Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Fixative/Stain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A compound that both fixes tissues or cells and stains it for microscopic study.

Colored leather hyperchromic/cleaning agent composite and preparation method thereof

InactiveCN102732390AColor enhancementCationic surface-active compoundsNon-ionic surface-active compoundsRefractive indexRare earth

The invention provides a colored leather hyperchromic / cleaning agent composite, which comprises the following raw materials in parts by weight: 5-95 parts of leather cleaning agent, 2-98 parts of darkening agent, 5-95 parts of film forming agent, 1-81 parts of solvent and 2-98 parts of dye-fixing agent, wherein the darkening agent is one or more of chitin, chitosan, silicone oil compounds, rare earth and resin (refractive index: less than 1.5). According to the invention, various auxiliary materials such as the darkening agent and the dye-fixing agent are added into the leather cleaning agent so as to obtain the colored leather hyperchromic / cleaning agent composite; and by using the composite, the original colors of colored leathers after being cleaned are fixed, and darkened, thereby achieving an effect of always keeping fresh through regular cleaning. The invention also provides a method for preparing the colored leather hyperchromic / cleaning agent composite.

Owner:吉林省亨泰服装洗染科学技术研究所

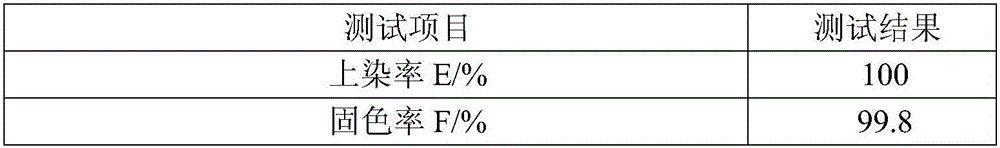

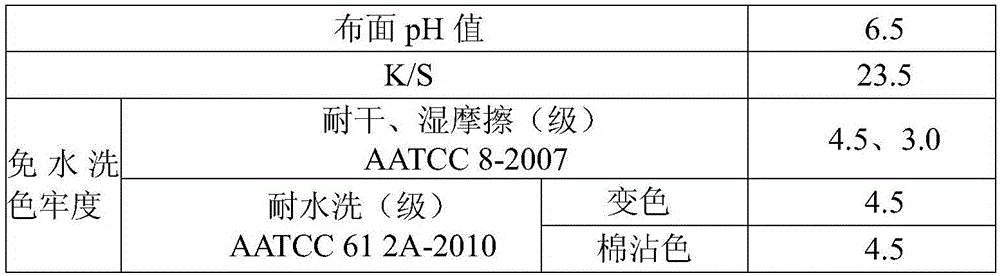

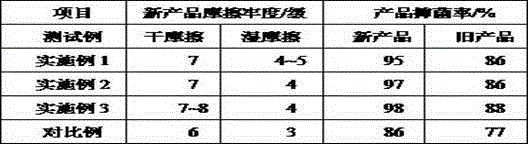

Non-aqueous solvent dyeing method of washing-free reactive dye

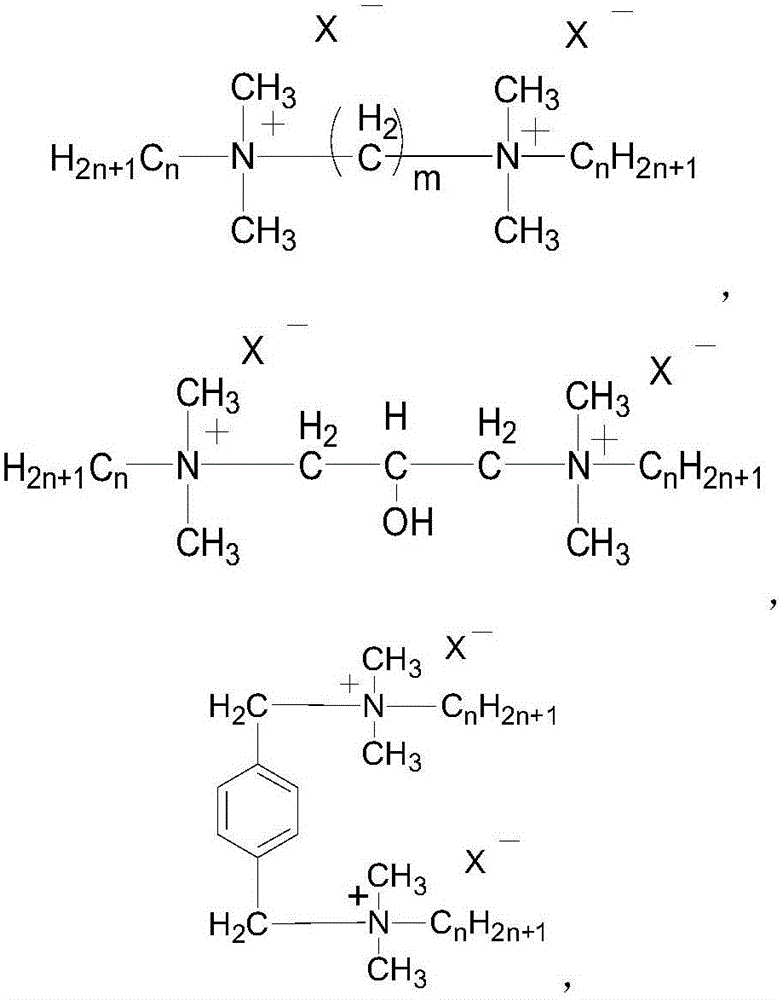

The invention provides a non-aqueous solvent dyeing method of a washing-free reactive dye. The non-aqueous solvent dyeing method comprises the following steps: mixing pre-treated loose fibers, yarns, fabric or clothes with an reactive dye, a micro-molecular quaternary ammonium salt and a good solvent of the reactive dye, so as to form a mixing system; raising the temperature of the mixing system; adding a bad solvent of the reactive dye into the mixing system before raising the temperature or in a temperature rising process; keeping the heat after raising the temperature to a dyeing temperature, wherein the volume ratio of the good solvent of the reactive dye and the bad solvent of the reactive dye is 1 to (3-30), the ratio of the volume of the good solvent of the reactive dye to the mass of the loose fibers, the yarns, the fabric or the clothes is (0.8-10)mL to 1g, and the mass ratio of the micro-molecular quaternary ammonium salt to the reactive dye is (0.1-0.5) to 1; and then drying and putting into a color fixation solution and carrying out color fixation treatment, wherein the color fixation solution contains a 5-100g / L color fixation agent.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Bamboo fiber garment fabric with anti-bacteria function

InactiveCN104997206AImprove antibacterial propertiesNovel functional designBiochemical fibre treatmentDyeing processUltravioletEngineering

The invention discloses a bamboo fiber garment fabric with an anti-bacteria function. The bamboo fiber garment fabric is made by blending the following raw materials, by weight, 95% of bamboo fiber, 1.7% of hemp fiber, 1.4% of aloe fiber, 1.2% of soybean protein fiber, 0.3% of silver fiber, and 0.4% of carbonized cotton sterilization fiber. The bamboo fiber garment fabric provided by the invention can make products have good anti-bacteria performance and protect the skin, and is smooth, moisture-permeable and resistant to ultraviolet. Natural finishing agent chitosan is adopted in products in the post-processing stage, which further increases the anti-bacteria effect of the fabric. All-natural plant color-fixing agent and dyeing agent are used in the process of dyeing, dyeing is uniform, the process is simple, and the color is solid. Natural materials are adopted in the whole making process of the blended bamboo fiber garment fabric provided by the invention, so that the fabric is environment-friendly and safe, low in cost, novel in function design, high in quality, capable of making products feel comfortable, and high in added value.

