl guanidine hydroxy-acid salt composite desulfurizing agent and a preparation method thereof. The tetramethyl guanidine hydroxy-acid salt composite desulfurizing agent comprises the following components in percentage by mass: 50 to 85 percent of 1,1,3,3-tetramethyl guanidine, 10 to 45 percent of Alpha-hydroxy acid, 0.01 to 1 percent of free radical inhibitor, 0.05 to 2 percent of metal ion complexing agent, and 1 to 5 percent of viscosity reducer, wherein the Alpha-hydroxy acid is one or mixture of more than one of glycolic acid, Alpha-hydracrylic acid, Alpha-hydroxybutyric acid, phenyllactic acid, malic acid, citric acid and Alpha-hydroxy diacid. The desulfurizing agent has the advantages of high desulphurization effect, high by-product recovery value,light secondary pollution, reproducible and recycling absorption liquid and the like, has good economic benefit and environmental protection effect, and can be widely used in the thermal power generation field.

Owner:王传良

Method for catalytically preparing tanshinol through planococcus rifietoensis

The invention discloses a method for producing R-(+)-3-(3,4-dihydroxyphenyl)-2-hydracrylic acid (D-tanshinol) through planococcus rifietoensis, and belongs to the technical field of bioengineering. By means of planococcus rifietoensis, D-tanshinol is catalytically prepared from substrates (cinnamic acid, cinnamyl aldehyde, cinnamyl alcohol, L-DOPA, L-tyrosine and L-phenylalanine). Specifically, the catalysis process A of adding the substrates to fermentation liquid in the liquid fermentation process or the catalysis process B of obtaining cells through liquid fermentation culture and putting the cells in a reaction system to catalyze the substrates is adopted. The method has good industrial application prospects.

Owner:汕头市佳禾生物科技有限公司 +1

Splitting method of 2-hydracrylic acid racemic mixture

ActiveCN103086877ALow priceLow costOrganic compound preparationCarboxylic compound preparationEconomic benefitsEndothelin receptor antagonist

The invention relates to a splitting method of 2-hydracrylic acid racemic mixture. The method comprises the following steps of: carrying out optical active alkali reaction on 2-hydracrylic acid racemic mixture and L-prolinamide, separating a single isomer L-prolinamide salt of 2-hydroxyl acrylic acid compound; and taking the single isomer of the 2-hydroxyl acrylic acid compound as important intermediate for synthetizing endothelin receptor antagonist for treating cardiovascular disease. Therefore, the single isomer with high optical purity is separated by the splitting method which is simple to operate and is provided by the invention; and the method is cheap in required material and reagent, and suitable for industrial production, and has good economic benefit.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD +1

