Colored cigarette paper coating solution with specific fragrance and application thereof

A technology of cigarette paper and coating solution, which is applied in paper coating, papermaking, coating, etc., can solve the problems of expensive flavors and fragrances for cigarettes, uneven color patches on the surface of paper, and increased production costs, and achieve color and aroma. Enrich, delay the drying process, and ensure the effect of suction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare a kind of yellow cigarette paper coating liquid with fruity fragrance, specifically comprise the steps:

[0038] (1) Raw material pulverization and sterilization: select gardenia 5kg as plant raw material to pulverize, first carry out primary pulverization with sander, obtain the gardenia slurry of particle diameter 2~4cm, adopt pulverizer to carry out secondary pulverization, obtain Gardenia serum with particle size below 1cm. The obtained gardenia slurry was sterilized in a sterilizing pot at 121° C. for 25 minutes.

[0039] (2) the fermentation of gardenia pigment specifically comprises the following steps:

[0040] 1) Expanded culture of microorganisms:

[0041] a. The Aspergillus oryzae YNCA9804 used in the experiment was inoculated in 50 mL of liquid medium, and cultured at 28° C. and 160 r / min for 24 hours to obtain activated liquid strains. Then transfer the liquid bacteria into 1 L of liquid culture medium according to the inoculum amount of 1%, and ...

Embodiment 2

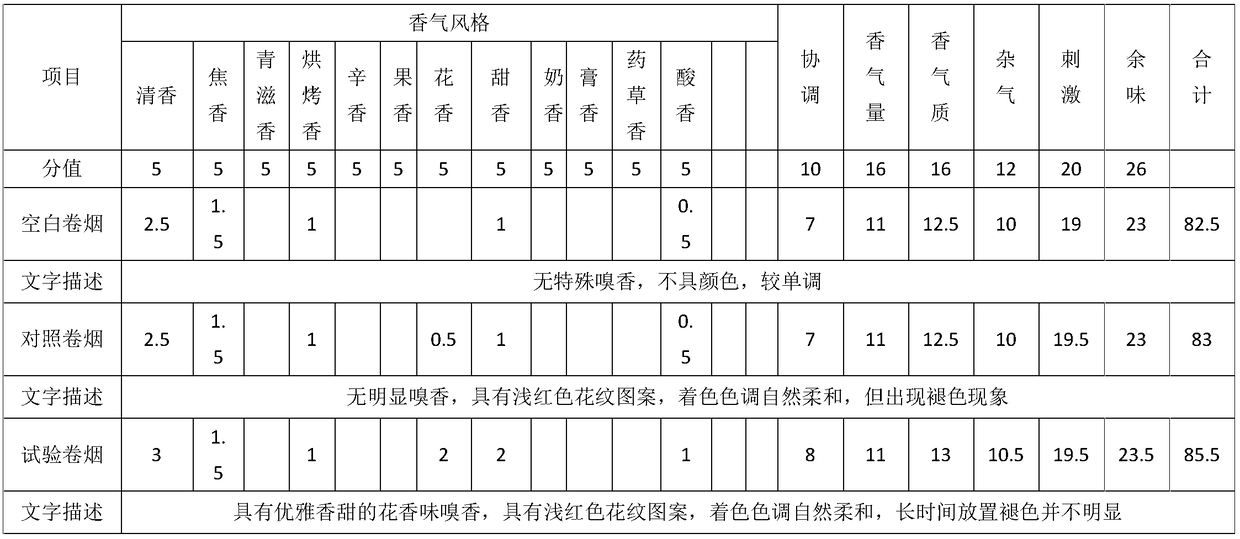

[0058] Prepare a kind of red cigarette paper coating liquid with floral fragrance, specifically comprise the following steps:

[0059] (1) Raw material crushing and sterilization: select 3 kg of roses as plant raw material, perform secondary crushing after drying, and perform primary crushing with a sander to obtain rose powder with a particle size of 2 to 4 cm, and use a grinder for secondary crushing Pulverize to obtain rose powder with a particle diameter below 1 cm. The obtained rose powder was sterilized in a sterilizing pot at 121° C. for 25 minutes.

