Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

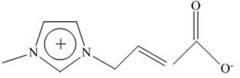

86 results about "Methylimidazoleacetic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thus, urinary Methylimidazoleacetic acid being the major and specific histamine metabolite is a clear marker of any changes in histamine metabolism in the body. The urinary excretion of methylimidazoleacetic acid is considered a reliable indicator of histamine turnover rate in the body.

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

Mould-proof anti-bacterial multi-fiber blended woven fabric and manufacturing method thereof

ActiveCN104593930AVersatileImprove technical indicatorsConjugated cellulose/protein artificial filamentsWoven fabricsFiberCarbon fibers

The invention discloses mould-proof anti-bacterial multi-fiber blended woven fabric. The mould-proof anti-bacterial multi-fiber blended woven fabric is formed by weaving warp yarns and weft yarns through an air jet loom and is characterized in that the warp yarns and the weft yarns comprise, by weight, 30-36 parts of isotatic polypropylene, 3-5 parts of cinnamyl aldehyde, 1-2 parts of thiocarbamide, 0.4-0.8 part of stannous mono-sulphate, 3-6 parts of kaolin, 25-34 parts of modal fibers, 20-25 parts of milk grass fibers, 19-26 parts of elastic cotton fibers, 23-28 parts of coconut carbon fibers, 7-9 parts of fluoro-siloxane resin, 8-12 parts of toluene diisocynate, 10-14 parts of butyl alcohol, 2-4 parts of root bark of white mulberry, 3-4 parts of skullcap, 80-90 parts of 1-butyi-3-methylimidazole acetate, 100-110 parts of 1-alyl-3-imidazolium chloride, 4-7 parts of assistant, and a proper amount of water. According to the manufacturing method of the mould-proof anti-bacterial multi-fiber blended woven fabric, the processes are simple, the method is easy to implement, and the functions of the manufactured woven fabric are comprehensive through reasonable selection of raw materials and scientific proportion design. According to the mould-proof anti-bacterial multi-fiber blended woven fabric, various plant fibers are added and are soaked through Chinese herbal medicine, in this way, the spinnability of plant fibers and the spinning quality are improved, all technical indexes of the woven fabric are increased, and the mould-proof anti-bacterial multi-fiber blended woven fabric has the excellent advantage of being resistant to mould and bacteria, soft in handfeeling, hygroscopic, breathable, capable of lowering noise, removing dust and insulating heat and the like.

Owner:深圳光煦科技有限公司

Nanometer antibacterial mothproof cashmere composite fiber and manufacturing method thereof

InactiveCN104911737AExcellent long-lasting antibacterial and anti-moth performanceAvoid breedingConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCocamidopropyl betaineSheep wool

The invention discloses a nanometer antibacterial mothproof cashmere composite fiber. The nanometer antibacterial mothproof cashmere composite fiber is prepared from 24-30 parts by weight of Xizang cashmere, 22-28 parts by weight of sheep wool, 7-9 parts by weight of polyamide fibers, 12-15 parts by weight of mulberry silk, 15-18 parts by weight of Jutecell, 18-22 parts by weight of modal fibers, 10-13 parts by weight of starch maize, 5-7 parts by weight of paraffin, 1.3-2.5 parts by weight of cocamidopropyl betaine, 11-13 parts by weight of butyl acrylate, 2-3 parts by weight of nanometer zinc oxide, 3-5 parts by weight of mint extract, 1-3 parts by weight of cocklebur fruit, 2-4 parts by weight of Angelica sylvestris, 100-110 parts by weight of 1-ethyl-3-methylimidazolium acetate, 90-100 parts by weight of 1-allyl-3-methylimidazolium chloride, 21-25 parts by weight of an assistant and a proper amount of water. Through optimization of formula and the preparation technology, the treated cashmere composite fibers have excellent and lasting antibacterial and mothproof performances, can effectively inhibit bacteria growing in cloth wear, can remove a peculiar smell, have no irritation, has safety, health and heath care effects, and can be used for making cashmere sweater suitable for people of all ages.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Extraction method of ginger essential oil

Owner:SOUTH CHINA UNIV OF TECH

Cotton regenerated cellulose fabric and preparation method thereof

ActiveCN103966688AHigh strengthGood drapeMonocomponent cellulose artificial filamentMelt spinning methodsOxidation resistantMasson pine

A cotton regenerated cellulose fabric is prepared from the following raw materials in parts by weight: 12-15 parts of water, 5-7 parts of nanometer chitosan, 2-3 parts of lecithin, 2-3 parts of collagen powder, 3-5 parts of poly butylene succinate, 1-2 parts of anthocyanidin, 7-10 parts of plastic starch, 65-70 parts of cotton fiber, 15-20 parts of masson pine fiber, 2-3 parts of Liqing grass, 1-2 parts of yellow cinnamon leaves, 50-60 parts of 1- ethyl-3- methylimidazole acetate, 50-60 parts of 1- allyl-3- methylimidazole perchlorate and 1-2 parts of a spin finish aid. According to the cotton regenerated cellulose fabric, as the masson pine fiber, the yellow cinnamon leaves and the Liqing grass are added, naturally antimicrobial and mothproof properties are achieved; the extracting solution of the Liqing grass can purge fire, remove toxin and prevent and treat eczema; as added collagen powder and the anthocyanidin are oxidation resistant and can be absorbed by human body, the skin health is facilitated; as the spin finish aid is adopted, the spinning melt can reach favorable spinning ability, the fiber is fuzz-free, the leveling of dyeing is good, the color and luster are favorable and the hand feeling is softer.

