Recombinant bacteria for producing copolymer of 3-hydracrylic acid and 4-hydroxybutyric acid and application thereof

A technology of hydroxybutyric acid and hydroxypropionic acid, which is applied in the field of recombinant bacteria producing copolymers of 3-hydroxypropionic acid and 4-hydroxybutyric acid and its application field, to achieve the effect of excellent thermodynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

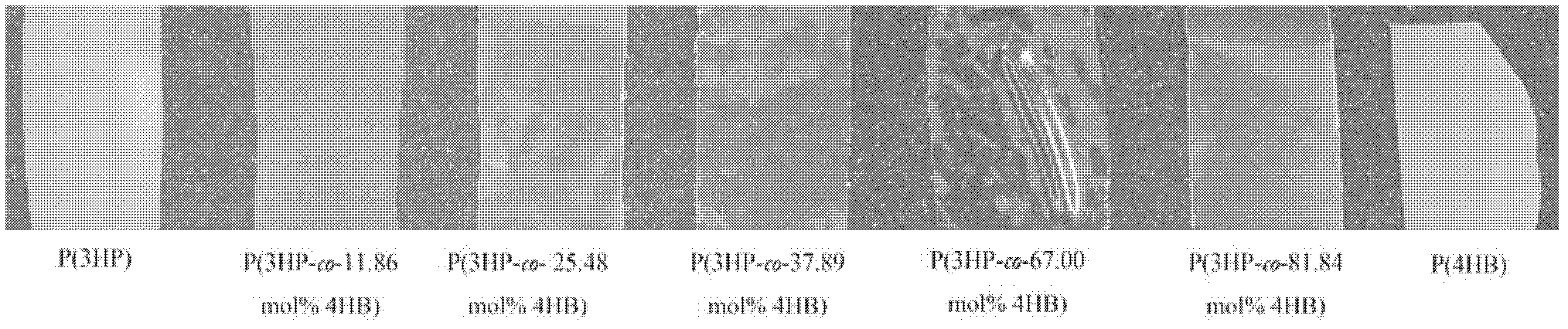

Image

Examples

Embodiment 1

[0050] Embodiment 1, the construction of expression engineering bacteria

[0051] 1. Construction of expression vector pZQ03-orfz

[0052] 1) Using plasmid pKSSE5.3 (Song, S.S., Hein, S., Steinbüchel, A., 1999. Production of poly(4-hydroxybutyric acid) by fed-batch cultures of recombinant strains of Escherichia coli. Biotechnol. Lett.21 , 193-197; the pKSSE5.3 plasmid is a well-known plasmid at present, and the public can obtain it from Tsinghua University) as a template, orfz Sense and orfz Antisense as primers, and use pfu enzyme to perform PCR reaction to amplify the target gene 4-hydroxybutyric acid Coenzyme A transferase gene (orfz), and designed to introduce enzyme cleavage sites at both ends of the fragment.

[0053] orfz Sense: 5'CGGTGT GGATCC CAAGGTGATG 3' (SEQ ID NO: 6)

[0054] Bam H I

[0055] orfz Ant i sense: 5' ATATA GGATCC CCGACTGGAAAGCG 3' (SEQ ID NO: 7)

[0056] Bam H I

[0057] PCR reaction conditions:

[0058] Pre-denaturation at 94°C for 10 minut...

Embodiment 2

[0070] Embodiment 2, the experiment of producing the copolymer P (3HP-co-4HB) of 3-hydroxypropionic acid and 4-hydroxybutyric acid with recombinant engineered bacteria

[0071] 1. Shake flask culture test

[0072] 1. Using TB as the medium to produce the copolymer P(3HP-co-4HB) of 3-hydroxypropionic acid and 4-hydroxybutyric acid

[0073] Recombinant engineering bacterium E.coliS17-1 (pZQ01, pZQ03-orfz) uses LB culture medium, at 37 ℃, 200rpm cultivates overnight; Then by 5% inoculum size (v / v, 10 11 cfu / ml), respectively inoculated into 50 mL of TB medium (BDO) containing 1,3-propanediol (PDO) and 1,4-butanediol (the amount of 1,3-propanediol, 1,4-butanediol (as described in Table 1), at 37° C., 200 rpm, shake the flask for 48 hours to obtain the bacterial liquid. Three sets of parallel experiments were set up for each experimental treatment. Use gas chromatography (GC, GC-2014, SHIMADZU) to verify the preliminary qualitative and quantitative analysis of polymers in cells ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com