Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve heat insulation and flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer far infrared ceramic fiber woven fabric and production method of nanometer far infrared ceramic fiber woven fabric

ActiveCN104593931AImprove heat insulation and flame retardant effectImprove wear resistanceConjugated cellulose/protein artificial filamentsWoven fabricsMethacrylateEpoxy

The invention discloses nanometer far infrared ceramic fiber woven fabric. The nanometer far infrared ceramic fiber woven fabric is formed by warp yarns and weft yarns in a woven mode through an air jet loom, and is characterized in that raw materials of the warp yarns and raw materials of the weft yarns comprise, by weight, 27 parts to 33 parts of syndiotactic polypropylene, 10 parts to 14 parts of linear low-density polyethylene, 8 parts to 10 parts of polyurethane films, 16 parts to 22 parts of epoxy resin, 0.4 part to 0.7 part of zinc nitrate, 0.6 part to 0.9 part of magnesium hydrate, 1 part to 3 parts of water glass, 20 parts to 25 parts of nylon yarns, 23 parts to 26 parts of colored cotton fibers, 18 parts to 23 parts of nanometer far infrared ceramic fibers, 21 parts to 24 parts of cellulose acetate fibers, 7 parts to 10 parts of isobutyl methacrylate, 5 parts to 9 parts of peach gum, 1 part to 3 parts of radix bupleuri, 2 parts to 5 parts of fossil fragments, 80 parts to 90 parts of 1-butyl-3-methylimidazolium acetate, 90 parts to 100 parts of 1-allyl-3-methylimidazolium chlorine salt, a proper amount of water and 4 parts to 8 parts of assistants. By means of the nanometer far infrared ceramic fiber woven fabric, the spinnability of plant fibers and the spinning quality are improved, the warmth keeping performance, the wearing resistance, the pilling resistance and the washing resistance of the woven fabric are further improved, and the market prospects are good.