Owner:JIESHOU SHUANGXIN TEXTILE

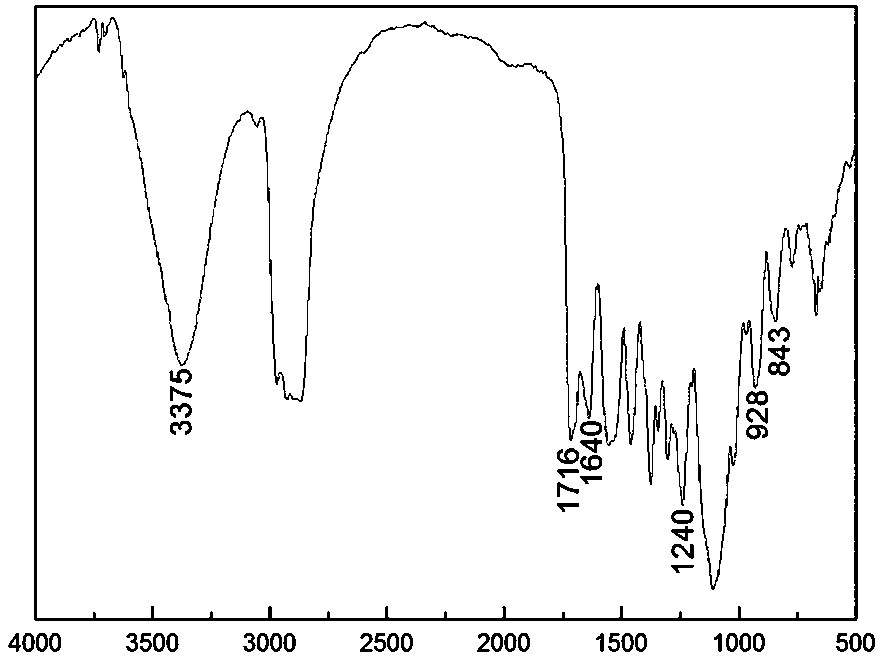

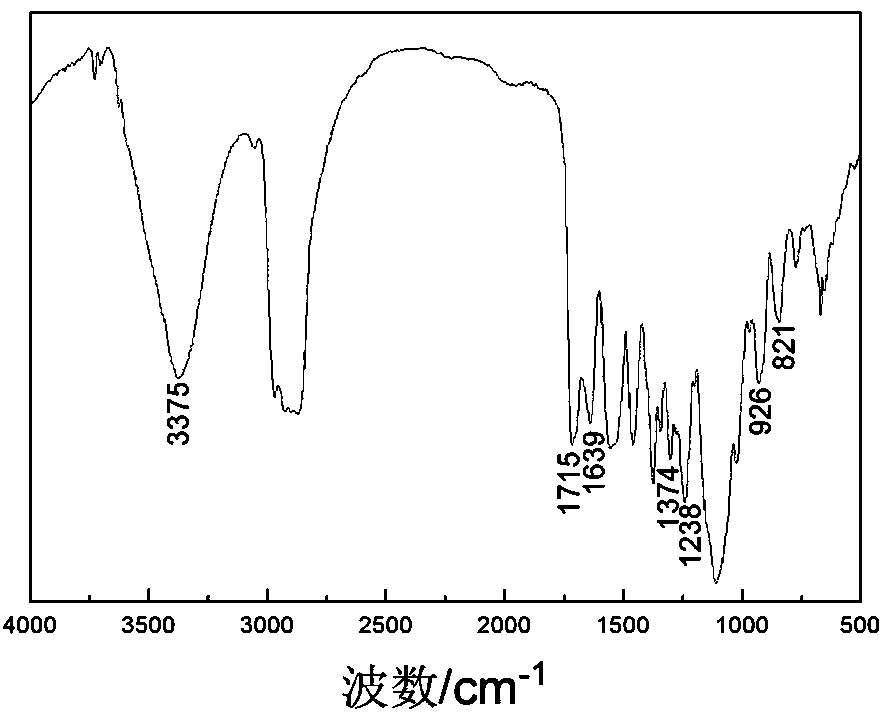

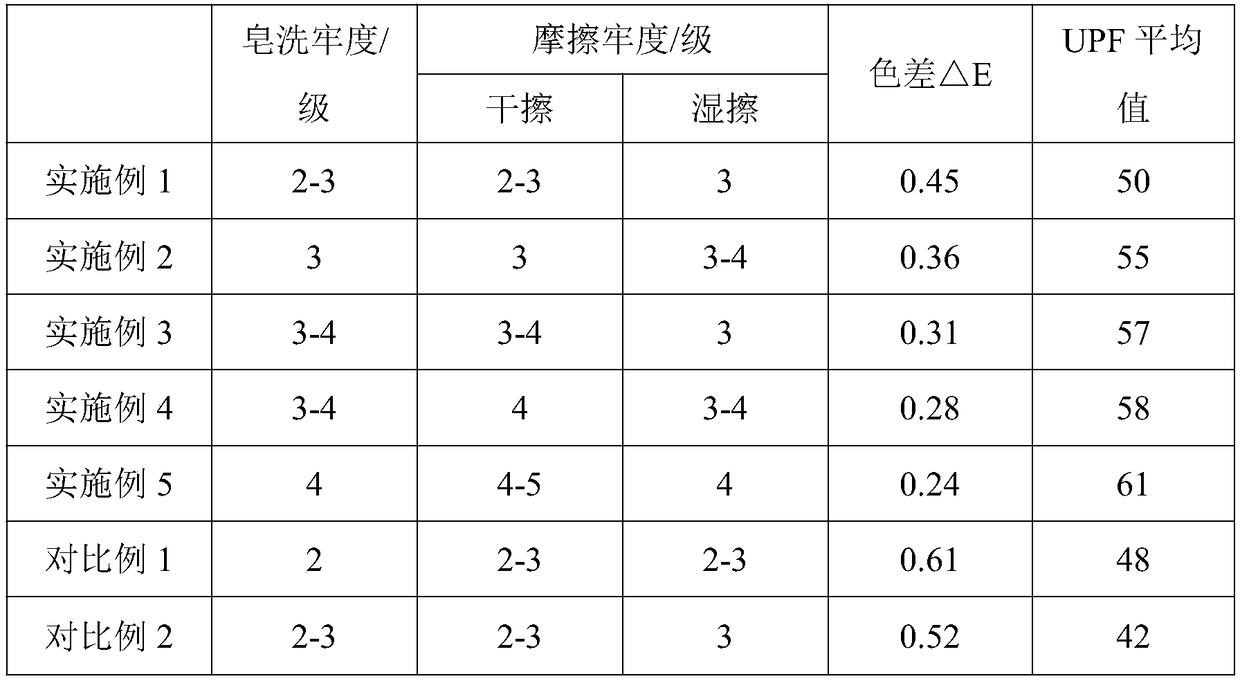

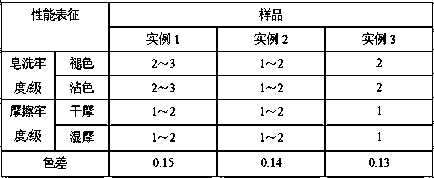

Method for preparing nano-titanium dioxide modified color fixing agent emulsion

ActiveCN104744642AImprove performanceImproves UV resistanceDyeing processEmulsionEmulsion polymerization

The invention relates to a method for preparing nano-titanium dioxide modified color fixing agent emulsion and aims to overcome the defect that color fixing emulsion is poor in ultraviolet resistance. According to the method, the nano-titanium dioxide modified color fixing agent emulsion is prepared from modified nano-titanium dioxide dispersion liquid, a cationic monomer, an organic silicon monomer, an emulsifier, an initiator and deionized water in a nuclear-shell emulsion polymerization mode. The method is simple and convenient in process, simple to control and stable in polymerization system, and by adjusting the proportions of monomer components of a core layer and a shell layer, nano-titanium dioxide, the cationic monomer and the organic silicon monomer are differently distributed, and thus a purpose of modifying the color fixing agent emulsion is achieved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Water-based black and transparent wax polishing leather surface finishing agent with color transfer resistance and preparation method of leather surface finishing agent

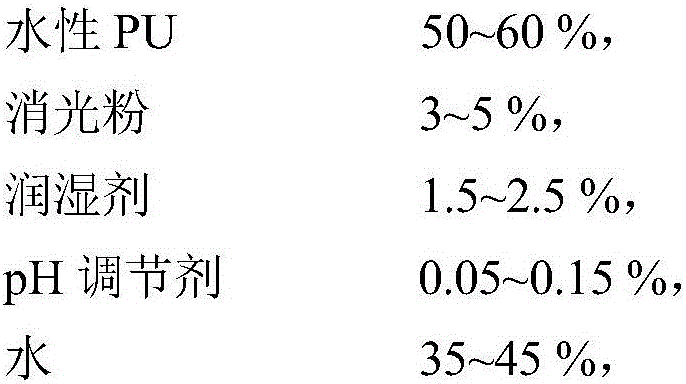

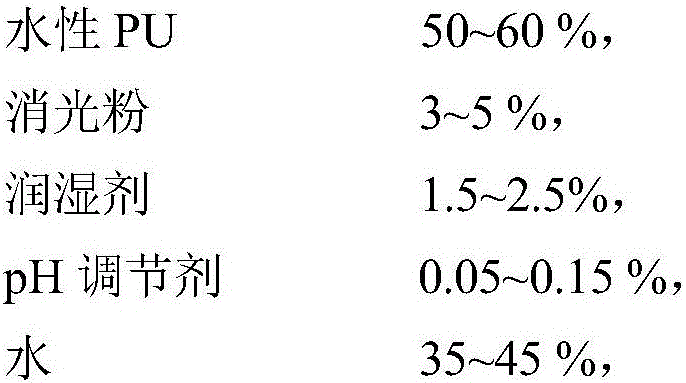

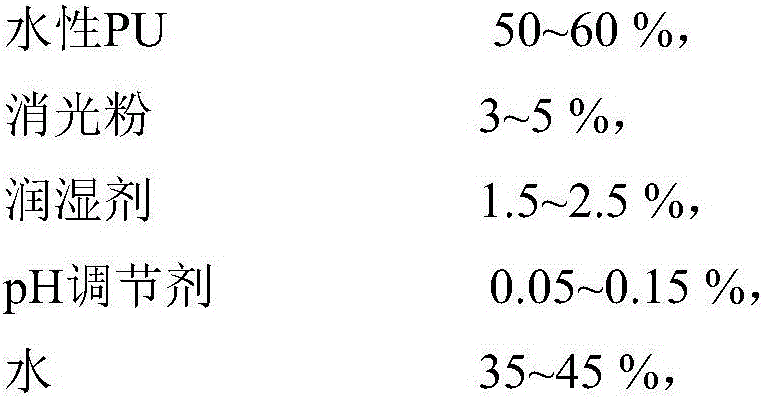

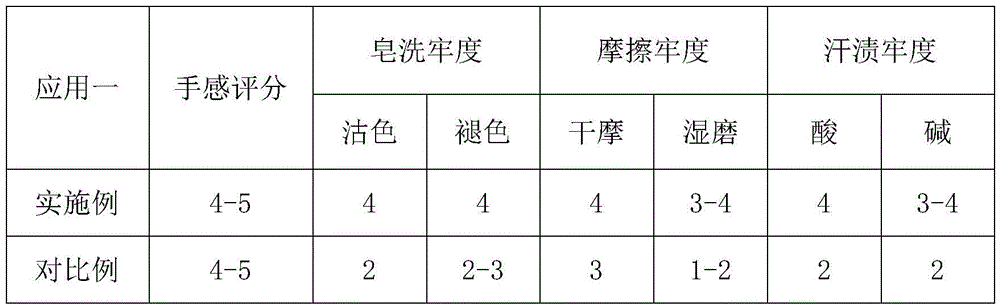

A water-based black and transparent wax polishing PU (polyurethane) leather surface finishing agent with color transfer resistance is prepared from water-based PU, matting powder, a wetting agent, a pH regulator and water, wherein water-based PU is prepared from diisocyanate, polyalcohol, a chain extender, a catalyst, a salt forming agent and a cosolvent through a reaction in water; polyalcohol is a mixture of a reactive type PU coloring agent and other polyalcohol, and the mass of the reactive type PU coloring agent is 40%-70% of the total mass of polyalcohol. Compared with a common wax polishing leather surface finishing agent, the water-based black and transparent wax polishing PU leather surface finishing agent with the color transfer resistance has the characteristics as follows: the consumption of an organic solvent is low, emission of volatile organic compounds in a production process is low, coloring groups are distributed uniformly, the color is uniform, the coloring firmness is high, the phenomena of color losing, decolorization, color fading and the like caused by color transfer are eliminated, addition of a color fixing agent is reduced, the safety and low toxicity are realized, the color is full and transparent, the agent has luster and chromaticity similar to those of leather, and the leather is endowed with waxy feeling and the like.

