Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Good anti-felting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finishing liquid, it preparation process and application for anti-lousiness and pilling resisting treatment of wool fibric thereof

InactiveCN1786330AImproves pilling resistanceImproved felting resistanceFibre treatmentWoolWoven fabric

The invention relates to a collating liquid. It is mainly compounded by nanometer silicasol, fortifier, and water. The percentage of the nanometer silicasol and fortifier to woven fabric weight are: the former is 2-100%; the later is 0.5-10%. Bath ratio is 1:6-60. The collating liquid manufacturing method includes the following steps: orderly adding nanometer silicasol, water and fortifier in the above proportion; stirring uniformly. The advantages of the invention are that the silicasol is treated with woven fabric by dipping and padding method to make it do gelatination on fabric to make fluffy not easy to pull out and intertwine. It can greatly improve woven fabric fluffing and balling-up resistance, felt resistance and colour woven fabric colour fastness to washing.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

Biological enzymatic production method of breathable polyester fiber and flax fiber blended yarn

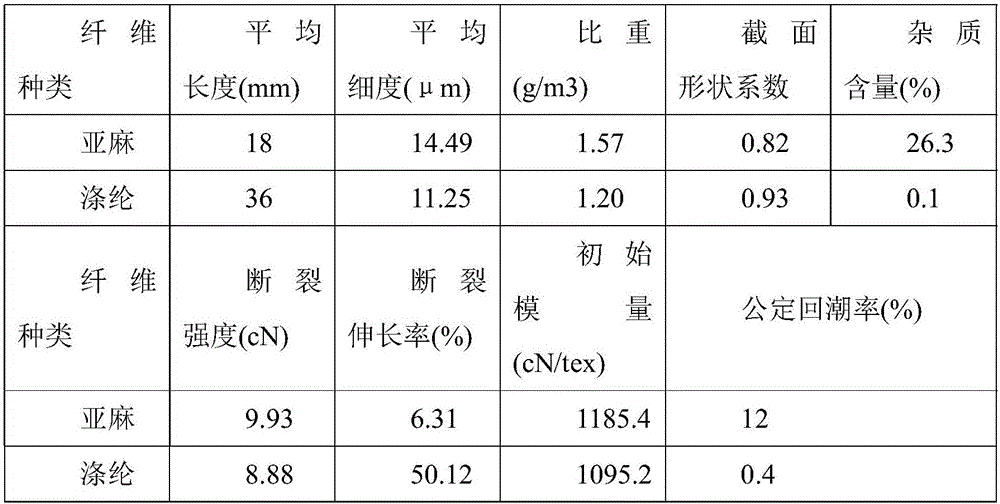

ActiveCN106087167AGood moisture absorptionImprove perspirationBiochemical treatment with enzymes/microorganismsYarnPolyesterYarn

The present invention discloses a production method of a breathable polyester fiber and flax fiber blended yarn, flax fiber is 40-80% by weight, and the balance is polyester fiber. The method comprises the steps of pretreating, cleaning, carding, drawing, roving and spinning. The production method provided herein allows for the production of the polyester fiber and flax fiber blended yarn that is hygroscopic, light and thin, glossy, breathable, antibacterial and mite-proof. The flax fiber is degummed by using a composite enzyme solution, with a degumming rate higher than and equal to 98%. In the case where enzyme usage is 15%, enzyme soaking temperature is 50 DEG C, enzyme soaking time is 1 h and stacking time is 16 h, gum residual rate of the flax fiber is only 1.83%. Fission rate of the flax fiber reaches 3.78 / dtex, with strength being 3.97 / CN per tex<-1>.

Owner:JIANGSU HUAXIN LINEN TEXTILE

Fluoride-free water-repellent antifouling finishing agent and preparation method and application thereof

ActiveCN106012543AEasy to makeLow costStain/soil resistant fibresBiochemical fibre treatmentFluorideCHITOSAN OLIGOSACCHARIDE