Owner:JIXI YUANDAO AGRI IND TECH

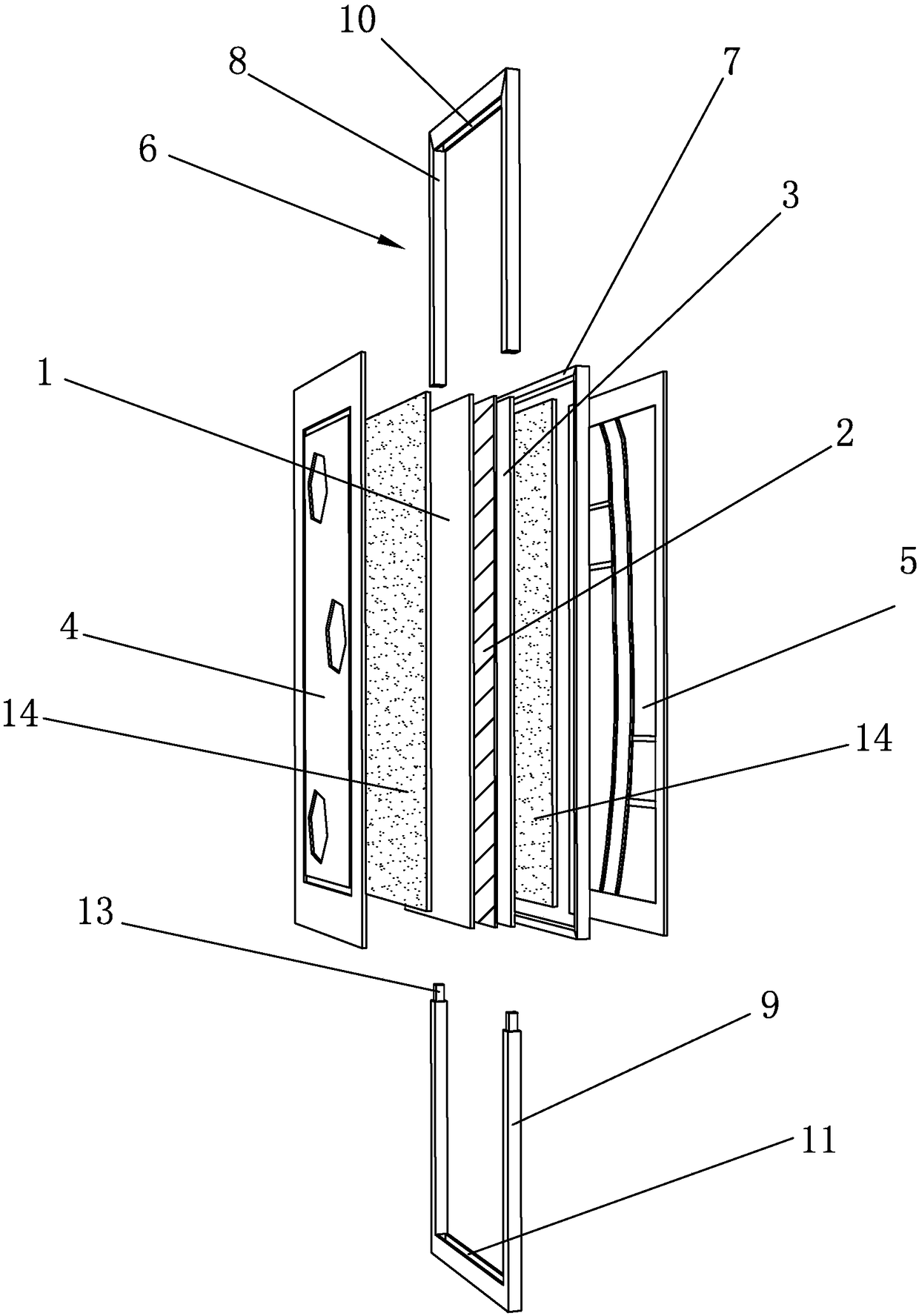

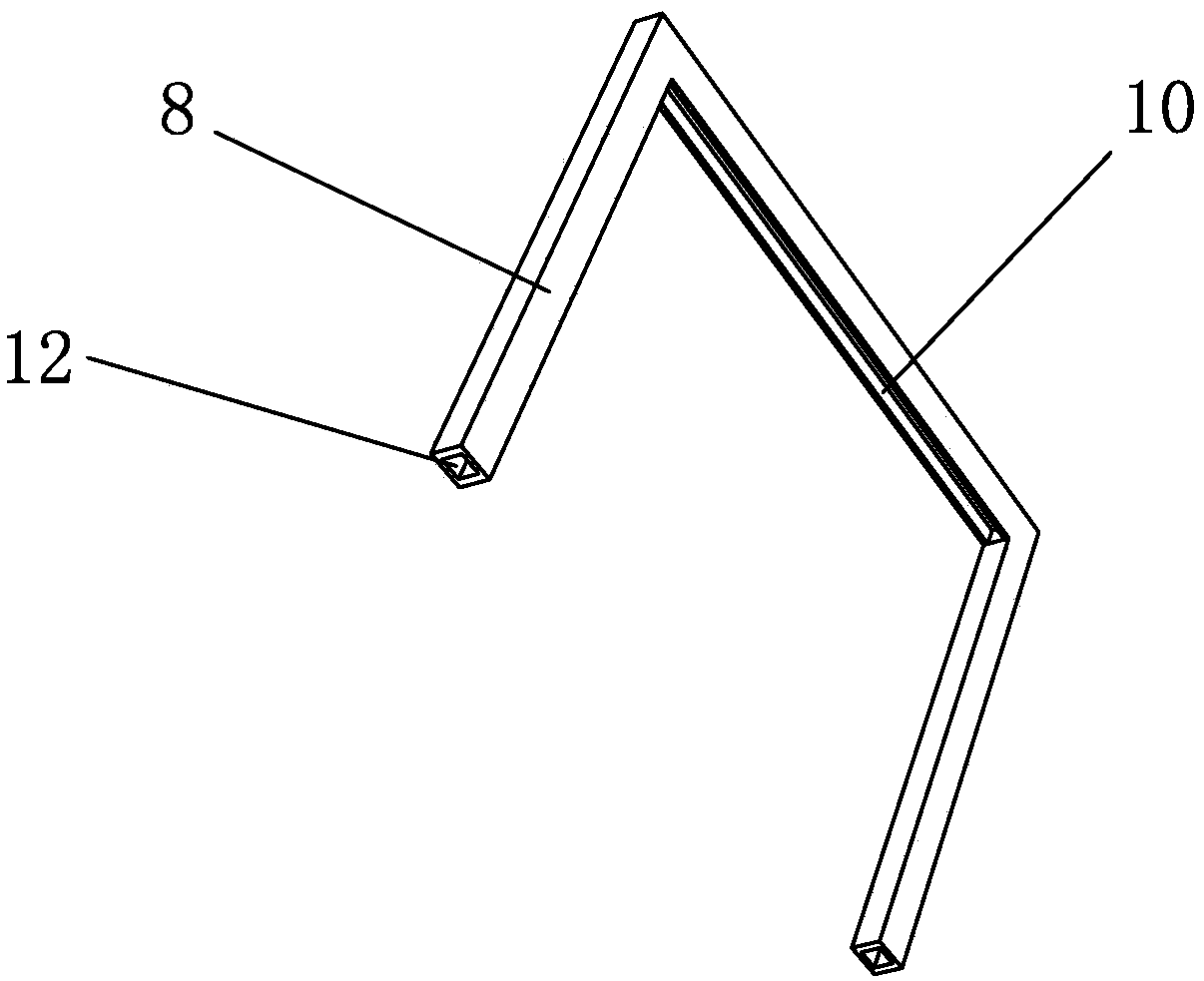

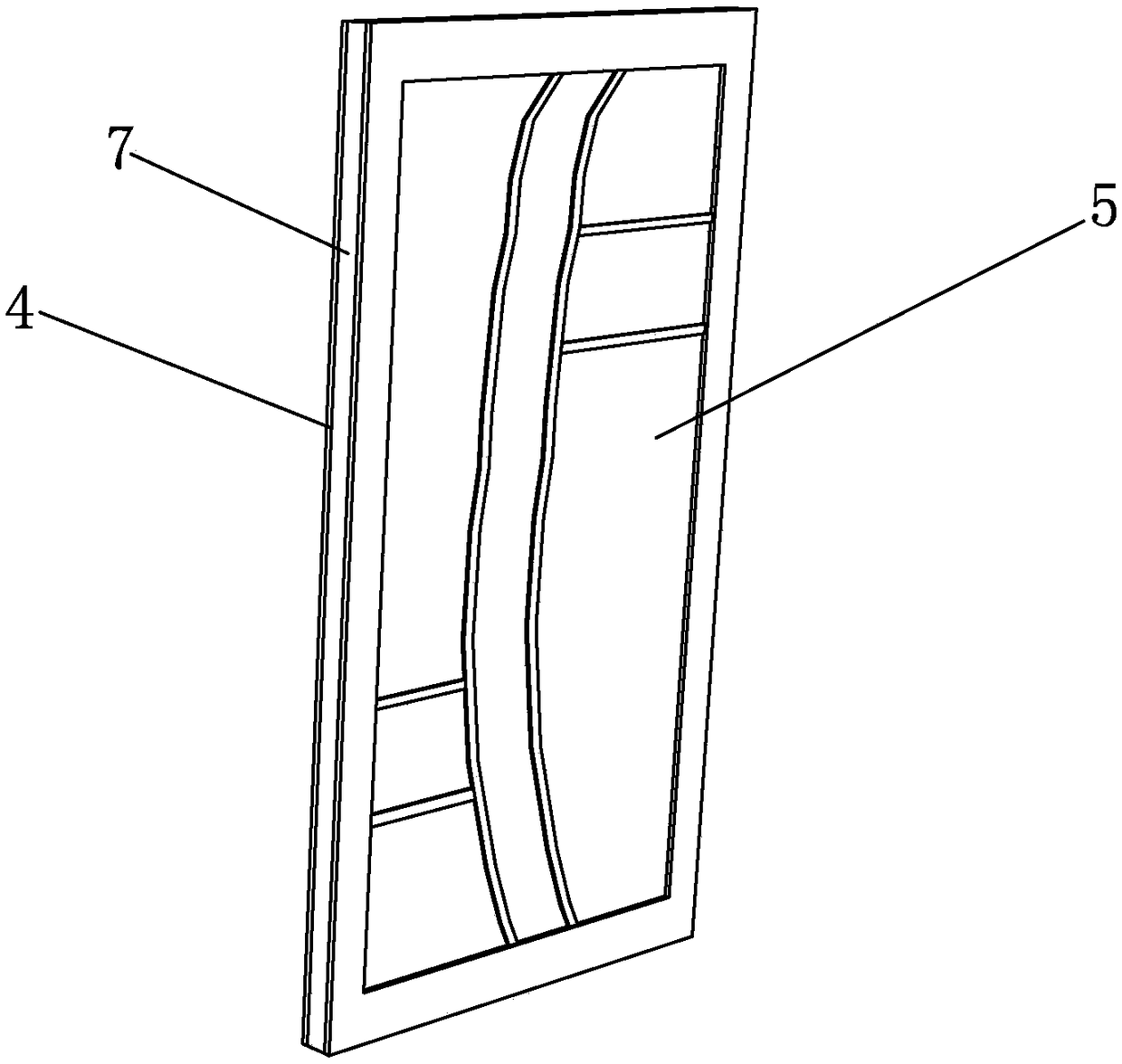

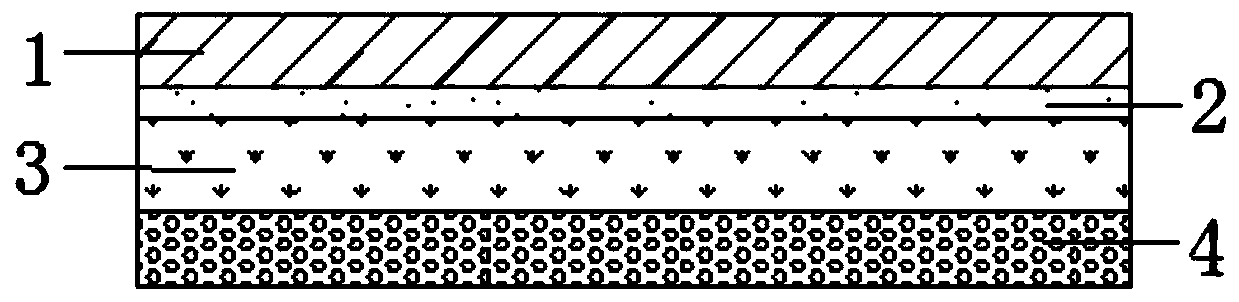

Assembled wooden door and manufacturing method thereof

ActiveCN108798398AStable structureCompact and reasonable structureFireproof doorsNoise insulation doors/windowsFixed frameUltimate tensile strength

The invention discloses an assembled wooden door comprising a wooden door base plate and a fixing frame. The wooden door base plate is connected into the fixing frame in a clamped mode and comprises afirst side base plate body, an inner core plate and a second side base plate body. The inner core plate is located between the first side base plate body and the second side base plate body. A firstdecorating layer is arranged on one side of the fixing frame. A second decorating layer is arranged on the other side of the fixing frame. The fixing frame comprises a limiting frame and an anti-collision frame. The limiting frame is connected into the anti-collision frame in a clamped mode and comprises an upper limiting frame body and a lower limiting frame body. A manufacturing method of the assembled wooden door comprises the following steps that (1) the wooden door base plate is prepared; (2) the fixing frame is prepared; (3) sound insulation pads are prepared; (4) the decorating layers are prepared; and (5) the wooden door is assembled. The assembled wooden door is ingenious and reasonable in overall structural design, the structural strength and stability of the wooden door are improved, droop deformation of the wooden door is effectively prevented, meanwhile, the four side edges of the wooden door can be protected through the design of the fixing frame, the service life of thewooden door is prolonged, and the comprehensive utilization rate is increased.

