Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Little impact on hand feeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological enzyme process antibacterial and anti-wrinkle finishing method of silk fabric

InactiveCN102677475AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentAnimal fibresCooking & bakingCatalytic oxidation

The invention discloses a biological enzyme process antibacterial and anti-wrinkle finishing method of a silk fabric, belongs to the field of a textile biotechnology, and aims to overcome the defects of high baking temperature, high probability of damage of silk fibers and reduced whiteness in real silk antibacterial and anti-wrinkle treatment of the conventional chemical method and realize enzyme-promoted antibacterial and anti-wrinkle functional modification of a real silk fabric. According to the method, a chitosan natural finishing agent with a primary amine structure is grafted to the surface of the silk fiber by utilizing the catalytic oxidation effect of tyrosinase, so that the antibacterial and anti-wrinkle effects of the silk fabric are improved. The process flow comprises the following steps of: pre-treating the silk fabric; catalyzing grafting modification treatment of chitosan by the tyrosinase; washing; and drying. Through the silk fabric treated by the invention, the antibacterial performance is improved, the wrinkle recovery performance is improved, and the mechanical property and the dyeing performance of the fabric are also improved. Compared with the conventional chemical method, the method has the advantages of adoption of the tyrosinase process for catalysis of the antibacterial and anti-wrinkle treatment process of the real silk, low energy consumption, high efficiency, less pollution and contribution to environmental protection.

Owner:FOSHAN CITY HANHAI YANBU SISTER FLOWER UNDERWEAR

Method for improving antibacterial property of wool by bio-enzymatic method

InactiveCN101565894AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentYarnPre treatment

The invention provides a method for improving antibacterial property of wool by a bio-enzymatic method, which belongs to the field of textile biotechnology. The method utilizes the catalysis of transglutaminase (MTG) to graft some natural compounds which contain primary amine groups and have antibacterial property onto wool to improve the antibacterial property of the wool. The method comprises the following process flows: wool pretreatment, treatment with an MTG-containing antibacterial finishing agent, washing and drying. Wool yarn or fabric treated by the method not only has improvement on the antibacterial property but also correspondingly has improvement on some other properties and particularly has great improvement in low-temperature dyeing property. Meanwhile, the method improves the strength of the wool yarn or the fabric, thereby playing a role in restoring strength. The strength-restoring function is an outstanding advantage of the method compared with other antibacterial finishing agents or antibacterial finishing processes. In addition, compared with chemical finishing, the treatment process of the method is free from pollution, healthier and friendlier to environment by adopting a bio-enzyme technique.

Owner:JIANGNAN UNIV

Method for improving wool fire-retardancy with biological enzyme

InactiveCN101509193AConform to modern green environmental protection requirementsMild reaction conditionsBiochemical fibre treatmentAnimal fibresYarnBiotechnology

A method for improving flame retardance of wool by bioenzyme treatment is disclosed, belonging to the field of textile biotechnology. The invention utilizes a catalytic action of transglutaminase (MTG) to graft a type of compounds containing primary amino groups and a large number of phosphorus elements onto the wool so as to improve the flame retardance of the wool, the technological procedures comprise: pretreatment, treatment with a phosphoric finishing agent containing the MTG, water rinsing and drying. Wool yarns and fabrics treated by the inventive technology can not only be improved in the flame retardance, but also be enhanced in some other performances to a certain extent, in particularly the strength of the wool yarns and the fabrics is enhanced to play a role of powerful repair, which is outstandingly superior to other flame-retardant finishing agents or flame-retardant finishing technologies. In addition, in contrast to chemical finishing, the invention is healthier and more environmentally-friendly due to the employment of bioenzyme technique and the pollution-free treatment technology.

Owner:JIANGNAN UNIV

Flame-proof treatment method of real silk fabrics by biological enzyme method

ActiveCN103526543AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentAnimal fibresTyrosineCatalytic oxidation

The invention discloses a flame-proof treatment method of real silk fabrics by a biological enzyme method, belonging to the biotechnical field of spinning. The method disclosed by the invention aims to overcome the deficiencies that real silk fabrics in flame-proof treatment by conventional chemical methods are not high in washability, the real silk is easy to damage in high temperature baking, the whiteness of fiber products is easy to decrease and the like. According to the method disclosed by the invention, tyrosine residues in silk fibroin are oxidized to dopaquinone structures with stronger reactivity by means of the characteristic of tyrosinase which has a catalytic oxidation effect on the tyrosine residues in real silk fiber to promote a grafting reaction on an organophosphorus flame retardant containing a primary amine base and the dopaquinone structures, and the flame retardant function of the real silk fabrics is improved through a nitrogen-phosphorus synergistic effect, so that flame-proof treatment of the real silk fabrics by the biological enzyme method is realized. The method disclosed by the invention comprises the following process flows: real silk fabric pre-treatment, and catalyzation of the organophosphorus flame retardant containing the primary amine base by the tyrosinase to graft, water-washing and drying post-treatment. For the fabrics treated by the method disclosed by the invention, not only is the flame retardant performance improved, but also the mechanical properties of the fabrics are further enhanced. Compared with conventional chemical methods, with the adoption of flame-proof treatment by tyrosinase catalyzation on the real silk fabrics, the method is low in energy consumption, high in efficiency and less in pollution in the processing process and is beneficial to environment protection.

Owner:苏州大上科高新材料有限公司

Processing method of natural wash-and-wear purified cotton fabrics

ActiveCN105350286AWith non-iron effectLittle impact on hand feelingBiochemical fibre treatmentDyeing processYarnEnzyme

The invention discloses a processing method of natural wash-and-wear purified cotton fabrics; the whole processing technology comprises yarn choosing, yarn dyeing, slashing, weaving, singeing, desizing, mercerizing, liquid ammonia treatment, bio-enzyme treatment, drying, wash-and-wear resin finishing, and preshrinking. The processing method has the advantages that the purified cotton fabrics obtained by the method enable the wash-and-wear grade to reach 3.0 or more, organosilicon is applied in actual production of the purified cotton wash-and-wear fabrics, and the obtained purified cotton fabrics have a wash-and-wear effect, also do not contain formaldehyde, are environmentally friendly, and are harmless to human bodies; and in addition, strong damage on the fabrics in the processing process is small, the influence on a fabric hand feeling is small, and the hand feeling of the fabrics obtained from processing is quite smooth and soft.

Owner:浙江盛泰服装集团股份有限公司

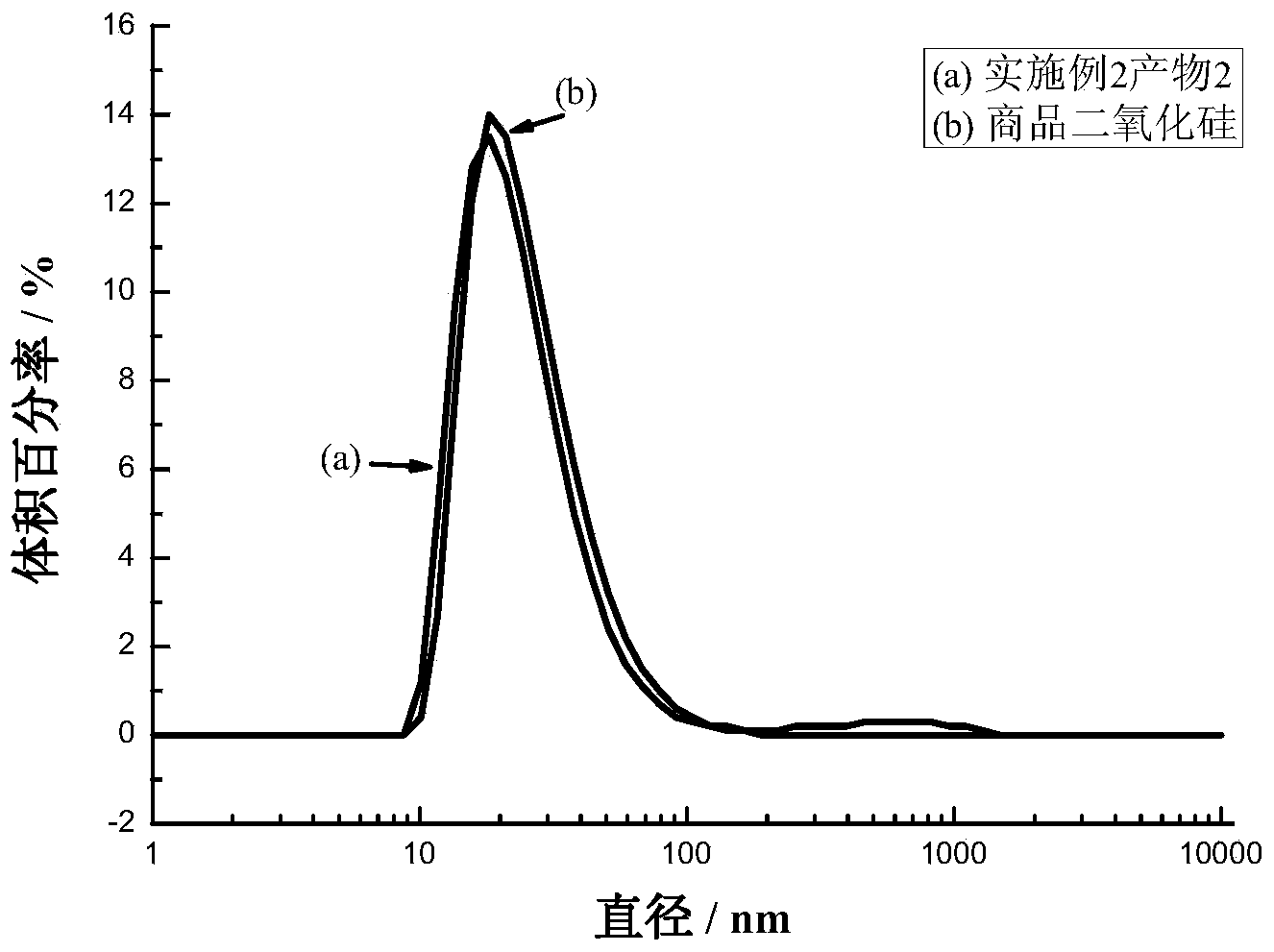

Silicon dioxide antireflection coating liquid, preparation method of silicon-dioxide antireflection coating liquid and application of silicon-dioxide antireflection coating liquid in polyester fabrics

The invention discloses silicon-dioxide antireflection coating liquid, a preparation method of the silicon-dioxide antireflection coating liquid and application of the silicon-dioxide antireflection coating liquid in polyester fabrics. The preparation method is simple, easy, mild in condition and easy to control, and the solid content of the prepared antireflection coating liquid is high. The preparation method comprises the following steps: adding a silicon-dioxide aqueous dispersion liquid which is sold on the market, and a silane coupling agent into alcohol so as to obtain a reaction liquid, adjusting the pH value of the reaction liquid to 3-8, rising the temperature to 20-50 DEG C, and reacting for 12-40 hours so as to obtain the nano-silicon-dioxide antireflection coating liquid with the alcoxyl groups on the surface finally. The prepared silicon-dioxide antireflection coating liquid with the alcoxyl groups on the surface can be used for deepening finish of one polyester fabric, and an antireflection film with a nanoporous structure is built on the surface of the fabric, so that the fabric has the rich-color effect, the deepening durability is improved and the hygroscopicity and the wearing comfort of the fabric are not changed.