Owner:嘉兴禾大科技有限公司

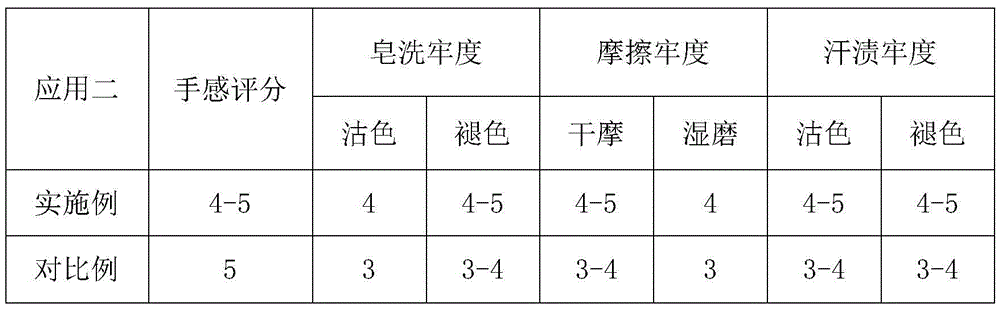

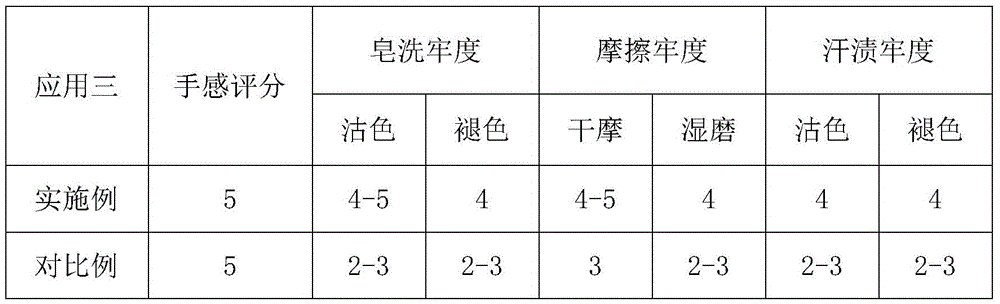

Synthesis method and application of formaldehyde-free acid dye fixing agent

InactiveCN105542074AMitigate the effect of hand qualityImprove water absorptionDyeing processFiberEnvironmental resistance

The invention discloses a synthesis method and an application of a formaldehyde-free acid dye fixing agent and belongs to the field of textile chemical technologies. Acrylic acid, 2-isonaphthol and 2-acrylamide-2-methyl propane sulfonic acid are used as raw materials, ammonium acetate is added to be used as an initiator, nickel chloride is added to be used as a catalyst, the formaldehyde-free acid dye fixing agent is synthesized and applied to fixation treatment of nylon, silk and wool textiles as well as nylon, silk and wool blended textiles, the color fastness is improved, soaping fastness, rubbing fastness, perspiration fastness and the like of fibers after fixation treatment are improved more obviously, the raw materials and the product do not contain formaldehyde, and compared with acid dye fixing agents for beds in the market, the formaldehyde-free acid dye fixing agent is environment-friendly and efficient; meanwhile, the preparation method is simple and beneficial to industrial popularization and has the higher economic benefit.

Owner:SUZHOU INSILK CO LTD

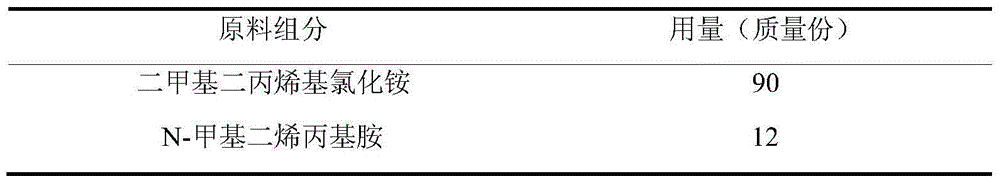

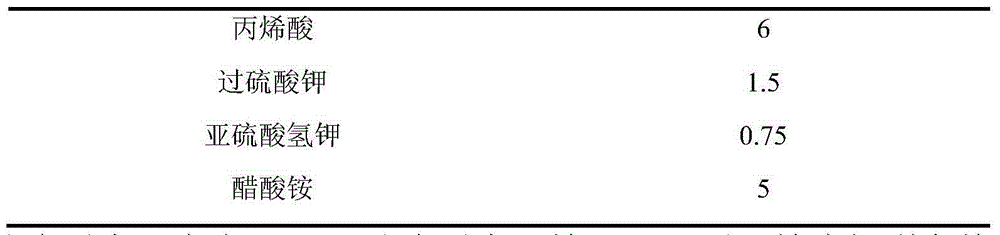

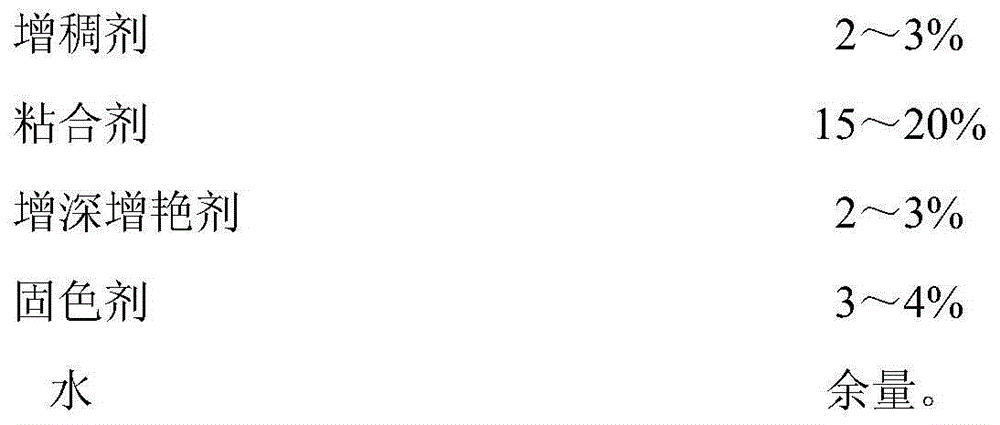

Polycationic formaldehyde-free color fixing agent and preparation method thereof

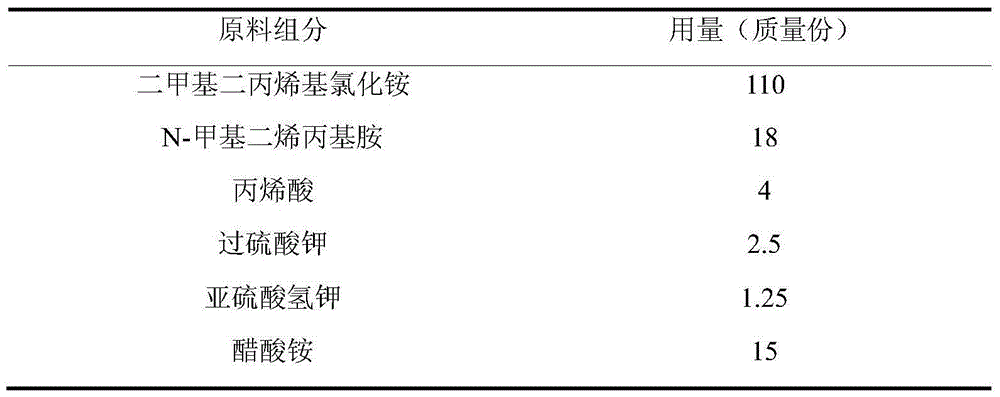

The invention discloses a polycationic formaldehyde-free color fixing agent and a preparation method thereof. The polycationic formaldehyde-free color fixing agent is prepared from the following raw material components in parts by mass: 90-110 parts of dimethyl diallyl ammonium chloride, 12-18 parts of N-methyldiallylamine, 3-8 parts of acrylic acid, 1.5-2.5 parts of persulfate, 0.75-1.25 parts of hydrosulphite, 5-15 parts of ammonium acetate and the balance of water. According to the polycationic formaldehyde-free color fixing agent disclosed by the invention, dimethyl diallyl ammonium chloride, N-methyldiallylamine and acrylic acid are adopted as monomers, and the monomers are water-soluble and non-toxic and can be in solution polymerization based on a free radical mechanism to ensure that the prepared color fixing agent is environment-friendly and safe and has strong color fixing capacity.