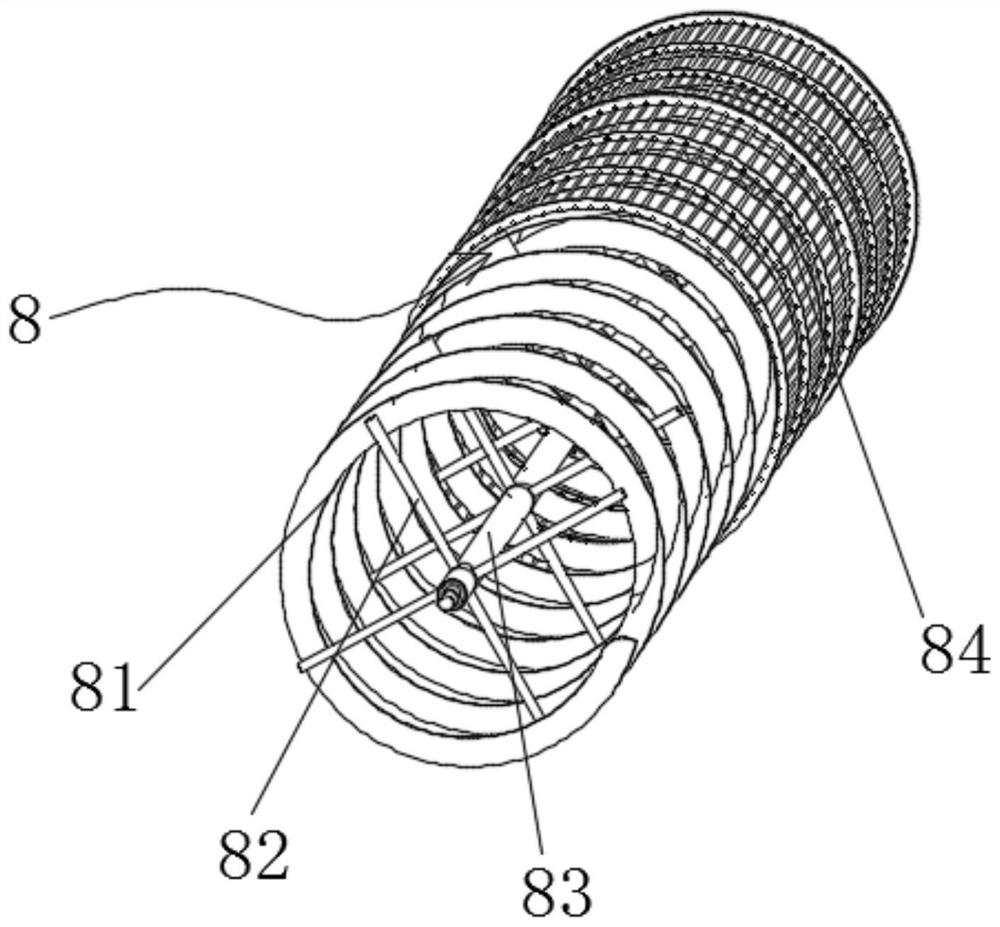

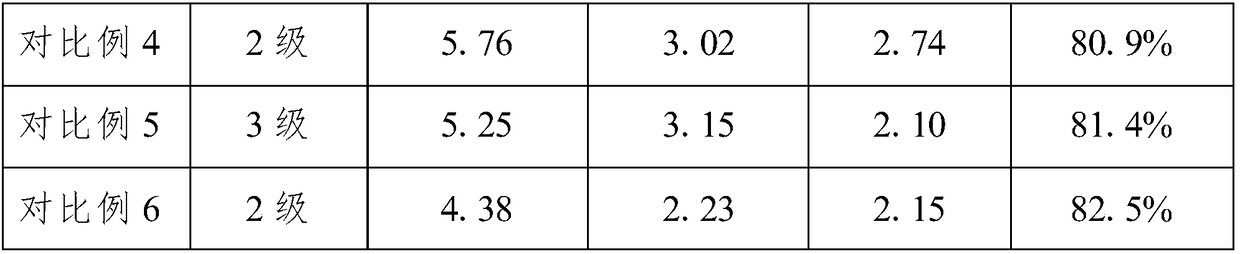

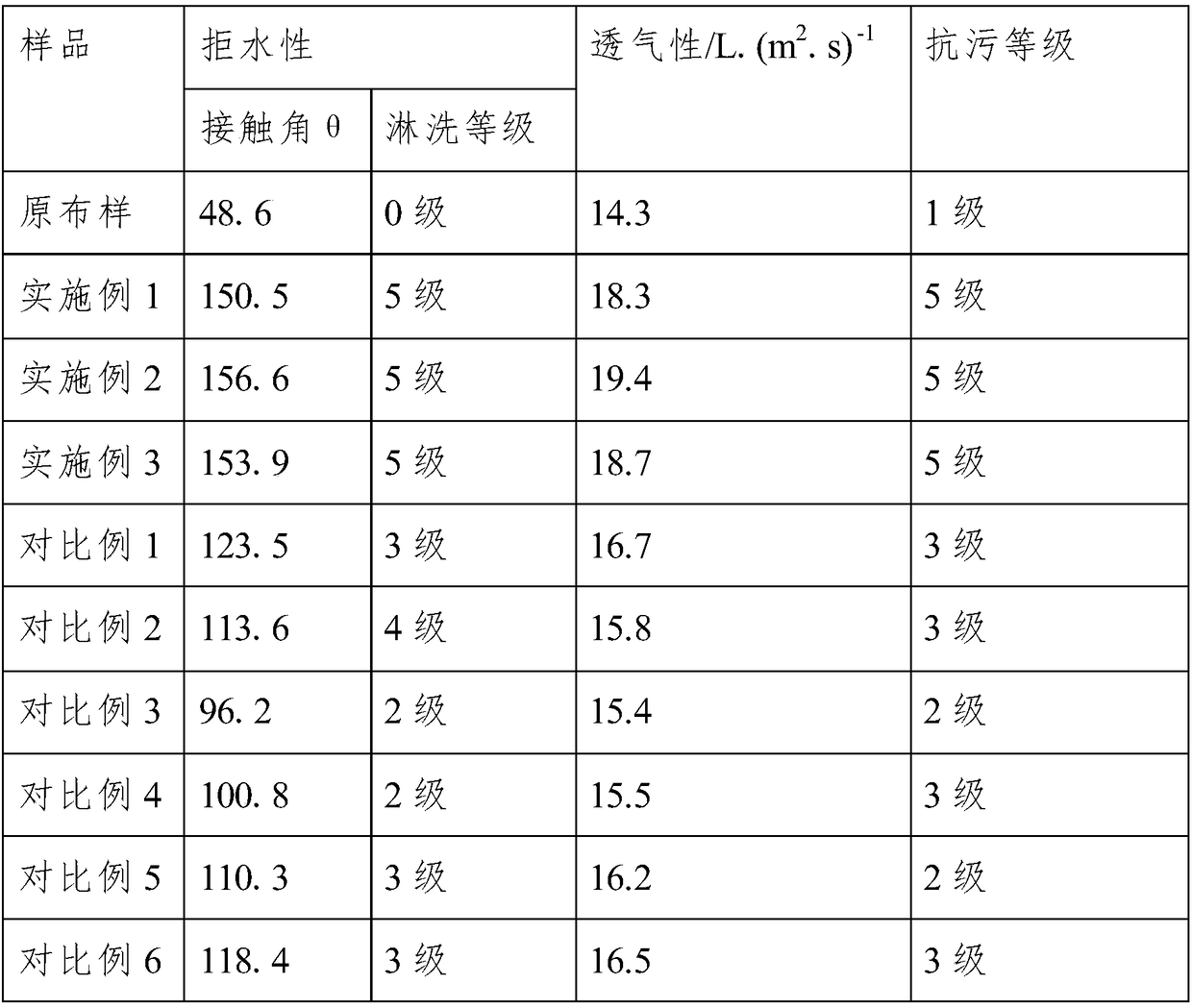

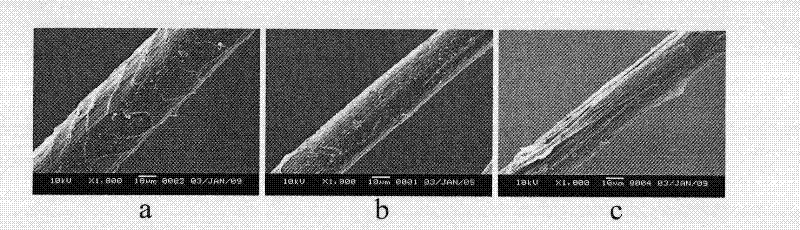

The invention belongs to the field of textile finishing agents, and particularly relates to a fluoride-free water-repellent antifouling finishing agent and a preparation method and application thereof. The finishing agent comprises a system A and a system B, the weight ratio of the system A to the system B is 1:(0.6-0.8), the system A is prepared from 0.3%-3% of chitosan oligosaccharide, 1%-10% of waterborne polyurethane and the balance water, and the system B is modified nanosilicon dioxide sol. According to the fluoride-free water-repellent antifouling finishing agent, a textile finished through the finishing agent has the super-water-repellent and antifouling effects, meanwhile, the good hand feeling and breathability of the textile can be kept, the excellent antibacterial property and shrink-proofing property are achieved, and a preparation process of the finishing agent is easy to operate and suitable for application and popularization.

