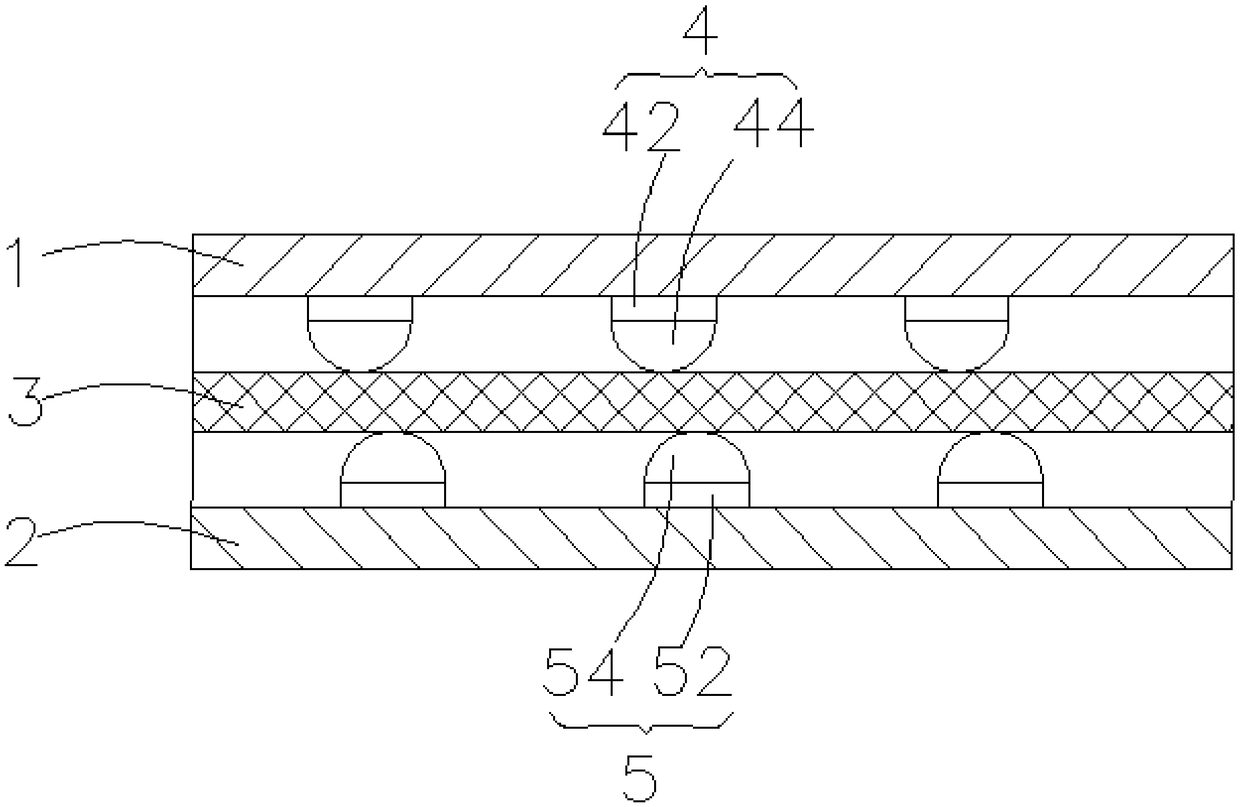

Functional film double-sided composite fabric and production method

A technology of composite fabric and functional film, applied in the textile field, can solve the problems that need to be further improved, and achieve the effects of facilitating control of the quality of composite textiles, not easy to foam and degumming, and improving the environmental conditions of production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