Owner:南通冠恒纺织有限公司

Nanometer far infrared ceramic fiber woven fabric and production method of nanometer far infrared ceramic fiber woven fabric

ActiveCN104593931AImprove heat insulation and flame retardant effectImprove wear resistanceConjugated cellulose/protein artificial filamentsWoven fabricsMethacrylateEpoxy

The invention discloses nanometer far infrared ceramic fiber woven fabric. The nanometer far infrared ceramic fiber woven fabric is formed by warp yarns and weft yarns in a woven mode through an air jet loom, and is characterized in that raw materials of the warp yarns and raw materials of the weft yarns comprise, by weight, 27 parts to 33 parts of syndiotactic polypropylene, 10 parts to 14 parts of linear low-density polyethylene, 8 parts to 10 parts of polyurethane films, 16 parts to 22 parts of epoxy resin, 0.4 part to 0.7 part of zinc nitrate, 0.6 part to 0.9 part of magnesium hydrate, 1 part to 3 parts of water glass, 20 parts to 25 parts of nylon yarns, 23 parts to 26 parts of colored cotton fibers, 18 parts to 23 parts of nanometer far infrared ceramic fibers, 21 parts to 24 parts of cellulose acetate fibers, 7 parts to 10 parts of isobutyl methacrylate, 5 parts to 9 parts of peach gum, 1 part to 3 parts of radix bupleuri, 2 parts to 5 parts of fossil fragments, 80 parts to 90 parts of 1-butyl-3-methylimidazolium acetate, 90 parts to 100 parts of 1-allyl-3-methylimidazolium chlorine salt, a proper amount of water and 4 parts to 8 parts of assistants. By means of the nanometer far infrared ceramic fiber woven fabric, the spinnability of plant fibers and the spinning quality are improved, the warmth keeping performance, the wearing resistance, the pilling resistance and the washing resistance of the woven fabric are further improved, and the market prospects are good.

Owner:JIXI YUANDAO AGRI IND TECH

Woven fabric with sound insulation and warm keeping properties and manufacturing method thereof

InactiveCN104652017AImprove spinnabilityImprove spinning qualityConjugated cellulose/protein artificial filamentsWoven fabricsFiberLophatherum

The invention discloses a woven fabric with sound insulation and warm keeping properties. The woven fabric is formed by weaving warp yarns and weft yarns through an air jet loom; the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30-34 parts of isotatic polypropylene, 1-3 parts of hargil, 3-7 parts of rock wool, 20-25 parts of modal fibers, 22-26 parts of fireproof fiber cotton, 25-28 parts of waste down feather fibers, 16-19 parts of bambusa texlitis pulp, 0.6-0.9 part of sodium hexametaphosphate, 8-10 parts of methyl methacrylate, 2-4 parts of eucalyptus oil, 12-15 parts of butyl glycidyl ether, 1-3 parts of jasmine, 2-5 parts of herba cepbalanoplosis segeti, 3-4 parts of lophatherum gracile, 85-95 parts of 1-butyl-3-methyl imidazole acetate, 95-110 parts of 1-allyl-3-methyl imidazole chlorine salt, proper amount of water and 5-8 parts of an auxiliary agent. The woven fabric has the sound insulation and warm keeping properties, and antibacterial and mould-proof, and inflaming retarding properties, is applied to automotive trims, and has the properties of low cost, high cost performance and good shape keeping performance and the like; the prospect is wide.

Owner:章云

Mothproof down feather composite fiber and preparation method thereof

InactiveCN104264277AAntibacterial and mothproofLightweight and high strengthConjugated cellulose/protein artificial filamentsArtifical filament manufactureAluminium silicateGluconates

The invention discloses a mothproof down feather composite fiber. The mothproof down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 16-18 parts of duck's down, 15-19 parts of chicken feather, 11-13 parts of mercerized wool fibers, 12-14 parts of mercerization cotton fibers, 4-7 parts of copper ammonia fibers, 15-19 parts of straw stalk, 4-6 parts of closed cell perlite powder, 1-3 parts of angelica sinensis, 2-4 parts of gastrodia elata, 2-3 parts of ligusticum wallichii, 0.2-0.4 part of zinc gluconate, 0.3-0.6 part of aluminium silicate, 100-105 parts of 1-butyl-3-methyl imidazole acetate, 110-115 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 2-4 parts of additives and a proper amount of water. The down feather composite fiber prepared by the invention has the advantages of sterilization, moth prevention, light weight, high intensity, thermal preservation, flame retardance and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Catechinic acid fiber blended deodorization flame-retardant woven fabric and manufacturing method thereof

ActiveCN104726994AVersatileImprove technical indicatorsFlame-proof filament manufactureMelt spinning methodsFiberPolyethylene glycol

The invention discloses catechinic acid fiber blended deodorization flame-retardant woven fabric. Raw materials of needed warp and needed weft for weaving comprise, by weight, 29 to 35 parts of syndiotactic polypropylene, 18 to 23 parts of polylactic acid, 8 to 12 parts of polyhydroxybutyrate, 3 to 5 parts of montmorillonoid, 0.02 to 0.05 part of canthaxanthin, 0.4 to 0.8 part of diprophylline, 0.5 to 0.9 part of calcium chloride, 23 to 28 parts of catechinic acid fibers, 25 to 30 parts of reed fibers, 18 to 24 parts of flame-retardant fibers, 17 to 23 parts of Lenzing modal fibers, 19 to 27 parts of zein fibers, 7 to 9 parts of oleic acid polyethylene glycol ester, 10 to 14 parts of ethylene glycol monoethyl ether acetate, 3 to 4 parts of peppermint, 2 to 5 parts of isatis roots, 1 to 3 parts of rheum officinale, 85 to 100 parts of 1-butyl-3-methylimidazolium acetate, 95 to 105 parts of 1-allyl-3-methylimidazolium chloride, 4 to 6 parts of auxiliaries and a proper amount of water. The fabric has the advantages of being resistant to odor, flames and abrasion, capable of absorbing sound and isolating heat and the like.