Owner:ZHEJIANG SCI-TECH UNIV

Fabric antistatic agent

InactiveCN104878597ALittle impact on hand feelingImprove antistatic performanceFibre treatmentEpoxyPolyethylene glycol

The invention belongs to the field of antistatic agent and particularly relates to a fabric antistatic agent. The fabric antistatic agent is composed of the following components in part by weight: 30-40 parts of alkylpolyamine ethoxylate, 10-15 parts of polyethylene glycol epoxy glyceryl ether, 10-20 parts of tetrabutyl titanate, 5-15 parts of surface active agent, 5-15 parts of zinc acetate, 15-25 parts of ethylene glycol, and 25-35 parts of glycerinum. The fabric antistatic agent futher contains 10-15 parts of hindered phenol compound. The fabric antistatic agent has the beneficial effects: the fabric antistatic agent is good in anti-static effect and good in water resistance and heat resistance; meanwhile, the fabric antistatic agent is slightly influenced on the hand feeling of the fabric and free from harm to skin.

Owner:张萍

Anti-static agent for cloth

The invention relates to an anti-static agent for cloth. The anti-static agent is prepared from the following raw materials including ethoxy alkylamine, polyethylene glycol diglycidyl ether, tetrabutyl titanate, surfactants, zinc acetate, glycol, glycerin, lauryl ether, octadecyl imidazoline, alkyl quaternary ammonium salts, isopropanol, linear alkylbenzene sulfonate, fatty alcohol-polyoxyethyleneether, sodium stearate, alkenyl sulphonate, white soap powder, phenol salicylate, epoxy resin, phenol, cyclohexanone, xylene and dibutyltin oxide. The anti-static agent has the beneficial effects that (1) the cost is low; a textile product can maintain the original flexibility and hand feeling after being treated by the anti-static agent; the anti-static effect is good; water washing resistance and heat resistance are good; meanwhile, meanwhile, the influence on the hand feel of the textile is small; no injury is caused on the skin; (2) the long-effect maintenance can be realized; the anti-static agent can be used for cloth and can also be widely applicable to various rubber and plastic products.

Owner:ANHUI HONGYUAN NONWOVEN FABRIC

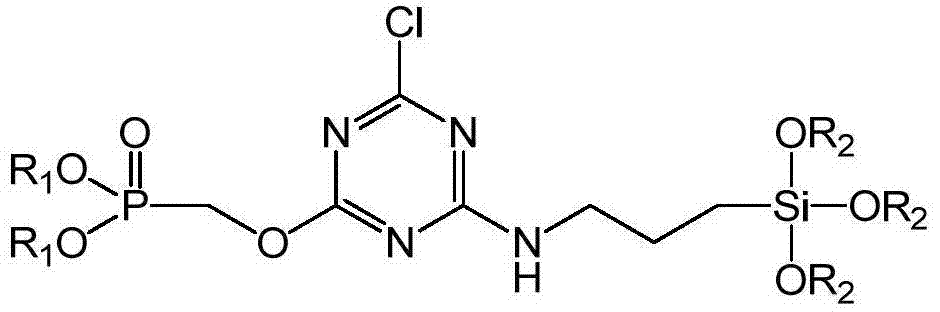

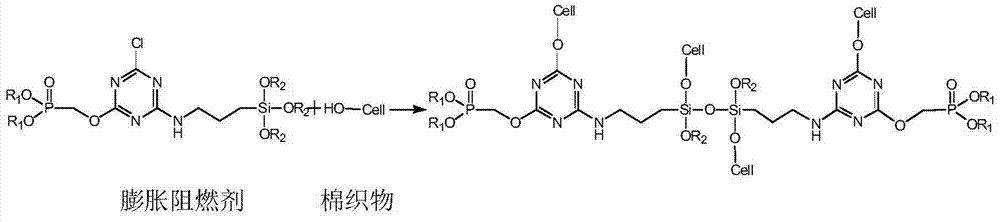

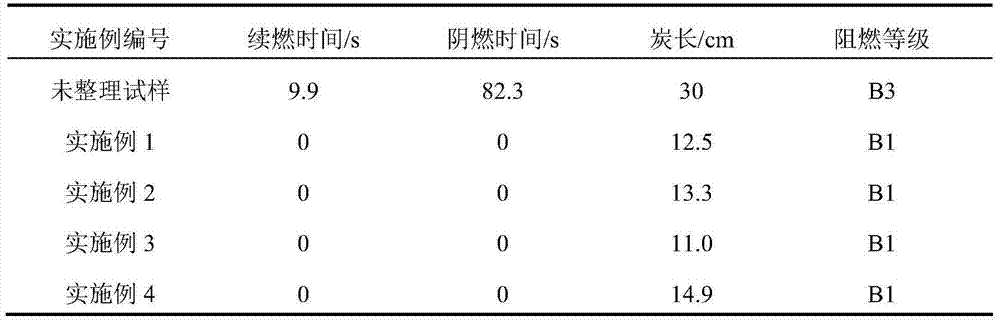

Flame-retardant finishing method of reactive expansion flame retardants on cotton fabrics

InactiveCN104846639AImprove flame retardant performanceSmall colorVegetal fibresEngineeringPulp and paper industry

The invention belongs to the field of cotton fabric flame-retardant finishing, and particularly relates to a flame-retardant finishing method of reactive expansion flame retardants on cotton fabrics. The method comprises the following steps that (1) flame-retardant finishing liquid is prepared; (2) cotton fabric raw cloth is subjected to alkali washing for removing paste and is then soaked in the flame-retardant finishing liquid after being dried, and a twice-soaking two-rolling process is utilized for carrying out flame-retardant finishing on the cotton fabrics; (3) the soaked and rolled cotton fabrics are dried for 5 to 8 minutes at 80 to 100 DEG C, finally, high-temperature baking is carried out for 2 to 5 minutes at 150 to 180 DEG C, and the flame-retardant fabrics are obtained. Compared with the prior art, the flame-retardant finishing method of the reactive expansion flame retardants on the cotton fabrics has the advantages that flame retardant molecules per se adopted by the flame-retardant finishing liquid contain a plurality of active reaction groups, and the reaction activity can be improved only through adding a proper number of catalysts, so that the flame-retardant durability of the cotton fabrics is improved, the addition of other auxiliaries is not needed, and the recipe is simple, reasonable and efficient.

Owner:ZHONGBEI UNIV

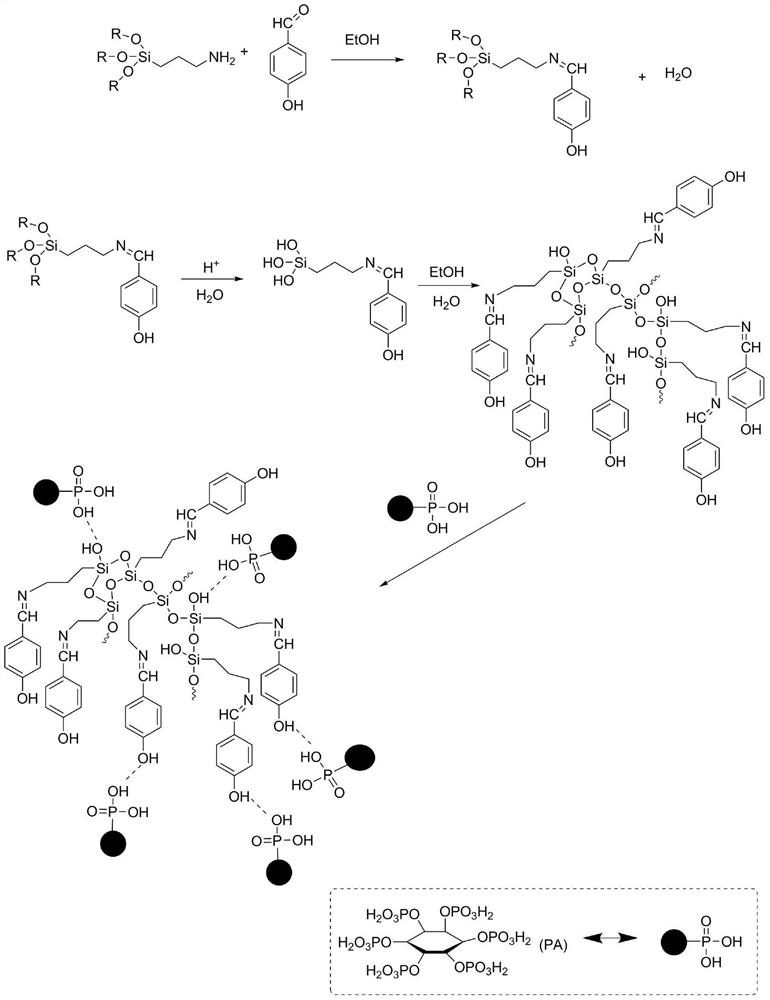

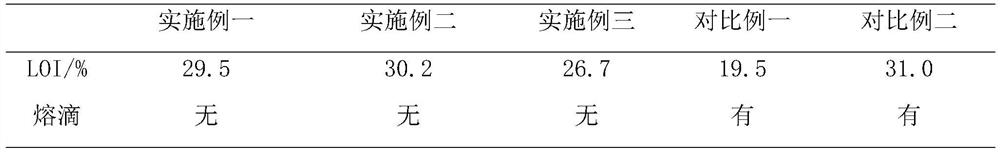

Anti-molten-drop finishing method for polyester

ActiveCN112921647AImprove charcoal abilityImproved droplet behaviorHeat resistant fibresPolyesterPhytic acid

The invention relates to an anti-molten-drop finishing method for polyester. The method comprises the following steps of step (1), preparing a silane precursor containing a Schiff base structure; dissolving amino-containing silane and p-hydroxybenzaldehyde in ethanol, heating and stirring to generate a silane precursor containing the Schiff base structure, and removing ethanol and unreacted silane; step (2), preparing a phytic acid sol working solution; dissolving the silane precursor containing the Schiff base structure prepared in the step (1) in a cosolvent of ethanol and water; taking a phytic acid aqueous solution, adjusting the pH of the phytic acid aqueous solution by taking a weakly alkaline organic solvent as a pH adjusting agent, adding the pH-adjusted phytic acid aqueous solution into the silica sol containing the Schiff base structure, and stirring at room temperature for 1-5 hours to obtain the prepared phytic acid sol working solution; and step (3), performing flame-retardant finishing processing on polyester by adopting the phytic acid sol working solution in the step (2).