Owner:WUXI DANGKOU TONGHE TEXTILE MACHINERY PLANT

Method for improving color fastness of acid fluorescent dyes

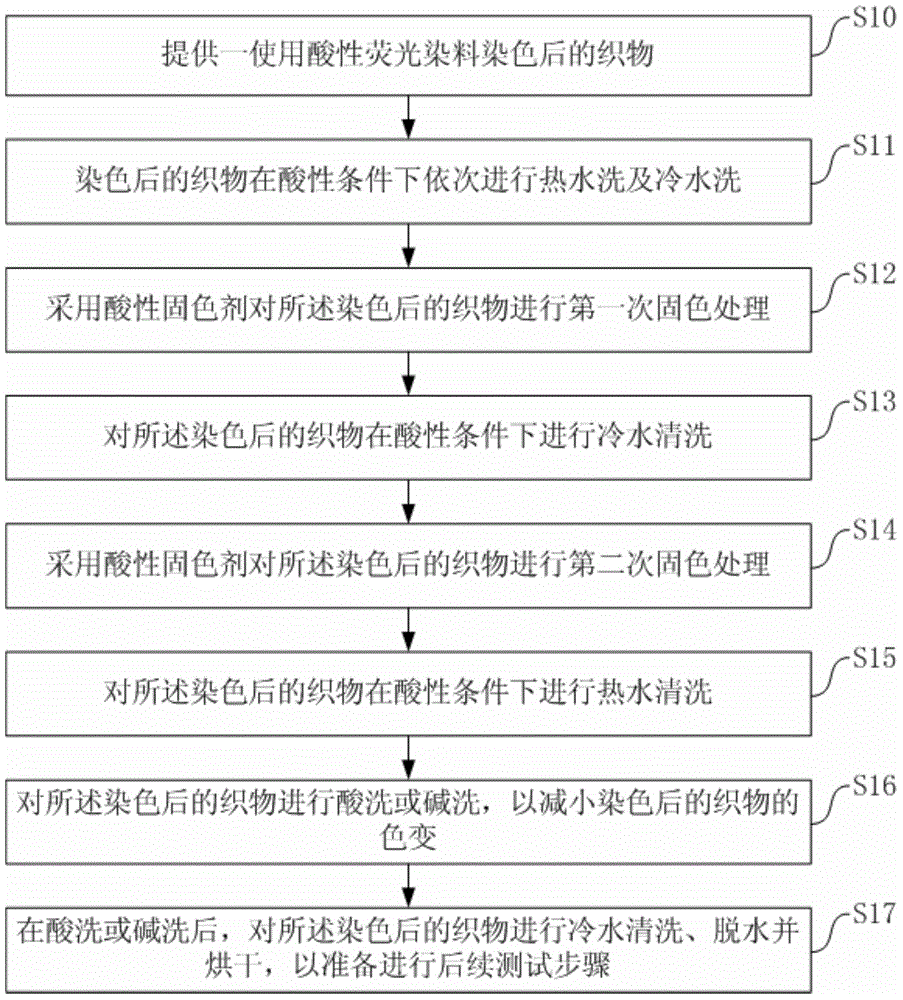

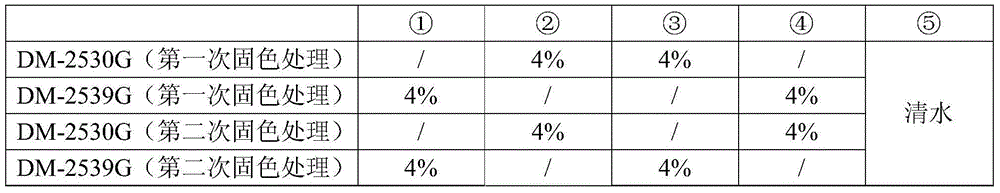

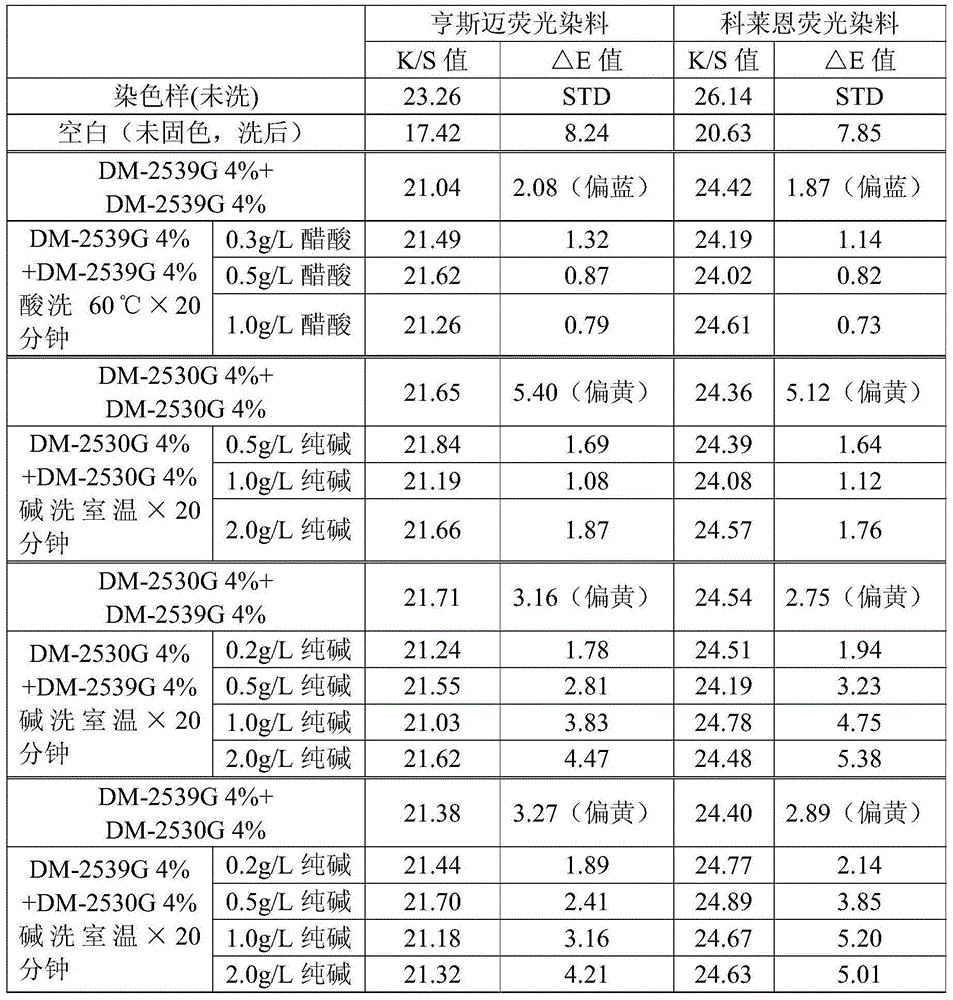

The invention provides a method for improving the color fastness of acid fluorescent dyes. The method includes the following steps: (1) a fabric dyed with the acid fluorescent dyes is provided; (2) first-time color fixing processing is carried out on the dyed fabric with an acid dye-fixing agent; (3) second-time color fixing processing is carried out on the dyed fabric with the acid dye-fixing agent. The method has the advantages that all steps are executed under the acid conditions, and two times of color fixing are continuously carried out with the acid dye-fixing agent. The dyes and the fabric can be bridged through the acid dye-fixing agent to form a compound; in other words, the acid dye-fixing agent can be in cross-linking reaction with -NH2 on the fabric while being bonded with dye molecules, cross-linking membrane formation can be carried out on the acid dye-fixing agent to form the high diversification cross-linked polymeric membrane of a cubic net structure, and the surface of the fabric is covered with the polymeric membrane, so that the dyes and the fabric are combined together more tightly and firmly, the dyes are effectively prevented from dropping from the fabric, and the color fastness of the acid fluorescent dyes is improved.

Owner:DYMATIC CHEM

Dyeing method of environmentally-friendly bamboo fiber bath towel

The invention relates to a dyeing method of a bamboo fiber bath towel, and especially relates to a dyeing method of an environmentally-friendly bamboo fiber bath towel. The method comprises the following steps: 1, extracting a plant color fixing agent; 2, drying the plant color fixing agent; 3, extracting a plant dyeing agent; 4, pre-processing; 5, carrying out primary color fixation; 5, dyeing; 7, carrying out secondary color fixation; and 8, dehydrating, and drying. Primary color fixation, dyeing and secondary color fixation are combined to dye the bamboo fiber bath towel, so the process is simple, the color is fastened, and a color fixation solution can be repeatedly used to save the cost; the above ultrasonic dyeing method realizes fast and uniform dyeing and softens the bamboo fiber bath towel; and plant extract products are adopted as the color fixation agent and the dyeing agent, have the characteristics of no heavy metal ions, natural plants, environmentally-friendly dyeing, weed removal, production facilitation and low cost, can clear heat, detoxify and prevent bacteria, and has a very good protection effect on skins.

Owner:JIESHOU SHUANGXIN TEXTILE

Dyeing production method of plant dye with natural bacteriostatic function

The invention relates to a dyeing production method of a plant dye with a natural bacteriostatic function. The dyeing production method comprises the steps that the crudely extracted Chinese herbal medicine plant pigments are utilized, a plant dyeing method without water drainage is used for dyeing, and the color is fixed by a natural color fixing agent after dyeing; a fabric or cloth is put intoultrasonic dyeing equipment filled with plant dye liquid, and the ultrasonic waves are started to intermittently dip-dye; a cylinder-refilling dyeing method is adopted, and the liquid is not drained after dyeing each time; the natural color fixing agent is used for fixing the color. The dyeing production method has the advantage that the crudely extracted natural plant dyes are adopted, and are matched with the natural color fixing agent, the cylinder-refilling dyeing processing without water drainage is performed on the clothes and fabrics, such as cotton, hemp fiber, viscose, Tencel and Modal, by the ultrasonic waves and the dyeing liquid is not drained in the dyeing process each time, so that the natural plant dyes and the natural color fixing agent can be effectively utilized, the water resource is greatly saved, the sewage treatment process is not required, and the natural bacteriostatic property of the product dyed by the plant dyes is effectively guaranteed.