Owner:浙江图森定制家居股份有限公司

Environment-friendly inner wall coating material and production process thereof

The invention discloses an environment-friendly inner wall coating material and a production process thereof. The coating material is prepared form the following raw materials in parts by weight: 100 to 120 parts of diatomite, 50 to 70 parts of bentonite clay, 15 to 30 parts of meerschaum, 20 to 30 parts of calcined kaolin, 8 to 20 parts of calcium hydroxide powder, 5 to 10 parts of bamboo carbon fibers, 1 to 5 parts of polyester fibers, 0.6 to 2 parts of sodium perborate, 1 to 3 parts of nano zinc oxide, 0.2 to 0.6 part of calcium perborate, 0.1 to 0.5 part of dispersant, 0.2 to 0.8 part of wetting agent, and 0.1 to 0.3 part of anti-foaming agent. The production process of the coating material comprises the following steps: purifying the diatomite, mixing the diatomite, and carrying out ball-milling on the diatomite. According to the environment-friendly inner wall coating material disclosed by the invention, all components are safe and environment-friendly, heat insulation and flame retardance performance are excellent, and the inner wall coating material is antibacterial and bacteriostatic, water-proof, mildew-proof and corrosion-resistant; the production process is simple, is saving in energy sources, and is suitable for massive production.

Owner:合肥永泰新型建材有限公司

Level-A flame-retardant aluminum oil bubble heat-insulation material and preparation method thereof

ActiveCN108621497AReduced air flow pathsLower oxygen levelsSynthetic resin layered productsLaminationSilicon nitrideFire retardant

The invention provides a nano composite heat-insulation material and a preparation method thereof. The nano composite heat-insulation material is characterized in that a flame-retardant glue layer, analuminum foil layer and an aerogel layer are successively arranged on one side of a flame-retardant bubble layer; and the flame-retardant bubble layer consists of hexagonal bubble structures which are arranged in a cellular manner, and comprises 50-85 parts by weight of low-density polyethylene and 20-60 parts by weight of a compound flame retardant. The compound flame retardant comprises the following components in parts by weight: 10-12 parts of nano aluminum oxide, 16-18 parts of silicon nitride, 20-30 parts of phenolic resin, 10-30 parts of an ethylene-vinyl acetate copolymer and 2-8 parts of a silane coupling agent. By the hexagonal bubble structures which are arranged in the cellular manner and the compound flame retardant, ventilation paths are reduced, the content of oxygen is reduced, and the combustion value of an aluminum foil bubble heat-insulation material is decreased.

Owner:ZHEJIANG PENGYUAN NEW MATERIAL TECH GRP CO LTD

Environment-friendly diatom mud decoration material and preparation method thereof

InactiveCN107083087AGood fire performanceEasy to prepareFireproof paintsAntifouling/underwater paintsCalcium hydroxideQuartz

The invention discloses an environment-friendly diatom mud decoration material and a preparation method thereof. The decoration material is prepared from the following raw materials in parts by weight: 60-80 parts of diatomite, 70-90 parts of quartz sand, 15-30 parts of sepiolite, 20-30 parts of talcum powder, 8-20 parts of calcium hydroxide powder, 5-10 parts of bamboo carbon fibers, 1-5 parts of polyester fibers, 0.6-2 parts of sodium perborate, 1-3 parts of nano-zinc oxide, 0.2-0.6 part of Kathon, 0.1-0.5 part of a dispersing agent, 0.2-0.8 part of a wetting agent and 0.1-0.3 part of a defoaming agent. The preparation method of the decoration material comprises the processes of purifying diatomite, mixing and carrying out ball milling. The environment-friendly diatom mud decoration material provided by the invention is safe and environment-friendly, has relatively good bacteria resistance, bacteriostasis, water resistance, mildew resistance and fire resistance and is suitable for being used as an internal wall coating, and the preparation method is simple.

Owner:合肥永泰新型建材有限公司

Mildewproof coating for internal wall

InactiveCN108624094AReduce weightImprove heat insulation and flame retardant effectFireproof paintsAntifouling/underwater paintsSodium PyrithioneAntioxidant

The invention discloses a mildewproof coating for an internal wall, and relates to the field of coatings. The mildewproof coating is prepared from the following raw materials: bamboo charcoal powder,talcum powder, kieselguhr, a composite filler, ground calcium carbonate powder, light calcium carbonate, hydroxyethyl cellulose, a pH regulator, zinc pyrithione, octyl isothiazolone, trimethylolpropane, texanol, lauryl sodium sulfate, white clamshell powder, nano-zinc oxide, nano titanium dioxide, bauxite, vanadium carbide, a defoaming agent, a leveling agent, a dispersant, a stabilizer, an emulsifier, a thickener, deionized water, a mildew preventive, an odor remover, a softener and an antioxidant. The mildewproof coating disclosed by the invention can absorb moisture, is breathable, can adsorb and remove most indoor harmful gas such as formaldehyde and hydrogen sulfide, and is antibacterial and bacteriostatic; and even in plum rain season or even if the humidity of air is too high for along time, no mildews and no germs are generated on a wall surface, and the mildewproof coating cannot discolor and fall off.

Owner:侯娟

Stone-like paint heat preservation plate

PendingCN110700426AImprove fire resistanceAvoid spreadingClimate change adaptationLaminationCalcium silicateRough surface

The invention relates to the technical field of heat preservation plates, and particularly relates to a stone-like paint heat preservation plate. The stone-like paint heat preservation plate comprisesa heat preservation layer, a bonding layer, a panel layer and a facing layer which are sequentially stacked, wherein a plurality of grooves are formed in the surface, making contact with the bondinglayer, of the heat preservation layer; the panel layer is made of a calcium silicate plate; the upper surface and the lower surface of the panel layer are rough surfaces; the facing layer comprises aprimer layer, a finish paint layer and a mask paint layer; the primer layer is polished once before the finish paint layer is sprayed, and the mask paint layer is polished once before the mask paint layer is sprayed; the rock wool heat preservation layer is adopted in the stone-like paint heat preservation plate and can bear the high temperature of 1000 DEG C or above, in a fire disaster, rock wool can effectively prevent fire spreading, and a fireproof barrier is formed; meanwhile, the stone-like paint heat preservation plate further has the beneficial effects of achieving heat preservation and heat insulation, absorbing sound, reducing noise, being hydrophobic, stable in size, not being damaged by worms or corroded and the like; and therefore, the rock wool heat preservation layer is adopted in the stone-like paint heat preservation plate, the heat preservation and fire resistance of the stone-like paint heat preservation plate are effectively improved, and the use safety of the stone-like paint heat preservation plate is obviously improved.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

Refractory brick for boiler

The invention discloses a refractory brick for a boiler. The refractory brick is prepared from, by weight, 35-48 parts of mullite powder, 25-35 parts of quartz sand, 10-15 parts of clay powder, 5-8 parts of sillimanite, 5-8 parts of zirconium dioxide, 5-10 parts of ceramic powder and 3-8 parts of floating beads. The refractory brick is high in high temperature resistance, high in endurance strength at high temperature, and high in corrosion resistance and heat insulation performance.

Owner:江苏东方电力锅炉配件有限公司

High-temperature-resistant flame-retardant battery diaphragm, and preparation method and application thereof

ActiveCN112397849AImproved magnification performanceExtended service lifeSecondary cellsElectro-spinningPolymer scienceCellulose fiber

The invention provides a high-temperature-resistant flame-retardant battery diaphragm, and a preparation method and an application thereof. The high-temperature-resistant flame-retardant battery diaphragm comprises nano cellulose fibers and basalt fibers, wherein the mass fraction of the nano cellulose fibers is 99%-60%, and the mass fraction of the basalt fibers is 1%-40%. The diaphragm preparedby optimally combining the nano cellulose fibers and the basalt fibers gives play to the advantages of the nano cellulose fibers and the basalt fibers, has high porosity, good electrolyte wettabilityand excellent heat resistance and mechanical properties, and can improve the rate capability, prolong the service life and improve the safety of the battery.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Corrosion-resistant heat-insulating tarpaulin material and production method thereof

InactiveCN112442901AFirmly connectedExtended service lifeConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolyesterPolythylene glycol

The invention discloses a corrosion-resistant heat-insulating tarpaulin (waterproof cloth) material and a production method thereof. The corrosion-resistant heat-insulating tarpaulin material is prepared from linen fibers, polyester fibers, bamboo fibers, polypropylene fibers, charcoal fibers, resin powder, polyethylene glycol oleate, propylene epoxide, reflective filler, a flame retardant, a filling solvent, a photo-thermal stabilizer, an environment-friendly plasticizer, an anti-wear agent, an anti-ultraviolet agent, sodium hydroxide, an anhydrous additive, an antioxidant, aluminum oxide, diatomite, deionized water and nano titanium dioxide. According to the tarpaulin material, a plurality of fibers are adopted for warp and weft weaving to serve as a base layer, so that the connecting performance of tarpaulin is improved, the phenomenon of breakage is avoided, the service life is prolonged, and the waterproof performance and the wear-resisting and corrosion-resisting performance areimproved; the front face and the back face of the base layer are coated with protective layers, and the protective layers have high reflection performance and heat-insulating and flame-retardant performance and can resist ultraviolet irradiation, so that the tarpaulin has high waterproof and corrosion-resistant performance, the wear-resistant performance is also improved, the service life of the tarpaulin is prolonged, and the production process is simple.