Owner:JIAXING UNIV

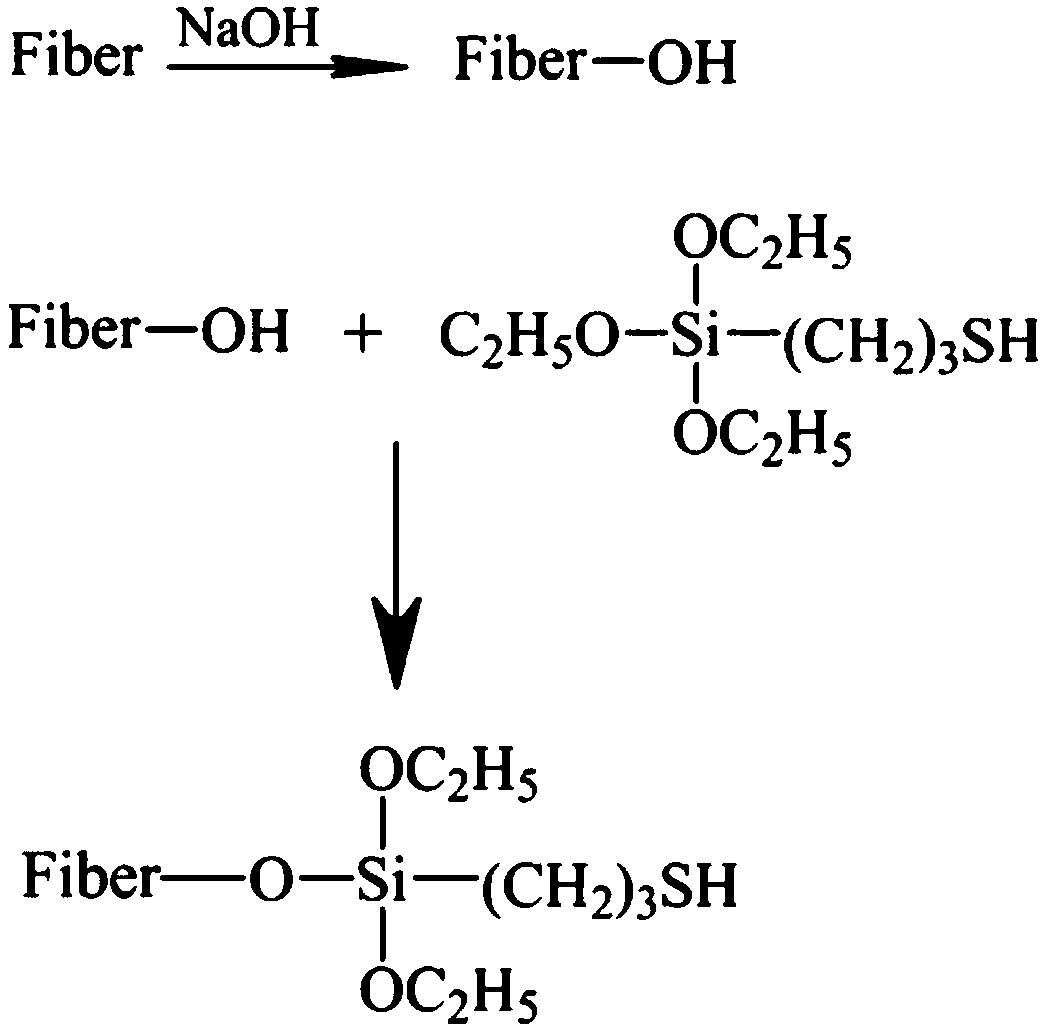

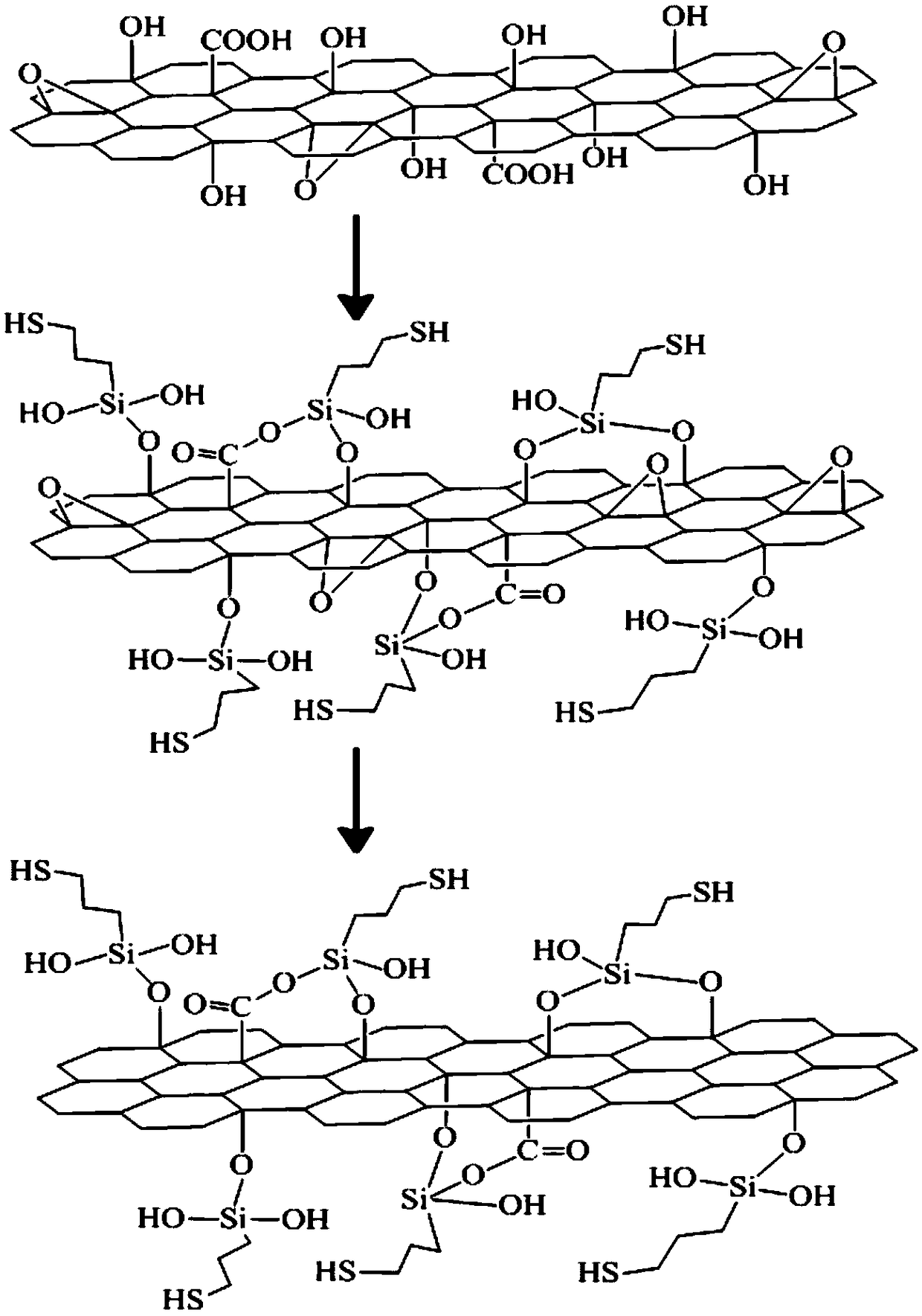

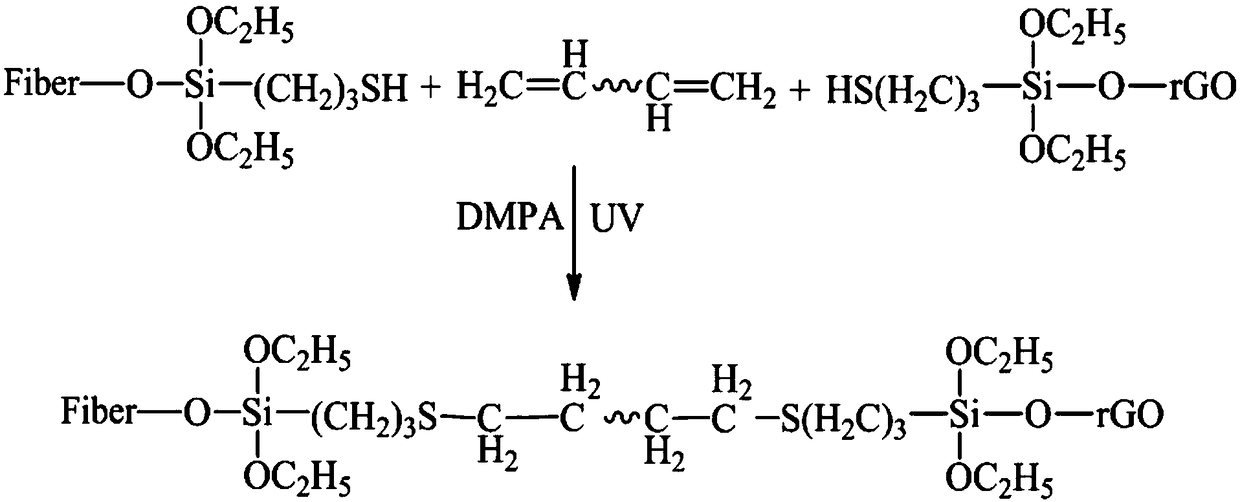

Polyester fabric moisture absorbing, sweat releasing and heat conducting finishing method based on click chemistry

ActiveCN108691208AProcess environmental protectionReduce the harm to the human bodyFibre typesChemistryPolyester

The invention relates to a polyester fabric moisture absorbing, sweat releasing and heat conducting finishing method based on click chemistry. The method comprises the following steps of preparing sulfydryl-modified polyester fabric, preparing sulfydryl-modified reduced graphene oxide, preparing finishing liquid and preparing moisture absorbing, sweat releasing and heat conducting polyester fabric. The method has the advantages that the pre-treated sulfydryl polyester fabric, the sulfydryl reduced graphene oxide and a polyurethane moisture absorbing and sweat releasing finishing agent are enabled to form firm chemical bonds through the click chemistry, so that the polyester fabric can obtain good moisture absorbing, sweat releasing and heat conducting performance; the operation is simple,a process is environmentally-friendly, energy-saving and efficient, and the wearability of the polyester fabric can be greatly improved; and the prepared moisture-absorbing and sweat-releasing polyester fabric has no influence on hand feeling and strength.