Owner:JIANGSU NEW REBA TECH CO LTD

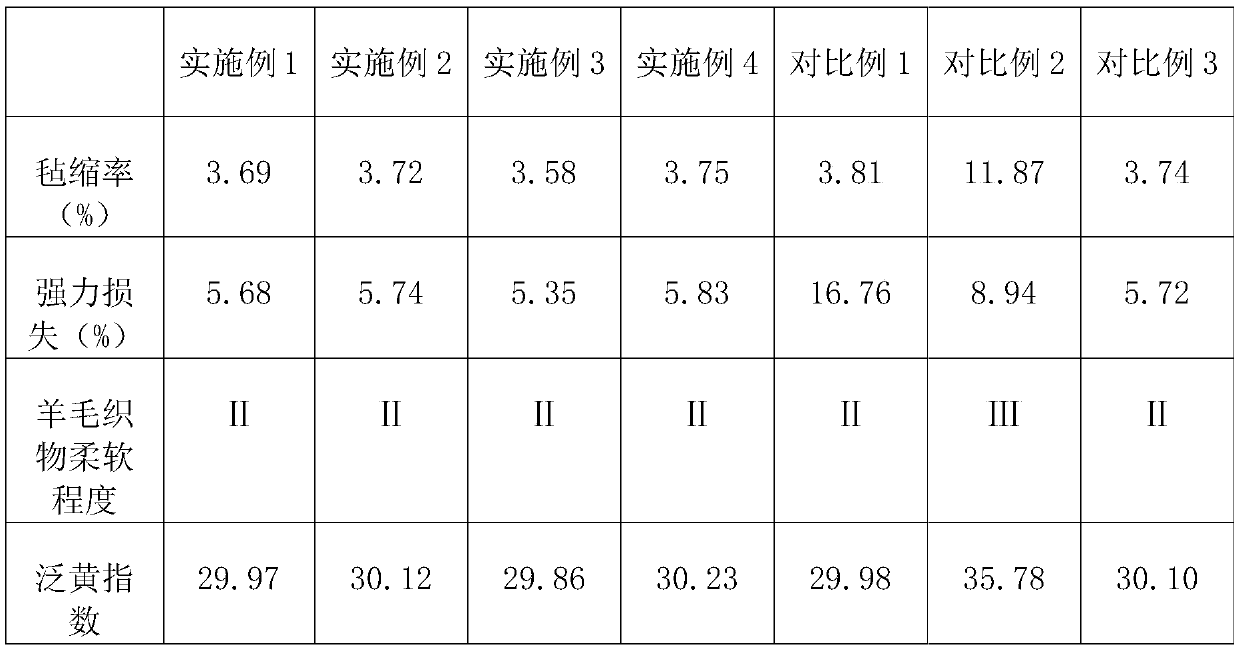

Method for felt proofing on wool fabric through proteinase K

ActiveCN109972390AHelps to swellGood for oxidationBiochemical treatment with enzymes/microorganismsShrinking resistant fibresCarbamide peroxideProteinase K

The invention discloses a method for felt proofing on a wool fabric through proteinase K and belongs to the technical field of application of dyeing and finishing and processing of the wool fabric inthe wool spinning industry. The problems are solved that during common proteinase felt proofing, the damage to wool strength is large, and the function of degrading keratin in a scale layer is small.The aim of optimizing proteinase felt proofing on the wool fabric is achieved. The optimization technology comprises the steps that the pure wool fabric is pretreated through urea peroxide, CMC is closed through chitosan oligosaccharide, and then the wool fabric is treated through the proteinase K. According to the wool fabric treated through the method, the felt proofing performance is obviouslyimproved, and the damage to the fabric strength is lowered. According to the method, the proteinase K is introduced into wool felt proofing for the first time, the wool scale cytokeratin is effectively degraded through the proteinase K, the good felt proofing effect on wool is achieved, and traditional chlorination felt proofing can be replaced.

Owner:JIANGNAN UNIV

Preparation method of elastic polyester fiber and flax fiber blended yarns by adopting bio-enzyme method

The invention discloses a preparation method of elastic polyester fiber and flax fiber blended yarns by adopting a bio-enzyme method. The weight content of flax fibers is 45 percent to 75 percent and the balance is elastic polyester fibers; the preparation method comprises: pre-treating, blowing, cotton carding, drawing, roving, degumming, bleaching, acid washing, washing and spinning. By adopting the preparation method provided by the invention, the elastic polyester fiber and flax fiber blended yarns with moisture absorption, lightness and thinness, glossiness, air permeability, antibacterial property and mite inhibition property can be prepared. The elastic polyester fiber and flax fiber blended yarns provided by the invention have high spinnability and good elasticity; cloth woven by the elastic polyester fiber and flax fiber blended yarns is light and soft, comfortable and breathable, has sweat-absorbing and antibacterial properties and has elasticity; the cloth has novel and fashionable appearance. The elastic polyester fibers and the flax fibers are blended and the disadvantage of low elasticity of the flax fibers can be made up; a prepared fabric has a comfortable hand feeling and has good elasticity; the style of the blended yarns can be improved and the hand feeling of the blended yarns can be improved.

Owner:JIANGSU HUAXIN LINEN TEXTILE

Method for preparing fiber and flax blended yarn

The invention discloses a preparation method of fiber and flax blended yarn. The weight content of the flax fiber is 45-75%, and the rest is elastic polyester fiber. The preparation includes: pretreatment, cleaning, carding, drawing and roving , degumming, bleaching, pickling, washing and spinning. The production method provided by the invention can prepare the elastic polyester fiber and flax fiber blended yarn with hygroscopicity, lightness, glossiness, air permeability, antibacterial property and anti-mite property. The blended yarn of elastic polyester fiber and flax fiber of the present invention has high spinnability and good elasticity, and the cloth woven with it is soft, comfortable, breathable, sweat-absorbing, antibacterial and elastic, and has a novel and fashionable appearance. The invention blends elastic polyester and flax fiber, which can make up for the low elasticity of the hemp fiber, and makes the fabric feel comfortable and elastic, and can improve the style and feel of the blended yarn.

Owner:江阴市博帆化纺有限公司

Special anti-wrinkle flame retardant finishing agent of wool hat

InactiveCN107938356AGuaranteed StrengthAvoid yellowingBiochemical fibre treatmentAnimal fibresWrinkle skinRare earth

The invention discloses a special anti-wrinkle flame retardant finishing agent of a wool hat. The finishing agent comprises the following raw materials in parts by weight: 20-38 parts of waterborne polyurethane emulsion, 2-10 parts of organic silicon emulsion, 1-5 parts of sodium cyanate, 3-8 parts of hydrogen peroxide, 1-5 parts of dicyandiamide, 2-10 parts of chitosan, 3-10 parts of mixed plantextracting solution, 2-10 parts of beta-cyclodextrin, 0.1-0.8 parts of cyclodextrin, 1-5 parts of organic acid, 1-4 parts of oxidized alginate, 2-10 parts of oxidized sodium carboxymethyl cellulose, 2-10 parts of rare earth oxide sol, 1-4 parts of hexa(4-aminophenoxy)cyclotriphosphazene and 1-5 parts of a hydrophilic surfactant. The special anti-wrinkle flame retardant finishing agent provided bythe invention has the advantage that the wool hat can be endowed with excellent wrinkle resistance and fire retardance.