Owner:JIXI YUANDAO AGRI IND TECH

Antimicrobial deodorizing down composite fiber and manufacturing method thereof

InactiveCN104762691APrevent mildew and insectsFlame retardantConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsParaffin waxFiber

The invention discloses an antimicrobial deodorizing down composite fiber which is prepared from the following raw materials in parts by weight: 10-15 parts of eiderdown, 15-20 parts of duck feather, 7-9 parts of cotton fiber, 6-10 parts of terylen fiber, 2.3-4.2 parts of polyvinyl alcohol nano fiber, 7-9 parts of vinylon fiber, 1-3 parts of liquid paraffin, 3-5 parts of argil, 1.2-3.1 parts of viscose fiber, 2-4 parts of Chinese yam, 1-3 parts of radix scutellariae, 0.4-0.7 part of ammonium polyphosphate, 0.02-0.04 part of sodium pentadecyl sulfonate, 0.6-0.9 part of polyethyleneimine, 0.5-0.8 part of tartaric acid, 120-130 parts of 1-butyl-3-methylimidazole acetate, 100-110 parts of dibutyl 1-butyl-3- methylimidazole phosphate, 2-4 parts of assistant and a right amount of water. The antimicrobial deodorizing down composite fiber can effectively prevent the down from mildewing and moth bite in the storage, transportation and use process for a long time, enables the corresponding product to have obvious antimicrobial and deodorizing functions, has the flame-retardant action, and has wide application prospects.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Waterproof noise-reduction multifunctional woven fabric and production method thereof

InactiveCN104652016AImprove spinnabilityImprove spinning qualityWoven fabricsMonocomponent polyesters artificial filamentFiberBenzoyl peroxide

The invention discloses a waterproof noise-reduction multifunctional woven fabric which is formed by weaving warp yarns and weft yarns by an air-jet loom, wherein the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30 to 36 parts of isotatic polypropylene, 10 to 14 parts of polyvinyl chloride, 20 to 24 parts of cowhair, 17 to 19 parts of alpinia fiber, 22 to 26 parts of kenaf fiber, 18 to 23 parts of cotton pulp, 7 to 9 parts of liquid paraffin, 8 to 10 parts of ethyl carbamate, 7 to 11 parts of polytetramethylene glycol, 1.1 to 2.5 parts of benzoyl peroxide, 2.1 to 3.2 parts of chitosan, 0.3 to 0.5 part of magnesium acetate, 2 to 4 parts of shell powder, 1 to 3 parts of rhizoma, 2 to 5 parts of mangnolia officinalis, 85 to 95 parts of 1-butyl-3-methyl imidazole acetate, 95 to 105 parts of 1-allyl-3-methyl imidazole chloride salt, a proper amount of water and 4 to 7 parts of assistant. The woven fabric has the advantages of warmth keeping, ventilation, wear resistance, antibacterial performance and the like.

Owner:章云

Moisture-absorbing thermal-insulation down composite fiber and manufacturing method thereof

InactiveCN104762692AIncrease elasticityGood moisture absorption and heat preservation performanceConjugated cellulose/protein artificial filamentsArtifical filament manufactureFine structureFiber

The invention discloses a moisture-absorbing thermal-insulation down composite fiber which is prepared from the following raw materials in parts by weight: 10-15 parts of goose down, 20-24 parts of wool, 16-18 parts of cowhair, 10-12 parts of French cotton, 6-9 parts of mulberry fiber, 8-10 parts of kendir fiber, 11-14 parts of plush fiber, 12-15 parts of lotus leaf, 2-4 parts of radix polygonati officinalis, 1-3 parts of rhizoma polygonati, 3-5 parts of medical stone, 4-6 parts of Shea Butter extracting solution, 0.03-0.06 part of sodium dodecyl benzene sulfonate, 0.4-0.8 part of polyethylene terephthalate, 0.7-1.2 parts of glycerol, 120-130 parts of 1-butyl-3-methylimidazole acetate, 110-120 parts of dibutyl 1-butyl-3-methylimidazole phosphate, 3-5 parts of assistant and a right amount of water. The down composite fiber has the characteristics of high flexibility, light weight, favorable elasticity, favorable moisture-absorbing and thermal-insulation properties, uniform and fine structure, favorable appearance quality and the like, and can be popularized and applied in the field of textiles or non-textiles.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Skin-relieving vegetable fiber fabric and preparation method thereof

ActiveCN103966685ABacteriostaticBreathableMonocomponent cellulose artificial filamentArtifical filament manufactureJojoba oilVegetable fibers