Owner:DONGHUA UNIV

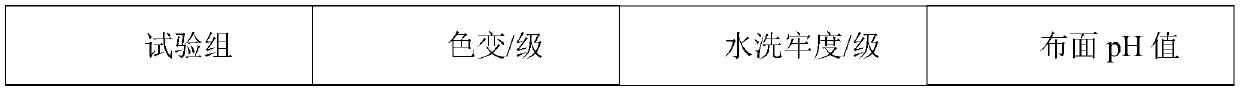

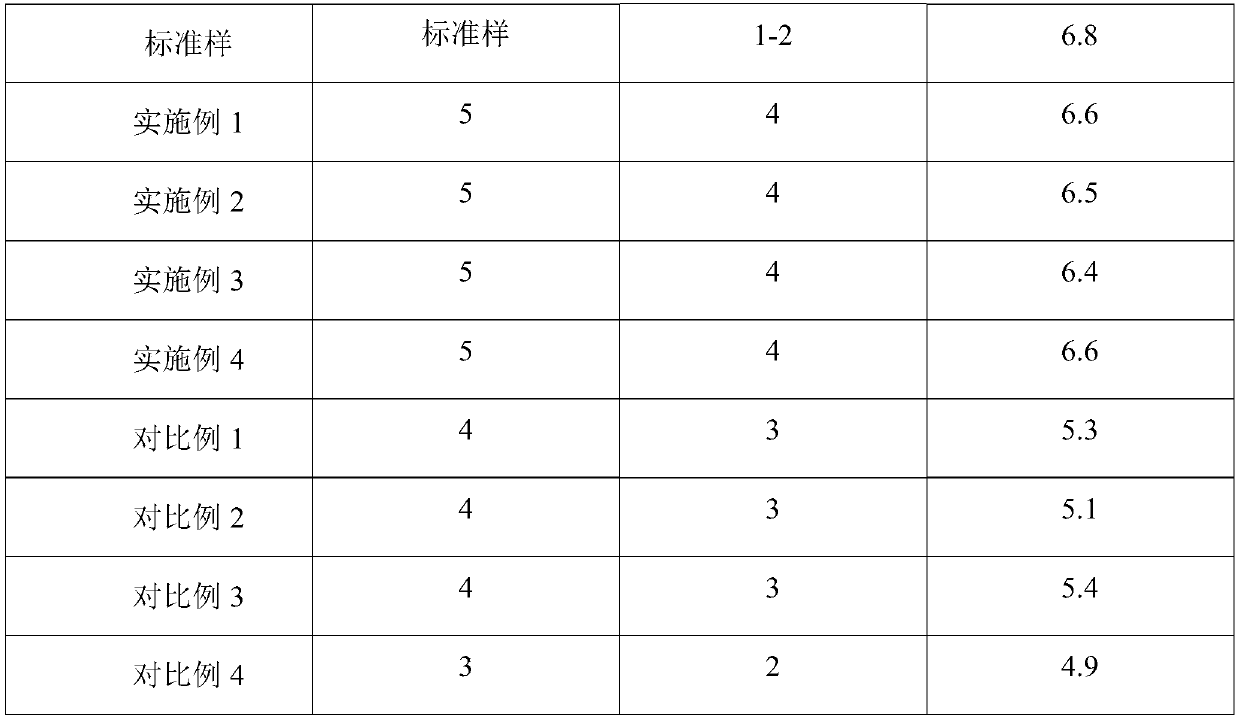

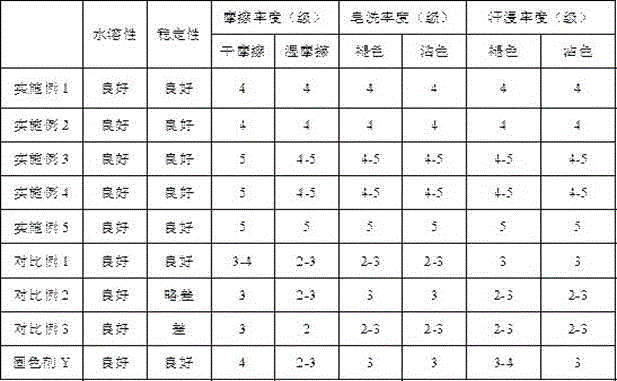

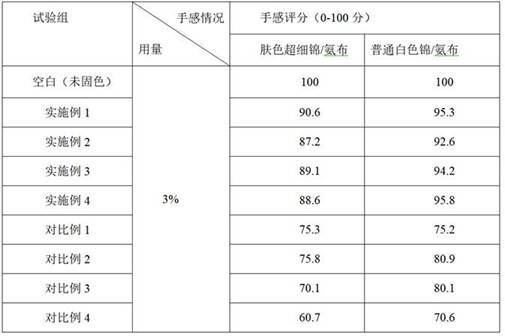

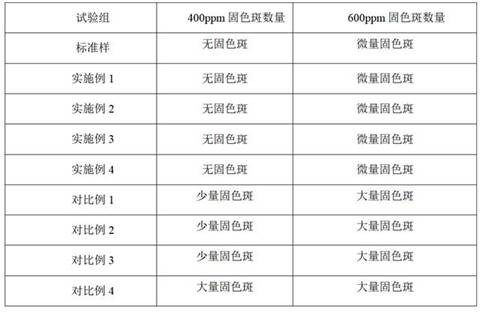

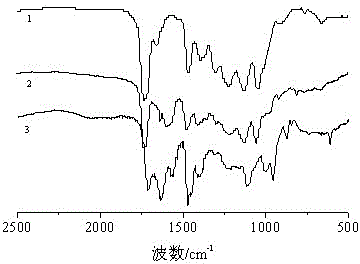

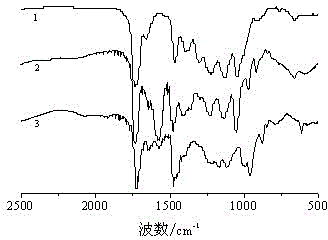

Synthesis method of multifunctional silk fabric fixing agent

InactiveCN103643567ALittle impact on hand feelingShort production processDyeing processTetramineSynthesis methods

The invention discloses a synthesis method of a multifunctional silk fabric fixing agent. The method comprises the following steps: (1) adding 5-8 parts by weight of diethylenetriamine and 3-6 parts by weight of triethylene tetramine into a three-opening flask, stirring, heating up to 65 DEG C at a speed of 5 DEG C / min, dropwise adding 5 parts by weight of ethyl acrylate within 20 minutes, maintaining the temperature at 78 DEG C in the adding process, and reacting for 4 hours; (2) dropwise adding 5 parts by weight of epoxy chloropropane through a constant pressure feeder, meanwhile, dropwise adding 12 parts by weight of distilled water within 35 minutes, maintaining the temperature at 63 DEG C, and reacting for 4 hours; and (3) adding 3 parts by weight of potassium peroxodisulfate, maintaining the temperature at 68 DEG C, reacting for 2 hours, cooling to 35 DEG C, and regulating the pH value to 5 through 30% acetum to obtain the multifunctional silk fabric fixing agent. According to the method disclosed by the invention, the production process is short, process conditions are easy to control, and a small effect is generated on the hand feel of a fabric after the multifunctional silk fabric fixing agent is used.

Owner:成路凯尔服装(苏州)有限公司

Direct injection digital printing pretreatment slurry for dacron fabric

InactiveCN103114443ALittle impact on hand feelingHigh color fixing rateFibre typesTextile printerCellulose

The invention discloses a direct injection digital printing pretreatment slurry for dacron fabric; the pretreatment slurry consists of urea, sodium alginate, sodium carboxymethylcellulose, ethanol, glycerol and water. Through pre-treating and digital-printing by using the slurry, the color yield is high, the pattern is clear, the thickening rheological property of thickener is excellent and the lag thixotropy is relatively low.

Owner:SUZHOU INST OF TRADE & COMMERCE

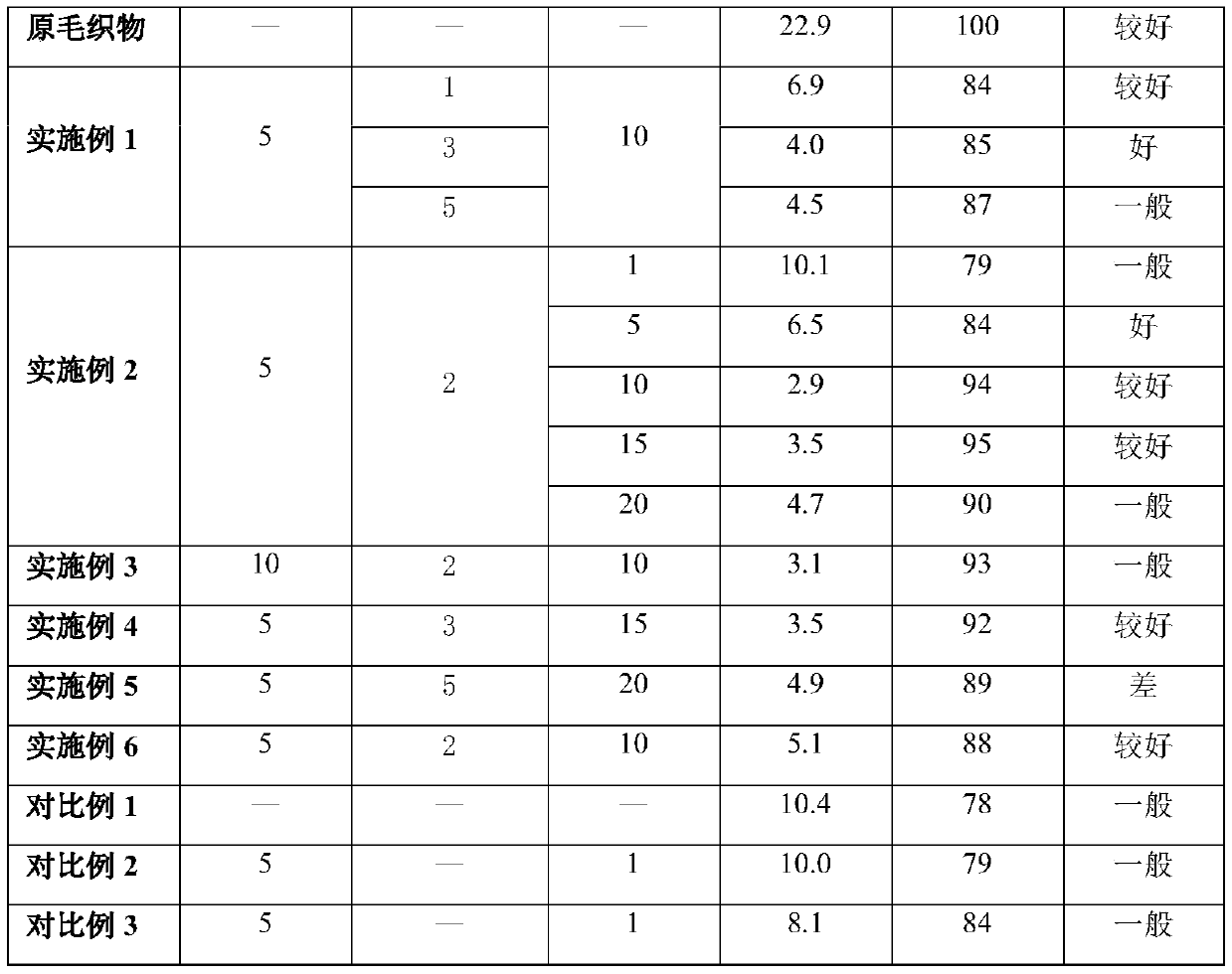

Low-strength-loss shrink-proof finishing method for wool fabric

ActiveCN109914106AReduce felt shrinkageReduce the amount of applicationAnimal fibresCelluloseEngineering

The invention discloses a low-strength-loss shrink-proof finishing method for a wool fabric and belongs to the technical field of wool fabric dyeing and finishing processing. According to the method,firstly, DCCA is adopted for conducting chlorination shrink-proof treatment on the wool fabric, then the wool fabric is soaked in a chitosan finishing solution and a cellulose nanocrystal solution insequence, assembly is conducted 10-20 times, the anti-felting performance of the treated wool fabric is obviously improved, in addition, the strength loss of the fabric is also greatly lowered, and the hand feeling of the wool fabric is good.