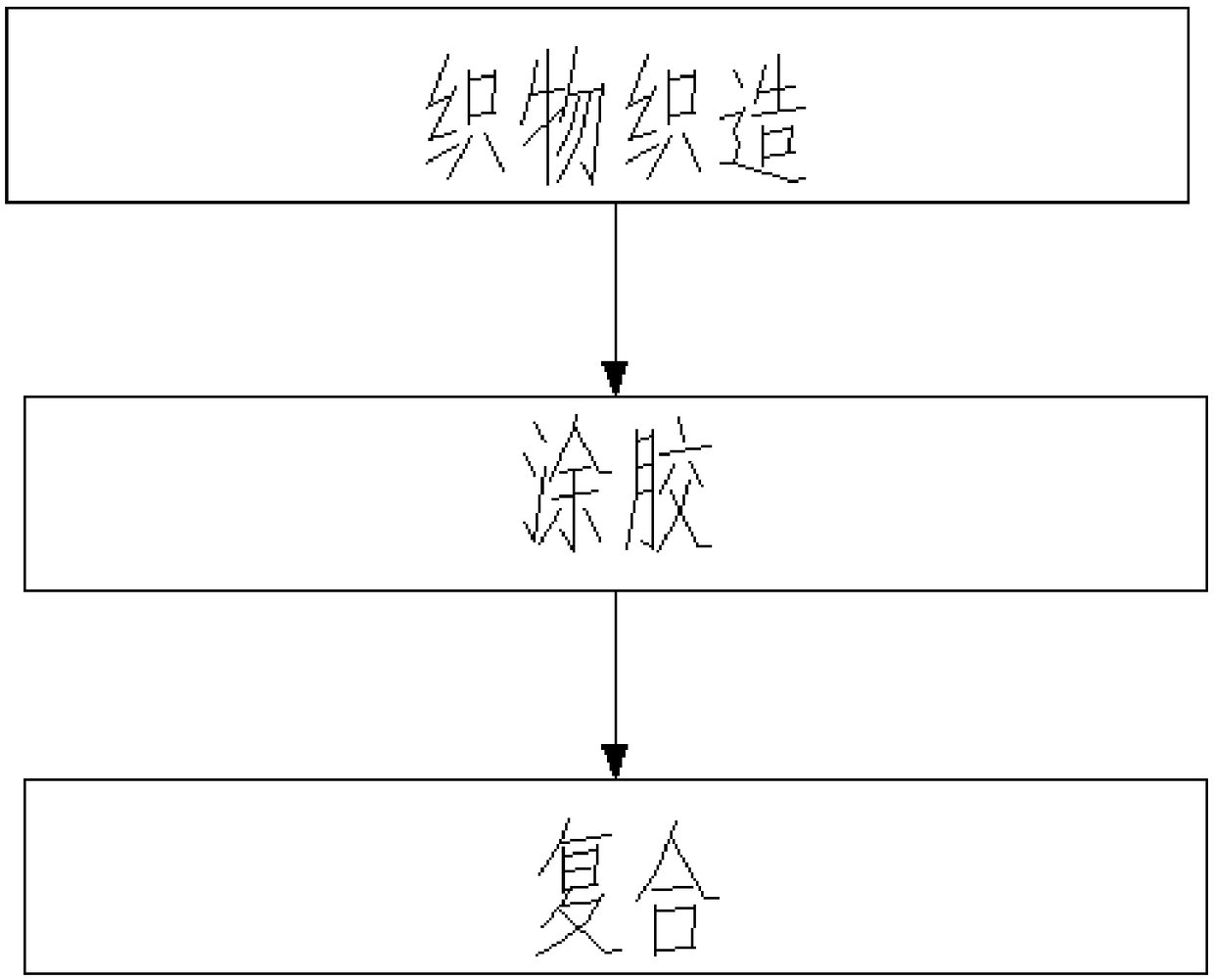

Method used

Image

Examples

Embodiment 1

[0052] Example 1: The fabric of the composite woven fabric on both sides of the functional film

[0053] The fabric of functional membrane double-sided composite woven fabric is mainly suitable for men's windbreaker or jacket. Three-layer composite fabrics for high-end windbreakers and rainproof and moisture-permeable jackets require a flat surface, with a little elasticity in the warp direction, and obvious elasticity in the weft direction for sports comfort. Reach 2000g / square meter x24h (the expression method of moisture permeability performance parameters refers to the amount of water vapor that can pass through per square meter of fabric in 24 hours under specific instruments and methods is greater than 2000 grams), water pressure greater than 10000mmH2O (water pressure resistance reaches 10000mm water High pressure without damage or permeable water pressure unit), the color fastness to dry and wet friction exceeds 3.5, the wear resistance exceeds 4, and the square gram w...

Embodiment 2

[0072] Embodiment 2: The fabric of functional membrane double-sided composite knitted fabric

[0073] This type of fabric is used to make outdoor sweatshirts and has the advantages of windproof, breathable, moisture-permeable and waterproof.

[0074] The specific production method of the fabric of the composite knitted fabric on both sides of the functional film is as follows:

[0075]In the above step A, the surface layer fabric 1 is a knitted fabric. When weaving the knitted fabric as the surface layer, use a 30-inch 44-needle double-sided circular machine weaving gray fabric from Xiamen PILOTELLI Company, use a plain jersey weave for the structure, and use polyester for the yarn DTY15D / 12F network yarn, the weaving wire length is 0.1826 cm / turn, and the unmachined weight is 20 kg / roll.

[0076] When overflow dyeing, first add degreasing agent, put hot water at 84-92 degrees into the cloth, then raise the temperature to 94 degrees and keep it warm for 15 minutes, then cool ...

Embodiment 3

[0088] Embodiment 3: The fabric of the two-sided composite warp-knitted and weft-inserted printed cloth of the functional film

[0089] This kind of fabric is used to make square down fashion down jacket, which has the advantages of windproof, breathable, moisture-permeable and waterproof.

[0090] In this embodiment, the specific production method of the fabric of the two-sided composite warp-knitted and weft-inserted printed cloth of the functional film is as follows:

[0091] In the above step A, the surface layer fabric 1 is a warp-knitted weft-inserted printed cloth, and when weaving the warp-knitted weft-inserted printed cloth as the surface layer, the warp-knitted weft-inserted machine of the HKS model 28 needles of Karl Mayer is selected. Weaving gray fabric, the warp and weft yarn specifications are PESDTY 30D / 24F X PES DTY 50D / 48F, the width of the upper machine is 86 inches, the weft density of the upper machine is 17.5 pieces / cm, 12 / 10 two-needle warp flat weave, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com