Low-strength-loss shrink-proof finishing method for wool fabric

An anti-shrinkage finishing and wool technology, applied in fiber processing, animal fibers, textiles and papermaking, etc., can solve the problem of large damage to fabric strength, improve anti-shrinkage performance, make up for fabric strength damage, and reduce felt shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

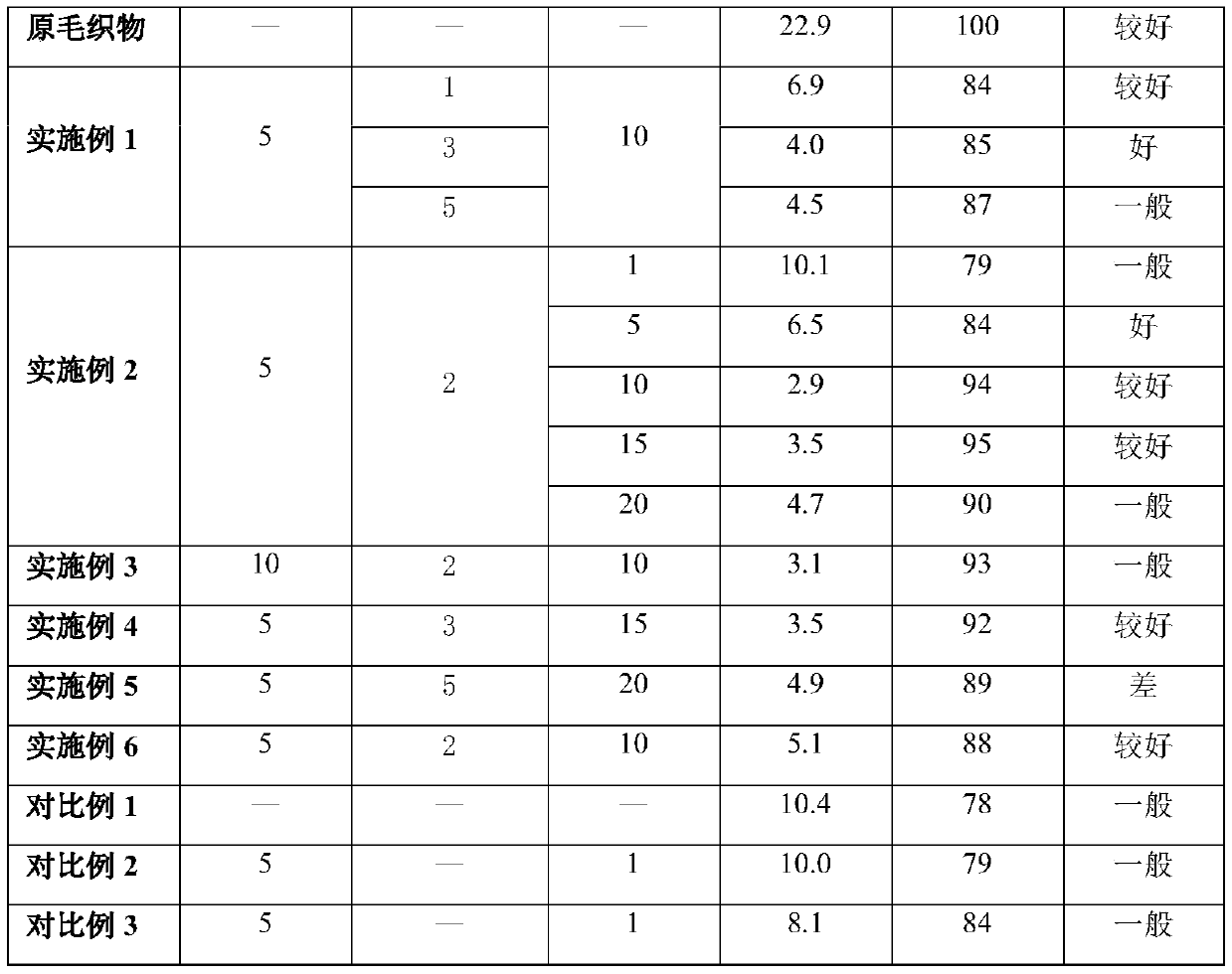

Embodiment 1

[0033] A low-strength and anti-shrinkage finishing method for wool fabrics, comprising the following steps:

[0034] (1) Put the wool fabric in a solution (pH 4) of 3wt% dichloroisocyanurate (DCCA), 1g / L penetrant JFC, and a bath ratio of 1:25 at room temperature for 30min at a bath ratio of 1:25, Then the fabric was mixed with 6wt% sodium bisulfite (NaHSO) at a bath ratio of 1:25 3 ) solution at 40°C for 20 minutes, and finally put the wool fabric in NaHCO with a pH of 8-9 3 solution, neutralize at 40°C for 20min.

[0035] (2) The woolen fabric treated in step (1) is first soaked in 5g / L chitosan finishing solution (bath ratio 1:50) for 5min, washed with water, and then soaked in 1g / L cellulose nanocrystal solution (bath ratio 1:50) ) for 5 minutes, washed with water, and then repeated the process of immersing in chitosan finishing solution and cellulose nanocrystal solution in turn, repeating the self-assembly procedure 10 times in total, and drying at 100°C for 10 minutes...

Embodiment 2

[0039] A low-strength and anti-shrinkage finishing method for wool fabrics, comprising the following steps:

[0040] (1) Put the woolen fabric in a solution (pH 4) of 3wt% dichloroisocyanurate (DCCA), 1g / L penetrant JFC, and a bath ratio of 1:25 for 30 minutes at room temperature, and then place the fabric in 6wt% Sodium bisulfite (NaHSO3 ) solution (bath ratio 1:25) at 40°C for 20 minutes, and finally put the wool fabric in NaHCO with a pH of 8-9 3 solution, neutralize at 40°C for 20min.

[0041] (2) The woolen fabric treated in step (1) is first soaked in 5g / L chitosan finishing solution (bath ratio 1:50) for 5min, washed with water, and then soaked in 2g / L cellulose nanocrystal solution (bath ratio 1:50) ) for 5 minutes, washed with water, and then repeated the process of immersing in the chitosan finishing solution and the cellulose nanocrystal solution in turn, repeating the self-assembly procedure 1, 5, 10, 15, 20 times in total, and drying at 100°C for 10 minutes .

...

Embodiment 3

[0044] A low-strength and anti-shrinkage finishing method for wool fabrics, comprising the following steps:

[0045] (1) Put the woolen fabric in a solution (pH 4) of 3wt% dichloroisocyanurate (DCCA), 1g / L penetrant JFC, and a bath ratio of 1:25 for 30 minutes at room temperature, and then place the fabric in 6wt% Sodium bisulfite (NaHSO 3 ) solution (bath ratio 1:25) at 40°C for 20 minutes, and finally put the wool fabric in NaHCO with a pH of 8-9 3 solution, neutralize at 40°C for 20min.

[0046] (2) The woolen fabric treated in step (1) is soaked in 10g / L chitosan finishing solution (bath ratio 1:50) for 5min, washed with water, and soaked in 2g / L cellulose nanocrystal solution (bath ratio 1:50) The self-assembly procedure was repeated 10 times in total, and then dried at 100°C for 10 minutes.

[0047] The felt shrinkage and tensile breaking strength of the finished fabric were tested according to the washing standard of Wool Bureau TM31 wool textile products and the sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com