Owner:JIANGNAN UNIV

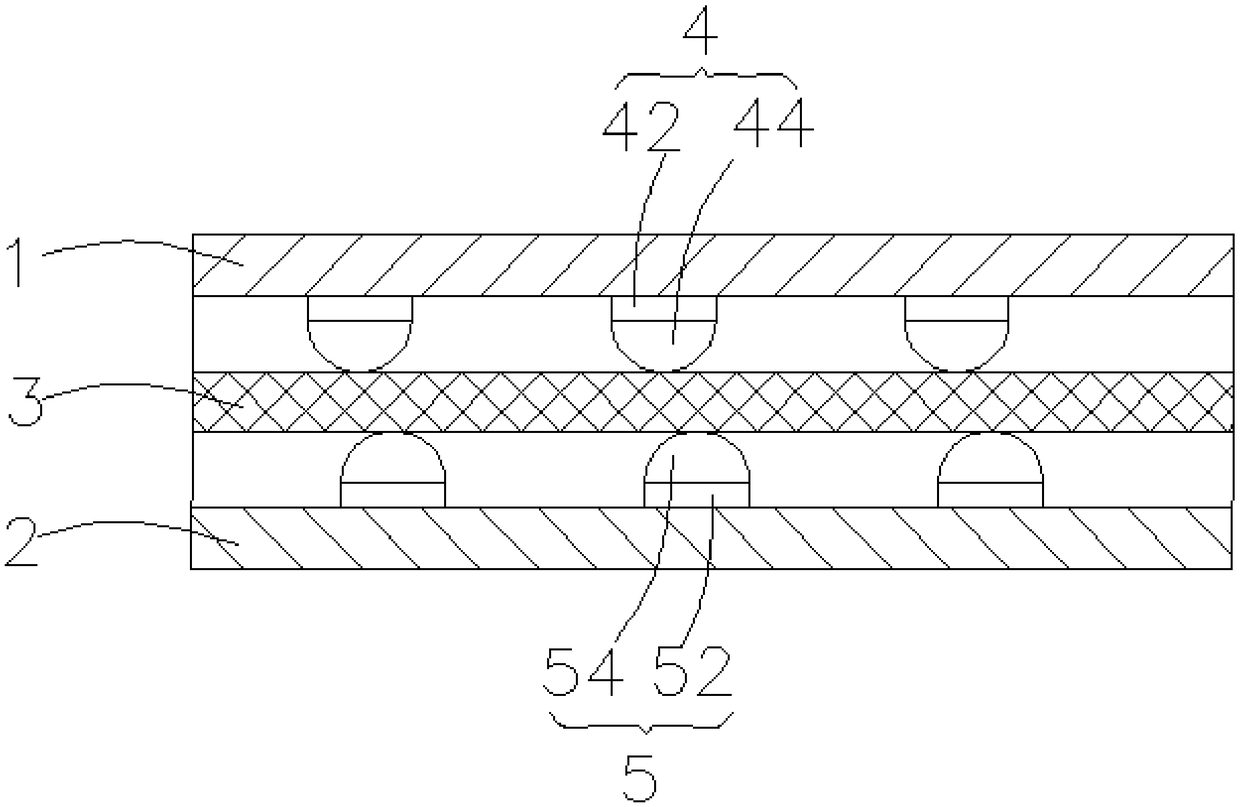

Functional film double-sided composite fabric and production method

PendingCN108556423AImprove production and operating environment conditionsSmall amount of coatingSynthetic resin layered productsLaminationSurface layerSolvent

The invention relates to a functional film double-sided composite fabric production method. The production method comprises the following steps of: processing a first double-point coating on a surfacelayer fabric through a double-point coating process; processing a second double-point coating on an inner layer fabric through a double-point coating process; using a three-layer unreeling compound machine for hot-pressing and compounding. The method comprises the following steps of: adjusting the parameters of hot-pressing and compounding of the three-layer unwinding compound machine; laying thecoating of the inner layer fabric face down on the cloth feeding conveying grid belt and putting it on the cloth feeding conveying mesh belt; putting the functional film on the roll-out position, andputting the functional film on the cloth-feeding mesh belt; laying the coating of the surface layer fabric face down on the cloth-feeding mesh belt; heating the surface temperature of the roller cylinder of the three-layer unwinding compound machine to a set temperature, and starting the multi-function machine, so that the first double-point coating and the second double-point coating are compounded on both sides of the functional film, and the winding is to be fully cooled. The production method disclosed is free of solvent and is extremely small in pollution. The invention also relates to afunctional film double-sided composite fabric.

Owner:CPL NEW MATERIAL TECH CO LTD

Acidic color-fixing agent and preparation method thereof

ActiveCN110699991AGood working fluid pH control abilityGood color fixing effectDyeing processSodium stearateSodium salicylate

The invention belongs to the field of dye color-fixing agents, and particularly relates to an acidic color-fixing agent and a preparation method thereof. The acidic color-fixing agent comprises polyethyleneimine, modified polyacrylic acid, sodium citrate, sodium salicylate, sodium laureth sulfate, sodium stearate and sodium phenolsulfonate; The preparation method is simple, the color-fixing agenthas a good color-fixing effect, contains no harmful substances such as formaldehyde, and has a good pH-control effect.

Owner:多恩生物科技有限公司

Method for carrying out antibacterial and antioxidant finishing on damask silk by enzyme method

PendingCN111809394AAchieve graftingImprove antibacterial propertiesBiochemical treatment with enzymes/microorganismsGrip property fibresPolymer scienceTyrosine

The invention discloses a method for carrying out antibacterial and antioxidant finishing on damask silk by an enzyme method, and belongs to the technical field of textile dyeing and finishing. The method comprises the following steps of: firstly, impregnating damask silk fabric in a catechin and chitosan oligosaccharide mixed solution, then adding laccase into a system, and by virtue of the catalytic oxidation effect of the laccase, realizing the polymerization of tyrosine in real silk and phenolic hydroxyl in catechin and the Schiff base reaction of the tyrosine in the real silk and amino onchitosan oligosaccharide, thus realizing the antibacterial and antioxidant finishing of the damask silk by the enzyme method. The method specifically comprises the following steps of: (1) adsorbing the catechin and the chitosan oligosaccharide by the damask silk; and (2) catalyzing the damask silk to graft the catechin and the chitosan oligosaccharide by the laccase. Compared with a method for carrying out chemical finishing on the damask silk by a high-temperature baking crosslinking method, the method disclosed by the invention has the advantages of lower production energy consumption, goodantibacterial and antioxidant effects and less yellowing and strength loss of damask silk fabric.

Owner:湖州绫绢研究所

A preparing method of a sensitive color fixing agent and the fixing agent

InactiveCN106948196AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processFixative/StainChemistry

A preparing method of a sensitive color fixing agent and the fixing agent are disclosed. During preparation, methyl ethyl ketone peroxide and a 6-hydroxy-2-naphthoic acid solution are mixed, heated and stirred; dimethylformamide is added into the mixture; the mixture is heated and stirred; then a tris(nonylphenyl)phosphite solution is added into the mixture; and the mixture is stirred at 110-112 DEG C for 20-25 min, then stirred at 65-70 DEG C for 50-55 min and cooled to room temperature to obtain the fixing agent. Under interactions of raw materials, the fixing agent has advantages of high dyeing fastness, capability of significantly increasing dry and wet rubbing fastness and water-washing color fastness, and the like. Hue changes do not occur substantially during color fixing of dye for sensitive colors such as turquoise blue and cobalt blue. The fixing agent is free of formaldehyde and is environmentally friendly. A production process is simple. The fixing agent does not influence chlorine fastness, light fastness or perspiration fastness of dyed fabrics, influences of color fixing treatment on fabrics by the fixing agent are low, and chromatic aberration can be controlled to be the 4-5 level. Treated fabrics have good color fixing effects and an influence on hand feeling is low.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