Owner:江苏泽昊新材料有限公司

Preparation process of real stone paint insulation board

PendingCN110700427AImprove fire resistanceAvoid spreadingClimate change adaptationHeat proofingFiberglass meshGlass fiber

The invention relates to the technical field of insulation boards, particularly relates to a preparation process of a real stone paint insulation board. The preparation process comprises the followingsteps: (1) coating the upper surface of an insulation layer with a first polymer mortar layer, coating the upper surface of the insulation layer with reinforced glass fiber mesh cloth, coating the upper surface of the insulation layer with a second polymer mortar layer, and finally coating the upper surface of the insulation layer with a panel layer; and (2) coating the panel layer with a first primer layer, after the first primer layer is dried, polishing, cleaning and drying the first primer layer, coating the panel layer with a second primer layer after 2-4h, after the second primer layeris dried, polishing, cleaning and drying the second primer layer, coating the panel layer with a finish paint layer after 3-6h, after the finish paint layer is dried, polishing, cleaning and drying the finish paint layer, and spraying the finish paint layer with finish paint after 3-6h to obtain the real stone paint insulation board. The primer and the finish paint are sprayed twice, polishing andcleaning operation is adopted in the two times of spraying, the interval time between the two times of spraying is controlled, the bonding strength between the primer and the finish paint is improved, the cracking probability is reduced, and the overall spraying quality of the real stone paint is improved.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

Preparation method of environment-friendly inflaming retarding LED heat dissipation coating

InactiveCN110317519AImprove adhesionFast curingFireproof paintsLighting heating/cooling arrangementsEpoxyEmulsion

The invention relates to the technical field of LED light decoration coatings, and particularly discloses an environment-friendly inflaming retarding LED heat dissipation coating. The coating comprises a bottom-layer coating body and a surface-layer coating body, the bottom-layer coating comprises 30-55 parts of epoxy resin, 5-8 parts of graphene, 10-15 parts of a filler, 3-5 parts of a dispersionagent, 6-10 parts of a curing agent, 1-3 parts of a thickening agent and 1-3 parts of a crosslinking agent, and the surface-layer coating body comprises 20-35 parts of an emulsion, 4-10 parts of titanium dioxide, 8-20 parts of kieselguhr, 10-15 parts of a charring agent and 20-40 parts of a fire retardant. The environment-friendly inflaming retarding LED heat dissipation coating overcomes the deficiencies in the prior art, the adhesion property and attachment force of the coating are improved, the curing speed is high, the bottom-layer coating body has high heat conduction and heat dissipation performance, and the surface-layer coating body has excellent high temperature resistance and inflaming retardance effects.

Owner:天长市天泰光电科技有限公司

A kind of thermal insulation flame retardant building material and preparation method thereof

The invention relates to the technical field of building materials, and particularly relates to a heat-insulating flame-retardant building material and a preparation method thereof. The building material comprises the following components in parts by mass: 40-60 parts of artificial light-weight aggregate, 40-60 parts of an inorganic gelling material, 10-20 parts of a nano cement additive, 0.2-1.2 parts of anti-cracking fibers, 0.5-2.5 parts of a defoaming agent, 0.5-2.5 parts of a dispersant, 10-20 parts of water, 6-8 parts of calcium carbonate whiskers, 8-10 parts of magnesium salt whiskers, 0.3-0.8 part of a mortar water retaining agent and 0.2-0.5 part of a water reducing agent. The building material has the beneficial effects that the compressive strength and the flexibility of the building material are improved by adding the calcium carbonate whiskers and the magnesium salt whiskers and further improved by adding the anti-cracking fibers, so that the technical deficiencies that an inorganic heat insulating material is high in hardness and easy to drop are well overcome.

Owner:徐州逸刻新型墙体材料有限公司

Preparation method of high-fastness elastic jean laminated fabric

ActiveCN112848542AImprove flame retardant performanceImprove water absorptionSynthetic resin layered productsLaminationAluminium chlorideMicrosphere

Owner:浙江陆晟纺织有限公司

Waterproof mildew-proof inner wall powder paint and the production process thereof

InactiveCN107382160AGood fire performanceGood sound insulation and sound absorptionNano zinc oxideDefoaming Agents

The invention discloses waterproof mildew-proof inner wall powder paint and a production process thereof. The powder paint comprises the following raw materials in parts by weight: 60 to 80 parts of diatomaceous earth, 70 to 90 parts of fly ash, 20 to 30 parts of talc, 15 to 30 parts of montmorillonite, 8 to 20 parts of aluminum hydroxide powder, 5 to 10 parts of bamboo charcoal fiber, 1 to 5 parts of antimony trioxide, 0.6 to 2 parts of sodium hypochlorite, 1 to 3 parts of nano-zinc oxide, 0.2 to 0.6 part of Kathon, 0.1 to 0.5 part of a dispersant, 0.2 to 0.8 part of a wetting agent and 0.1 to 0.3 part of a defoaming agent. The production process includes diatomaceous earth purification and mixed ball milling. The waterproof mildew-proof inner wall powder paint has the advantages of safety, environmental friendliness, bacteria resistance and bacteriostasis, water proofness, mildew proofness, good fire-proofing performance and simple production process and is suitable as inner wall powder paint.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Heatproof automobile cover plate

InactiveCN105385340AGood insulation performanceImprove heat resistanceFireproof paintsPolyether coatingsGraphitePolymer

The invention relates to a heatproof automobile cover plate. The automobile cover plate comprises an automobile cover plate body. The external surface of the automobile cover plate body is covered by a layer of thermal insulation coating. The thermal insulation coating is composed of a polymer A, a polymer B, and an inorganic mixture according to a ratio of 2.5:1:0.8; wherein the polymer A comprises polyol (a), polyol (b), polyether polyol (a), and polyether polyol (b), the polymer B comprises polyimide resin, polyethylene glycol dimethacrylate, and polyvinyl chloride resin, and the inorganic mixture comprises silicon dioxide, graphite powder, and inorganic fiber. The provided heatproof automobile cover plate can improve the comfort level for passengers and avoid high temperature accidents at the same time.

