Alkali-resistant chlorine-resistant type aldehyde-free active dye color fixing agent and preparation method thereof

A technology of reactive dyes and color-fixing agents, which can be used in dyeing, textiles, papermaking, and fiber processing. It can solve environmental and human harm problems, achieve good alkali and chlorine resistance, improve wet treatment fastness, and excellent anti-corrosion properties. The effect of electrostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

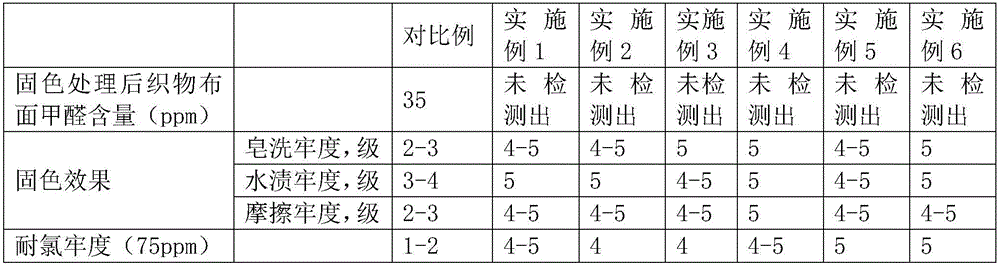

Image

Examples

Embodiment 1

[0047] An alkali-resistant and chlorine-resistant type formaldehyde-free reactive dye fixing agent, in parts by weight, comprises the following components:

[0048] 5 parts of silicone monomer, 12 parts of acrylic acid,

[0049] 8 parts of butyl acrylate,

[0050] 6 parts of sodium butyl diphenyl ether disulfonate,

[0051] Cardanol polyoxyethylene ether 1 part,

[0052] 7 parts of polyethylene glycol, 1.5 parts of carbon nanotubes,

[0053] 2 parts of calcium silicate, 0.5 parts of initiator, 10 parts of deionized water.

[0054] Its preparation method comprises the following steps:

[0055] (1) Mix and stir acrylic acid, butyl acrylate and deionized water evenly, heat up to 50-60°C, add organosilicon monomer and initiator, and react at constant temperature for 1.5 hours to obtain mixed solution 1;

[0056] (2) adding carbon nanotubes and an initiator to the mixed solution 1 obtained in step (1), raising the temperature to 70° C., and reacting at a constant temperature f...

Embodiment 2

[0060] An alkali-resistant and chlorine-resistant type formaldehyde-free reactive dye fixing agent, in parts by weight, comprises the following components:

[0061] 10 parts of silicone monomer, 15 parts of acrylic acid,

[0062] 13 parts of butyl acrylate,

[0063] 10 parts of sodium butyl diphenyl ether disulfonate,

[0064] Cardanol polyoxyethylene ether 4 parts,

[0065] 10 parts of polyethylene glycol, 2 parts of carbon nanotubes,

[0066] 3 parts of calcium silicate, 1 part of initiator, 20 parts of deionized water.

[0067] Its preparation method comprises the following steps:

[0068] (1) Mix and stir acrylic acid, butyl acrylate and deionized water evenly, heat up to 50-60°C, add organosilicon monomer and initiator, and react at constant temperature for 3 hours to obtain mixed solution 1;

[0069] (2) Add carbon nanotubes and an initiator to the mixed solution 1 obtained in step (1), heat up to 90° C., and react at a constant temperature for 5 hours to obtain a mix...

Embodiment 3

[0073] An alkali-resistant and chlorine-resistant type formaldehyde-free reactive dye fixing agent, in parts by weight, comprises the following components:

[0074] 7 parts of silicone monomer, 13 parts of acrylic acid,

[0075] 10 parts of butyl acrylate,

[0076] 8 parts of sodium butyl diphenyl ether disulfonate,

[0077] Cardanol polyoxyethylene ether 3 parts,

[0078] 10 parts of polyethylene glycol, 1.6 parts of carbon nanotubes,

[0079] 2 parts of calcium silicate, 1 part of initiator, 18 parts of deionized water.

[0080] Its preparation method comprises the following steps:

[0081] (1) Mix and stir acrylic acid, butyl acrylate and deionized water evenly, heat up to 50-60°C, add organosilicon monomer and initiator, and react at constant temperature for 2 hours to obtain mixed solution 1;

[0082] (2) adding carbon nanotubes and an initiator to the mixed solution 1 obtained in step (1), raising the temperature to 70° C., and reacting at a constant temperature for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com