The invention relates to a skin-relieving vegetable fiber fabric and a preparation method thereof. The skin-relieving vegetable fiber fabric is prepared from the following raw materials by weight: 100-120 parts of 1-ethyl-3-methyl imidazole acetate, 4-5 parts of nanometer chitin, 1-2 parts of jojoba oil, 8-10 parts of water, 7-10 parts of plastic starch, 2-4 parts of polycaprolactone, 1-2 parts of whiting oil, 1-2 parts of vitamin E, 3-4 parts of lavender, 4-6 parts of rosemary, 10-14 parts of natural silk fiber, 54-58 parts of ramie, 25-27 parts of banana fiber, and 0.4-0.8 part of spinning auxiliaries. The skin-relieving vegetable fiber fabric adopts ramie as a raw material, so that the fabric has the performances of bacteriostasis, ventilation, cool, corrosion protection, mould prevention and sweat absorption; through the adoption of banana fiber and natural silk fiber, the gloss and softness of the fiber fabric are enhanced; through the adoption of vitamin, lavender and rosemary, the fiber fabric can be skin-relieving, the secretion of grease can be balanced, acne can be controlled, and inflammation can be eliminated; moreover, through the adoption of the spinning auxiliaries, spinning melt can be favorable in spinning property, the fiber fabric is fuzziness-free, is dyed uniformly, is excellent in the color and luster, and touches soft.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

Waterproof down feather composite fiber and preparation method thereof

InactiveCN104264275AWaterproofAntibacterialConjugated cellulose/protein artificial filamentsArtifical filament manufactureEpoxyFiber

The invention discloses a waterproof down feather composite fiber. The waterproof down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 10-15 parts of duck's down, 16-21 parts of rabbit hair, 15-17 parts of merino super fine wool, 8-10 parts of gabardine fibers, 3-5 parts of acetate fibers, 0.1-0.3 part of zinc oxide, 0.4-0.8 part of methyl sodium silicate, 2-4 parts of kieselguhr, 1.2-2.3 parts of polystyrene foam particles, 1-3 parts of gastrodia elata, 0.6-0.9 part of prunella vulgaris, 0.8-1.3 parts of mint, 3-5 parts of melon vine, 4-7 parts of epoxy butyl oleate, 100-115 parts of 1-butyl-3-methyl imidazole acetate, 105-115 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 2-4 parts of additives and a proper amount of water. Polystyrene foam particles, methyl sodium, gastrodia elata, prunella vulgaris, mint and other ingredients are added; the technology is simple, convenient and feasible, and is low in production cost; the prepared down feather composite fiber has the advantages of water prevention, bacteria resistance, bacteriostasis, mildew and moth prevention and the like, so that the down feather composite fiber has no odor in using, and is clean and sanitary.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Chinese herbal medicine antibacterial cotton fibers and production method thereof

InactiveCN104278356AHas antibacterial functionHigh strengthConjugated cellulose/protein artificial filamentsArtifical filament manufactureEthylene glycol monophenyl etherFiber

The invention discloses Chinese herbal medicine antibacterial cotton fibers. The Chinese herbal medicine antibacterial cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 20-23 parts of cotton fibers, 10-13 parts of modal fibers, 8-10 parts of bamboo pulp fibers, 7-9 parts of banana stem fibers, 5-8 parts of down feather fibers, 1-3 parts of sophora alopecuroide extract powder, 1-2 parts of attapulgite, 0.4-0.8 part of ammonium persulfate, 1.3-3.5 parts of glycine betaine, 18-22 parts of ethylene glycol monophenyl ether, 15-17 parts of benzyl benzoate, 4-5 parts of wild chrysanthemum, 3-4 parts of jasmine flowers, 1-2 parts of lonicera japonica, 100-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 106-110 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the Chinese herbal medicine antibacterial cotton fibers, the operation is simple, the cost is low and the operability is strong; the wild chrysanthemum, jasmine flowers and lonicera japonica are added so that the Chinese herbal medicine antibacterial cotton fibers have an antibacterial function and also have a flower flavor; and meanwhile, various animal and plant fibers are also added to the Chinese herbal medicine antibacterial cotton fibers so that the strength and the heat preservation performance of the cotton fibers are remarkably improved.

Owner:ANHUI SWAN TECH IND GRP

Method for improving deinking performing of mixed office wastepaper

ActiveCN102337692AHigh boiling pointNo vapor pressurePaper recyclingWaste paper working-upFiberPrinting ink

Owner:QILU UNIV OF TECH

Woven fabric capable of releasing negative ions and preparation method thereof

InactiveCN105155030AImprove the environmentImprove the defect of single functionConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsNoise reductionIon

The invention discloses woven fabric capable of releasing negative ions. The woven fabric is woven by warp yarn and weft yarn through an air jet loom, and the warp yarn and the weft yarn are prepared from raw materials in parts by weight as follows: 25-35 parts of polypropylene resin, 18-22 parts of polyethylene, 1-2 parts of silica, 3-5 parts of tourmaline powder, 15-20 parts of alginate fiber, 18-28 parts of Bamdal fiber, 24-30 parts of fine denier polyamide yarn, 4-5 parts of polyethylene wax, 3-6 parts of methylene diphenyl diisocyanate, 10-14 parts of methyl acrylate, 2-4 parts of folium artemisiae argyi, 3-5 parts of mint, 80-100 parts of 1-butyl-3-methylimidazolium acetate, 100-110 parts of 1-allyl-3-methylimidazolium chloride, an appropriate amount of water and 4-7 parts of an auxiliary. The fabric has multiple functions, can release the negative ions, improves the inner environment of an automobile and has the advantages of noise reduction, thermal insulation, moisture absorption, breathability, wear resistance, waterproofness, pilling resistance and the like, further, the production is simple and easy, and the cost is low.