[0060] (2) Fermentation of rose pigment: except that Aspergillus oryzae YNCA 9804 and Bacillus subtilis Van3 were used to ferment the rose powder for 2 days and 3 days respectively, the remaining operations were the same as step (2) of Example 1.

[0061] (3) Extraction: put the fermented rose powder into a multi-functional extraction tank, add 10 kg of 95% acidic ethanol with a pH value of 3, and heat and reflux at 60° C...

Embodiment 3

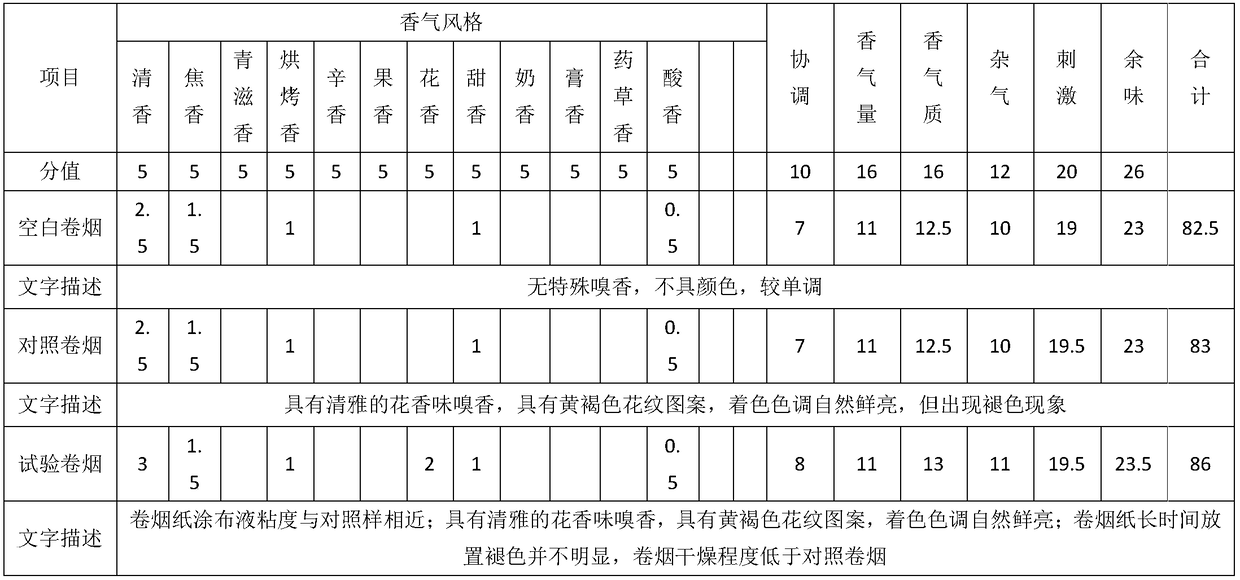

[0073] Prepare a kind of yellow-brown cigarette paper coating liquid with floral fragrance, specifically comprise the steps:

[0074] (1) Raw material pulverization and sterilization: select 2 kg of marigold as the plant raw material and carry out secondary pulverization after drying, and carry out primary pulverization with a sander to obtain marigold powder with a particle size of 2 to 4 cm, and use a pulverizer for secondary pulverization. Grade crushing to obtain marigold powder with a particle size below 1 cm. The obtained marigold powder was sterilized in a sterilizing pot at 121° C. for 25 minutes.

[0075](2) Fermentation of marigold pigments: except that Aspergillus oryzae YNCA 9804 was used for fermentation and Bacillus subtilis Van3 was used to ferment marigold powder for 2 days respectively, the rest of the operations were the same as step (2) of Example 1.

[0076] (3) Extraction: Put the fermented marigold powder into a multi-functional extraction tank, add 12kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com