Crosslinked polyethylene insulated polyvinyl chloride sheath shielding power cable

A polyvinyl chloride sheath and cross-linked polyethylene technology, which is applied to power cables with shielding/conductive layers, power cables, insulated cables, etc., to achieve good anti-corrosion, good anti-interference, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

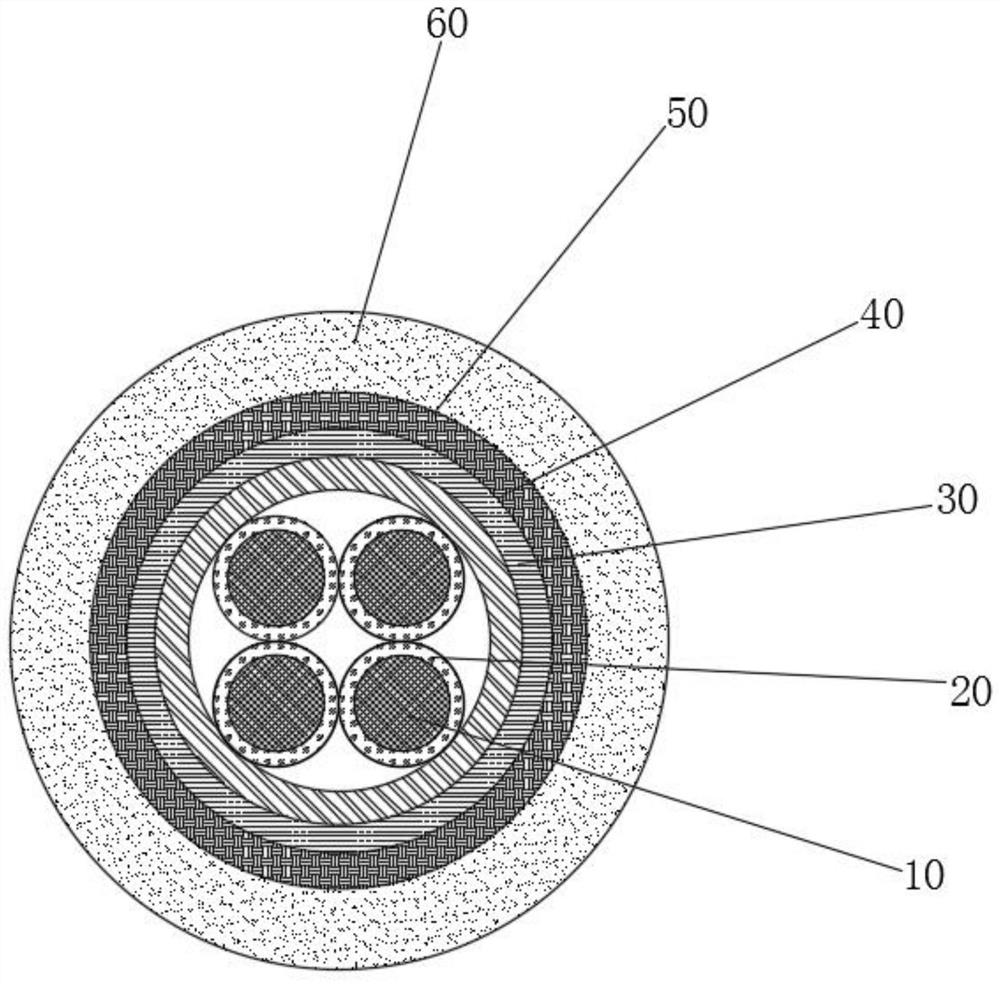

[0038] see figure 1 As shown, this embodiment is a cross-linked polyethylene insulated polyvinyl chloride sheathed shielded power cable, including a conductive wire 500, a copper wire braided shielding layer 30, a galvanized steel wire armor layer 40, and a ceramic fiber heat-insulating braided layer 50 1. PVC outer sheath 60, the conductive wires 500 are made of metal conductors 10 and the cross-linked polyethylene insulating layer 20 coated on the outside of the metal conductors 10, and the four conductive wires 500 are provided with copper wire braided shielding Layer 30, filled with filling wires between the conductive wire 500 and the copper wire braided shielding layer 30, the outside of the copper wire braided shielding layer 30 is provided with a galvanized steel wire armor layer 40, and the galvanized steel wire armor layer 40 is provided with a ceramic fiber heat-insulating braid 50, and the exterior of the ceramic fiber heat-insulation braid 50 is covered with a pol...

Embodiment 2

[0040] see Figure 1-11 As shown, this embodiment is a preparation process of a cross-linked polyethylene insulated polyvinyl chloride sheathed shielded power cable, including the following steps:

[0041] Step 1: first wrap the cross-linked polyethylene insulating layer 20 on the surface of the metal conductor 10 to obtain the conductive wire 500, wind the copper wire on the winding roller 216 of the wire braiding equipment, and connect the end of the copper wire to the conductive wire 500 After loading, install the arc-shaped plate 204 on the rotating cylinder 202 through bolts, and then pass one end of the conductive wire 500 through the feeding and conveying mechanism 100, the weaving mechanism 200, and the unloading and conveying mechanism 300 in sequence;