Owner:安徽省中日农业环保科技有限公司

Wear-resisting easy-to-dye cashmere composite fiber containing Bamdal fibers and preparation method thereof

InactiveCN105040145AWaterproofAntibacterial and moth-proofConjugated cellulose/protein artificial filamentsArtifical filament manufactureCarbon fibersSODIUM NAPHTHALENESULFONATE

The invention discloses a wear-resisting easy-to-dye cashmere composite fiber containing Bamdal fibers, which is prepared from following raw materials, by weight, 21-24 parts of Angora wool fibers, 15-19 parts of coconut charcoal fibers, 16-20 parts of the Bamdal fibers, 20-23 parts of long stapled cotton fiber, 14-17 parts of viscose fibers, 2.1-3.2 parts of tea saponin, 10-12 parts of ethylene glycol, 6-8 parts of polyoxyethylene oleate, 4-7 parts of 1-methoxyl-2-propanol, 2-4 parts of nano diatomite, 0.3-0.6 parts of sodium citrate, 3-5 parts of bee wax, 0.4-0.7 parts of [beta]-sodium naphthalenesulfonate, 2-3 parts of agastache rugosus, 1-4 parts of chrysanthemum, 100-110 parts of 1-ethyl-3-methylimidazole acetate, 105-110 parts of 1-allyl-3-methylimidazole chloride, 23-26 parts of additives and a proper amount of water. The cashmere composite fiber has the special functions of being wear-resisting and easy-to-dyeing, being waterproofing, being antibacterial and moth-resistant and being not liable to pill.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Antibacterial deodorizing cashmere composite fiber containing chitin fiber and preparation method thereof

InactiveCN105040144ASoft and friendlyImprove insulation effectConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsMorpholineApocynum venetum

The invention discloses an antibacterial deodorizing cashmere composite fiber containing chitin fiber, which is prepared from following raw materials, by weight, 24-28 parts of Australian wool, 20-24 parts of black yakwool fibers, 15-18 parts of nandina fiber, 17-19 parts of the chitin fiber, 8-12 parts of polyethylene fiber, 16-19 parts of apocynum venetum fibers, 9-13 parts of short acrylic fibers, 5-7 parts of wool lubricating oil, 3-6 parts of morpholine, 6-8 parts of alkylphenol ethoxylates, 2-4 parts of carbon nano tubes, 0.03-0.06 parts of nano silver fibers, 3-4 parts of mica powder, 0.4-0.8 parts of silicon carbonate, 0.5-0.8 parts of sodium cocoate, 3-5 parts of dandelion, 2-3 parts of folium eucalypti, 85-105 parts of 1-ethyl-3-methylimidazole acetate, 100-110 parts of 1-allyl-3-methylimidazole chloride, 20-27 parts of additives and a proper amount of water. The cashmere product is soft and gentle in handfeel, is stimulation-free, is high in heat preservation and has an antibacterial and deodorizing function.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

Down feather composite fibers with jasmine fragrance and preparation method thereof

InactiveCN104294399AAnti-staticAntibacterialConjugated cellulose/protein artificial filamentsArtifical filament manufactureFiberNicotiana langsdorffii

The invention discloses down feather composite fibers with a jasmine fragrance, and is characterized in that the down feather composite fibers comprise the following raw materials in parts by weight: 13-16 parts of goose down, 16-21 parts of ox hair, 8-10 parts of glass fibers, 5-8 parts of polynosic, 3-6 parts of conductive fibers, 3-6 parts of jasmine, 1-3 parts of fructus toosendan, 2-4 parts of radix paeoniae rubra, 6-9 parts of mineral wool fibers, 18-22 parts of tobacco straws, 1.2-3.1 parts of triethyl acetyl citrate, 2.1-3.2 parts of propyl acetate, 0.2-0.5 parts of triethyl citrate, 0.6-1.4 parts of a nano pearl powder, 100-110 parts of 1-butyl-3-methylimidazolium acetate, 110-130 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 3-5 parts of an auxiliary agent, and a proper amount of water. With addition of jasmine, fructus toosendan, radix paeoniae rubra and other components, the down feather composite fibers not only have the jasmine fragrance, but also can effectively remove dirt on the feather composite fibers, and have better conditioning and nursing effects on down feather; and the prepared down feather composite fibers have the advantages of static electricity resistance, large elasticity, good filling power, bacteria resistance, bacteriostasis, wash durability and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

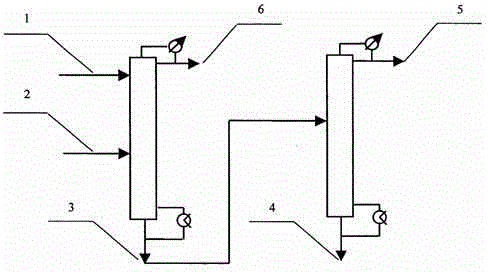

Method for separating isobutanol and ethyl isobutyrate azeotrope by continuous extractive distillation

InactiveCN104693003ALow costReduce pollutionOrganic compounds purification/separation/stabilisationOxygen-containing compound preparationHigh concentrationIsobutanol

The invention relates to a method for separating an isobutanol and ethyl isobutyrate azeotrope by continuous extractive distillation. Glycol and 1-ethyl-3-methylimidazolium acetate [Emim] [OAc] which is an ionic liquid are used as extracting agents to carry out extractive distillation; high-purity ethyl isobutyrate is obtained on the top of an extractive distillation tower, high-purity isobutanol is obtained on the top of a solvent recovery tower, and high-concentration glycol is obtained on the bottom of the solvent recovery tower; and the extracting agents can flow back to a solvent tank to serves as the supplement to the solvent.