Owner:韩登鹤

Energy-saving and environment-friendly heat insulation material and preparation method thereof

The invention discloses an energy-saving and environment-friendly heat insulation material and a preparation method thereof, and relates to the technical field of heat insulation materials. The heat insulation material is prepared from the following raw materials in parts by weight: 20-38 parts of acrylic emulsion mortar, 6-12 parts of polyurethane, 16-22 parts of porous aluminum phosphate, 8-12 parts of phosphorus-containing glue, 6-10 parts of hollow glass microbead, 4-8 parts of barium carbonate, 3-7 parts of modified polyimide fiber, 5-10 parts of epoxy-terminated polydimethylsiloxane, 3-5parts of nano zinc borate and 1-2 parts of a complex antioxidant. The heat insulation material has very outstanding heat insulation effect, and very high anti-press and anti-bending strength and flame retardant property.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

Environment-friendly inner wall coating material and preparation process thereof

The invention discloses an environment-friendly inner wall coating material and a preparation process thereof. The environment-friendly inner wall coating material is prepared from, by weight, 60-80 parts of diatomite, 70-90 parts of quartz sand, 15-30 parts of sepiolite, 20-30 parts of nano calcium silicate, 8-20 parts of calcium hydroxide powder, 5-10 parts of bamboo charcoal fibers, 1-5 parts of glass fibers, 0.6-2 parts of potassium perborate, 1-3 parts of nano zinc oxide, 0.2-0.6 part of kathon, 0.1-0.5 part of a dispersing agent, 0.2-0.8 part of a wetting agent and 0.1-0.3 part of an antifoaming agent. The preparation process of the inner wall coating material includes diatomite purification and mixed ball milling. The environment-friendly inner wall coating material has advantages of safety, environmental friendliness and excellent antibacterial, waterproof, mould-proof and fireproof performances and is suitable for serving as coating for inner walls, and the preparation process is simple.

Owner:合肥市一片叶装饰工程有限公司

An integrated thermal insulation board with decorative function

ActiveCN110435242BImprove the performance of compressive insulationImprove flexibilityLayered productsFiberPolymer science

Owner:HUANGSHAN RUISHENG NEW MATERIAL TECH CO LTD

Polyvinyl chloride plastic masterbatch and preparation process thereof

The invention discloses a polyvinyl chloride plastic masterbatch and a preparation process thereof. The polyvinyl chloride plastic masterbatch is prepared from, by weight, 80-120 parts of high-polymerization-degree polyvinyl chloride, 5-15 parts of alkyl betaine, 10-30 parts of modified kaolin, 5-18 parts of flame retardant plasticizer, 10-25 parts of composite nano-calcium carbonate powder, 10-20parts of modified nano-silica, 3-9 parts of cocoanut fiber, 5-12 parts of flake mica, 6-16 parts of graphite fluoride, 8-18 parts of aluminate coupling agent and 1-4 parts of mould inhibitor. The preparation process is simple, and the prepared polyvinyl chloride plastic masterbatch has high strength, high temperature resistance and corrosion resistance.

Owner:FOSHAN CHANCHENG JUYI PLASTIC FACTORY

Aramid tying belt for aerospace and preparation method thereof

InactiveCN112609292AImprove mechanical propertiesImprove surface activityFibre typesWoven fabricsPolymer scienceCarbon fibers

The invention discloses an aramid tying belt for aerospace and a preparation method thereof. The preparation method includes the steps of (1) warp preparation: grafting polar oxygen-containing groups on the surfaces of meta-aramid fibers to obtain modified meta-aramid fibers, and performing cotton opening, cotton carding, drawing, roving, spinning and shaping on the obtained modified meta-aramid fibers in sequence to obtain warps; (2) weft preparation: blending para-aramid fibers and carbon fibers, and sequentially carrying out cotton opening, cotton carding, drawing, roving, spinning and shaping processes to obtain wefts; and (3) respectively stranding and shaping the obtained warps and wefts, weaving and shaping, and carrying out after-treatment to obtain the aramid tying belt for aerospace. The aramid tying belt for aerospace has excellent flame retardancy and better mechanical properties, and can better adapt to the use requirements in severe environments.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Preparation method for heat insulating coating for improving heat resistance of automobile

InactiveCN105349027AImprove heat resistanceImprove comfortPolyether coatingsFiberPolyethylene glycol

The invention relates to a preparation method for a heat insulating coating for improving the heat resistance of an automobile cover plate. The preparation method comprises the following steps: (1) preparing a polymer A, wherein the polymer A comprises a polyol a, a polyol b, a polyether polyol a and a polyether polyol b; (2) preparing a polymer B, wherein the polymer B comprises polyimide resin, polyethylene glycol dimethyl acrylate and polyvinyl chloride resin; (3) preparing an inorganic mixture, wherein the inorganic mixture comprises silicon dioxide, graphite powder and inorganic fiber; (4) preparing the heat insulating coating. The heat insulating coating can coat the outer surface of the automobile cover plate, so that the heat resistance of the automobile can be improved, the passenger comfort degree can be improved, and high-temperature accidents can be avoided.

Owner:韩登鹤

High-fastness elastic jean laminated fabric and preparation method thereof

ActiveCN111516332AImprove practicalityImprove crispnessLamination ancillary operationsSynthetic resin layered productsAluminium chlorideMicrosphere

The invention discloses a high-fastness elastic jean laminated fabric and a preparation method thereof. The laminated fabric comprises a pretreated base fabric, a surface fabric and a TPE film, the surface fabric is laminated to the pretreated base fabric through a hot melt adhesive, and the TPE film is laminated to the surface fabric through a hot melt adhesive; wherein the pretreated base fabricis prepared by modifying a base fabric and a surface modifier; the surface modifier is prepared from the following raw materials in parts by weight: 5-7 parts of a flame retardant, 10-12 parts of water-absorbing microspheres, 8-10 parts of aluminum chloride hexahydrate, 25-30 parts of absolute ethyl alcohol, 4-6 parts of formamide, 4-6 parts of tetraethyl orthosilicate and 10-14 parts of 1, 2-epoxypropane. The invention discloses the high-fastness elastic jean laminated fabric and the preparation method thereof, the process design is reasonable, the operation is simple, a three-layer laminated fabric with excellent flame retardant property is prepared, and the laminated fabric has good stiffness and smoothness, can be widely applied to the field of clothing, and has high practicability.

Owner:浙江腾马纺织有限公司

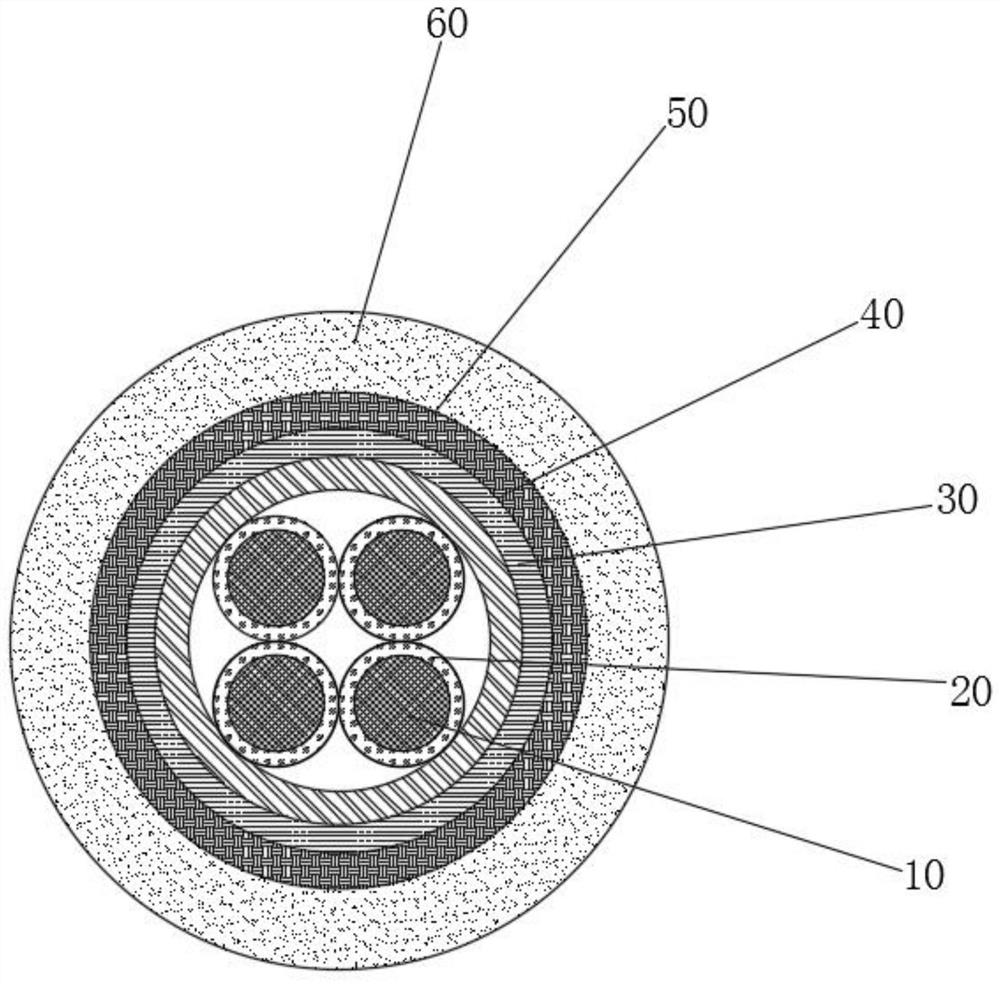

Crosslinked polyethylene insulated polyvinyl chloride sheath shielding power cable