Owner:安徽中福毛纺制帽有限公司

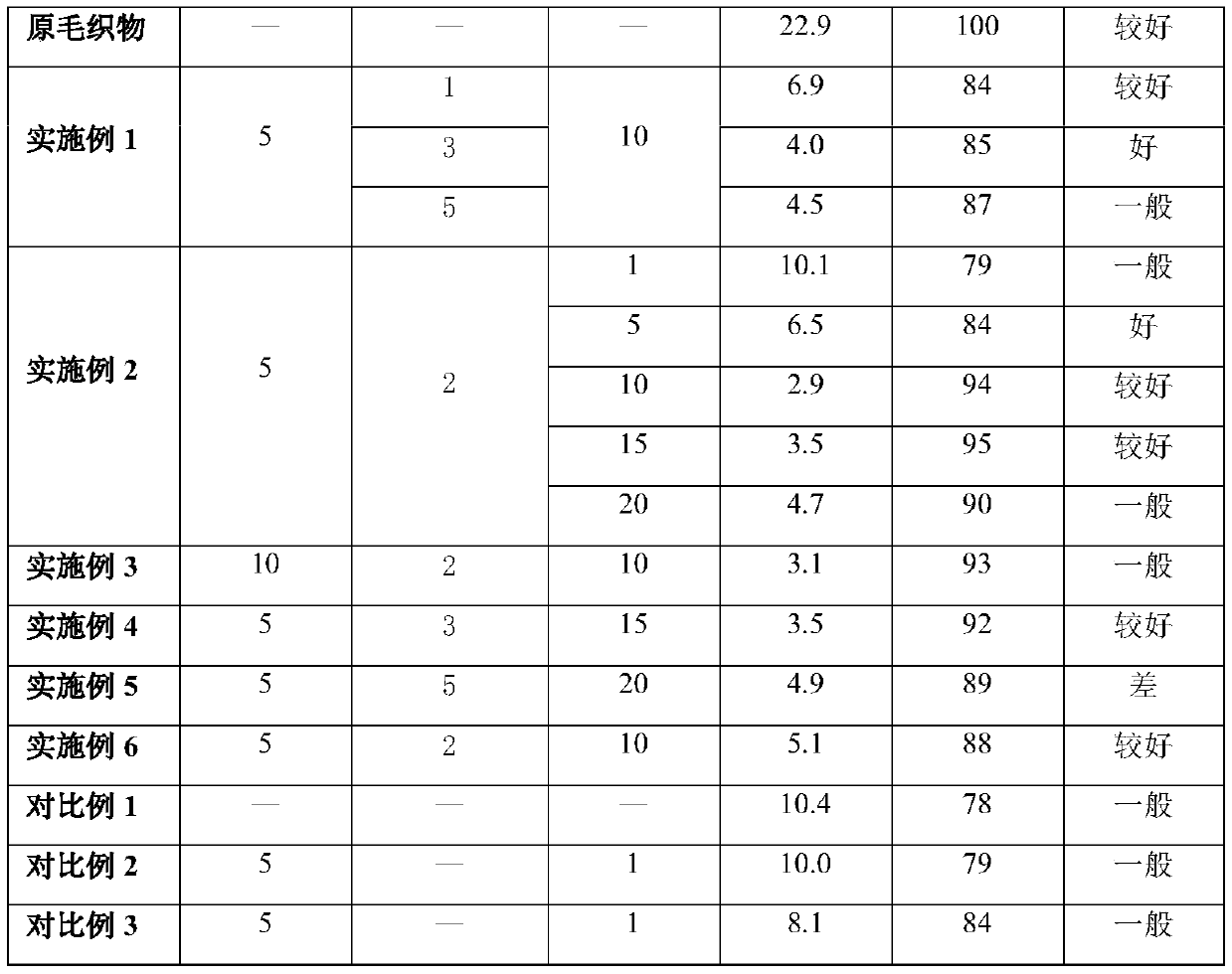

Low-strength-loss shrink-proof finishing method for wool fabric

ActiveCN109914106AReduce felt shrinkageReduce the amount of applicationAnimal fibresCelluloseEngineering

The invention discloses a low-strength-loss shrink-proof finishing method for a wool fabric and belongs to the technical field of wool fabric dyeing and finishing processing. According to the method,firstly, DCCA is adopted for conducting chlorination shrink-proof treatment on the wool fabric, then the wool fabric is soaked in a chitosan finishing solution and a cellulose nanocrystal solution insequence, assembly is conducted 10-20 times, the anti-felting performance of the treated wool fabric is obviously improved, in addition, the strength loss of the fabric is also greatly lowered, and the hand feeling of the wool fabric is good.

Owner:JIANGNAN UNIV

Production process of wool fabric

InactiveCN108301151AMaintain humiditySuitable temperatureHeating/cooling textile fabricsDyeing processAntistatic agentPulp and paper industry

The invention discloses a production process of a wool fabric. The production process includes the steps of dyeing, spinning and weaving; after weaving, an after-finishing process is also involved andcomprises the steps of soaking, fulling milling, drying, shearing and rolling; a softening agent accounting for 3-5% of the weight of the wool fabric is put into a fulling milling machine, and the wool fabric is put into the fulling milling machine for soaking for 20-30 min and then subjected to fulling milling in the fulling milling machine for 10-12 min at the rotation speed of 20-30 turns / minute; under a temperature condition of 120-160 DEG C, the wool fabric which is subjected to fulling milling is subjected to tentering for shaping at the speed of 3-5m / min; a rolling machine is preheatedto 80-85 DEG C, the wool fabric is put into the rolling machine, the temperature is raised to 130 DEG C and maintained for 3-5 min, humidification is conducted for 10-30 s, then the temperature is lowered to 80 DEG C, and discharging is conducted to obtain a finish product. By conducting dyeing after raw material wool is cleaned and adding a levelling agent and an auxiliary agent, damage to the wool can be reduced to the minimum degree, an antistatic agent is added to ensure a high moisture regain rate, the processed wool fabric can be directly in contact with water for manual cleaning or mechanical cleaning, and the shrinkage resistance of felting is great.

Owner:JIANGSU YREDAR TEXTILE TECH CO LTD

Processing method of water washable wool fabric

ActiveCN102230264AStrong clusteringImprove smoothnessHeating/cooling textile fabricsDyeing processAntistatic agentEngineering

The invention provides a processing method of a water washable wool fabric, comprising the steps of: (1) dyeing raw material wools after washing; (2) spinning; (3) weaving; and (4) post-processing. A levelling agent, wool combining oil and an antistatic agent are added in the dyeing step. The water washable wool fabric processed by the invention can be directly dipped in the water for hand washing, or can be washed by a machine; and the effect of felt shrinkage resistance is good.

Owner:LUOLAI LIFESTYLE TECH CO LTD +1

Nanometer treating technology for plush surface

InactiveCN1558020AColor stableExcellent physical and chemical propertiesAnimal materialNanometreWool

The nano woolen fiber surface treating process includes mixing wool, chloridizing to eliminate scale, dechloridizing, neutralizing, washing, nano treatment, storing and opening. Especially, by means of controlling the ZnO, TiO2, SiO2 and other components and the preparation process, woolen fiber with stable color, excellent physical and chemical performance, less balling up, easy nursing antibiotic and deodorizing woolen fiber is obtained. The present invention makes it possible to expand woolen fiber apply range.

Owner:品德羊毛(太原)有限公司 +1

Reactive dye printing technology for wool textiles

InactiveCN107956149AGood anti-felting performanceHigh color fastnessDyeing processMaterials preparationSilicone oil

The invention discloses a reactive dye printing technology for wool textiles. The reactive dye printing technology comprises steps as follows: (1), paste material preparation: 20%-25% of sodium alginate, 8%-12% of compound enzyme, 5%-10% of acrylic acid and 58%-65% of water are taken and put in a reaction vessel, and the components are heated and stirred at 45-55 DEG C until a mixture is transparently pasty; (2), color paste preparation: 50%-55% of the paste material prepared in the step (1), 8%-13% of a reactive dye, 5%-9% of a penetrant, 10%-15% of silicone oil and 16%-22% of sodium hydroxide are taken, put in the reaction vessel and stirred and mixed uniformly, and color paste is obtained; (3), printing; (4), steaming fixation; (5), soaping and drying; (6), shaping. The technology is simple and easy to control, and the wool textiles prepared with the technology have excellent anti-felting performance and are high in color fastness, low in energy consumption and good in environmentalprotection property.