Owner:UNIV OF JINAN

Bactericidal mildewproof down composite fibers and manufacturing method thereof

InactiveCN104762694AStrong antibacterial and bactericidalStrong anti-inflammatoryConjugated cellulose/protein artificial filamentsArtifical filament manufactureKapok fiberIrritation

The invention discloses bactericidal mildewproof down composite fibers prepared from the following raw materials in parts by weight: 11-14 parts of goose down superfine powder, 15-20 parts of puffed goose feather powder, 6-9 parts of kapok fibers, 8-12 parts of coconut palm fibers, 17-19 parts of sugarcane skins, 3-5 parts of bentonite, 5-8 parts of hollow vitrified micro bubbles, 1-3 parts of Chinese thorowax roots, 2-4 parts of white peony roots, 0.1-0.3 part of aluminum sulfate, 0.04-0.08 part of zinc oxide, 2.3-4.6 parts of polyacrylate, 0.05-0.08 part of sodium dodecylbenzene sulfonate, 1.2-3.5 parts of nano silicon dioxide, 100-120 parts of 1-butyl-3-methylimidazol acetate, 110-130 parts of 1-butyl-3-methylimidazol dibutylphosphoric acid ester, 1-3 parts of an auxiliary agent and an appropriate amount of water. The down composite fibers prepared by a method disclosed by the invention have relatively strong bacteriostatic, bactericidal, inflammation diminishing, deodorant and mildewproof effects, are irritation-free to skin, are lightweight and warm-keeping, and are deeply loved by consumers.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Ultraviolet-proof cotton fiber and preparation method thereof

InactiveCN104357933AGood moisture absorption and air permeabilityGood drapabilityMonocomponent cellulose artificial filamentCellulose/protein filament chemical after-treatmentAcetic anhydrideKapok fiber

The invention discloses ultraviolet-proof cotton fiber. The ultraviolet-proof cotton fiber is characterized by being prepared by raw materials in parts by weight as follows: 18-24 parts of cotton fiber, 6-8 parts of acrylic fiber, 7-9 parts of kapok fiber, 12-14 parts of milkweed fiber, 10-12 parts of silk worm protein fiber, 1.3-2.7 parts of hydroxyethyl cellulose, 2.1-4.5 parts of hollow glass beads, 4-6 parts of aloe vera gel, 2-4 parts of lonicera japonica, 3-5 parts of chrysanthemum, 1-3 parts of rose, 0.6-1.1 parts of calcium fluoride, 1.6-2.8 parts of cationic polyacrylamide, 3.1-4.7 parts of N-methyl pyrrolidone, 15-18 parts of acetic anhydride, 16-19 parts of triphenyl phosphite, 100-115 parts of 1-butyl-3-ethylimidazolium dibutyl phosphate, 115-120 parts of 1-butyl-3-methylimidazole acetate, 4-8 parts of an auxiliary and appropriate amount of water. Ultraviolet light can be absorbed by the added triphenyl phosphite; the cotton fiber has the advantages of good breathability and hygroscopicity, excellent drapability, comfortable hand feeling and the like by means of the added silk worm protein fiber; and meanwhile, by means of other added effective ingredients, the prepared cotton fiber further has the advantages of light mass, warm keeping, good elasticity, antibacterial and mouldproof performance, avoidance of fuzzing and pilling and the like.

Owner:安徽颍元农业科技股份有限公司

Washable light down feather composite fiber and preparation method thereof

InactiveCN104278355AIncrease profitLow costConjugated cellulose/protein artificial filamentsArtifical filament manufactureRhizomeMaterials science

The invention discloses a washable light down feather composite fiber. The washable light down feather composite fiber is characterized by being prepared from the following raw materials in parts by weight: 12-14 parts of goose down, 15-20 parts of pig hair, 14-17 parts of camel hair, 6-8 parts of plumetis fibers, 10-12 parts of tencel fibers, 7-9 parts of cheviot fibers, 2.1-3.3 parts of sorbitol, 1.2-3.4 parts of glycerol monolaurate, 10-13 parts of grapevine, 1.2-3.1 parts of citric acid, 2-4 parts of phellodendron amurense, 1-3 parts of white atractylodes rhizome, 2-3 parts of the root bark of white mulberry, 0.3-0.5 part of magnesium chloride, 3-5 parts of oxidized castor oil, 100-120 parts of 1-butyl-3-methylimidazolium acetate, 110-130 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 1-3 parts of assistants and an appropriate amount of water. According to the washable light down feather composite fiber, the pig hairs and the camel hairs are added, and therefore, the feather utilization rate is increased and the cost is reduced; and the phellodendron amurense, the white atractylodes rhizome, the root bark of white mulberry and other Chinese herbal medicines are added, so that the washable light down feather composite fiber has the advantages of health keeping, sterilization, excellent breathability, washing durability and the like.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Cotton fibers capable of releasing far infrared negative ions and production method of cotton fibers

InactiveCN104278357AGood antibacterial effectAntibacterial, anti-mite and flame retardantConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsNano al2o3Staphylococcus aureus