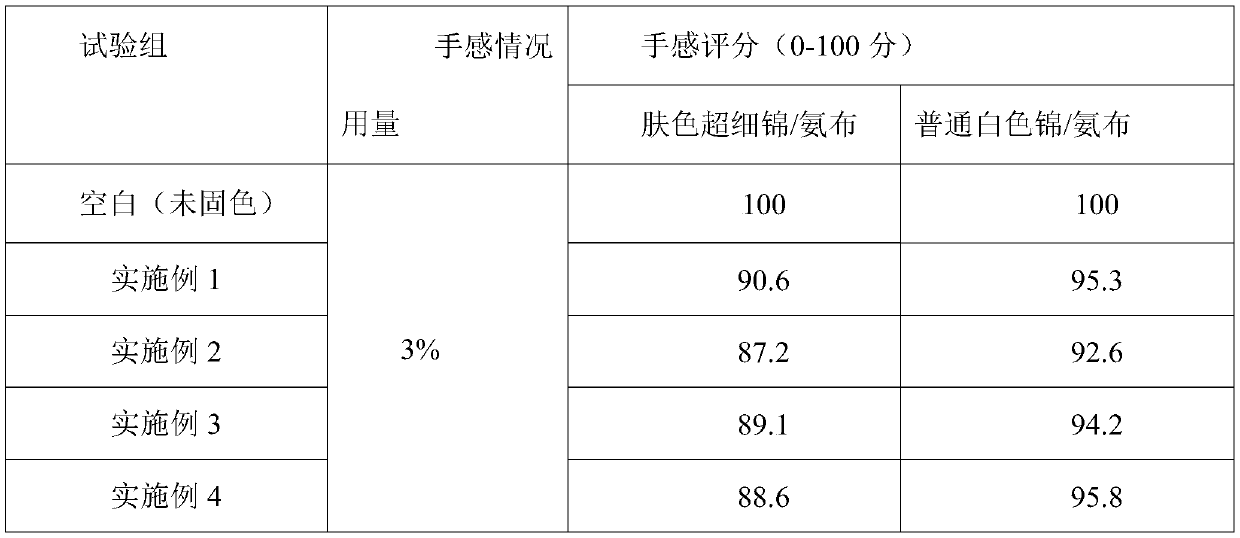

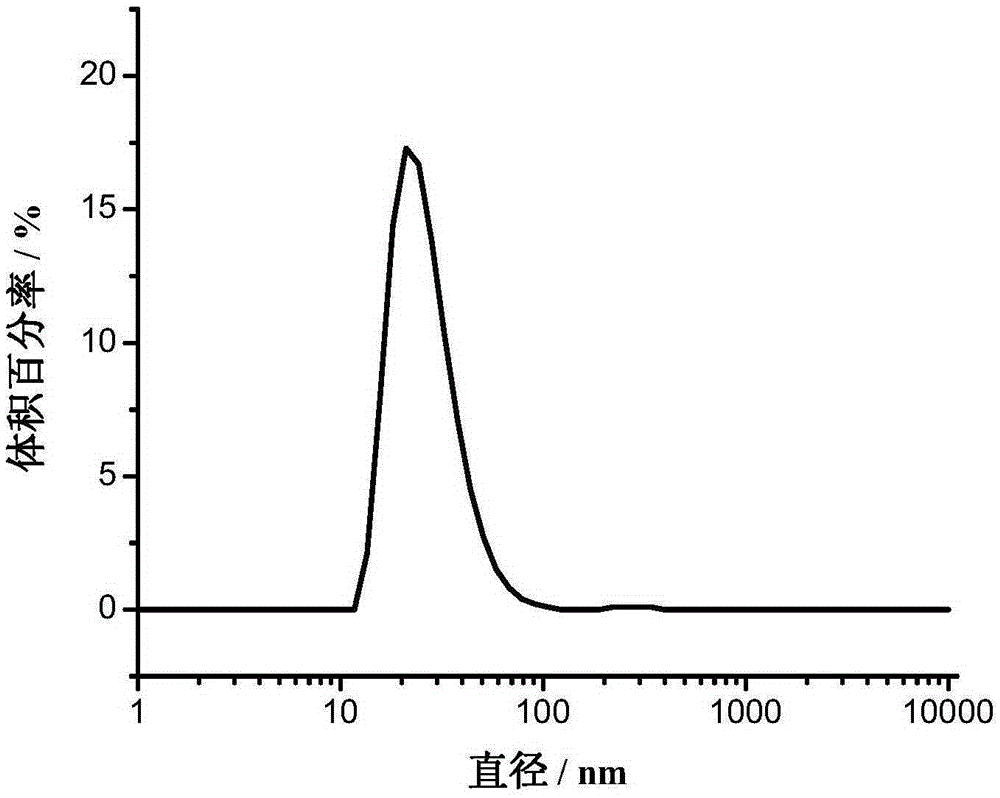

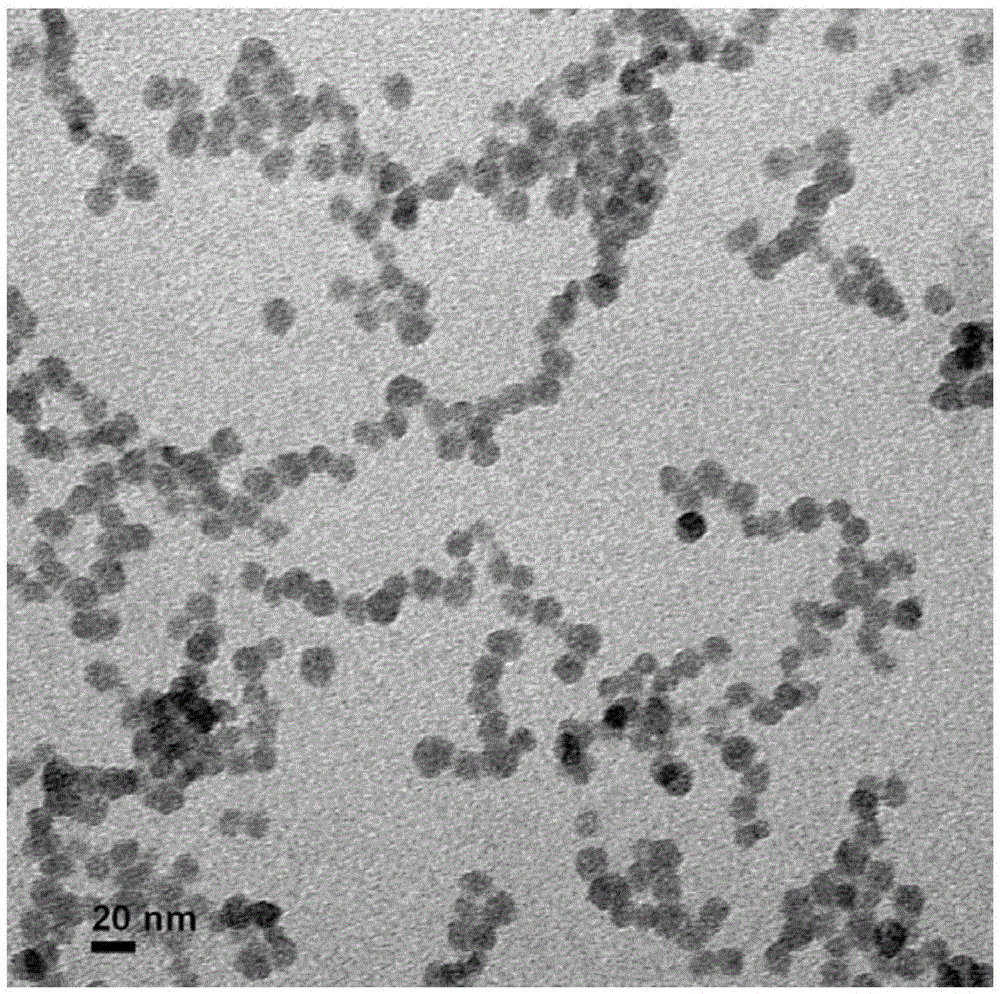

Application of fabric darkening agent in darkening of real silk fabric

InactiveCN105133297AAvoid damageLittle impact on hand feelingAnimal fibresSilica particlePolyvinyl alcohol

The invention discloses an application of a fabric darkening agent in darkening of a real silk fabric. The adopted specific fabric darkening agent is prepared from the following raw materials in parts by weight: 50 to 150 parts of silicon dioxide dispersing solution, 50 to 300 parts of water and 0.075 to 13.5 parts of polyvinyl alcohol, wherein the solid content (percentage by weight) of silicon dioxide in the silicon dioxide dispersing solution is 20 to 40%. A rapid preparation method of the fabric darkening agent comprises the following steps: diluting the silicon dioxide dispersing solution with water, then adding polyethylene glycol (PEG), and uniformly mixing to obtain the fabric darkening agent. The fabric darkening agent is prepared by blending the silicon dioxide particle dispersing solution and an appropriate amount of polyethylene glycol (PEG); the preparation method is simple and rapid, and easy to implement. The real silk fabric is finished by a simple dipping process and is then baked, so that the darkening effect of the real silk fabric is remarkable.