Owner:CHANGSHU HULIAN PRINTING & DYEING

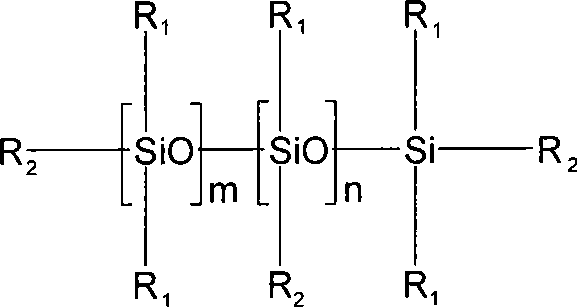

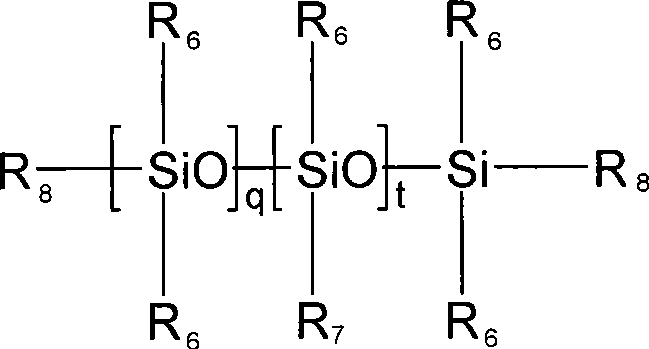

Soft smoothing agent for finishing after slopwork of wool and cashmere

The invention aims to provide a softening-smoothing agent for the after-finishing of wool / cashmere garments. Special amino silicone oil and linear polysiloxane which is non-crosslinked or can not be crosslinked are compounded and then mixed with a silane or siloxane matter which can be crosslinked to form the softening-smoothing agent which is stable to store and is used for finishing the wool / cashmere garments, so as to obtain better softness, fluffy sense and smoothness degree, obviously reduce felting trend or shrinkage. Therefore, the wool / cashmere garments can be washed by a machine.

Owner:JIAXING UNITED CHEM

Durable anti-felting finishing method for wool fabric

InactiveCN111501355AGood anti-felting performanceImprove water resistanceUltrasonic/sonic fibre treatmentBiochemical treatment with enzymes/microorganismsWoolPlasma treatment

The invention relates to the technical field of wool fabrics, and discloses a durable anti-felting finishing method of a wool fabric. The method comprises the following steps of 1) placing a wool fabric in a plasma treatment instrument for plasma pretreatment to obtain a wool fabric a; 2) putting the wool fabric a into a tetrabutyl titanate solution, then dropwise adding the mixed solution into the tetrabutyl titanate solution, and putting the wool fabric in a drying oven for drying treatment to obtain a wool fabric b; 3) adding protease into water, uniformly stirring to obtain a protease finishing solution, soaking the wool fabric b in the protease finishing solution, and drying the wool fabric in a drying oven to obtain a wool fabric c; and 4) soaking the wool fabric c in a trimesoyl chloride solution at first, then putting the wool fabric c in a polyethyleneimine solution for reaction, and drying the wool fabric in a drying oven to obtain. The anti-felting wool fabric has excellentanti-felting performance and felting durability.

Owner:胡剑安

Preparation method of modified PU (polyurethane) processing liquid for felt proofing of wool

InactiveCN108755142ASoft to the touchGood anti-felting effectGrip property fibresShrinking resistant fibresChemistryYarn

The invention discloses a preparation method of a modified PU (polyurethane) processing liquid for felt proofing of wool. The preparation method is characterized by comprising steps as follows: S1, awaterborne PU solution is prepared; S2, chitosan is dissolved in an acid solution and sufficiently stirred, and a chitosan solution is prepared; S3, the chitosan solution is added to the waterborne PUsolution, heated and subjected to a reaction for 5-10 h under the ultrasonic condition, pH is regulated to 7-8 by a saturated sodium hydrogen carbonate solution, and a finished modified PU solution product is prepared. The chitosan is introduced into an existing waterborne PU processing liquid, a uniform film is formed on the textile surface by the chitosan and a waterborne PU polymerization system, obtained wool fabric and wool yarn touch smooth, the felt proofing effect is good, and color of the wool fabric and the wool yarn before and after processing is not changed obviously.

Owner:JIANGSU SUNSHINE

Production method of decoloring-preventing wool fabric

InactiveCN104120611ADamage as little as possibleSave energyDyeing processAnimal fibresAntistatic agentHydrogen

The invention discloses a production method of a decoloring-preventing wool fabric. The method is characterized by comprising the following steps: washing raw wool, pre-treating for dyeing, dyeing, spinning, weaving and carrying out after-finishing. The step of pre-treating for dyeing is carried out in a pre-treating solution with the pH value of 8.3-8.5, and the pre-treating solution is a water solution composed of an oil removing agent, neutral electrolyte and sodium hydrogen carbonate, wherein the use amount of the oil removing agent is 1.5-1.8 g / L, the use amount of the neutral electrolyte is 4.2%-4.5% (o.w.f), and with proper amount of sodium hydrogen carbonate, the pH value of the pre-treating solution ranges from 8.3 to 8.5. In the step of dyeing, a penetrating agent, a metal chelating agent, an in-bath smoothening agent, a leveling agent, an antistatic agent and a softening agent are added into dyes. The acid neutralization step is carried out in an after-finishing solution with the pH value of 4-6. The cloth cover condition of the wool textile is good and all color fastnesses of the wool textile are good; the wool textile can be directly washed with water by hand and the anti-felting effect of the wool textile is good.

Owner:NANTONG FANGKE TEXTILE TECH

Anion easy-nursing Australasian wool strip

InactiveCN106811958AGood anti-felting performanceFor complete easy-care resultsShrinking resistant fibresAnimal fibresPolymer chemistryWool

The invention discloses an anion easy-nursing Australasian wool strip, comprising an Australasian wool strip main body and an anion resin film coated at the outer surface of the Australasian wool strip; the preparation technique of the anion easy-nursing Australasian wool strip includes steps of (1), configuring anion finishing liquid, wherein the anion finishing liquid is prepared from, by weight, 9-12% of tourmaline powder, 35-45% of polyurethane resin, 3-5% of binding agent, 2-6% of dispersing agent, 1-3% of penetrating agent, the rest is water; (2), padding the anion finishing liquid; (3), drying. Through above methods, the Australasian wool strip main body is padded by anion finishing liquid with reasonable component and mixture ratio; the outside of the Australasian wool strip is formed with a layer of anion resin film with uniform thickness, thus the Australasian wool strip has excellent felt shrinkage preventing performance, and reach the complete easy-nursing effect; meanwhile, the Australasian wool strip has health-care performance of releasing anion.