The invention discloses cotton fibers capable of releasing far infrared negative ions. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 20-23 parts of cotton fibers, 7-9 part of active carbon fibers, 6-10 parts of camel hair fiber, 10-12 parts of ramie fibers, 5-7 parts of polypropylene fibers, 3-5 parts of fructus xanthii extract, 2-4 parts of far infrared negative ion powder, 1-2 parts of nano aluminum oxide, 1-3 parts of medical stones, 2.1-3.5 parts of hot melt adhesive powder, 15-18 parts of C12 alcohol polyoxyethylene ether, 9-12 parts of citric acid, 12-15 parts of monoacetin, 2-4 parts of divaricate saposhnikovia root, 1-3 parts of isatis tinctoria, 100-110 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-105 parts of 1-butyl-3-methylimidazolium acetate, 4-6 parts of an addition agent and a proper amount of water. According to the cotton fibers capable of releasing the far infrared negative ions, the fructus xanthii extract is added into the raw materials by using an ultrasonic technology and has a good bacterium inhibition effect on staphylococcus aureus; and meanwhile, active ingredients including the far infrared negative ion powder, divaricate saposhnikovia root, isatis tinctoria and the like are added so that the prepared cotton fibers can release the negative ions beneficial to a human body and also have the effects of resisting bacteria, preventing mites, retarding flame and the like.

Owner:ANHUI SWAN TECH IND GRP

New anti-pilling natural plant anti-bacterial cashmere composite fabric and manufacturing method thereof

InactiveCN106835703AImproves UV protectionGood anti-felting performanceBiochemical fibre treatmentLight resistant fibresFiberSericin

The invention discloses a new anti-pilling natural plant anti-bacterial cashmere composite fabric. The composite fabric is prepared from the following steps: 31-33 parts of Tibetan antelope cashmere, 20-22 parts of rabbit plush, 8-10 parts of bamboo fiber, 10-11 parts of cottonrose hibiscus bark pectin, 33-35 parts of 40%(owf) natural sericin solution, 3-4 parts of tourmaline powder, 5-7 parts of peanut protein powder, 1.1-1.3 part of stearyl dimethyl benzyl ammonium chloride, 2.1-2.4 parts of hyaluronic acid, 1.8-2.1 parts of silicone acrylic emulsion, 0.1-0.2 part of phellodendron amurense essence oil, 185-195 parts of 1-butyl-3-methylimidazole acetate, and an appropriate amount of water. An optimal formula provided by the invention improves the production process, and the cashmere composite fiber is obtained through a wet spinning process, and the antibacterial performance, the anti-ultraviolet performance and the felting-shrinkage resistance of the cashmere are improved through the dipping treatment of the mixed finishing liquor; the manufactured felt composite fabric is anti-pilling and washable, has pearlescent graceful gloss, and the skin friendliness is further improved.

Owner:倪进培

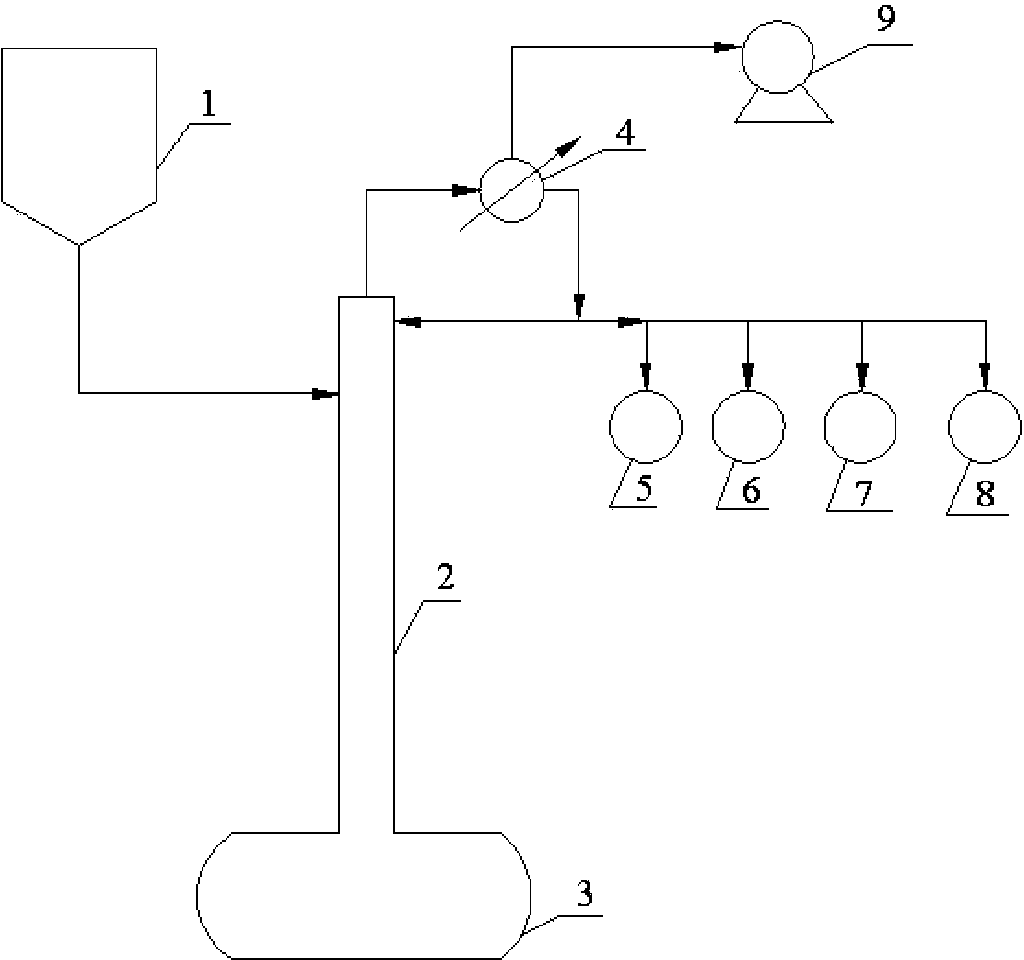

Separation method of isobutanol-ethyl isobutyrate azeotrope by batch extraction rectification