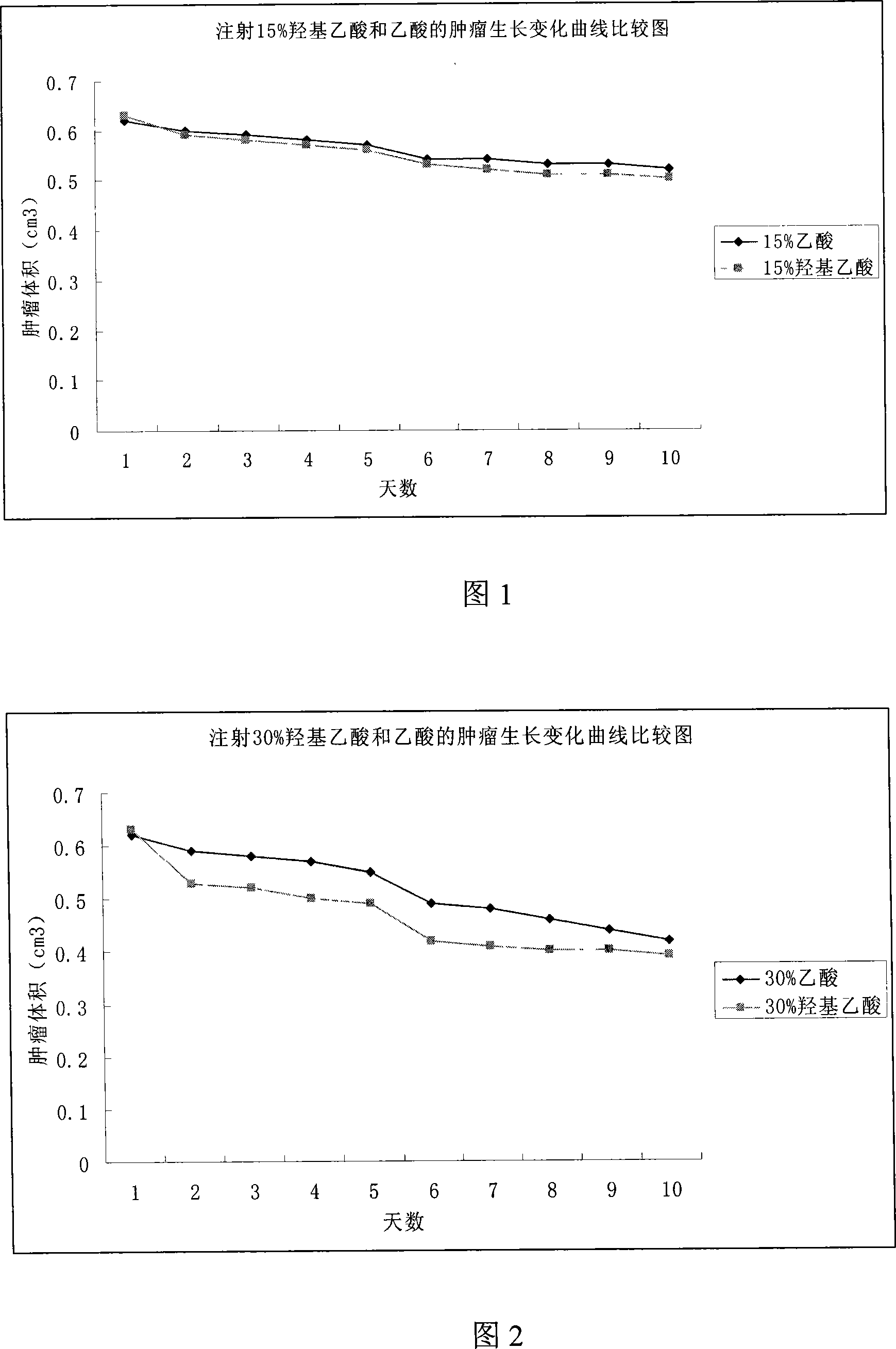

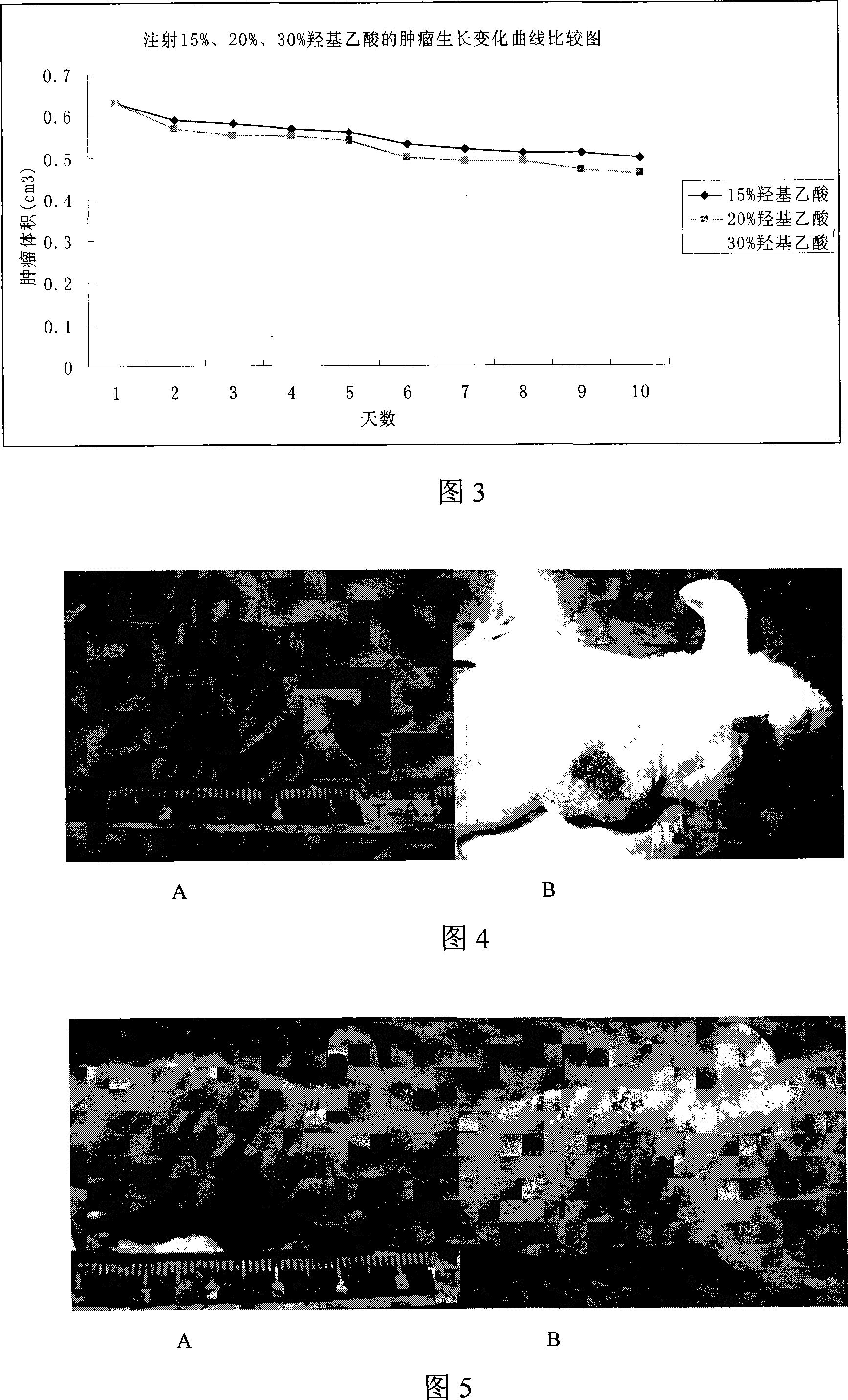

Application of alpha-hydroxy-acid in preparing cancer and tumor in vivo injection therapeutic medicine

InactiveCN101214234AEnhanced inhibitory effectAnhydride/acid/halide active ingredientsAntineoplastic agentsIn vivoAlpha hydroxy acid

The present invention relates to the medicine technical field and concretely indicates an application of alpha-hydroxy acid for preparing a cancerous tumour internal injection treatment drug. The alpha-hydroxy acid of the present invention indicates hydroxyacetic acid or alpha-hydracrylic acid. With the present invention, the hydroxyacetic acid aqueous solution with different concentrations is prepared to be processed for medicine efficacy tests such as a naked rat experiment, a rat experiment and a cell test, which are compared with the medicine efficacy of electropositive medicine acetic acid used for liver cancer internal injection which has the same concentration with the hydroxyacetic acid aqueous solution. The naked rat experiment and a rat liver damnification experiment show that under the same concentration, the hydroxyacetic acid has similar anti-liver-cancer effect as and even better anti-liver-cancer effect than the acetic acid. The cell test shows that the hydroxyacetic acid is applied to the tumour internal injection with great inhibiting effect towards hepatic tumour, pulmonary tumour, oesophagus tumour, etc. The present invention also approves that the alpha-hydracrylic acid (lactic acid) has similar anticancer effect as the hydroxyacetic acid. The present invention provides the novel cancerous tumour internal injection treatment drug which has strong inhibiting effect towards tumour cells, such as the hepatic tumour, the pulmonary tumour, the oesophagus tumour, etc.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Microbial transformation method

The invention relates to a method for transforming Providencia microorganisms into levodopa to produce R-(+)-3-(3,4-dihydroxyphenyl)-2-hydracrylic acid. The method is simple in process and has significant industrial application value.