InactiveCN112102986AImprove insulation performanceAvoid breakingApparatus for feeding conductors/cablesPlastic/resin/waxes insulatorsFiberPower cable

The invention discloses a crosslinked polyethylene insulating polyvinyl chloride sheath shielding power cable, which is characterized in that a crosslinked polyethylene insulating layer coats outsidea metal conductor, a copper wire braided shielding layer is arranged outside the crosslinked polyethylene insulating layer, and a galvanized steel wire armor layer is arranged outside the copper wirebraided shielding layer. A ceramic fiber heat insulating braided layer is arranged outside the galvanized steel wire armor layer, and a polyvinyl chloride outer sheath wraps the ceramic fiber heat insulating braided layer. The power cable is provided with the crosslinked polyethylene insulating layer, so that the insulating performance is good, the copper wire braided shielding layer and the galvanized steel wire armor layer are arranged, so that the anti-interference effect is good, meanwhile, the tensile property of the metal conductor is improved, and the heat insulating and flame retardance of the power cable are improved by arranging the ceramic fiber heat insulating braided layer. The polyvinyl chloride outer sheath effectively protects the power cable, so that the power cable has good waterproof, oil-proof and anti-corrosion effects, and the service life of the power cable is prolonged.

Owner:吴云

Preparation method of high-fastness elastic jean laminated fabric

ActiveCN112848541AImprove flame retardant performanceImprove water absorptionSynthetic resin layered productsLaminationAluminium chlorideMicrosphere

The invention discloses a preparation method of a high-fastness elastic jean laminated fabric, the laminated fabric comprises a pretreated base fabric, a surface fabric and a TPE film, the surface fabric is laminated on the pretreated base fabric through a hot melt adhesive, and the TPE film is laminated on the surface fabric through the hot melt adhesive; the pretreated base fabric is prepared by modifying a base fabric and a surface modifier; the surface modifier is prepared from the following raw materials in parts by weight: 5 to 7 parts of flame retardant, 10 to 12 parts of water-absorbing microspheres, 8 to 10 parts of aluminum chloride hexahydrate, 25 to 30 parts of absolute ethyl alcohol, 4 to 6 parts of formamide, 4 to 6 parts of tetraethyl orthosilicate and 10 to 14 parts of 1, 2-epoxypropane. According to the high-fastness elastic jean laminated fabric and the preparation method thereof, the process design is reasonable, the operation is simple, a three-layer laminated fabric with excellent flame retardant property is prepared, and the laminated fabric is high in stiff and smooth property, can be widely applied to the field of clothing, and is relatively high in practicability.

Owner:浙江唐创服装有限公司

Preparation method of waterproof fireproof paint

InactiveCN110157283AHigh strengthImprove insulation performanceFireproof paintsProtein coatingsCelluloseFiber

The invention relates to a preparation method of a waterproof fireproof paint, and belongs to the technical field of paint preparation. According to the preparation method, expandable graphite and sericite are taken as raw materials to form a carbonaceous layer with excellent bonding effect with a building substrate; sea-tangle is adopted as a raw material to provide an obtained fireproof paint with water resistance; glass fiber excellent in thermal insulation effect is adopted to improve the water resistance of the fireproof paint greatly, glass fiber and an alkali solution are reacted to improve the bulking capacity of glass fiber, glass fiber thermal insulation performance flame resistance are improved greatly, and the thermal insulation performance flame resistance of the fireproof paint are improved; rice husk is taken as a raw material to obtain lignin, lignin is decomposed into cellulose for bonding and stretching effect in the fireproof paint; a modified inorganic matter powder, standby modified glass fiber, the above modified phenolic resin, and egg white protein are mixed and stirred to form a structure similar to a foam thermal insulation layer, so that the thermal insulation performance flame resistance of the fireproof paint are improved greatly, and a promising application prospect is achieved.

Owner:曾祥民

Anti-radiation high temperature resistant heat insulating composite bushing and preparation method

ActiveCN102278569BGood anti-radiation performanceImprove heat insulation and flame retardant effectThermal insulationStarch coatingsCyclohexanoneAlkali free

The invention provides an anti-radiation high temperature resistant heat insulating composite bushing and a preparation method. The anti-radiation high temperature resistant heat insulating composite bushing comprises a lining bushing, a high temperature resistant heat insulating coating layer coated on the lining bushing, and a thin type aluminum film winding band winded on the high temperature resistant heat insulating coating layer. The thickness of the high temperature resistant heat insulating coating layer is 1-2mm, the high temperature resistant heat insulating coating layer is made from raw materials in component parts as follows, the parts are weight parts, wherein: adipic acid: 25-35 parts; trimethylolpropane: 16-20 parts; dechlorane plus: 20-30 parts; diantimony trioxide: 3-10 parts; ammonium borate: 5-12 parts; starch: 8-15 parts; zinc oxide: 5-12 parts; ammonium polyphosphate: 10-20 parts; and cyclohexanone or xylene 100-200 parts. The thin type aluminum film winding band is formed via cutting after synthesis of alkali-free glass fiber cloth and an aluminum plated film via a high temperature resistant flame retardant adhesive, and is winded on the high temperature resistant heat insulating coating layer in a mode of 1 / 2 hasp.

Owner:衡阳凌云特种材料有限公司

A kind of nanometer far-infrared ceramic fiber woven fabric and its manufacturing method

ActiveCN104593931BImprove heat insulation and flame retardant effectImprove wear resistanceConjugated cellulose/protein artificial filamentsWoven fabricsEpoxyLinear low-density polyethylene

The invention discloses a nanometer far-infrared ceramic fiber woven fabric, which is woven from warp yarns and weft yarns through an air-jet loom, and is characterized in that the warp yarns and weft yarns are made of the following raw materials in parts by weight: Propylene 27‑33, linear low density polyethylene 10‑14, polyurethane film 8‑10, epoxy resin 16‑22, zinc nitrate 0.4‑0.7, magnesium hydroxide 0.6‑0.9, water glass 1‑3, nylon yarn 20‑ 25. Colored cotton fiber 23‑26, nanometer far-infrared ceramic fiber 18‑23, acetate fiber 21‑24, isobutyl methacrylate 7‑10, peach gum 5‑9, Bupleurum 1‑3, keel 2‑5 , 1-butyl-3-methylimidazole acetate 80-90, 1-allyl-3-methylimidazole chloride salt 90-100, appropriate amount of water, auxiliary agent 4-8; the present invention not only improves plant The spinnability and spinning quality of the fiber also improves the thermal insulation, flame retardancy, abrasion resistance, anti-pilling and washability of the woven fabric, and the market prospect is promising.