InactiveCN104370694AHigh purityReduce energy consumptionOrganic compounds purification/separation/stabilisationOxygen-containing compound preparationIsobutanolBatch extraction

The invention relates to a separation method of an isobutanol-ethyl isobutyrate azeotrope by batch extraction rectification, which comprises the following steps: ethylene glycol and an ionic liquid 1-ethyl-3-methylimidazolyl acetate are used as extractants; under normal pressure or reduced pressure, the mass ratio of the extractants entering an extraction rectification tower to the overhead is (1.8-5):1; the charging temperature of the extractants is 20-40 DEG C, and a qualified transition section I of ethyl isobutyrate, ethyl isobutyrate and isobutanol and a transition section II of isobutanol, isobutanol and ethylene glycol are sequentially produced from the tower top; and when the components of the extractants at the tower bottom satisfy the requirements, the tower is shut down for cooling, and the extractants are pumped into a higher-position storage tank for use of the next batch of material. The extraction rectification device used by the method comprises an extraction rectification tower, a heating kettle, a condenser, a higher-position storage tank, a receiving tank, a product tank and a vacuum pump.

Owner:UNIV OF JINAN

Compound warm down feather composite fiber and producing method thereof

InactiveCN104831407AGood warmth retentionImprove flame retardant performanceConjugated cellulose/protein artificial filamentsArtifical filament manufactureFiberPhosphate

The invention discloses compound warm down feather composite fiber which is characterized by comprising the following raw materials: 14-17 parts of duck down, 16-19 parts of chicken feather fragments, 8-12 parts of jute pulp fiber, 9-11 parts of black bamboo charcoal fiber, 4-6 parts of nano seaweed powder, 2-4 parts of konjac gum, 2-3 parts of expanded vermiculite, 3-4 parts of chlorinated paraffin, 1.1-2.1 parts of costustoot, 0.7-1.2 parts of honeysuckle, 0.8-1.4 parts of semen cassiae torae, 8-11 parts of waxberry bark, 10-14 parts of dry flos sophorae, 100-110 parts of 1-butyl-3-methyl imidazole dimethyl phosphate, 105-120 parts of 1-butyl 3-methyl imidazole acetate, 3-5 parts of an additive and a moderate amount of water; by effective compounding of the components, the prepared compound warm down feather composite fiber has good warmth retention property, flame retardant effect, green environmental protection, spinnability and tailorability, and enormous market demand potential.

Owner:ANHUI SANSEN TEXTILE

Radiation-proof flame-retardant cotton fiber and preparation method thereof

InactiveCN104357946AImprove flame retardant performanceAdd radiation protection functionFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsPolyesterFiber

The invention discloses radiation-proof flame-retardant cotton fiber. The radiation-proof flame-retardant cotton fiber is characterized by being prepared by raw materials in parts by weight as follows: 20-25 parts of the cotton fiber, 2-5 parts of polyester, 4.6-7.3 parts of nano-silver fiber, 12-14 parts of pinus massoniana fiber, 10-12 parts of water soluble polyurethane resin, 12-14 parts of polyethylene glycol oleate, 2.1-3.2 parts of isopropanolamine, 2-4 parts of maca, 1-3 parts of forsythia suspense, 2-5 parts of dandelion, 1.1-2.5 parts of zinc stearate, 3-5 parts of nano organically modified montmorillonite, 5-7 parts of jojoba oil, 105-110 parts of 1-butyl-3-ethylimidazolium dibutyl phosphate, 90-100 parts of 1-butyl-3-methylimidazole acetate, 4-6 parts of an auxiliary and appropriate amount of water. Through synergistic flame retardant function of the nano organically modified montmorillonite, the nano-silver fiber, the polyester and the like, the flame retardant effect and the radiation-proof function of the cotton fiber are improved, and the cotton fiber can be widely applied to the field of radiation-proof textile weaving.

Owner:安徽颍元农业科技股份有限公司

Odor-removing down feather composite fiber and preparation method thereof

InactiveCN104790063AMothproofMildew proofConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPotassiumFar infrared

The invention discloses an odor-removing down feather composite fiber which is prepared from the following raw materials in parts by weight: 13-16 parts of duck down, 16-23 parts of duck hair, 5-9 parts of wood fiber, 4-6 parts of viscose, 1.3-3.2 parts of far infrared ceramic fiber, 7-10 parts of chinlon fiber, 4-6 parts of polyoxyethylene fiber, 0.1-0.3 part of carboxymethylcellulose, 0.4-0.7 part of nano titanium dioxide, 1-3 parts of radix pseudostellariae, 2-4 parts of poria cocos, 0.1-0.3 part of potassium tetraborate, 0.2-0.5 part of zinc borate, 3-6 parts of bentonite, 100-120 parts of 1-butyl-3-methylimidazole acetate, 110-130 parts of 1-butyl-3-methylimidazole dibutyl phosphate, 2-5 parts of an additive and a proper amount of water. The odor-removing down feather composite fiber disclosed by the invention has the functions of moth resistance, mold resistance, bacterium resistance and odor removal, and further has functions of improving microcirculation and activating cells when being used as garment packing to wear.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com