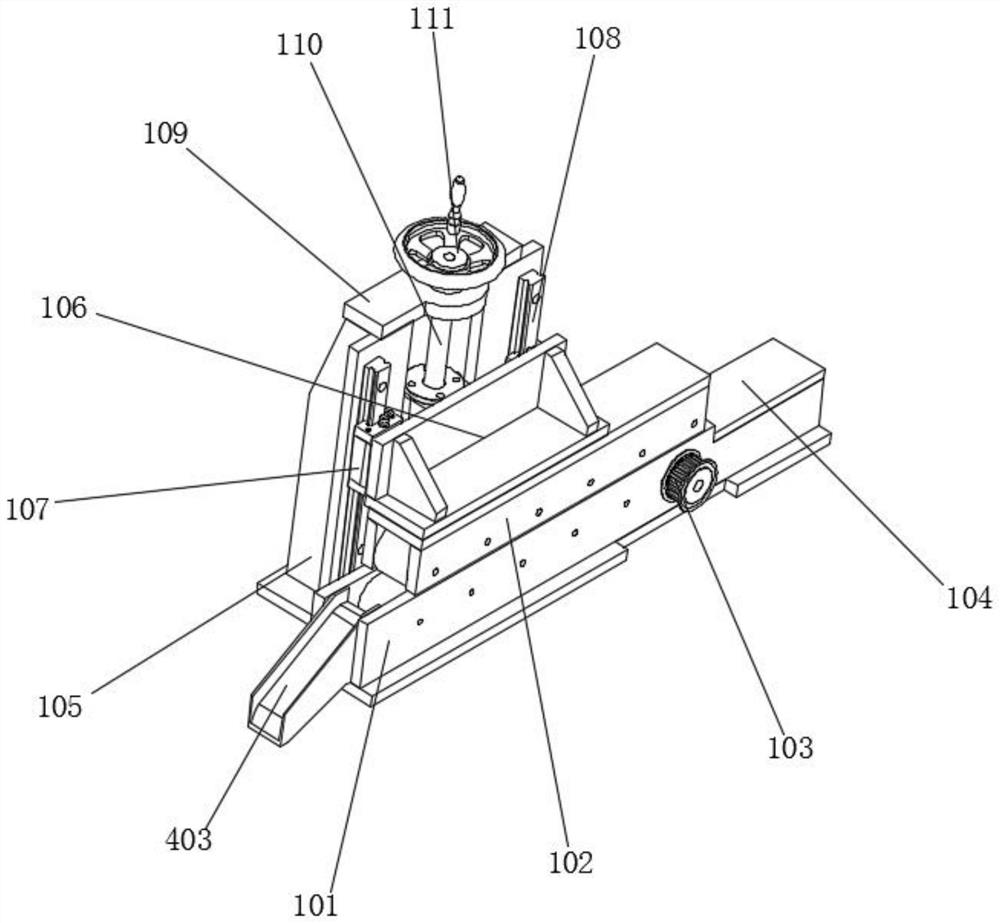

[0042] Step 2: Rotate the adjusting handwheel 111 on the feeding conveying mechanism 100 and the unloading conveying mechanism 300, and drive the supporting frame 106 and the second installation box 102 to descend thr...

Embodiment 3

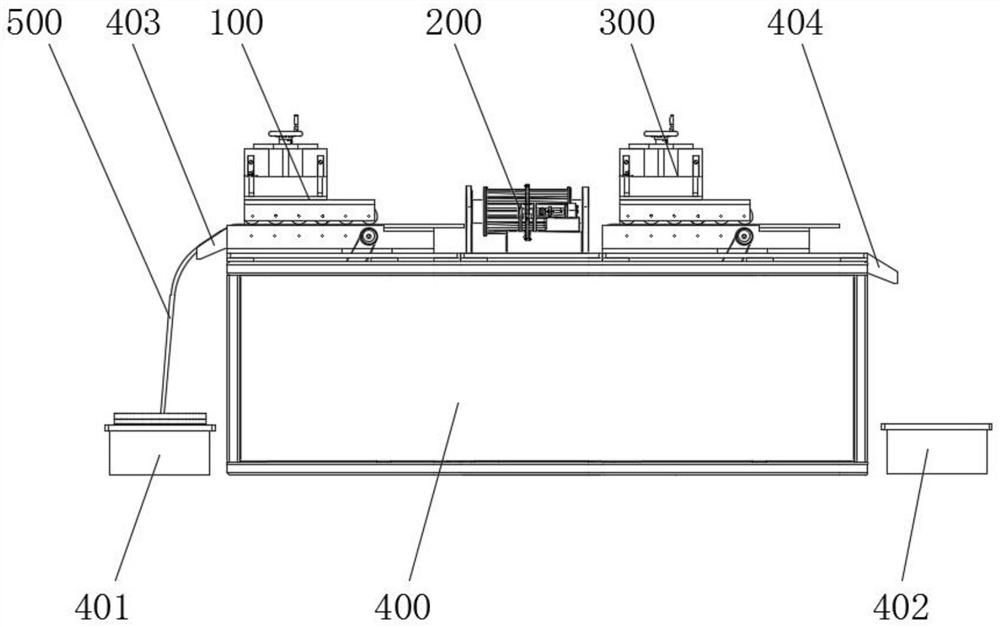

[0048] see Figure 2-11 As shown, the wire braiding equipment in this embodiment includes a feeding conveying mechanism 100, a weaving mechanism 200, a feeding conveying mechanism 300, a mounting table 400, and a conductive wire 500, and upper and lower ends of the top of the mounting table 400 are installed respectively. The feeding conveying mechanism 100 and the unloading conveying mechanism 300, the top of the installation platform 400 is installed with the weaving mechanism 200 between the feeding conveying mechanism 100 and the unloading conveying mechanism 300, and the installation platform 400 is close to one end of the feeding conveying mechanism 100 A feeding box 401 is arranged at the bottom, and a feeding box 402 is arranged at the bottom of one end of the mounting table 400 close to the feeding conveying mechanism 300, and a feeding guide groove 403 is arranged directly above the feeding box 401, and the feeding guide Groove 403 is installed on the bottom of one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com