Owner:JIXI YUANDAO AGRI IND TECH

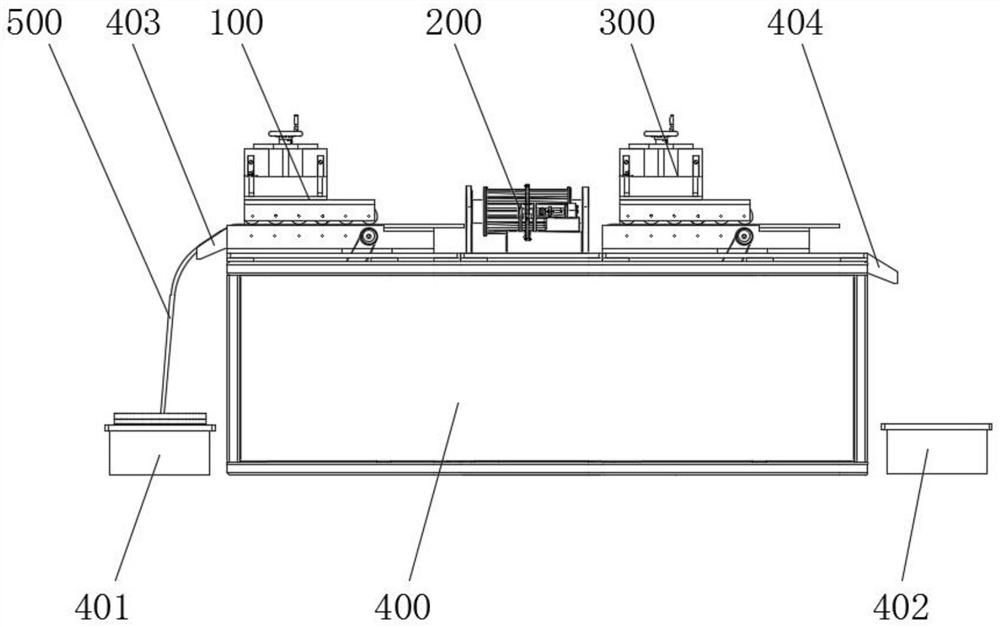

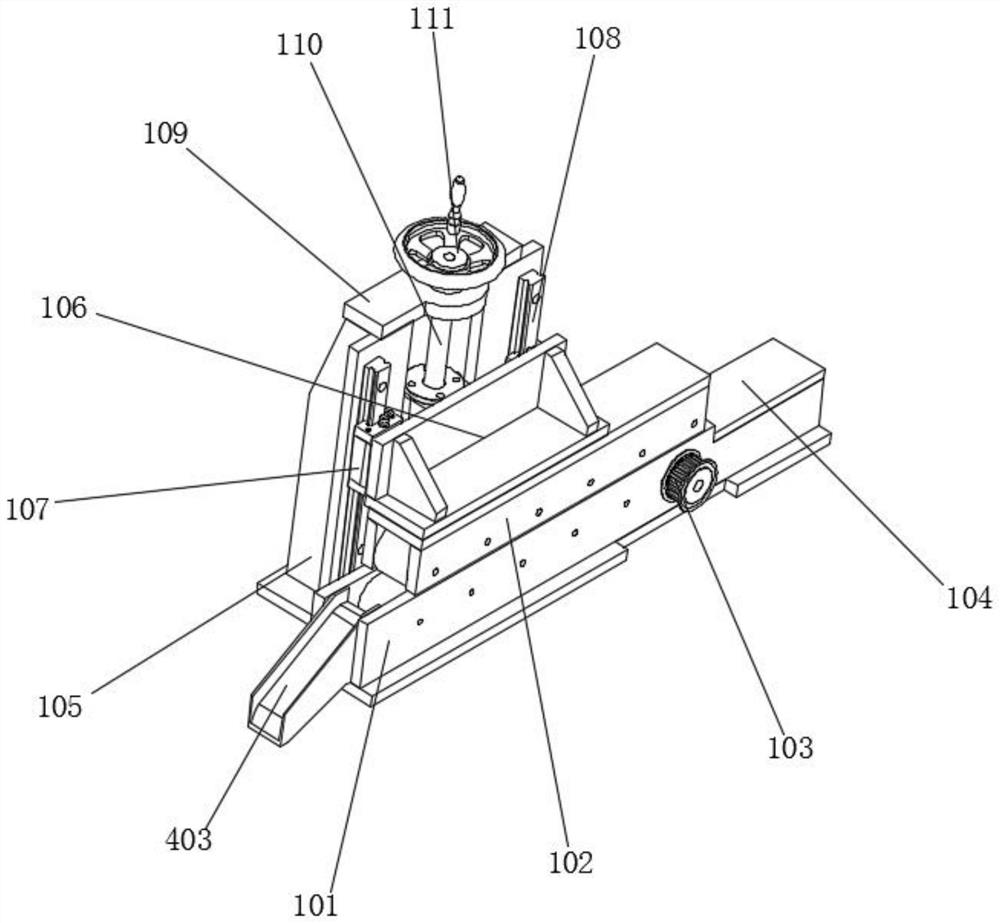

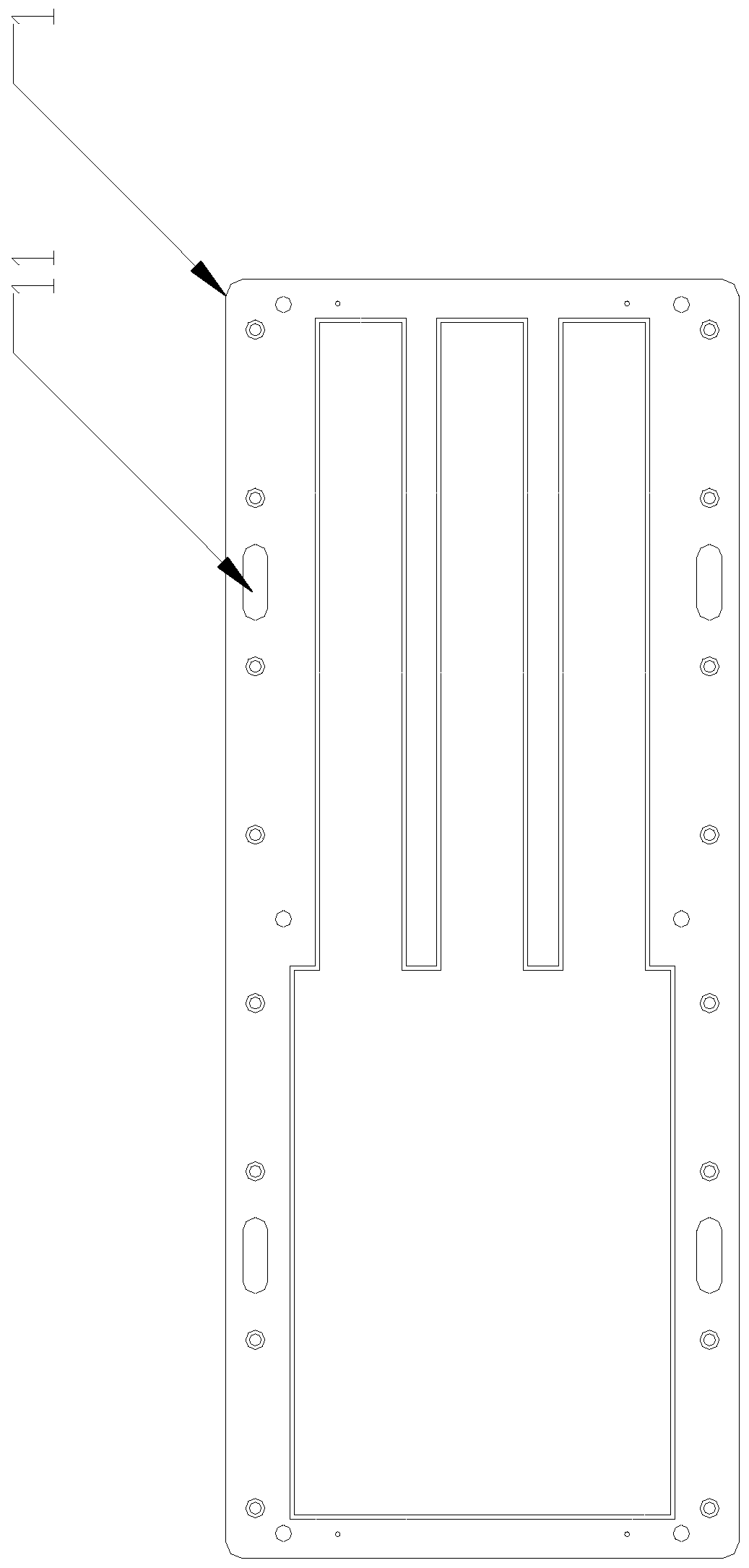

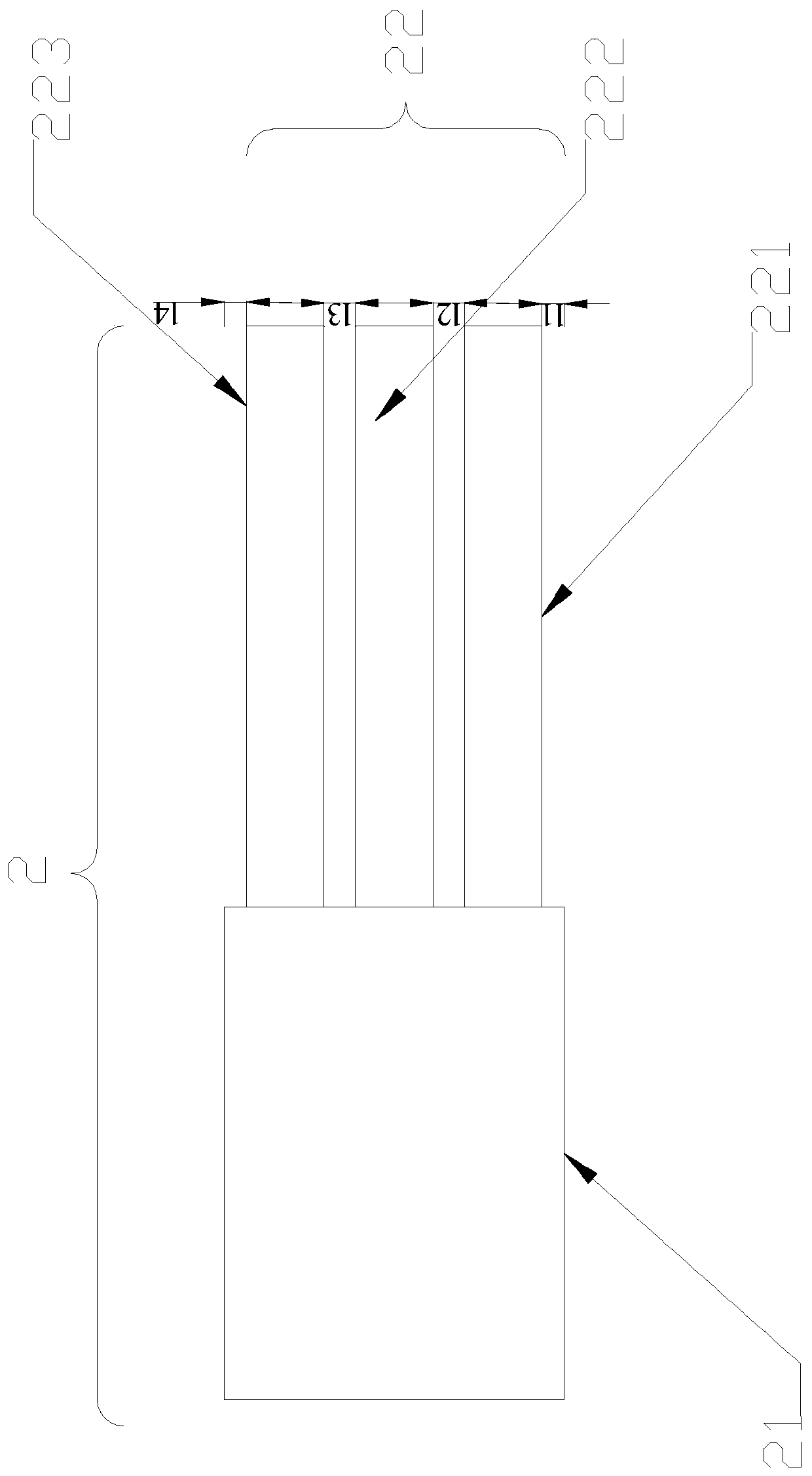

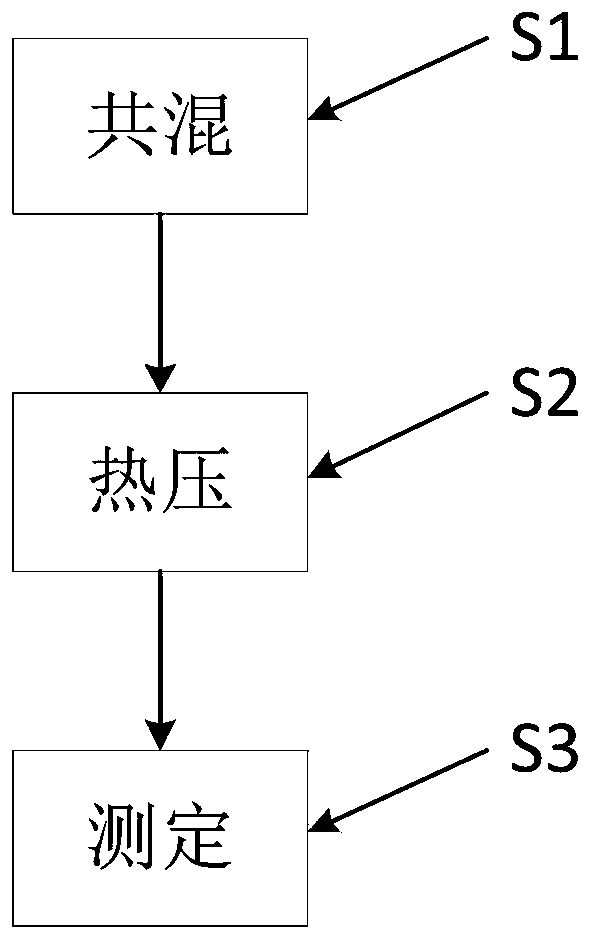

Hot pressing and forming mold of PP and PET two-component non-woven fabric sound insulation cotton

InactiveCN109878011AImproves dry sliding wear performanceIncrease dynamic elastic responseEngineeringTest material

The invention relates to a hot pressing and forming mold of PP and PET two-component non-woven fabric sound insulation cotton. The hot pressing and forming mold comprises a base, and the base is marked with a circular dividing line for mounting a sheet material; the sheet material comprises a rectangular first pressing plate and a strip-shaped second pressing plate for injecting PP and PET two-component test materials; the length of the first pressing plate is 652mm; the width of the first pressing plate is 452mm; the total length of the second pressing plate is 770mm; the width of the secondpressing plate is 422mm; the second pressing plate comprises a first limit plate, a second limit plate, and a third limit plate; the distance between the side of the first pressing plate and the sideof the first limit plate is l1, and l1 = 30 mm; the distance between the side of the first limit plate and the side of the second limit plate is l2, and l2 = 41.5 mm; the distance between the side ofthe second limit plate and the side of the third limit plate is l3, and l3 = 41.5 mm; and the distance between the side of the third limit plate and the side of the first pressing plate is l4, and l4= 30mm. The hot pressing and forming mold can reduce input of the labor cost, and greatly improve the production efficiency.