Owner:祝洪哲 +1

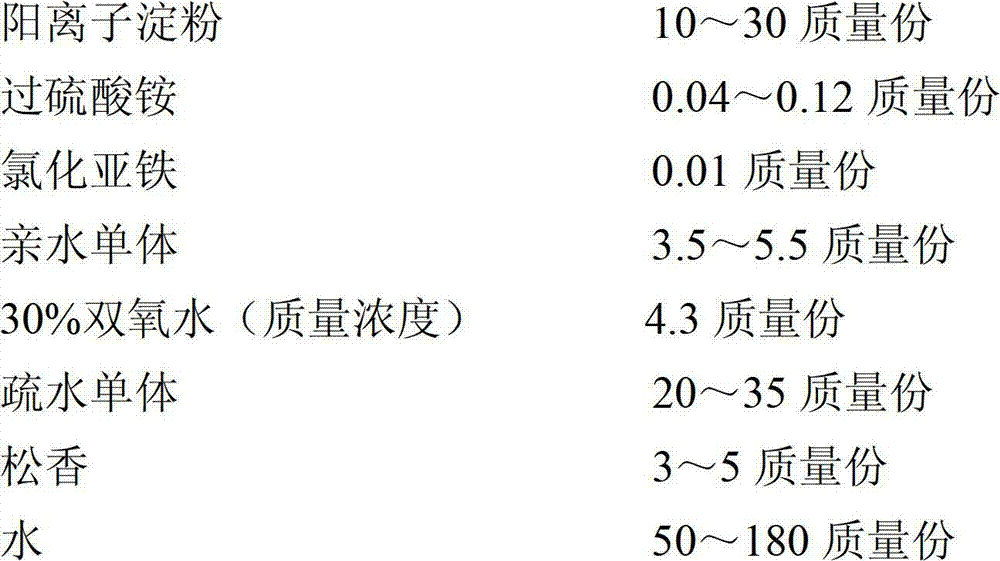

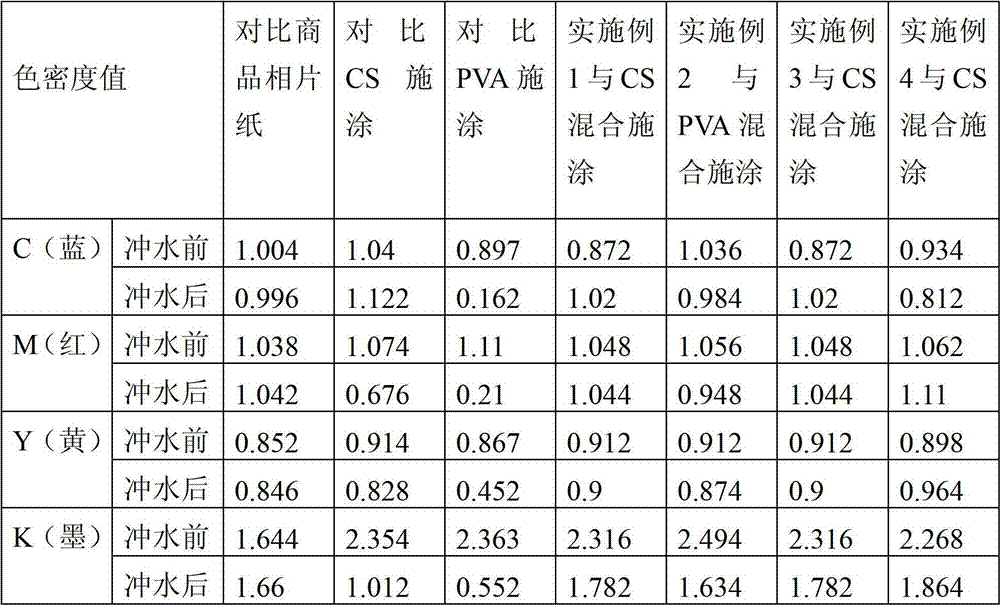

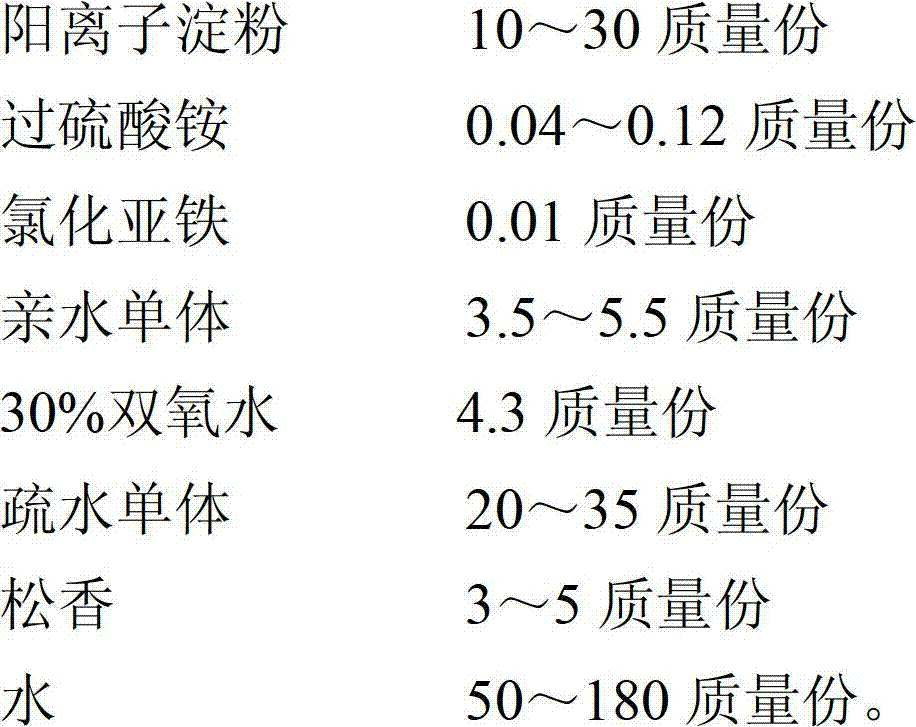

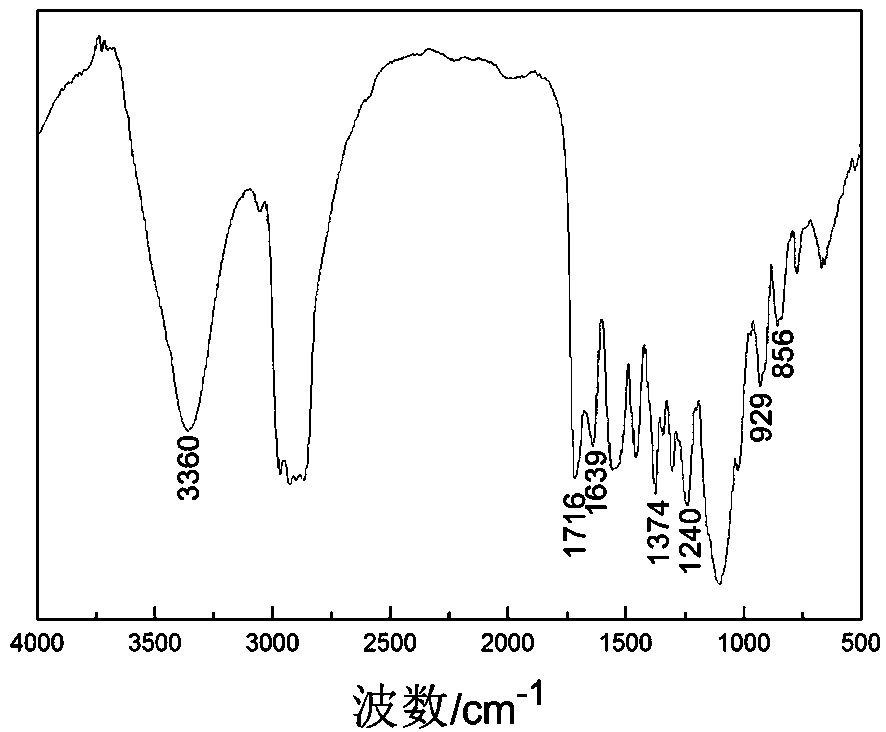

Surface-sizing fixing agent for color ink-jet paper and preparation method and application thereof

ActiveCN103074805AHigh cationic degreeImprove hydrophobicityNon-fibrous pulp additionHydrophilic monomerWater baths

The invention discloses a surface-sizing fixing agent for color-jet paper and a preparation method and the application thereof, and belongs to the field of preparation technologies of papermaking chemicals. The method comprises the following steps: gelatinizing cationic starch, ammonium persulfate and water under water bath stirring; adding ferrous chloride water solution and hydrophilic monomer solution; dripping hydrogen peroxide diluent for initiation; adding hydrophobic monomer and rosin into a reaction system for monomer pre-emulsification; increasing the temperature to 90-92 DEG C, and dripping hydrogen peroxide diluent for initiation and then reaction for 2-3h; and increasing the temperature to 95-99 DEG C for reaction for 1h, and then naturally cooling to 20-50 DEG C to manufacture the surface-sizing fixing agent for color-jet paper. The prepared surface-sizing fixing agent for color-jet paper is formulated into water solution and then mixed with the cationic starch or polyvinyl alcohol, and meanwhile, an album paper coating cross-linking agent is added for being mixed and applied to improve the surface quality of printing paper, improve the printing quality and particularly greatly improve the water resistance of finished paper.

Owner:FENGKAI JIACHENG PAPER CO LTD

Method for preparing color fixing agent by using water-based polyurethane grafting collagen peptides

The invention discloses a method for preparing a color fixing agent by using water-based polyurethane grafting collagen peptides, which belongs to the field of the color fixing agent. The method comprises the following steps: first preparing a water-based polyurethane prepolymer, extracting collagen peptides from hogskin and fish bladder skin, allowing the collagen peptides to react with the water-based polyurethane prepolymer to form covalent bonds, deblocking water-based polyurethane when the color fixing treatment is carried out, combining the unblocked isocyanate groups with hydroxyl on fibers or reactive hydrogen on dye molecules by virtue of covalent bonds to achieve the color fixing effect; and then interweaving the collagen peptides and fibers to form a net, so that the viscosity is good, dyes can be firmly wrapped and are uneasy to drop or discolor, and a purpose of improving the color fastness can be achieved. The hydrophilia and oxidation resistance can be improved. A prepared curing agent is formaldehyde-free, bright in color and uneasy to discolor in friction, so that the color fastness can be effectively improved; and moreover, the process is simple, and the dyeing effect is good.

Owner:仇颖超

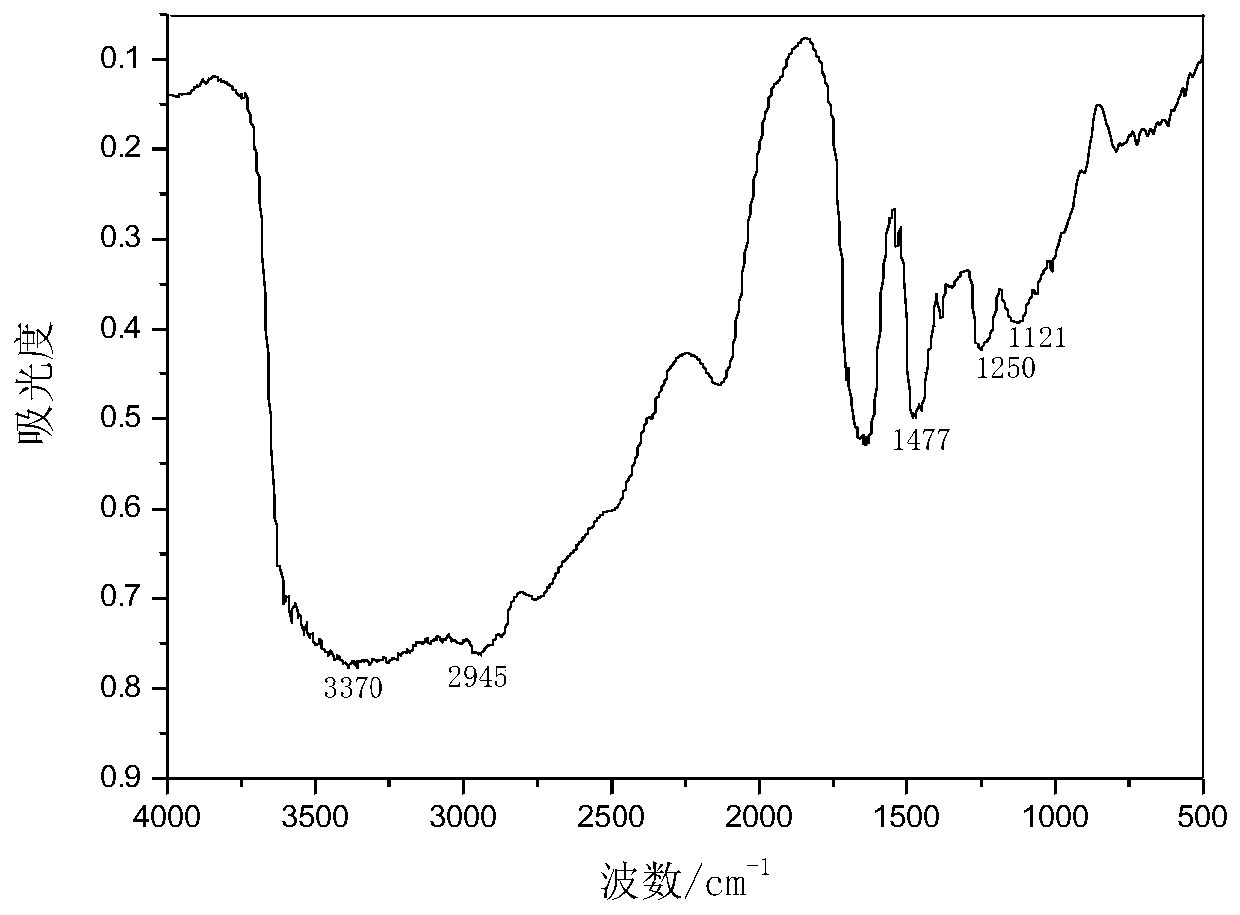

Dye-fixing agent used for active dyes, and preparation method thereof

The invention discloses a dye-fixing agent used for active dyes, and a preparation method thereof. According to the preparation method, monoethanolamine and 1, 4-butanediol diglycidyl ether are takenas raw materials to synthesize a chain extender, isophorone diisocyanate, polypropylene glycol, and the chain extender are reacted to obtain polyurethane, the obtained polyurethane is subjected to endcapping with methyl ethyl ketoxime, and high speed shearing emulsion is carried out so as to obtain the dye-fixing agent used for active dyes. Coulomb attractive force combination of cations contained by the dye-fixing agent with anions of dye molecules can be realized, so that dye hydration capability is reduced; uncapping of the end capped isocyanate groups in the dye-fixing agent molecules isrealized in high temperature roasting, and crosslinking effect with some active groups on fiber and dyes can be realized;ring-opening reaction of epoxy groups contained by dye-fixing agent molecules with the active groups on fiber and dyes under certain conditions is realized, so that crosslinking effect is achieved; and at the same time, the dye-fixing agent is a polyurethane, possesses relatively excellent film forming capacity, the formed film is used for covering dyes, so that firm adhesion of the dyes onto fabric is realized, and dye fixation is realized.