Owner:ZHEJIANG YASHILIN NECKTIE & GARMENT

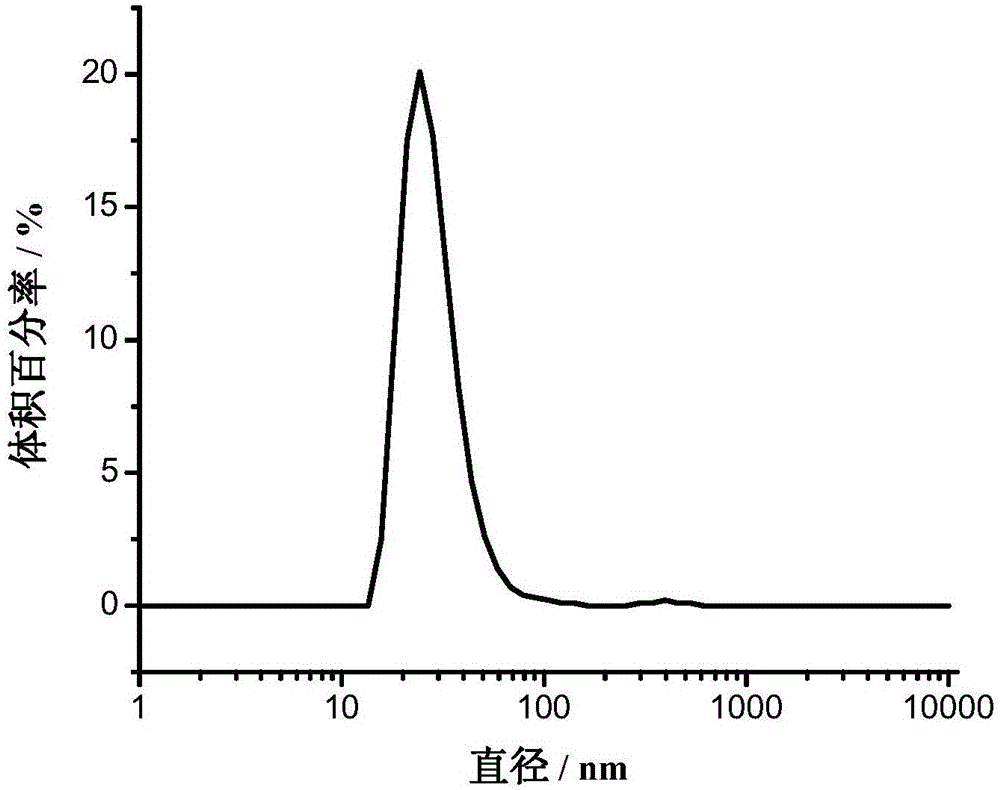

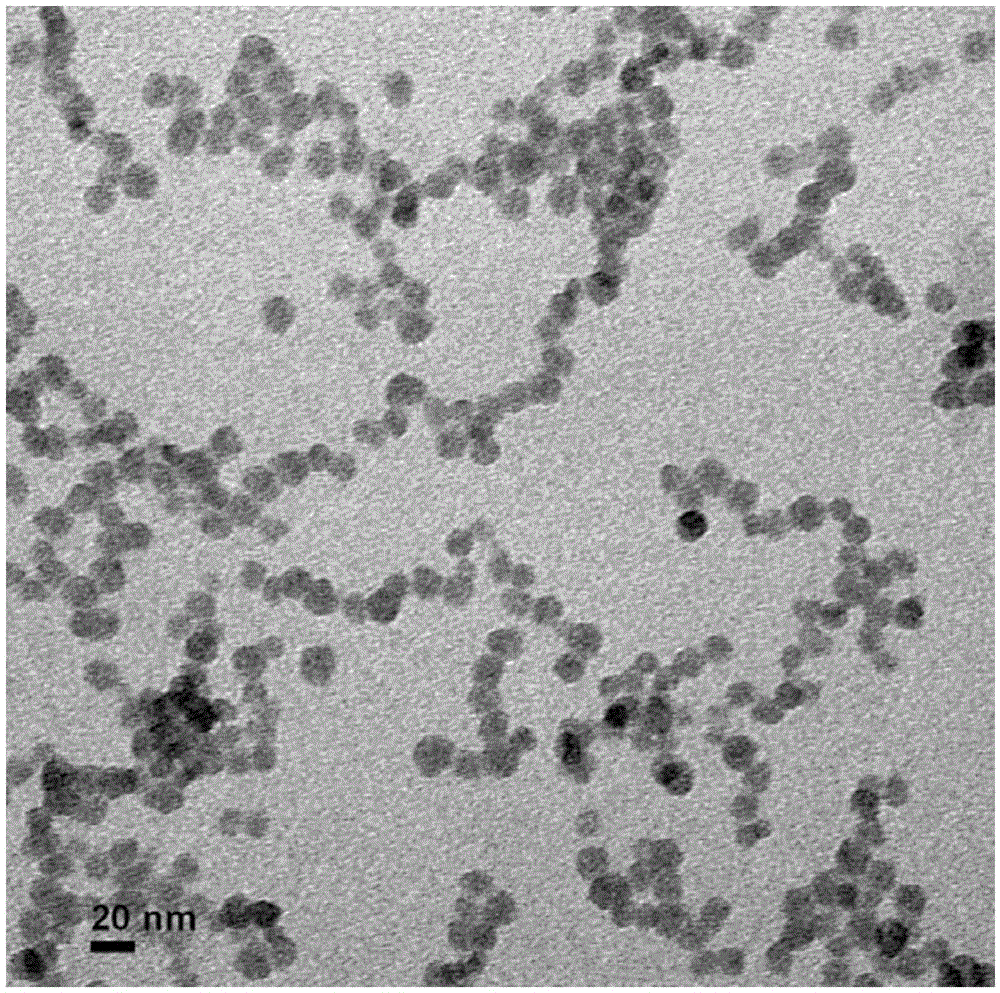

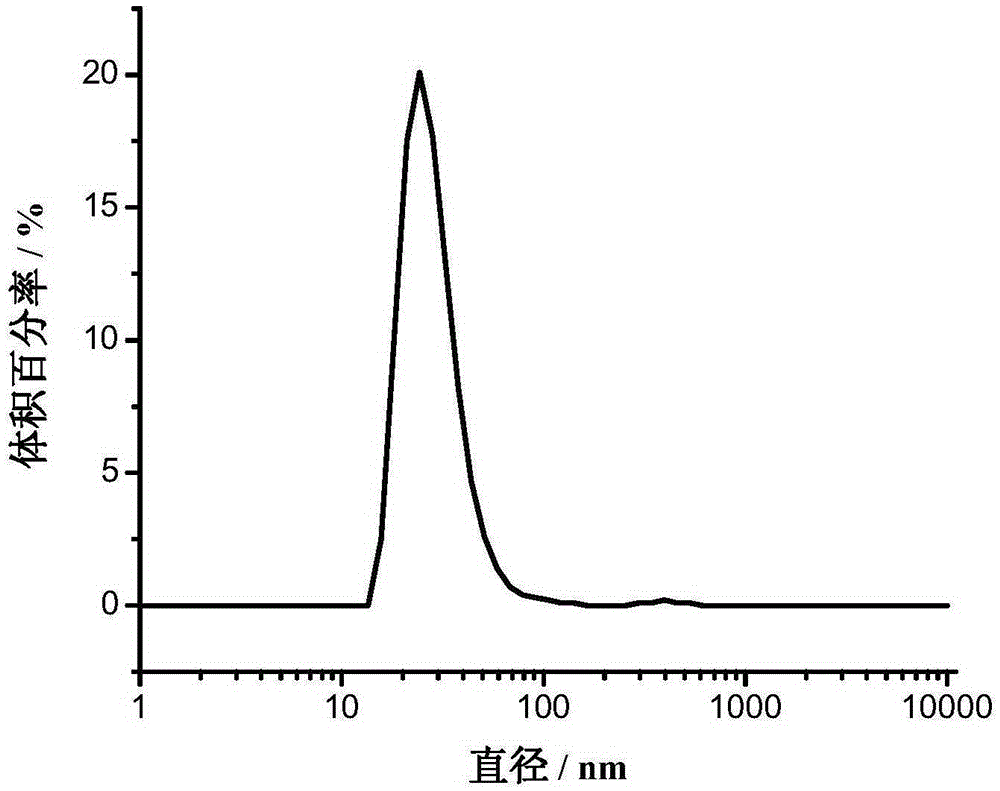

Fabric darkening agent and preparation method thereof, and applications of fabric darkening agent in polyester fabric darkening

The present invention discloses a fabric darkening agent and a preparation method thereof, and applications of the fabric darkening agent in polyester fabric darkening, wherein the fabric darkening agent is prepared from the following raw materials by weight: 50-150 parts of a silica dispersion, 50-300 parts of water, and 0.075-13.5 parts of polyethylene glycol, wherein the solid content of the silica in the silica dispersion is 20-40 wt%. The fast preparation method of the fabric darkening agent comprises: diluting the silica dispersion with the water, then adding the polyethylene glycol (PEG), and uniformly mixing to obtain the fabric darkening agent. According to the present invention, the silica particle dispersion and a suitable amount of the polyethylene glycol (PEG) are blended to prepare the fabric darkening agent, and the preparation method is simple and rapid, and is easy to perform; and the polyester fabric is finished through the simple impregnation process and then baking is performed, such that the fabric darkening effect is obvious and the durability is provided.

Owner:ZHEJIANG SCI-TECH UNIV

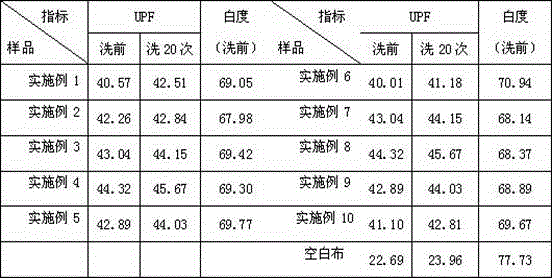

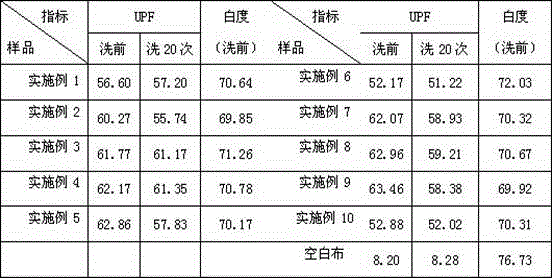

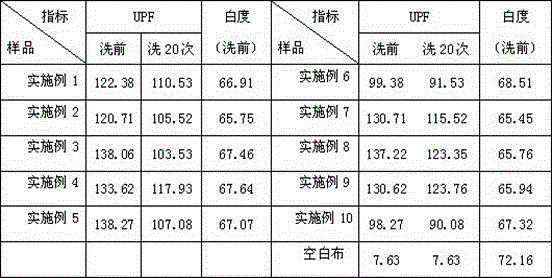

Universal durable anti-ultraviolet finishing agent for cotton and polyester and preparation method thereof

ActiveCN105131174BImproves UV resistanceLittle impact on hand feelingFibre treatmentPolyesterPolymer science

The invention discloses a durable uvioresistant finishing agent applicable to both cotton and terylene and a preparation method thereof. The durable uvioresistant finishing agent applicable to both cotton and terylene comprises, in percent by mass, 60-85% of a cationic silicone-acrylic emulsion and 15-40% of an ultraviolet-ray absorber solution. The preparation method for the durable uvioresistant finishing agent comprises the following steps: preparing the cationic silicone-acrylic emulsion through an emulsion polymerization reaction, preparing the ultraviolet-ray absorber solution, and mixing the ultraviolet-ray absorber solution and the silicone-acrylic emulsion, and performing emulsification. The durable uvioresistant finishing agent is universally applied to cotton, terylene, polyester cotton and other fabric with highest demand, and also is universally applied to technologies of dip padding, dipping, coating, printing, spraying and the like. The product storage stability is excellent. Fabric arranged by employing the finishing agent is excellent in ultraviolet resistance and excellent in washing fastness.

Owner:DYMATIC CHEM

A kind of processing method of natural non-ironing pure cotton fabric

ActiveCN105350286BWith non-iron effectLittle impact on hand feelingBiochemical fibre treatmentDyeing processYarnPulp and paper industry

The invention discloses a processing method of a natural non-ironing pure cotton fabric. The whole processing process is as follows: yarn selection → yarn dyeing → sizing → weaving → singeing → desizing → mercerizing → liquid ammonia → biological enzyme treatment → drying → Non-ironing resin finishing → Pre-shrinking; the advantage is that the non-ironing grade of pure cotton fabrics processed by this method can reach above 3.0, realizing the application of silicone in the actual production of pure cotton non-ironing fabrics, and the obtained pure Cotton fabric has a non-ironing effect, does not contain formaldehyde, is environmentally friendly, and is harmless to the human body; in addition, the strong damage to the fabric during the processing process has little impact on the feel of the fabric, and the processed fabric feels very smooth and soft.

Owner:盛泰智造集团股份有限公司

Oxidation and keratin cashmere after-finishing liquid and finishing method

ActiveCN112981938AImprove pilling performanceLittle impact on hand feelingBiochemical treatment with enzymes/microorganismsGrip property fibresFiberPolymer science

The invention discloses an oxidation and keratin cashmere after-finishing liquid and a finishing method. The cashmere after-finishing liquid (oxidation liquid) comprises sodium percarbonate, TAED, an oxygen bleaching stabilizer and the balance of water. The cashmere after-finishing liquid (keratin liquid) comprises keratin and the balance of water. According to the finishing method, the cashmere fabric is subjected to low-temperature oxidation treatment through sodium percarbonate, so that a scale layer of fibers is thinned, surface hairiness is effectively removed, the directional friction effect is reduced, and the anti-pilling performance can be improved; and after keratin treatment, keratin is attached to the surfaces of the fibers, crosslinking is achieved in protein peptide chains, a formed keratin film is coated on the surface of the fiber to ensure that the color difference and the hand feeling of the cashmere fabric are basically unchanged, and the anti-pilling performance of the cashmere fabric subjected to oxidation and keratin finishing is improved by one level or above compared with the original level.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

