Environment friendly sulfur coating type sustained-release chemical fertilizer

A technology of coating and chemical fertilizers, applied in fertilization devices, fertilizer mixtures, agriculture, etc., can solve the problems of poor impact resistance, unstable release period, and high cost, and achieve low cost, long release period, and long release period stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

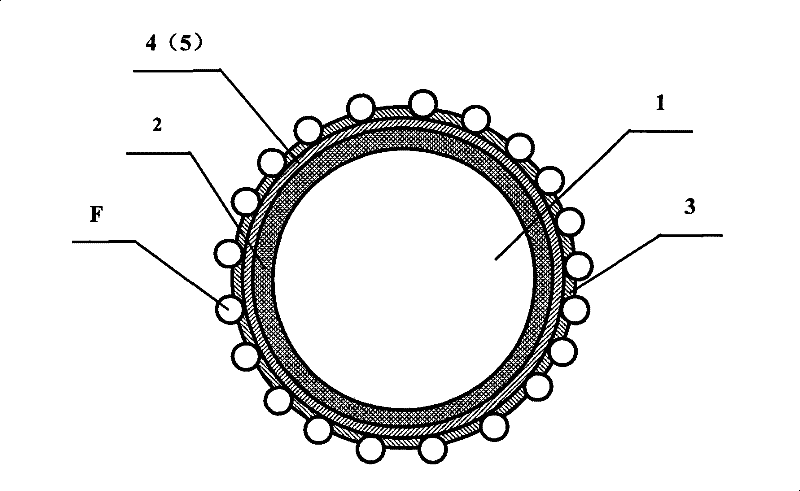

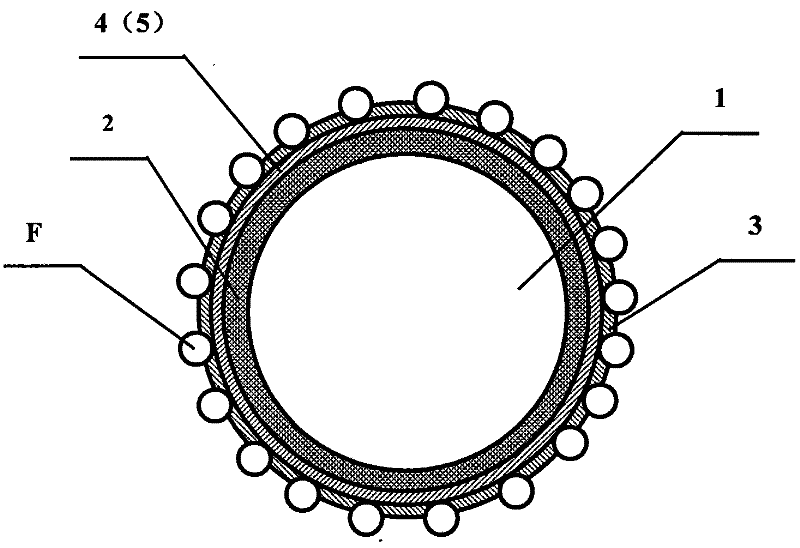

[0038] Add spherical urea with a particle size of 2.9 to 3.1mm into the fluidized bed coating equipment, and keep the spherical urea in a boiling state, and keep the temperature of the spherical urea in the fluidized bed at 90°C. Slowly spray molten sulfur at about 150°C on the surface of urea until the quality of the sulfur film reaches 11% of the total mass of the final product, environmentally friendly sulfur-coated slow-release urea (thickness is about 40 μm). Then, spray the urea-formaldehyde resin prepolymer aqueous solution (the urea-formaldehyde resin prepolymer is that urea: formaldehyde molar ratio is 1: 1.5 is prepared by the reaction of urea and formaldehyde containing poplar wood powder (150 μ m) on the surface of the sulfur film layer, Poplar wood powder: urea-formaldehyde resin prepolymer mass ratio is 3: 2), spray until urea-formaldehyde resin / poplar wood powder composite film quality reaches 5% of the final finished product environmental protection sulfur coati...

Embodiment 2

[0040] Add spherical urea with a particle size of 2.9 to 3.1mm into the fluidized bed coating equipment, and keep the spherical urea in a boiling state, and keep the temperature of the spherical urea in the fluidized bed at 90°C. Slowly spray molten sulfur at about 150°C on the surface of urea until the quality of the sulfur film reaches 11% of the total mass of the final product, environmentally friendly sulfur-coated slow-release urea. Then, spray the melamine-formaldehyde resin prepolymer aqueous solution (melamine-formaldehyde resin prepolymer is melamine: formaldehyde mol ratio is 1: 3 melamine and formaldehyde that contain bagasse powder (average particle diameter 150 μm)) Prepared by reaction, bagasse powder: the mass ratio of melamine-formaldehyde resin prepolymer is 7: 3), spray until the quality of melamine-formaldehyde resin / bagasse powder composite film layer reaches the final product environmental protection sulfur coated slow-release urea 6% of the total mass (re...

Embodiment 3

[0042] Add spherical urea with a particle size of 2.9 to 3.1mm into the fluidized bed coating equipment, and keep the spherical urea in a boiling state, and keep the temperature of the spherical urea in the fluidized bed at 90°C. Slowly spray molten sulfur at about 150°C on the surface of urea until the quality of the sulfur film reaches 11% of the total mass of the final product, environmentally friendly sulfur-coated slow-release urea. Then, spray melamine-formaldehyde resin prepolymer aqueous solution (melamine-formaldehyde resin prepolymer is that melamine: formaldehyde mol ratio is 1: 3 is prepared by the reaction of melamine and formaldehyde) at the surface of sulfur film layer again, spray until melamine-formaldehyde resin The quality of the film layer reaches 1% of the total mass of the final product, environmentally friendly sulfur-coated slow-release urea. Subsequently, spray the melamine-formaldehyde resin prepolymer aqueous solution (melamine-formaldehyde resin pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com