Owner:CHANGSHU XINGUANG WOOL TOP SPECIALIST PROCESSOR

Efficient dyeing process for improving anti-felting performance of wool fabric

InactiveCN110042680AImprove the degree of stainingGood anti-felting and resistance to external physical and chemical effectsDyeing processChemical effectsPre treatment

The invention discloses an efficient dyeing process for improving the anti-felting performance of wool fabric. The method includes the following steps that 1), the wool fabric is added into a nano titanium dioxide water solution to vibrate under ultrasonic waves and then dried; 2), after the wool fabric and cationic ceratin graft polymer powder are mixed, the mixture is treated with a negative pressure-positive pressure interaction method under high-speed stirring; 3), the wool fabric is subjected to ultrasonic treatment in the wet air environment; 4), the wool fabric is heated and dyed; 5), the dyed wool fabric is treated with a high-pressure treatment-pressure relief treatment interaction method and then washed and dried. According to the dyeing method, the wool fabric is subjected to aseries of pretreatment, it is promoted that dye seeps into wool fibers, and thus, the dyeing degree of the wool fabric is improved. By means of the method, scale layers of the wool fibers cannot be damaged, and the dyed wool fabric has good anti-felting performance and the capacity of resisting the external physical and chemical effect.

Owner:合肥巧织纺织科技有限公司

Preparation method and product of comprehensive easy-care wool tops

InactiveCN111139641AAntibacterialBreathableBiochemical fibre treatmentLight resistant fibresWool fiberChemical engineering

The invention discloses a preparation method and a product of comprehensive easy-care wool tops. The preparation method comprises the following steps of: carrying out raw material preparation; carrying out anion treatment, i.e., padding wool fibers in anion solution, after completing padding, washing with deionized water, then taking out the wool fibers and carrying out natural air-drying; carrying out flame retardant treatment; carrying out oxidation descaling treatment, i.e., impregnating the flame retardant wool fibers with degradation fluid, after completing impregnation, rinsing with clear water, and then drying; loading nanometer titania, i.e., placing the wool fibers into titania solution, placing the titania solution into a sealed container, gradually heating, after finishing loading, repeatedly washing with deionized water, and drying to obtain wool fibers loaded with the nanometer titania; and preparing the wool tops. In the preparation method, by a series of machining treatment such as anion treatment, flame retardant treatment, oxidation descaling treatment and loading of the nanometer titania on the wool fibers, the comprehensive easy-care wool top product with antibacterial, breathable, anti-pilling shrink-proof and self-cleaning functions can be prepared.

Owner:张家港保税区宇联羊毛工业有限公司

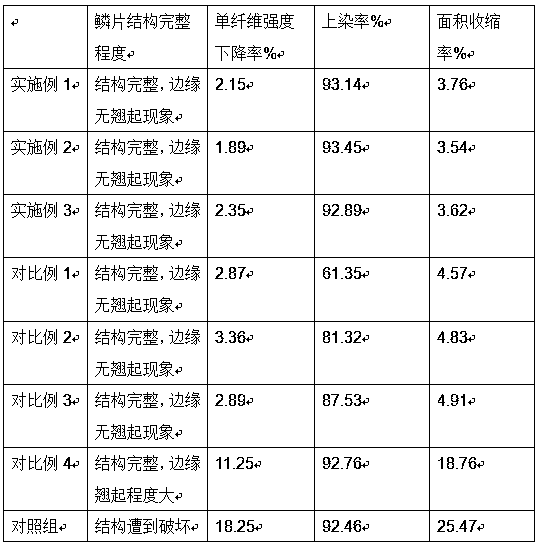

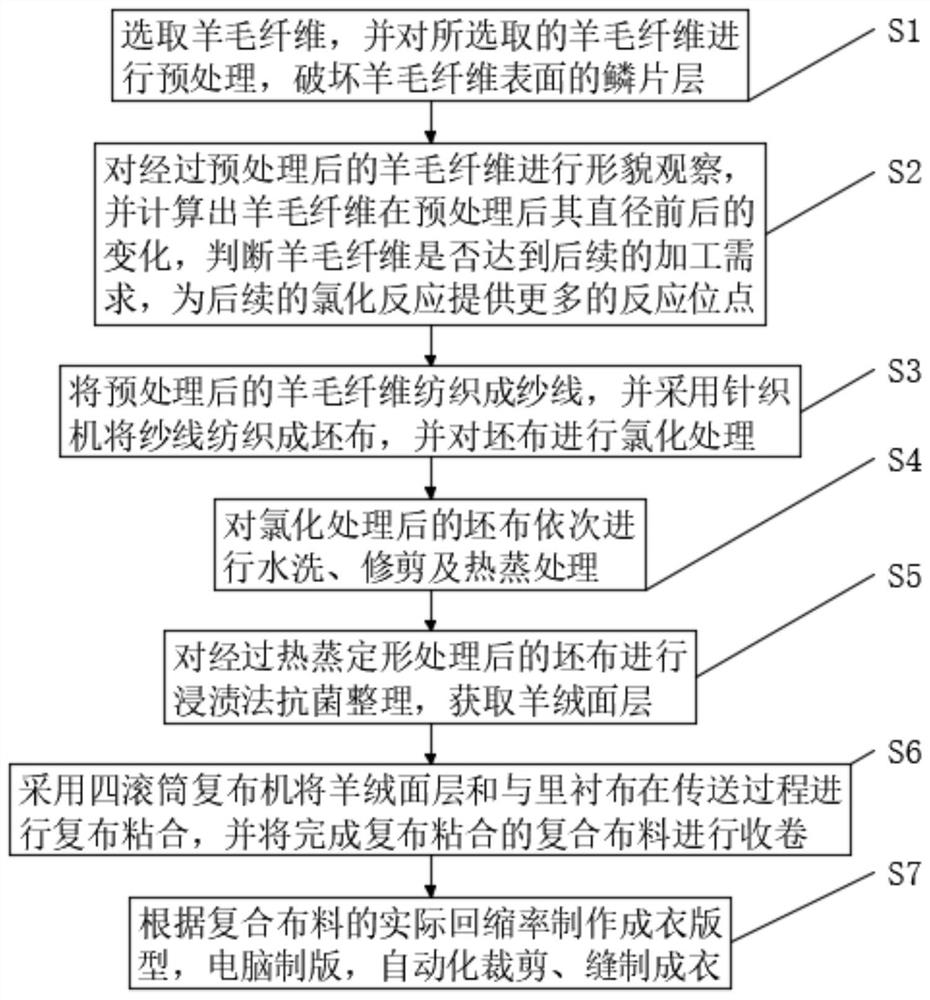

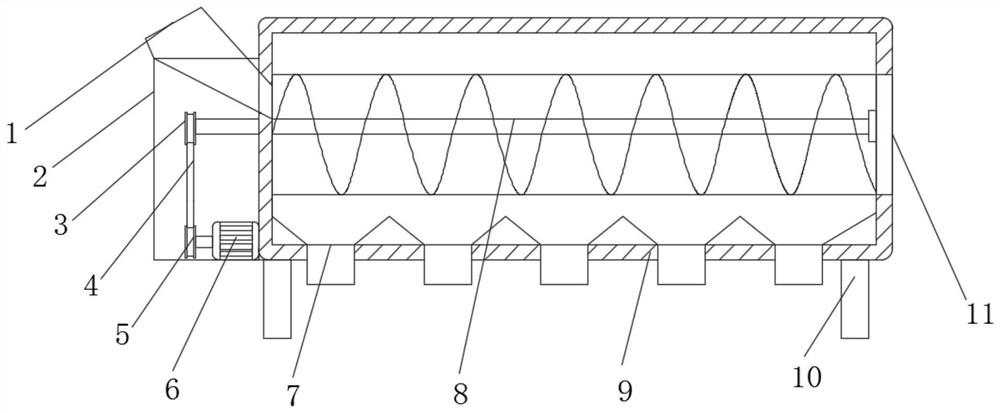

Cashmere overcoat with high shape-preserving property and antibacterial function and manufacturing process thereof