Owner:卓虹超源生物科技(郑州)有限公司

Alkali cyanide-free copper-plated anode dissolving accelerator

InactiveCN103014789AEasy to usePreventing Anode Passivation ProblemsOXALIC ACID DIHYDRATECopper plating

The invention discloses an alkali cyanide-free copper-plated anode dissolving accelerator and relates to a copper-plated anode. The accelerator comprises the following materials in parts by weight: 5-8 parts of accelerator A, 1-2 parts of accelerator B and 1-3 parts of accelerator C, wherein A is selected from 2-hydroxysuccinic acid(malic acid) and sodium salt or potassium salt thereof, or succinic acid (succinic acid) and sodium salt or potassium salt thereof; B is one substance selected from cis-butenedioic acid (maleic acid) and sodium salt or potassium salt thereof, trans-butenedioic acid (fumaric acid) and sodium salt or potassium salt thereof, and 2-hydracrylic acid(lactic acid) and sodium salt or potassium salt thereof; and C is one substance selected from malonic acid and sodium salt or potassium salt thereof, oxalic acid and sodium salt or potassium salt thereof, hydroxyacetic acid and sodium salt or potassium salt thereof, glutaric acid and sodium salt or potassium salt thereof, and adipic acid and sodium salt or potassium salt thereof. A, B and C are mixed to obtain the product. The alkali cyanide-free copper-plated anode dissolving accelerator can ensure that the anode dissolving is normal during a using process of a cyanide-free alkali copper-plating process using citrate or / and tartrate as complexing agent, and the plating solution is stably used for a long time.

Owner:XIAMEN UNIV

Preparing method for glycolic acid-hydracrylic acid random copolymer

InactiveCN105111417AQuality improvementHigh polymerization conversion ratePhosphorous acidPolymer science

The invention provides a preparing method for a glycolic acid-hydracrylic acid random copolymer. The preparing method includes the steps of raw material pretreatment, pre-polycondensation and polycondensation, wherein the step of raw material pretreatment includes the substeps that a glycolic acid water solution and a hydracrylic acid water solution are treated with ultrasonic waves and filtered; the step of pre-polycondensation includes the substep that the pretreated mixed solution is subjected to pre-polycondensation at low temperature and low pressure to obtain a pre-polycondensation intermediate product; the step of polycondensation includes the substep that butyl titanate and triphenyl phosphate are added into the pre-polycondensation intermediate product for polycondensation. By means of the improved raw material components and the optimized preparing technology, the prepared glycolic acid-hydracrylic acid random copolymer has stable quality, and is large in polymerization conversion rate, large in molecular weight, high in intrinsic viscosity and particularly suitable for manufacturing medical biodegradable macromolecular structure devices such as a biodegradable medical ligation clamp and a gastrointestinal tract anastomat .

Owner:HANGZHOU MEDZONE BIO-TECH CO LTD

Preparation method of recombinant organism 3-hydracrylic acid

The invention relates to a preparation method of 3-hydracrylic acid, which can be explained by the production of 3-hydracrylic acid (3-HP) from glycerol in a bacterial host. 3-HP is a useful raw material for production of a polymeric material. A genetic engineering bacteria host of two enzymes is enough to produce 3-HP. One enzyme is glycerol dehydratase and the other enzyme is acetaldehyde dehydrogenase. The recombinant microorganism host, which is allowed to be established, can synthesize 3-HP from glycerol or glucose used as a starting material. Glycerol or glucose is converted and then transformed into 3-HP.

Owner:XINCHANG GUANYANG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com