Owner:SUZHOU UNIV

Preparation method of coconut shell extract/modified konjac glucomannan compound dye-fixing agent

InactiveCN109440503AImproves UV protectionIncrease forceDyeing processRotary evaporatorFreeze-drying

The invention provides a preparation method of a coconut shell extract / modified konjac glucomannan compound dye-fixing agent. The method includes the steps: crushing coconut shells into powder, extracting the powder by ethanol solution, extracting the extracted powder by n-butyl alcohol solution to obtain n-butyl alcohol extracts, adding the n-butyl alcohol extracts into a rotary evaporator to concentrate the n-butyl alcohol extracts, and drying concentrated solution to obtain coconut shell extract powder for standby application; taking konjac glucomannan, placing the taken konjac glucomannaninto a reaction kettle, adding acetic acid aqueous solution and glycidol to perform reaction, cooling mixture to remove redundant reaction liquid, freeze-drying the mixture to obtain modified konjac glucomannan, adding the modified konjac glucomannan into a reactor, adding deionized water to sufficiently mixing mixture, adding the coconut shell extract powder and Twain-20, heating and uniformly stirring mixture to obtain the compound dye-fixing agent. The prepared compound dye-fixing agent can effectively improve color fastness after dyeing, particularly, effectively improve wet rubbing fastness and can also prevent color losing caused by ultraviolet irradiation, and the color fastness is further improved.

Owner:嘉兴珠韵服装有限公司

Preparation method for environmentally-friendly plant type cotton fiber fixing agent

InactiveCN108103812AHigh color fastnessHigh bonding strengthDyeing processFiberEnvironmental resistance

The invention relates to a preparation method for environmentally-friendly plant type cotton fiber fixing agent, and belongs to the technical field of textile materials. Apple slags are decomposed andextracted, and pectin is collected as the basic material of the material; through hydroxy, amido or a small quantity of carboxyl rich in pectin materials, active groups are in the presence on the surface of a cotton fiber to be subjected to crosslinking to form a film; meanwhile, the pectin material, dyes and groups on the fiber are subjected to crosslinking combination, the pectin material, thedye and the group on the fiber also can form a hydrogen bond to be bound with force among modules; in addition, through lycopodium spore powder, ball milling is carried out, certain condensation is generated through the carboxyl and the hydroxy contained in the ball milling of the lycopodium spore powder, a reticular macromolecule is formed under a certain condition, so that dye is adhered to fabric, meanwhile, cutinase can be used for effectively modifying the surface structure of cotton fibers, the binding strength of the dye on the surface of the cotton fibers is improved, and the color fastness of materials is effectively improved.

Owner:常州文诺纺织品有限公司

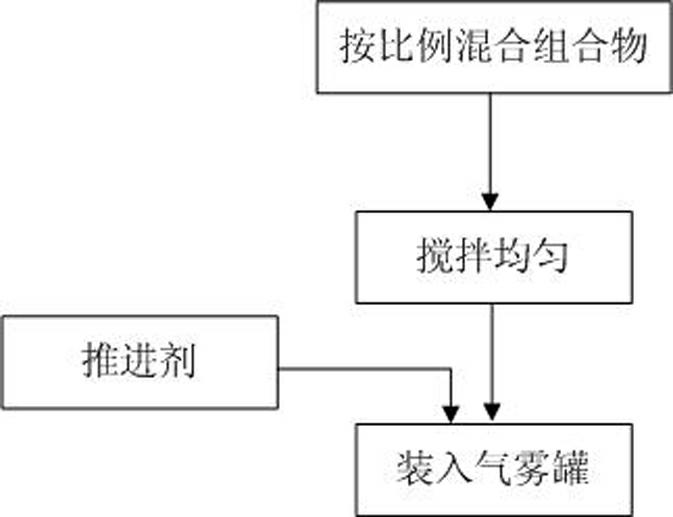

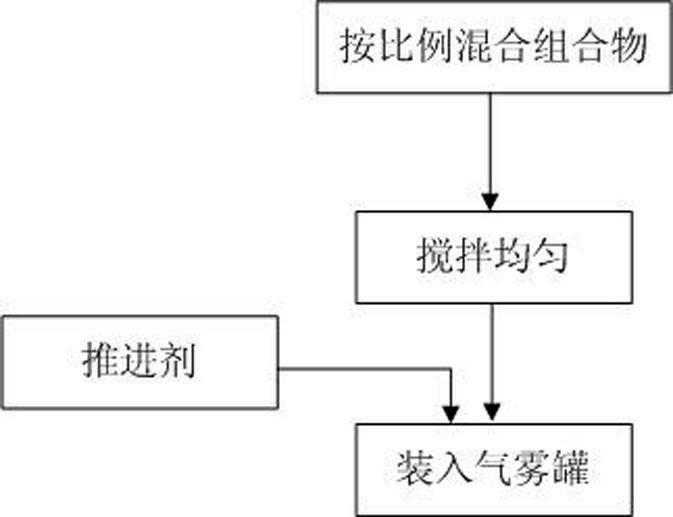

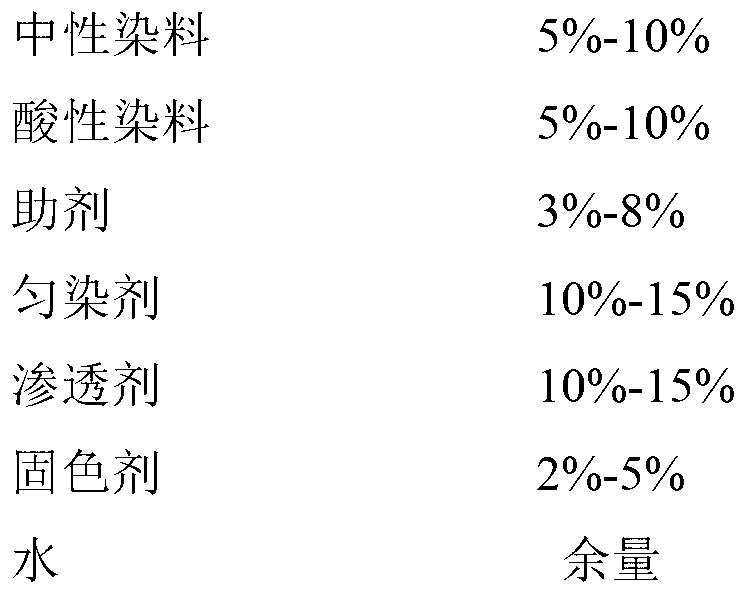

Multi-effect suede nursing agent

The invention discloses a multi-effect suede nursing agent. Components of the nursing agent include, by weight, 75.0-95.0 parts of solvents, 1.5-10.0 parts of superfatting agents, 0-6.0 parts of dyes, 0.5-5.0 parts of dye-fixing agents, 2.0-10.0 parts of softening agents and 1.0-5.0 parts of brightening agents. The multi-effect suede nursing agent has fine coloring and color-complementing effects, softness of original suede can be kept, part of oil is supplemented to suede leather, the leather is protected, and aging of the leather is delayed. The dye-fixing agents and the other components are ingeniously and reasonably matched, a protective film can be formed, and durability and waterproof, anti-fouling and electrostatic effects are achieved.

Owner:HUANGBAO TECH SHANGHAI

Dyeing technology for wool/acrylic blended fabric

InactiveCN107237184AHigh removal rateHigh whitenessPhysical treatmentBiochemical treatment with enzymes/microorganismsEngineeringCleansing Agents

Owner:NANTONG BOAO TEXTILE CO LTD

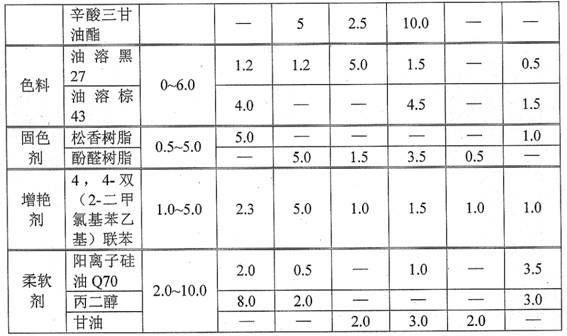

Components of colorant composition

InactiveCN103290704AGood colorGood color fixing effectOrganic dyesDyeing processColor effectTextile dyeing

The invention discloses components of a colorant composition. Dyeing raw materials consist of a neutral dye and an acidic dye, further added is a color fixing agent which is beneficial for coloring effect and dyeing fixation effect of fabrics. The colorant composition which adopts common agents as raw materials is suit for dyeing not only woven fabrics, but also knitted fabrics; and the colorant also has the characteristics of good dyeing effects, high color durability and stability, and sun-endurance, so that people's higher requirements of textile dyeing are achieved.

Owner:TAICANG QISHENG CHEM FIBER FACTORY

Denim water washing color-fixing agent and water washing technology

InactiveCN106638058ARaw material environmental protectionGood color fixing effectDyeing processEnvironmental resistancePolyethylene glycol

The invention discloses a denim water washing color-fixing agent, and prepared from a GS612 auxiliary agent, a softening agent and water, wherein the mass ratio of the GS612 auxiliary agent to the softening agent to the water is equal to 1: 0.3: (100-200); the GS612 auxiliary agent is prepared from 10-30 parts of waterborne polyurethane, 1-10 parts of polyethylene glycol (PEG)-100, 10-35 parts of PEG-6000 and 25-79 parts of water. The color-fixing agent is environmentally-friendly in raw materials, low in environmental pollution and good in color fixing effect; the denim fabric, subjected to fixation of the color-fixing agent, does not easily fade, can reach the test standard for children clothing in China, and is safe and reliable. The invention also provides a water washing technology. The water washing technology comprises the following steps: a. rinsing; b. carrying out fixation, specifically, washing denim clothes with the denim water washing color-fixing agent for 20-30min; c. drying. The water washing technology is simple in process, mild in conditions, short in treatment time, high in efficiency and low in energy consumption and cost, thus being suitable for industrial batch operation; after being washed by using the water washing technology, the denim clothes are high in fastness to wet rubbing, do not easily fade, meet the quality test standard for children clothing in China, and are good in comfortableness.