InactiveCN113317570AGood anti-felting performanceAvoid damageWeft knittingWarp knittingPolymer scienceWater chlorination

The invention discloses a cashmere overcoat with a high shape preserving property and an antibacterial function and a manufacturing process thereof and belongs to the technical field of garment manufacturing of cashmere surface and lining. According to the method, the grey cloth is washed, so the treated grey cloth is more fluffy, plump, soft and smooth, after the grey cloth is subjected to nickel catalytic chlorination treatment, effective chloride ions in hypochlorous acid can be fully utilized, the stripping effect on grey cloth scales is enhanced, meanwhile, damage to wool fibers is reduced, and compared with direct chlorination, the wool fibers are less damaged; hand feeling, fineness, strength and other properties of the modified wool are more uniform, the gray fabric is steamed to achieve flat appearance, flexible hand feeling and shaping effect, the shrinkage rate and the steaming shrinkage rate of the gray fabric are improved, crosspiece marks can be prevented, the shrinkage rates in the warp and weft directions are 0.01% and 0.15% respectively, the wrinkle recovery angle is corrected to be 295 degrees, the gray fabric is more stiff, soft and smooth, and combination of the antibacterial agent and the fabric can be firmer through high-temperature baking.

Owner:保定月上服饰制造有限公司

Si/Ti composite sol and application thereof

InactiveCN1888297ALow baking temperatureSolve the problem of severe yellowingFibre treatmentSiliconMaterials science

The present invention provides a Si / Ti compound sol and its application in fabric anti-felting finishing process. Said Si / Ti compound sol is made up by using silicon sol and titanium sol through a certain compounding process. By using said Si / Ti compound sol to treat the fabric, its curing temperature is low, it only has need of curing for 3 minutes at 100-600deg.C, it can obtain good anti-felting finishing effect.

Owner:DONGHUA UNIV

A kind of warm fluffy duvet and its preparation process

ActiveCN109911837BGood antibacterialEasy to keep warmBlanketBed linenAnti bacterialAntibacterial agent

The invention discloses a heat-insulating fluffy down quilt and a preparation process thereof. The heat-insulating fluffy down quilt comprises a down quilt cover and an inner core, wherein the inner core is coated with the down quilt cover; the inner core is filled with bamboo charcoal fibers and pretreated wool and down feather. The heat-insulating fluffy down quilt is prepared by the following steps: 1) pretreatment of down feather: sterilizing-stem removal of raw materials-removal of sand dust-refining-primary cleaning-washing-dehydration-drying; 2) pretreatment of wool; 3) preparation of the down quilt: uniformly mixing the bamboo charcoal fibers and the pretreated wool and down feather, and then filling an inner core sleeve of the down quilt with the mixture. According to the heat-insulating fluffy down quilt disclosed by the invention, the down feather, wool and bamboo charcoal fibers are taken as the raw materials, the down feather is screened twice through a down feather screening machine to select high-quality large down feather, and then mixed with the wool and bamboo charcoal fibers for filling, and the mixture is treated with an anti-bacterial agent, so that the prepared down quilt has a good anti-bacterial effect, heat-insulating performance and fluffiness.

Owner:宁波博洋家纺集团有限公司

Wear-resistant natural plant antibacterial cashmere composite fabric with high thermal stability and making method thereof

InactiveCN106758230AGood antibacterialImproves UV protectionBiochemical fibre treatmentLight resistant fibresFiberProtein solution

The invention discloses a wear-resistant natural plant antibacterial cashmere composite fabric with high thermal stability, which is prepared from the following raw materials in parts by weight: 30-32 parts of inner Mongolia white cashmere, 21-22 parts of mulberry silk, 8-9 parts of 3D conductive fibers, 9-11 parts of hibiscus mutabilis stem and bark pectin, 36-38 parts of 40 percent of (owf) natural sericin protein solution, 6-8 parts of chitosan, 2-3 parts of paraffin, 4-6 parts of guar gum, 7-8 parts of lignocellulose, 3-5 parts of medical stone powder, 0.1-0.3 part of tea tree essential oil, 180-190 parts of 1-butyl-3-methyl imidazole acetate and a proper amount of water. The wear-resistant natural plant antibacterial cashmere composite fabric disclosed by the invention has the advantages that a formula is optimized, a production process is improved, cashmere composite fibers are prepared through a wet spinning process, and then the antibacterial property, the ultraviolet protection and the felting shrinkage resistance of cashmere are improved through the dipping treatment of mixed finishing liquid; the prepared cashmere composite fabric has the wearing properties of abrasion resistance, high thermal stability and strong spinning property.

Owner:倪进培

Anti-bacterial and anti-felting finishing method for woolen cap

InactiveCN107956106ALow densityReduce areaBiochemical fibre treatmentAnimal fibresArginineSalicylic acid

The invention discloses an anti-bacterial and anti-felting finishing method for a woolen cap. The method comprises steps as follows: the woolen cap is soaked in an aqueous solution of a penetrating agent JFC and subjected to ultrasonic treatment and drying, then the woolen cap is added to hydrogen peroxide and subjected to soaking, washing and drying, and a pretreated woolen cap is obtained; ethanol and acetic acid are mixed, butyl titanate is added, silver fluoride and tetrabutylammonium fluoride are added, the mixture is placed at the room temperature and then washed to be neutral, filteringand drying are performed, and a material A is obtained; salicylic acid and arginine are added to water, the material A is added, the mixture is soaked at the room temperature, filtered, washed and dried, and modified nano titanium dioxide is obtained; organosilicon quaternary ammonium salt, protease, chitosan, sodium silicate, lauryl sodium sulfate, modified nano titanium dioxide, polycarbamouylsulfonate esters, catechin, sulfonic-beta-cyclodextrin and a coupling agent are added to water, a mixed solution is subjected to ultrasonic treatment, and a finishing agent is obtained; the pretreatedwoolen cap is soaked in the finishing agent to be subjected to padding, cleaning, drying and braking, and the anti-bacterial and anti-felting finished woolen cap is obtained.

Owner:安徽中福毛纺制帽有限公司

Scoured wool with high felting shrinkage resistance and manufacturing method of scoured wool

InactiveCN111411508AImprove the effect of oxidation treatmentImproved anti-felting propertiesUltrasonic/sonic fibre treatmentShrinking resistant fibresPolymer chemistryWool fiber

The invention provides a scoured wool with high felting shrinkage resistance and a manufacturing method of the scoured wool, and relates to the field of wool manufacturing. By sequentially conductingultraviolet light treatment, ozone oxidation treatment, ultrasonic treatment and chitosan treatment on the wool, the wool has the good felting shrinkage resistance, wherein specific operation of ultraviolet light treatment is as follows: wool fibers are evenly spread at the bottom of an ultraviolet light irradiation device flatly, the distances between the wool fibers and a ultraviolet lamp tube are 12-14 cm, the irradiation time is 20-30 min, after the time is up, the wool fibers are turned over and then irradiated for 20-30 min, and after irradiation is completed, the wool fibers are taken out, scoured with clear water for 10-15 min and then dried.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

High count cashmere yarn comfort finishing process

ActiveCN105544199AComfortable to wearReduce frictionUltrasonic/sonic fibre treatmentGrip property fibresYarnSodium silicate

The present invention relates to a high count cashmere yarn comfort finishing process, and belongs to the technical field of cashmere yarn finishing. The comfort finishing process comprises the following steps: (1) carrying out pretreatment by using a pretreatment aqueous solution containing sodium dodecyl sulfate and sodium silicate; and (2) carrying out plasma treatment by using a mixed plasma of H2 and NH3 in a vacuum chamber; and (3) impregnating high count cashmere yarn treated in the step (2) into a finishing agent, conducting two impregnation and two rolling, and drying. The comfort finishing process reduces the friction of cashmere yarn surface, and has good anti-felting performance; the woven fabric is comfortable to wear next o the skin, and is rigidity-free, so as to maintain the characteristics of softness, slipperiness, fluffiness and high elasticity of cashmere.