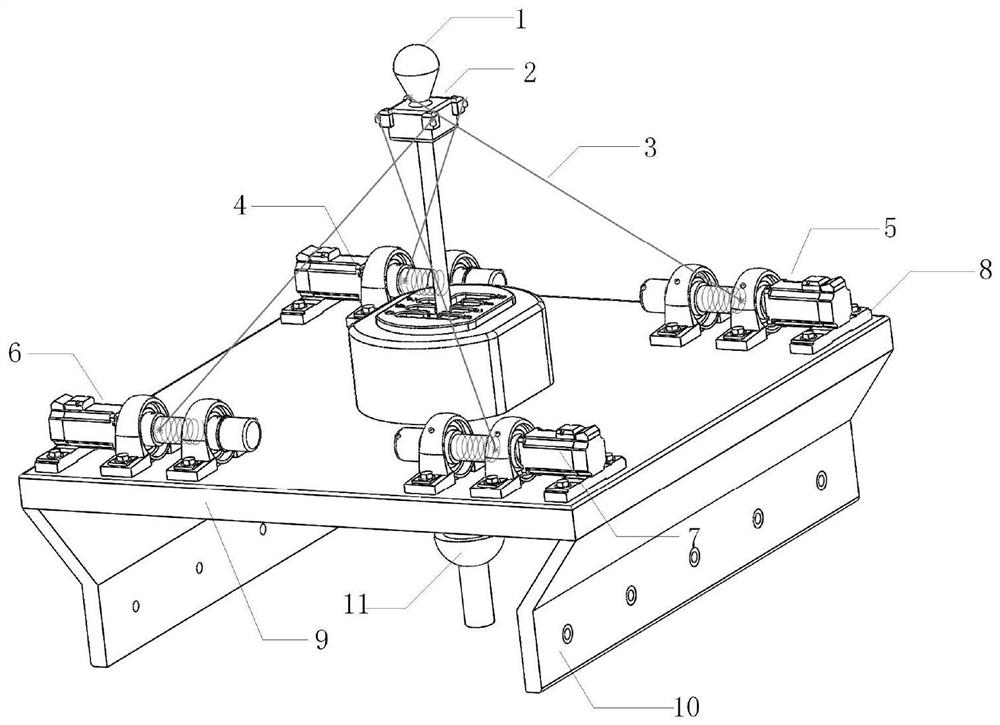

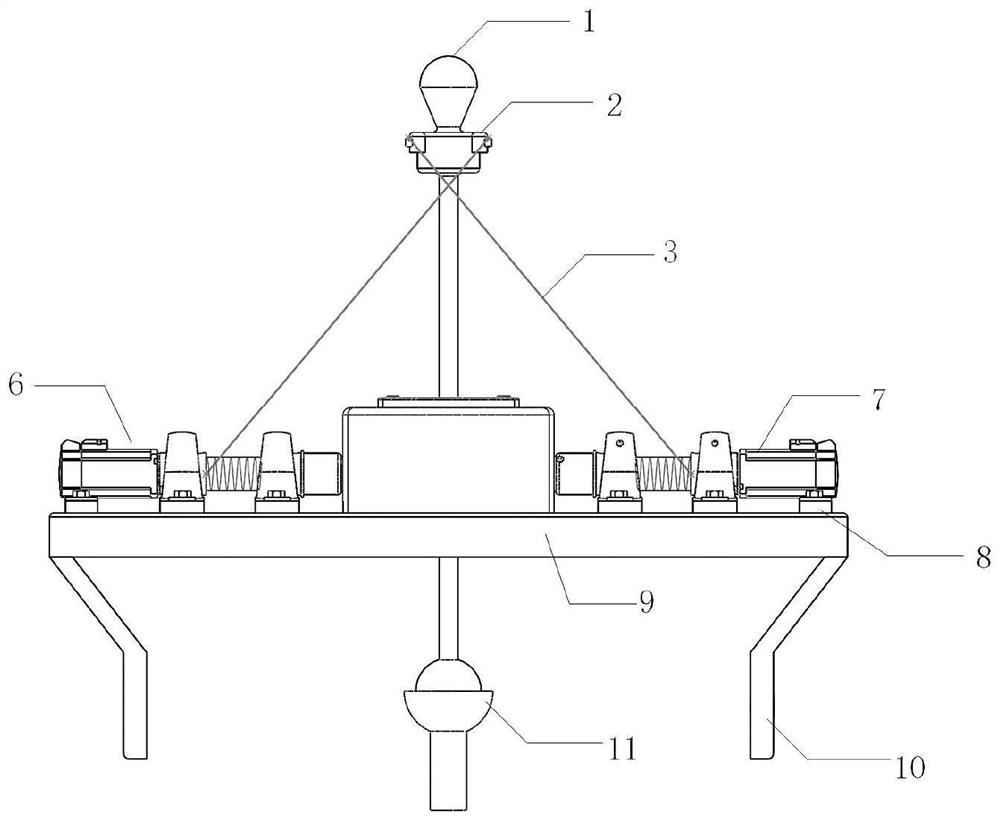

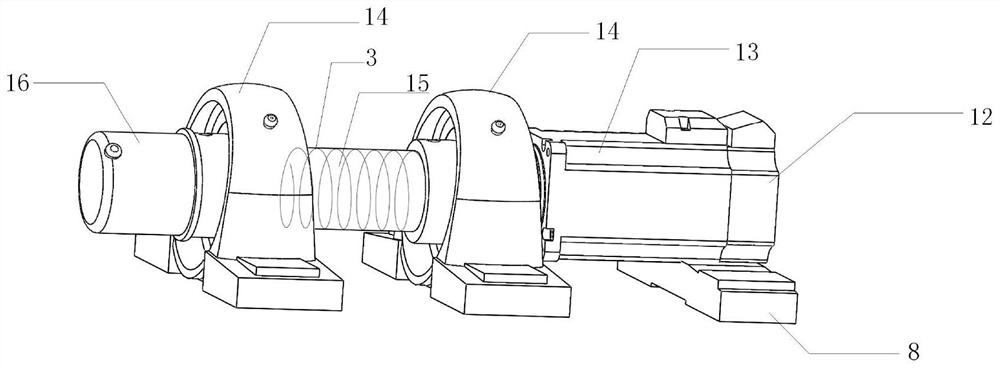

Rope-driven automobile gear shifting robot

PendingCN113650035AHigh precisionGood repeatabilityProgramme-controlled manipulatorControl engineeringElectric machinery

The invention relates to the technical field of robot automatic driving, and discloses a rope-driven automobile gear shifting robot which comprises a gear shifting rod. A gear shifting rod clamp is arranged at the bottom of the gear shifting rod, a steel wire rope is arranged at the bottom of the gear shifting rod clamp, and a motor and winding drum assembly is arranged at one end of the steel wire rope. The motor and winding drum assembly comprises a first motor winding drum, a second motor winding drum, a third motor winding drum and a fourth motor winding drum, motor bases are arranged at the bottoms of the first motor winding drum, the second motor winding drum, the third motor winding drum and the fourth motor winding drum correspondingly, a base plate is arranged at the bottoms of the motor bases, and a base plate clamping device is arranged at the bottom of the base plate. According to the rope-driven automobile gear shifting robot, the winding drums are driven through four motors correspondingly, then torque is transmitted to the gear shifting rod through the steel wire rope, gear shifting operation is achieved, the device can actively control the spatial three-translational motion freedom degree of the head of the gear shifting rod, the device can be matched with the H-type gear shifting form, control is accurate, and the structure is simple.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Preparing method of novel acidic dye-fixing agent for seamless underwear and prepared dye-fixing agent

ActiveCN106544905AImprove color fixationStrong alkali resistance and high temperature resistanceDyeing processAlcoholDibutyltin oxide

The invention discloses a preparing method of a novel acidic dye-fixing agent for seamless underwear and the prepared dye-fixing agent. The preparing method comprises the steps of mixing bisphenol S, dibutyltin oxide and an alkanolamide solution, conducting heating and stirring processing on the mixture, then adding hexamethyldisilazane into the mixture, and conducting cooling and stirring processing on the mixture, wherein the mass ratio of bisphenol S to dibutylin oxide to hexamethyldisilazane is (28-36):(1-5):(5-13) and the volume ratio of hexamethyldisilazane to the alkanolamide solution is 1:(6-8); adding a citric acid solution into the mixture, and stirring the mixture at the temperature of 62 DEG C, wherein the volume ratio of hexamethyldisilazane to the citric acid solution is 1:(15-17); dropwise adding an isomeric alcohol ethoxylate solution into the mixture, conducting stirring processing on the mixture at the temperature of 55 DEG C, and lowering the temperature to a normal temperature so as to obtain the novel acidic dye-fixing agent. According to the preparing method of the novel acidic dye-fixing agent for seamless underwear and the prepared dye-fixing agent, the dye-fixing agent is free of formaldehyde, excellent in color fixation effect, and very strong in alkali resistance and high temperature resistance; the dye-fixing agent has no influence on bright hues of reactive dyes; the dye-fixing agent is free of color change, has no influence on chlorine fastness, light fastness and perspiration fastness of dye materials, is green and environmentally friendly, and is suitable for industrialized production.

Owner:江西德盛精细化学品有限公司

Pigment dyeing method for improving leveling property and cloth cover effect

InactiveCN113338054AUniform dyeingBright colorBiochemical treatment with enzymes/microorganismsDyeing processPolymer scienceCellulase

The invention provides a pigment dyeing method for improving the leveling property and the cloth cover effect. The pigment dyeing method comprises the following steps of pretreatment scouring and bleaching, neutral cellulase polishing, dust removal and wool washing, cationization modification treatment, water washing, pigment dyeing, water washing, fixation, dewatering, drying and setting. The process formula of dust removal and wool washing comprises the following steps of selecting 2-5 g / L of 550, heating to 70-80 DEG C at a heating speed of 2-3 DEG C / min according to a bath ratio of 1: (8-10), keeping the temperature for 20-30 minutes, and then washing with water. The process formula of the cationization modification treatment comprises the following steps of selecting 2 g / L of a modifier DM-2019, performing dyeing at room temperature, heating to 60-70 DEG C at a heating speed of 1-2 DEG C / min according to a test bath ratio is 1: (20-30), keeping the temperature for 20-30 minutes, performing normal-temperature water washing, and performing pigment dyeing. A fabric is uniform in dyeing, bright in color, clear in cloth cover texture, high in fastness, short in process and good in fabric comfort, and a processing technology is reasonable and easy to operate.

Owner:DYMATIC CHEM

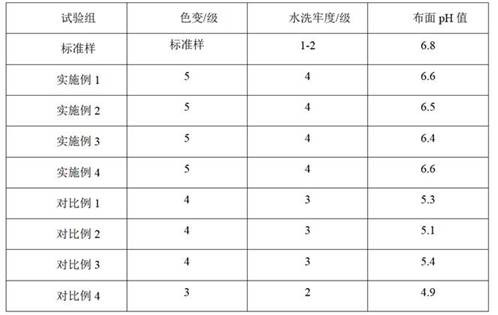

A kind of acid color fixing agent and preparation method thereof

ActiveCN110699991BGood working fluid pH control abilityGood color fixing effectDyeing processSodium stearateSODIUM PHENOLSULFONATE

The invention belongs to the field of dye fixing agents, and in particular relates to an acidic color fixing agent and a preparation method thereof. Including the following components: polyethyleneimine, modified polyacrylic acid, sodium citrate, sodium salicylate, sodium laureth sulfate, sodium stearate, sodium phenolsulfonate; the preparation method is simple, the color fixing agent It has good color fixing effect, does not contain harmful substances such as formaldehyde, and has good pH value control effect.

Owner:多恩生物科技有限公司

Antistatic agent for dacron textile and preparation method of antistatic agent

The invention discloses an antistatic agent for a dacron textile as well as a preparation method and an application of the antistatic agent. The preparation method comprises the following steps of: carrying out grafting modification on hyperbranched polyester BoltornH20 by trimethyl oxiranemethaminium chloride and acrylic acid according to the ratio of the amount of substance from 1: 1 to 1: 2; and taking an obtained modified substance to react with acrylamide, dimethyl diallyl ammonium chloride and allyl glycidyl ether to prepare the antistatic agent. According to the antistatic agent of the dacron textile as well as the preparation method and the application of the antistatic agent disclosed by the invention, the process is simpler and a reaction process is convenient to control; the prepared antistatic agent has the stronger cation property and the antistatic function of the dacron textile can be obviously improved; and meanwhile, a lot of reactive functional groups in the antistatic agent can generate cross-linking effect in a finishing and drying process of the dacron textile, the antistatic water-washing resisting performance of the finished textile can be effectively improved, the influences on the hand feel of the textile by the antistatic agent are small.

Owner:SUZHOU UNIV

Plant dyeing method for polylactic acid fiber fabric and garment

PendingCN113550158AEco-friendly dyeing processLow carbon dyeing processNatural dyesDyeing processBiotechnologyFiber

The invention relates to a plant dyeing method for a polylactic acid fiber fabric and a garment. Plant dye is adopted for the polylactic acid fiber fabric and the garment. Water, the polylactic acid fiber fabric and the garment are added into a dyeing machine; 0-5 g / l of a natural dyeing aid DA and the plant dye are added; the temperature is increased to 75-98 DEG C and kept for 30-90 minutes; 10-50 g / l of a natural dyeing aid for promoting dyeing is added; the temperature of 75-98 DEG C is kept for 20-40 minutes; and after dyeing, liquid discharging, hot water washing and color fixing are performed to finish normal-pressure and low-temperature plant dyeing. The method has the advantages that the optimized plant dye is adopted to replace petroleum chemical dye to carry out plant dyeing on the polylactic acid fiber fabric and the garment, so that the dyeing process of the polylactic acid fiber fabric and the garment is more environment-friendly and low-carbon.

Owner:苏州麻朵纺织科技有限公司

Synthesis and application of durable flame retardant of nitrogen-phosphorus synergistic system for cotton without halogen and formaldehyde release

ActiveCN107761377BLittle strengthLittle impact on hand feelingGroup 5/15 element organic compoundsVegetal fibresSodium methoxideSynthesis methods

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com