Owner:深圳市安奈儿股份有限公司

Processing method for color-deepening and brightening of pigment printed textiles

The invention provides a processing method for color-deepening and brightening of pigment printed textiles and aims at solving the problem of simultaneously meeting color light and fastness requirements in pigment printing. The method mainly comprises the processes of color paste preparation, printing, drying, baking, after-finishing and the like; a color-deepening and brightening agent capable of increasing the color and luster and a color-fixing agent capable of increasing the fastness to wet rubbing are added during pigment printing, and consequently, towel and quilt type high-standard pigment printed products bright in color and luster and relatively high in fastness to wet rubbing can be produced.

Owner:JINAN ZHENGQI BIOTECHNOLOGY CO LTD

Natural dye fixing agent and preparation method thereof

The invention discloses a fixing agent for textile printing and dyeing and particularly relates to a natural dye fixing agent. The fixing agent is a polymer compound, has a large quantity of 3-chloro-2-hydroxypropyl, has high reactivity with hydroxyl and amino under the alkaline condition, can react with hydroxyl or amino in natural dyes and cotton, hemp and wool fibers to form covalent bonds andcan bond the natural dyes and fabric fibers which cannot react originally by the covalent bonds; meanwhile, the invention also discloses a preparation method of the natural dye fixing agent. The preparation method comprises the steps as follows: 1) in presence of ammonium persulfate, dimethyl diallyl ammonium chloride and allylamine monomers are subjected to a polymerization reaction in water; 2)epichlorohydrin is added to water, ethylenediamine is dropwise added, the reaction temperature is controlled to be not higher than 80 DEG C, and after addition, a product is kept at certain temperature for a certain period; 3) products in steps 1) and 2) are mixed, and the mixture is kept at certain temperature for a certain period.

Owner:SHAOXING CHINA TEXTILE CHEM

A preparing method of a sensitive color fixing agent and the fixing agent

InactiveCN106948196AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processFixative/StainChemistry

A preparing method of a sensitive color fixing agent and the fixing agent are disclosed. During preparation, methyl ethyl ketone peroxide and a 6-hydroxy-2-naphthoic acid solution are mixed, heated and stirred; dimethylformamide is added into the mixture; the mixture is heated and stirred; then a tris(nonylphenyl)phosphite solution is added into the mixture; and the mixture is stirred at 110-112 DEG C for 20-25 min, then stirred at 65-70 DEG C for 50-55 min and cooled to room temperature to obtain the fixing agent. Under interactions of raw materials, the fixing agent has advantages of high dyeing fastness, capability of significantly increasing dry and wet rubbing fastness and water-washing color fastness, and the like. Hue changes do not occur substantially during color fixing of dye for sensitive colors such as turquoise blue and cobalt blue. The fixing agent is free of formaldehyde and is environmentally friendly. A production process is simple. The fixing agent does not influence chlorine fastness, light fastness or perspiration fastness of dyed fabrics, influences of color fixing treatment on fabrics by the fixing agent are low, and chromatic aberration can be controlled to be the 4-5 level. Treated fabrics have good color fixing effects and an influence on hand feeling is low.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Environment-friendly type synthetic tannin color fixing agent as well as preparation method and application thereof

The invention discloses an environment-friendly type synthetic tannin color fixing agent as well as a preparation method and application thereof. The color fixing agent is a synthetic tannin color fixing agent prepared from the following raw materials in percentage by mass: 15-30% of a phenol compound, 10-30% of an aromatic sulfonic acid compound, 1-5% of a catalyst, 5-15% of a formaldehyde solution, 0.5-2% of a chelating agent, 0.5-3% of a modifier, 1-4% of a dispersant and the balance of water. When being applied to color fixation of chinlon and blended fabrics, the synthetic tannin color fixing agent disclosed by the invention has the advantages of being good in acid resistance stability, small in color change, good in color fastness, and the like.

Owner:东莞市中纺化工有限公司 +1

Method of dyeing pine wood with tea polyphenol

InactiveCN109278145AMaintain stabilityWater resistantWood treatment detailsWood heatingFiberPhenolic content in tea

The invention discloses a method of dyeing pine wood with tea polyphenol, which includes: 1) placing the pine wood in a NaOH solution, heating the solution and moving out, cleaning and drying the pinewood; 2) dyeing the dried pine wood in a tea polyphenol solution, pH being maintained at 9-11, and adding a mordant for mordanting; 3) after the mordanting is completed, moving out the pine wood, performing color fixation in a mixed solution containing a color fixation agent and a penetrant, and moving out and air-drying the pine wood. In the method, a pine wood block is dyed with the natural plant dye; when the pine wood is dyed with the plant dye, due to the mediation effect of the mordant, a chemical affinity reaction is carried out between the tea polyphenol and wood fibers, thus generating a new color. The dyed pine wood has certain color fastness and water-washing resistance.

Owner:GUANGXI UNIV +2

Surface corrosion-preventing and color-fixing agent for metal, preparation method and application

InactiveCN106319491APlay a protective effectAvoid changeMetallic material coating processesBenzoxazoleAlloy

The invention relate to a surface corrosion-preventing and color-fixing agent for metal, a preparation method and the application. The surface corrosion-preventing and color-fixing agent comprises 2-mercapto benzimidazole MBI, 2-mercapto benzoxazole MBO, benzotriazole BTA, imidazole derivatives, polyacrylic resin, polyethylene wax, a lubricating agent and a surface active agent. The weight ratio of the 2-mercapto benzimidazole MBI to the 2-mercapto benzoxazole MBO, the benzotriazole BTA, and the imidazole derivatives is 2:1:1:1. According to the surface corrosion-preventing and color-fixing agent for metal, the preparation method and the application, by using the imidazole derivatives, the surface corrosion-preventing and color-fixing agent can effectively prevent color changing and color fading of the surface of aluminum alloy and can also protect non-ferrous metal against corrosion and solve the problem that the benzotriazole cannot be used for corrosion prevention in an acid environment, and thus the surface corrosion-preventing and color-fixing agent can be used for protecting aluminum alloy against corrosion in all environments.

