Alkali cyanide-free copper-plated anode dissolving accelerator

A cyanide-free copper plating and anode dissolution technology, which is applied in the field of alkaline cyanide-free copper plating anode dissolution accelerator, can solve problems such as not specifying the plating solution, prevent anode passivation, stabilize the use of the plating solution, and ensure normal anode dissolution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

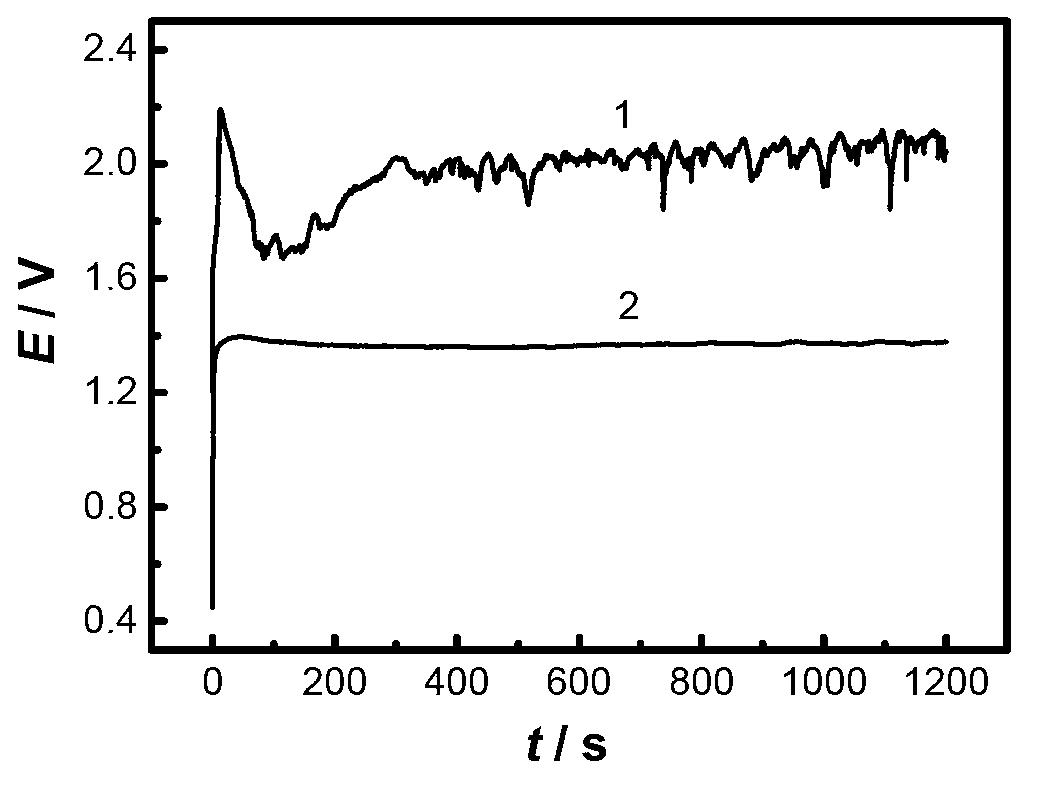

Image

Examples

Embodiment 1

[0031] An alkaline cyanide-free copper-plating anode dissolution accelerator, its raw material components are calculated per kilogram of raw material, and its composition content is as follows:

[0032] Accelerator A 500g

[0033] Accelerator B 200g

[0034] Accelerator C 300g

[0035] The accelerator A is succinic acid (succinic acid); the accelerator B is maleic acid (maleic acid); the accelerator C is malonic acid;

Embodiment 2

[0043] An alkaline cyanide-free copper plating anodic dissolution accelerator, its raw material components are calculated per kilogram of raw material, and its composition content is as follows:

[0044] Accelerator A 800g

[0045] Accelerator B 100g

[0046] Accelerator C 100g

[0047] The accelerator A is 2-hydroxysuccinic acid (malic acid); the accelerator B is 2-hydroxypropionic acid (lactic acid); the accelerator C is adipic acid;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com