Owner:湖州珍贝羊绒制品有限公司

A fluorine-free water-repellent and antifouling finishing agent and its preparation method and application

ActiveCN106012543BEasy to makeLow costStain/soil resistant fibresBiochemical fibre treatmentPolymer scienceOligosaccharide

The invention belongs to the field of textile finishing agents, and particularly relates to a fluoride-free water-repellent antifouling finishing agent and a preparation method and application thereof. The finishing agent comprises a system A and a system B, the weight ratio of the system A to the system B is 1:(0.6-0.8), the system A is prepared from 0.3%-3% of chitosan oligosaccharide, 1%-10% of waterborne polyurethane and the balance water, and the system B is modified nanosilicon dioxide sol. According to the fluoride-free water-repellent antifouling finishing agent, a textile finished through the finishing agent has the super-water-repellent and antifouling effects, meanwhile, the good hand feeling and breathability of the textile can be kept, the excellent antibacterial property and shrink-proofing property are achieved, and a preparation process of the finishing agent is easy to operate and suitable for application and popularization.

Owner:JIANGSU NEW REBA TECH CO LTD

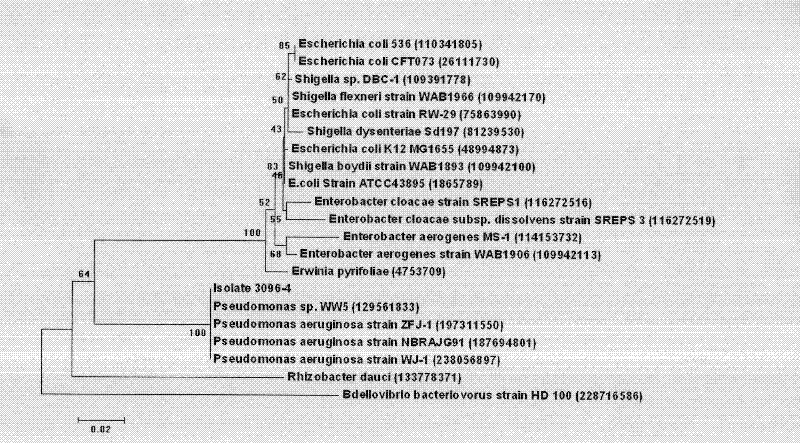

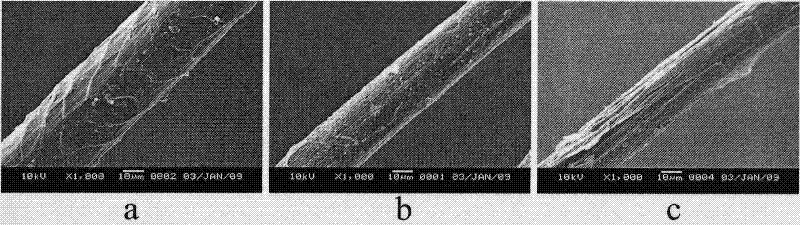

Strain for degrading wool scale layer

InactiveCN101935632BHigh activityReduce intensityBacteriaMicroorganism based processesChlorideMicrobiology

The invention relates to pseudomonas sp. 3096-4 for degrading a wool scale layer, wherein the preservation number of the pseudomonas sp. is CGMCC (China General Microbiological Culture Collection Center) No.3888, and the 16S rRNA sequence thereof is shown as the table 1. Protease produced by the stain has the advantages of high activity, good felting resistance to wool textiles, moderate action condition and good stability. The stain can be used for independently degrading the wool scale layer without pretreatment steps, cannot cause the reduction of the strength of the wool textiles and can be used for replacing the traditional chlorination-resin method in the wool spinning industry so as to avoid the generation of organic chloride and influence on the environment and the human body health.

Owner:DONGHUA UNIV

Super-soft shrinkproof mercerizing Australian wool strip

InactiveCN106811980AHigh glossIncrease elasticityBiochemical treatment with enzymes/microorganismsGrip property fibresAmylaseChloride

The invention discloses a super-soft shrinkproof mercerizing Australian wool strip. The preparation process includes the steps of 1), pretreatment; 2), mercerizing treatment, namely dipping the ordinary Australian wool strip treated in the step 1) in a mercerizing treatment solution, and after 30-40 minutes, taking out the wool strip and drying the same to botain the mercerizing Australian wool strip, wherein the mercerizing treatment solution comprises, by weight, 10-15% of a penetrating agent, 8-12% of amylase, 15-20% of sodium hydroxide and 58-62% of water; 3), super-softening finish. By the above mode, the ordinary Australian wool strip is subjected to mercerizing shrinkproof treatment by adopting self-developed chloride-free mercerizing finish liquid, and super-softening finish is then performed; the finished Australian wool strip is good in glossiness, elasticity and handfeel softness, good shrinkproffness is achieved, and the preparation process is environment friendly and safe.

Owner:CHANGSHU XINGUANG WOOL TOP SPECIALIST PROCESSOR

Natural plant antibacterial cashmere composite fabric having skincare healthcare effect and production method of natural plant antibacterial cashmere composite fabric

InactiveCN106835704AGood antibacterialImproves UV protectionCarbon fibresBiochemical fibre treatmentBetaineSilanes

The invention discloses a natural plant antibacterial cashmere composite fabric having a skincare healthcare effect. The natural plant antibacterial cashmere composite fabric is prepared from the following raw materials in parts by weight: 34 to 36 parts of Australian cashmere, 12 to 15 parts of aramid fiber, 17 to 19 parts of black bamboo charcoal fibers, 8 to 10 parts of cottonrose hibiscus stem and peel pectin, 32 to 33 parts of 40 percent (owf) natural sericin solution, 0.2 to 0.4 part of sodium sulfate, 5 to 6 parts of pineapple protein powder, 1.5 to 1.8 parts of dodecyldimethyl betaine, 3 to 5 parts of nano calcium carbonate, 1.2 to 1.6 parts of amino silane, 0.1 to 0.3 part of lemon essential oil, 170 to 190 parts of 1-butyl-3-methylimidazolium acetate, and an appropriate amount of water. By optimizing formula and improving the production process, the cashmere composite fiber is prepared by virtue of a wet-method spinning process, the antibacterial performance, anti-ultraviolet performance and anti-shrinking performance of the cashmere can be improved by virtue of the soaking treatment of a mixed finishing solution, the prepared cashmere composite fabric has the characteristics of cashmere and araid fibers, and is natural and soft, and has a skincare effect.

Owner:倪进培

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com