Owner:张超

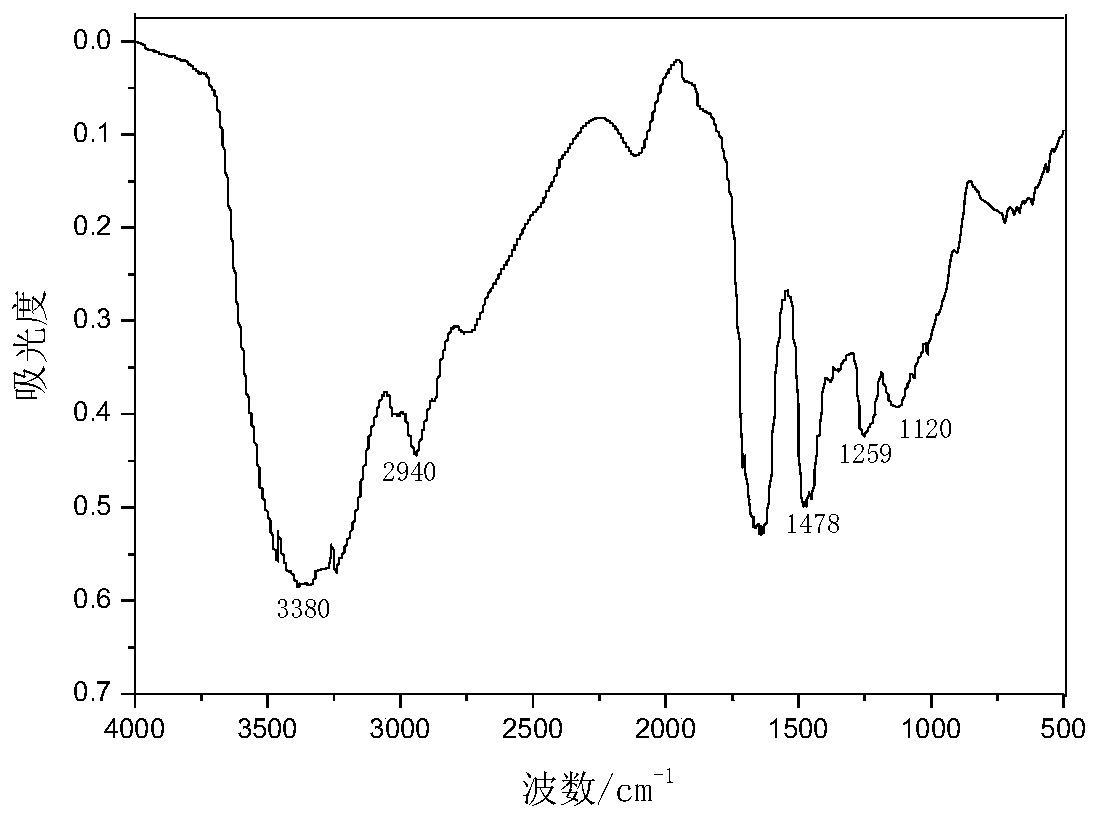

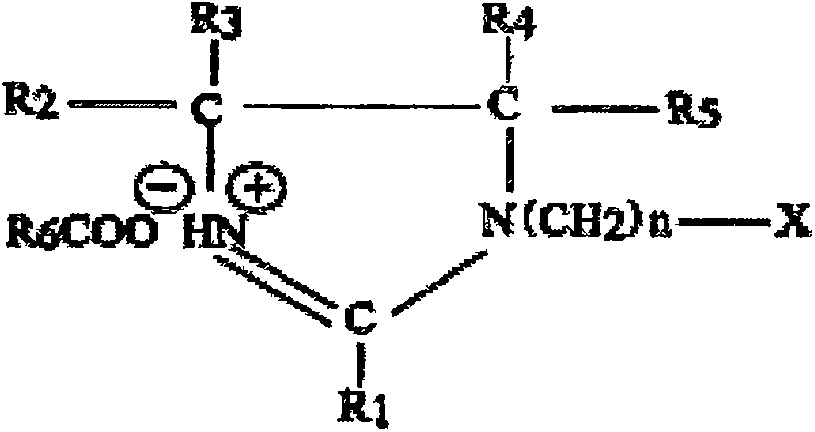

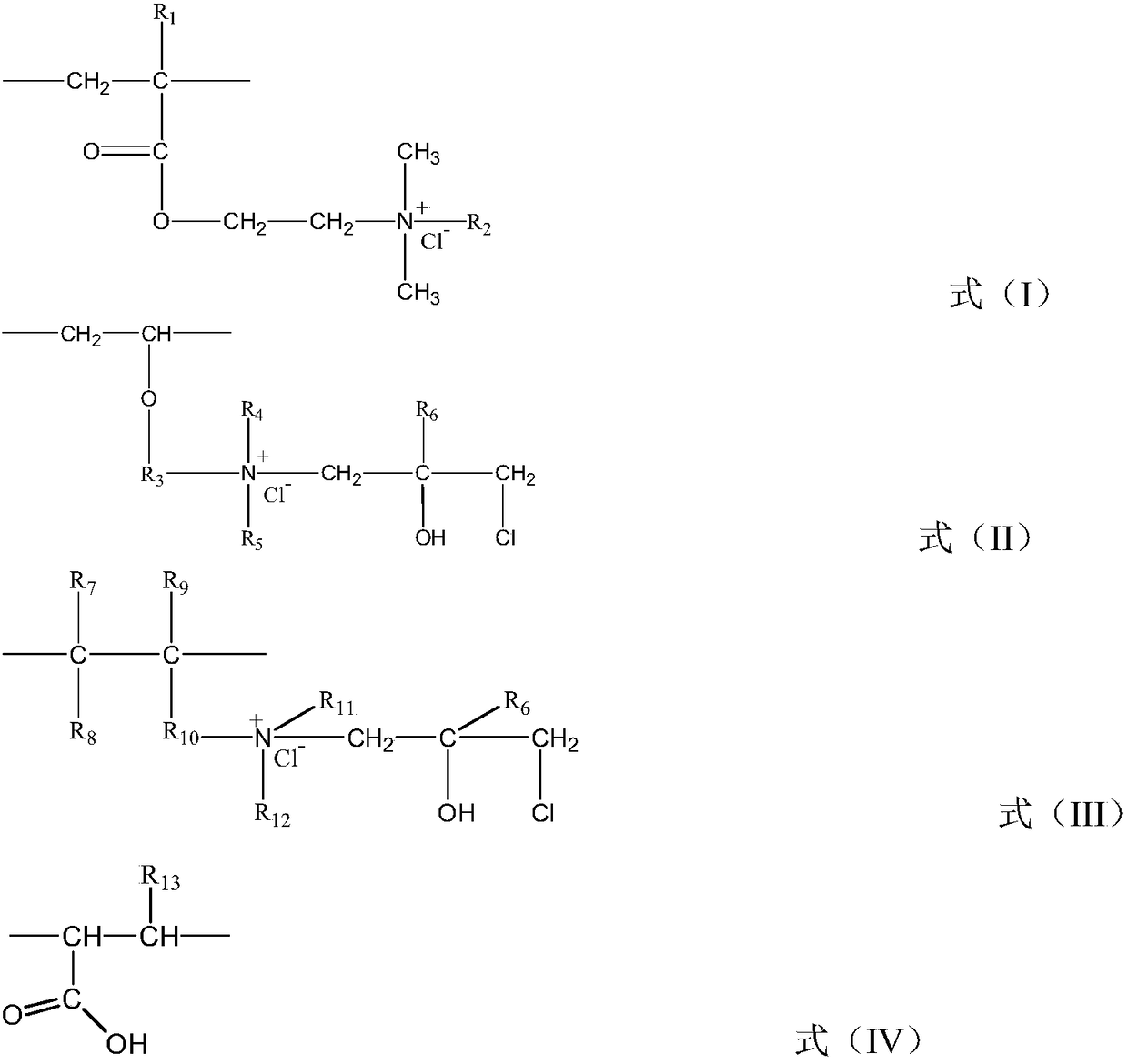

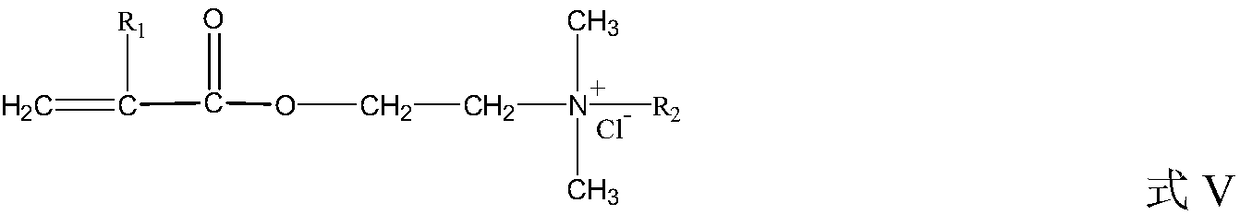

Hydrophilic strong base resistant color fixing agent and preparation method thereof

The invention discloses a hydrophilic strong base resistant color fixing agent which contains a copolymer unit expressed by a mole formula (I), a copolymer unit expressed by b mole formula (II), a copolymer unit expressed by c mole formula (III) and a copolymer unit expressed by d mole formula (IV), and a preparation method thereof. The hydrophilic strong base resistant color fixing agent disclosed by the invention is excellent in color fixing effect and alkali resistance, good in hydrophilia and small in textile color change.

Owner:TAICANG BAONI IND CO LTD

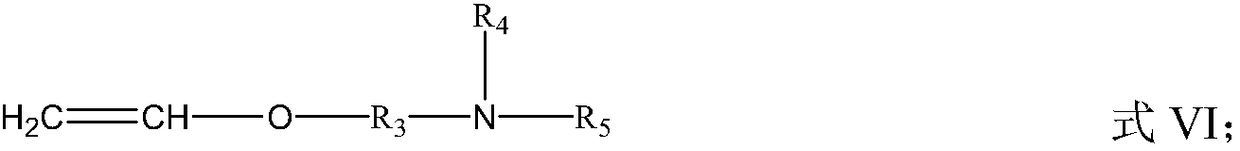

Color fixing agent for paper surface and preparation method for color fixing agent

ActiveCN106480779AImprove surface propertiesImprove water resistanceNon-fibrous pulp additionPaper coatingDiethylenetriaminePollution

The invention discloses a color fixing agent for a paper surface and a preparation method for the color fixing agent. The color fixing agent is prepared from the following raw materials in parts by weight: 14 to 22 parts of diethylenetriamine, 5 to 13 parts of boric acid, 3 to 7 parts of isoamyl alcohol, 10 to 20 parts of propylene glycol monomethyl ether and 21 to 29 parts of styrene-acrylic emulsion. The preparation method comprises the following steps: mixing, heating and stirring the styrene-acrylic emulsion and the diethylenetriamine, adding the isoamyl alcohol dropwise, and performing cooling stirring treatment; adding a boric acid solution for heating and stirring; adding a propylene glycol monomethyl ether solution dropwise for heating stirring treatment, and reducing the temperature to room temperature to obtain the color fixing agent. The color fixing agent is used for coating the paper surface, the cationic degree of a styrene-acrylic emulsion color fixing agent is increased, the surface property of printing paper can be remarkably improved, the printing quality is improved, and particularly, the water resistance of finished paper is greatly improved. According to the color fixing agent, the color density value of the finished paper mixed with water is greatly increased, the raw materials are simple and extensive, the color fixing agent is free of formaldehyde, environment-friendly, pollution-free, low in production cost, stable in performance and suitable for industrial production, and has good color fixing effects and broad market prospect, and a production process is convenient.

Owner:温州富捷科技股份有限公司

Preparation method of water-resistant high-color-fastness color fixative

InactiveCN106835748AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processFreeze-dryingEvaporation

The invention discloses a preparation method of a water-resistant high-color-fast color-fixing agent, which belongs to the technical field of printing and dyeing auxiliaries. In the present invention, the camellia pollen is vacuum-dried first, crushed and sieved, and the broken pollen particles are collected, then ultrasonically oscillated with petroleum ether, filtered, and the filter cake is collected, washed, mixed with deionized water, heated and centrifuged after adjusting the pH, Collect the filtrate and let it stand for aging, then filter, freeze-dry the filter cake to obtain pollen protein, then dry and grind the camellia leaves, mix and heat with ethyl acetate, filter, spin-steam the filtrate until dry to obtain dry camellia wax, and then extract the peach gum After freeze-drying and grinding, it is homogenized with pollen protein, dried camellia wax, etc. and heat-treated. Finally, it is filtered while it is hot and the filtrate is collected. After standing and cooling, a water-resistant high-color-fast color-fixing agent can be prepared. While improving the water resistance of the colorant, it can effectively improve the dry and wet rubbing color fastness of the fabric, and it is not easy to stick to the roller during the production process, so it has a good application prospect.

Owner:孙祎

Color fixing agent for natural decorative wood veneer

The invention relates to a color fixing agent for a natural decorative wood veneer, which is composed of an active agent, a stabilizing agent and a PH neutral adjusting agent. The color fixing agent has the advantages that the technical property is excellent; the color fixing agent is environment-friendly, contains no heavy metal, such as chromium, arsenic, and the like, and contains no other pollutants; the color fixing agent has no harm to human body; the color fixing function is obvious; the color fixing cost is low; and the color fixing agent is conveniently used.

Owner:张家港市创成纺织有限公司

Method for preparing plant dye fixing agent

InactiveCN107938400AHas antioxidant activityPlay a role in color fixationDyeing processCelluloseFiber

The invention relates to a preparation method of a plant dye fixing agent, which belongs to the technical field of color fixing agent preparation. In the present invention, firstly, the iron-rich plant spinach is used as raw material to obtain a self-made functional liquid rich in ferrous ions, and then the green tea extract containing tea polyphenols is obtained by water extraction, and the catechol and the green tea extract are blended to obtain phenols Mixed solution, then blend and ferment aloe vera and grape skins, use microbial degradation to produce a large number of active groups such as free amino groups and carboxyl groups, and finally mix and concentrate each raw material to obtain a color-fixing agent. The color-fixing agent of the present invention uses phenolic mixed liquid As a substrate, ferrous ions are activated under the action of sodium peroxide and laccase to generate free radicals, and the combined free radicals can trigger the catalytic polymerization of the substrate during the dyeing process to generate large molecular weight directly in the cellulose "in situ". Polymer, the polymer is finally deposited on the fiber, and the dyeing agent on the surface of the fiber is coated and fixed, so as to improve the color fastness of the vegetable dye, and has a broad application prospect.

Owner:闫博文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com