Owner:苏州壬和控股有限公司

A kind of airgel flame retardant thermal insulation foam coating with graded pore microstructure and preparation method thereof

ActiveCN110527396BEasy constructionHierarchical Pore Microstructural EnhancementFireproof paintsFiberFoaming agent

The invention provides a preparation method of aerogel flame retardant insulating foam coating with a grade hole microstructure. The preparation method includes the steps that a thickening agent, a curing agent, a foaming agent and a reinforced fiber are dispersed in a solvent, and a thickening solution is obtained; the thickening solution and water-base resin are mixed to obtain a mixed solution;and the mixed solution and aerogel powder are mixed to obtain butyrous coating, and that is the aerogel flame retardant insulating foam coating. The prepared aerogel flame retardant insulating foam coating has good sagging performance and construction performance, either the facade or the ceiling can be coated, and adhesives used in insulation boards do not need to be used; the density of the prepared aerogel flame retardant insulating foam coating is small (minimum: 100 mg / cm3), the aerogel flame retardant insulating foam coating has lower thermal conductivity than traditional external wallouter insulating materials, and thermal insulating performance and fireproof performance are achieved; and at the same time, by changing the content of the curing agent, the resin, aerogel and the reinforced fiber, the grade hole microstructure, the density and the mechanical performance of the coating can be controlled.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com